Technologies and processes during the workshop

During the workshop we had the opportunity to understand the application of the following technologies and their interaction on the construction of in site structures.

-Generative design allowed the creation of a system composed by individual building blocks, this elements are unique in the system and generated from structural needs of the design. This creates complexity to manufacture this elements.

-Additive manufacturing allowed for manufacturing each of this elements without raising the cost of manufacturing and allowing complex, unique shapes to be made from the design file. Using a pellet extruder the printing time was reduced considerably from ordinary 3D printing methods.

-The system was projected real time to the assembly team throw hololens in order to allow a faster assembly of the structure, this required ID’s for each of the element to be attached in the element.

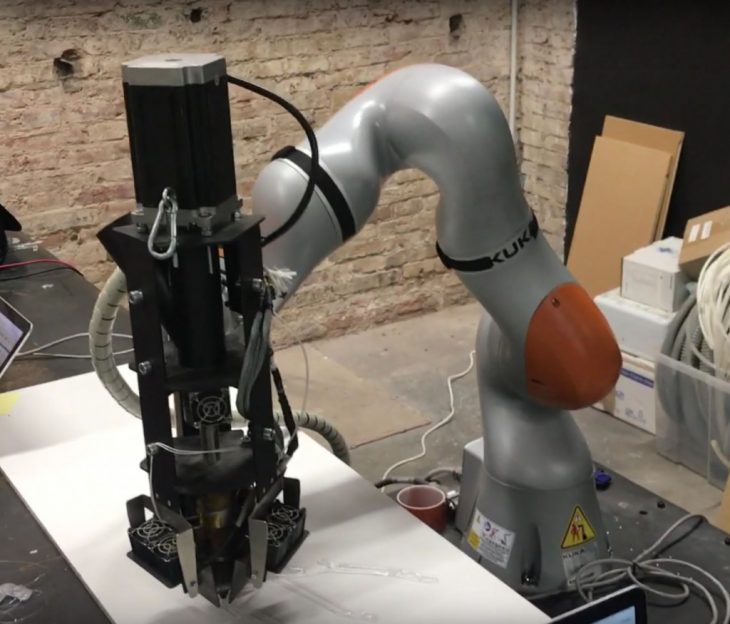

-After the complete assembly of the structure using robotic arms with a pellet structure allowed us to reinforce the structure by scanning the optimum paths where the reinforcement layer should be deposited.

-Finally scanning the elements and final assembly we are able to update the 3d model considering human error and other variables .

Workshop 3A | MRAC 2018-2019

Faculty: Roland Snooks

Faculty assistants: Natalie Alima | Kunaljit Chadha