Study of ureolytic bacterial calcium carbonate precipitation.

Urbanisation today is on the rise and it’s development has detached itself from the natural environment, creating a separation between the urban living and the source of life we depend on from nature. The estimated cost of the global construction process is just over one third of the greenhouse carbon emissions, primarily through the use of fossil fuels during their operational phase. Our built environment is constructed mainly from five primary material components, bricks, concrete, steel, glass and wood and these materials all contain high embodied energy, with cement, brick, steel and gypsum accounting for about 12% of all carbon emission. Instead of relying exclusively on these high embodied energy materials, microorganism involvement in the process of carbonate precipitation in biomineralization, can offer a new approach to the anatomy of structures by the deposition of a hard calcareous material. Building design could be able to respond to its environment and grow material that reduces CO2 emission and requires less energy to produce, compared to traditional construction materials.

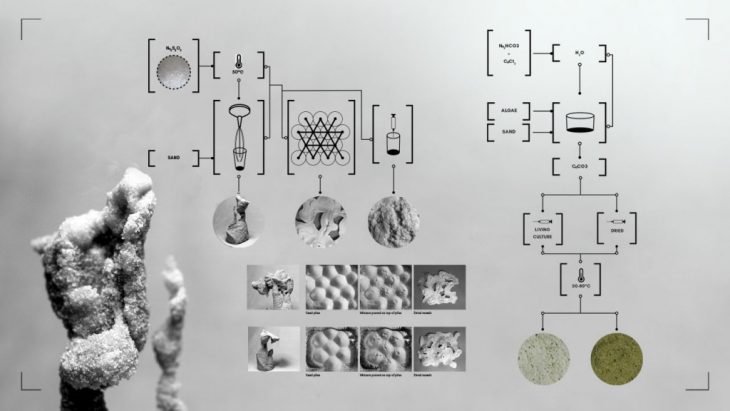

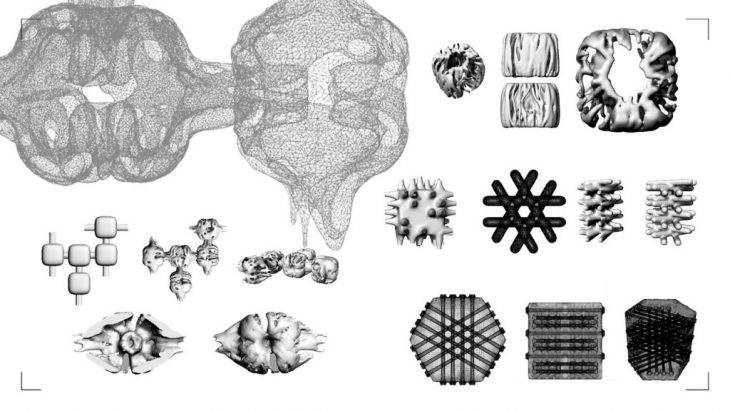

By studying this formation, this project presents the results of a research in which Sporosarcina pasteurii (formerly known as Bacillus pasteurii) was used to induce biological cementation in loose sand medium. The bacteria was injected into sand, which led to the development of biocementation (calcium carbonate crystal) between sand grains. The calcification was observed using a microscope.

Biocementation was achieved in a thin crust in this study. The bacteria were injected into a range of aggregates and led to the development of cementation (calcium carbonate crystal) between sand grains and cement aggregate tests. The crystallization was clearly observed in bacterial tests, both solid and liquid form, using a microscope.

