Source: Author

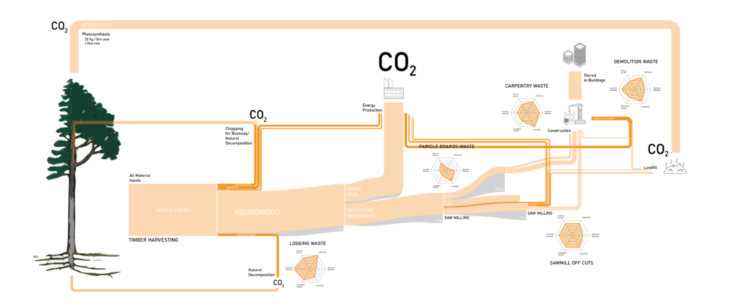

‘’While a number of environmentally reasoned policies are driving an impact

on material use of wood, large part of unutilized timber serves to particleboards,

paper production and other low-value uses. Different forms of wood

waste are abandoned from further investigation of their specific character.

Through digital analysis and focus on individual properties of the waste components

this research aims to reimagine them as an innovative resource for

timber construction’’

Prototype 01: Offcut Laminated Panel (Source: Autor)

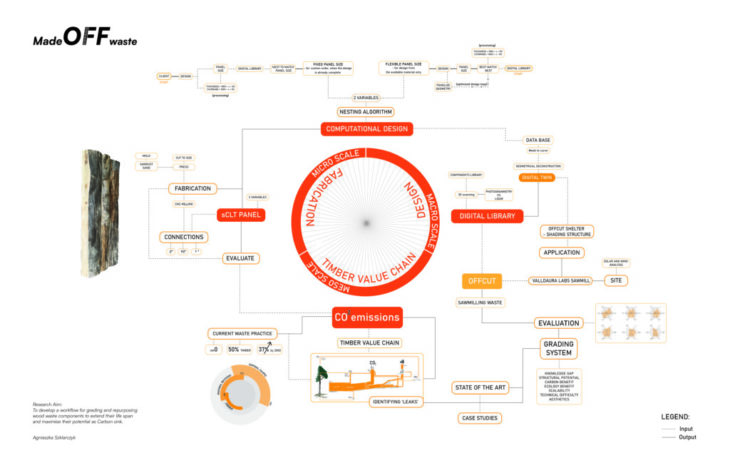

Abstract:

Rapidly growing interest in contemporary timber buildings and engineered wood products like CLT (Cross Laminated Timber) striving to address the ecological emergency suggests raising

a question on where will all the additional wood needed to fulfill this mass-transition come from? At the same time the way we are dealing with waste timber highly disregards its unique

qualities and potential for high-value use. This paper begins with a review of the existing literature to identify the knowledge gap on the advancements made in regards to design tools

and innovative building components using waste wood in architecture applications. Through identification and assessment of the ‘leaks’ of waste in timber value chain the focus was given to

the waste components coming from sawmilling processes. This theoretical approach gave basis to practice-based prototypes using ‘’offcuts’’ collected at a small-scale sawmill and inventoried

based on photogrammetry technology. According to the geometrical data collected a digital twin library was generated to support the most efficient use of the material. The prototypes

reference directly to CLT construction and investigate how the function of a structural panel could be achieved using waste wood. Additionally, previously discarded characteristics of the

collected material were explored to serve in an architectural context. In conclusion the paper highlights the potential to make way for waste wood in sustainable timber construction and opens up questions for further research necessary to implement this concept towards commercial application.

Research Map (Source: Autor)

Perhaps, it is possible to relate wood and its waste to the concept of a hyperobject as defined by Timothy Morton in his book ”Dark Ecology”. Wood waste, particularly when it is generated on a large scale, could be seen as a hyperobject because it is a massive and diffuse phenomenon that is distributed in time and space relative to humans.

Waste as a HyperObject (Source: Author)

At the MICRO SCALE, starting from a living tree, wood is highly heterogeneous material. Its depend on the species, environmental circumstances, growth and many other factors, which present challenges on a practical level. Trees of the same species grown in diverse conditions may grow very differently. The increase in girth of a tree grown in the open is twice as much as one grown in woodland. Mechanical properties are also affected by the presence of knots and moreover their living state. This characteristic has even more layers when is comes to waste wood, which beyond all the above also represents the impact of time and treatment. At the MESO SCALE, the properties of waste coming from sawmilling, carpentry etc. present a vast pallet of shapes, where no elements

are identical. And at the MACRO SCALE where all those peculiar objects are stacked into waste bags, piled up on landfills, where they form those vast, uncomprehend organisms existing everywhere and nowhere.

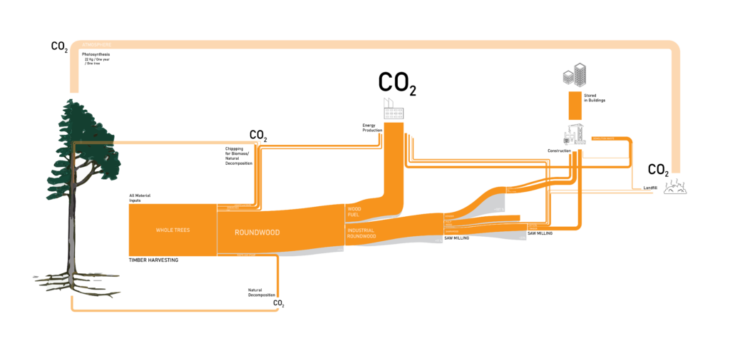

State of the Art, Timber Value Chain and its ”leaks”:

Timber Value Chain – Material Flow (Source of data: FAOSTAT-Forestry Database

Pointed out Waste Leaks in Timber Value Chain (Source: Author)

Grading System:

There are multiple types of wood waste, coming from various stages of timber harvesting and timber industry processes. To analyze the research potential of the different types of wood

waste those two processes were combined into one streamline and later a grading system based on the six following qualities was established. These qualities have the purpose to indicate: the potential, feasibility and benefits of the research, but also to underline the importance of understanding material properties and trace its impacts on the environment. This grading system was customized to support the research hypothesis.

KNOWLEDGE GAP– the relevance of the topic in relation to current trends in construction and the potential for further exploration. The search for projects related to a certain type of waste was conducted in order to contribute where there still is a research gap. The highest score was given when there are not many existing projects related to the graded type of waste.

STRUCTURAL POTENTIAL –to promote additional cascades of wood and wood waste prior to the use for fuel and composting (woodfuel removals accounted for 49 % of all roundwood

produced in 201913 ) the potential of becoming a structural component, preferably closest to its first stage of recovery is primary to the score. Looking at the macroscopic level of structural variation this quality takes into account the length of the grain and the gross features such as knots and grain direction, since these are the first level features which are highly significant when it comes t o reducing structural performance. Another important feature is the usual level of degradation – (demolition waste vs. offcuts) this

specifically looking into the possibility of having cracks, holes or being attacked by insects or water.

CARBON BENEFIT – Carbon benefit is the positive impact that something has on the amount of carbon in the atmosphere. In this case – recovering waste in a way which reduces the amount of carbon emissions. The amount of embedded energy (transportation, processing) is significant to justify if the recovery process has a positive impact on the environment. Intense processing may increase the material life-span, however there may be negative effects to end-of-life scenarios* (Ramage et al., “The Wood from the Trees”). Today’s recycling methods involve chipping timber and downcycling it into low value products such as particleboard, fuel etc. These short-lived outputs cause more rapid carbon release and represent final material use.