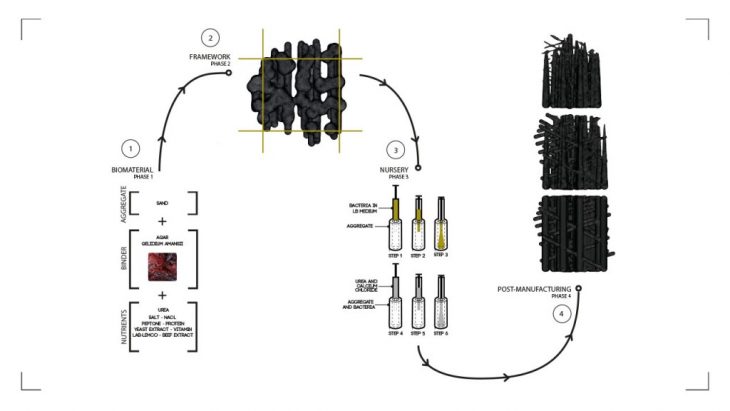

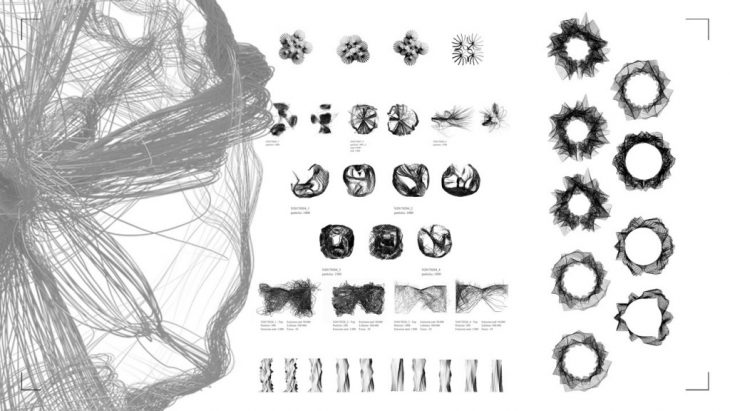

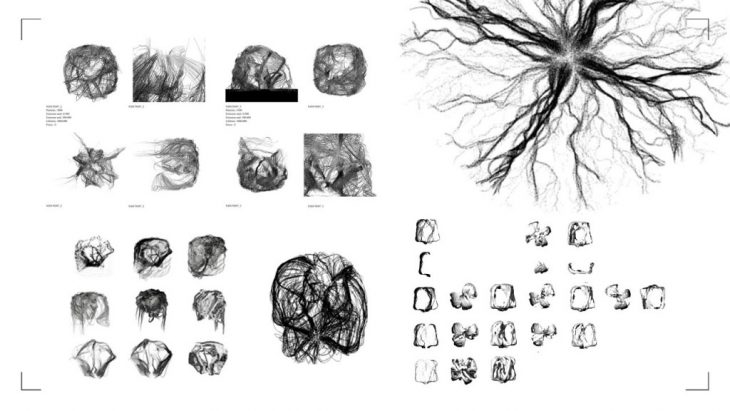

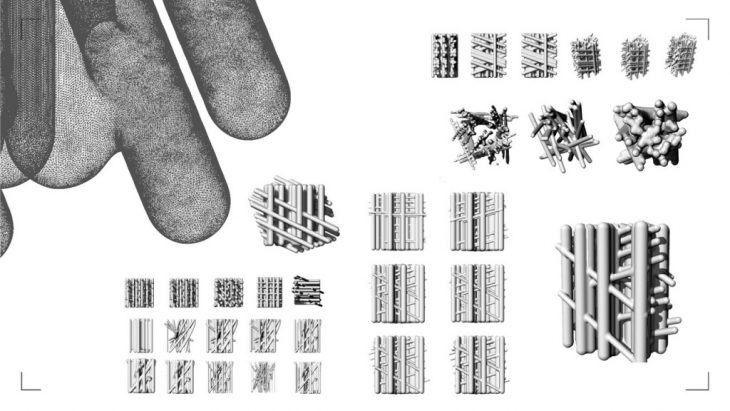

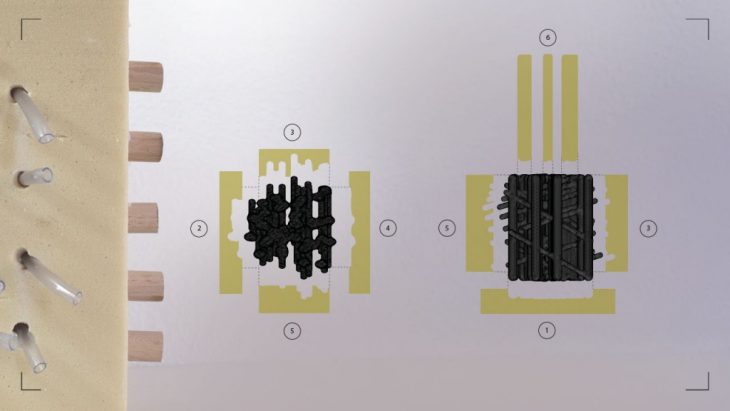

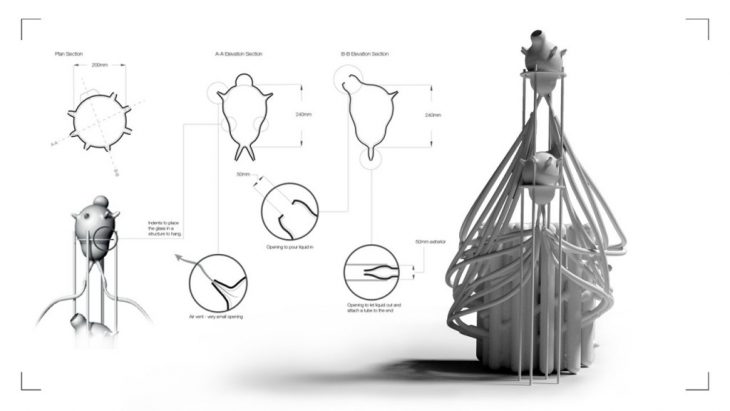

This study is a part of a project that aims to develop biotechnological methods for large-scale applications in construction and uses a scaffolding system pre-cast out of a biopaste (agar, beef and yeast extract, peptone, NaCl, CaCI3, urea and sand) with inner channels that focus on an initial irrigation system to transport the bacteria in liquid form through the temporary scaffold. Injection points allow the bacteria to be fed into the structure along with the crystallization catalysts. This perforated layered geometry allows the bacteria to penetrate the biopaste and maximize the growth area on the scaffold to biomineralized the final solid structure as the temporary biopaste scaffolding will erode over time.

MICROBIAL SCAFFOLDING is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture, MAA02 in 2016/17 by:

Student:

Thora H Arnardottir (website)

Tutor: Marcos Cruz

Assistant: Nina Jotanovic

Biology Support: Nuria Conde Pueyo

Computational Support: Rodrigo Aguirre & Angelos Chronis

Fabrication Support: Kunal Chadha & Ricardo Valbuena