ECOLOGY BENEFIT– The waste recovery serves to increase the percentage of forest area globally in the same way serves to local ecosystems and biodiversity. Therefore it is necessary

to analyze each stream of waste and what ecological processes are involved in it. As an example we can refer to harvesting biomass with high nutrition content which causes mineral nutrient depletion. Compared to agricultural products wood is a crop with extremely low content of nitrogen. However, it is very different whether we take into account wood alone or wood with other biomass (crown/branches)* (Glatzel, “The Impact of Historic Land Use and Modern Forestry on Nutrient Relations of Central European Forest Ecosystems”). This puts some of the types of waste to be important players in after harvesting recovery of the forests. In other words this quality takes into account ecosystem services provided by the material if not repurposed.

SCALABILITY– Capacity for engineered standardization is crucial for safety measures and to make it easier for the product to be placed on the market. These standards are typically

developed by experts and manufacturers and are based on principles of engineering, science and available technology. This can improve reliability and performance of the product. These characteristics are graded together with principles for customization in order to develop a product which can serve for many typologies and answer different design needs.

TECHNICAL DIFFICULTY– technological readiness and availability to allow large scale repurposing of the waste. This scoring scale was conducted on the basis of TRL scale which estimates the maturity of technologies during the the acquisition phase of a project* (“Technology Readiness Level”).

Architectural References and Grading System

Methodology:

This study is divided into two parts, analysis of existing literature and research gaps in the light of wood waste qualities and their potential in architecture applications. Secondly, developing a framework for production of CLT panels, which is studied to find new opportunities to integrate sawmill timber waste material for new waste timber building component. The methodology for this research is to address three objectives of the investigation: the impact on Timber Waste Streams, the fabrication of the architectural component (CLT panel) and the geometry (architectural application). Following this investigation technique the project can evolve with the feedback provided by each method, finally becoming an informed prototype design.

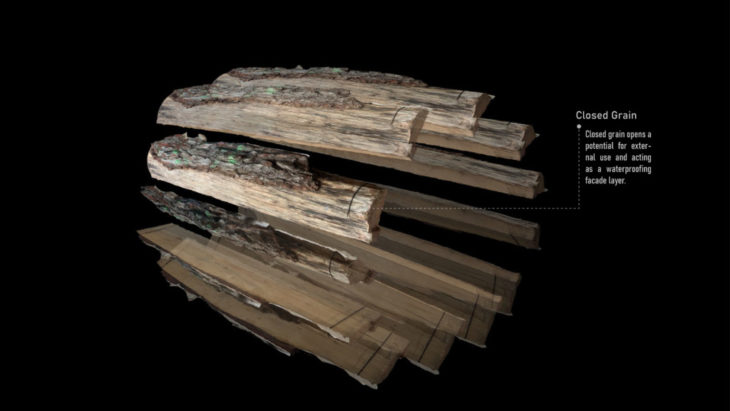

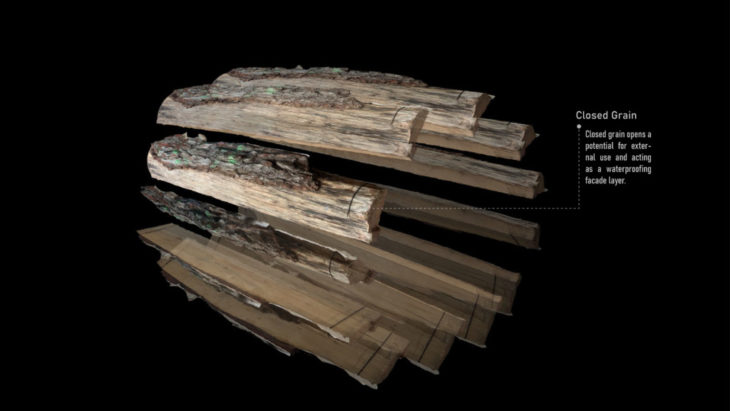

Quality: Raw Aesthetics (Source: Autor)

Quality: Rich in thickness (Source: Autor)

Quality: Long Grain (Source: Autor)

Quality: Closed Grain (Source: Autor)

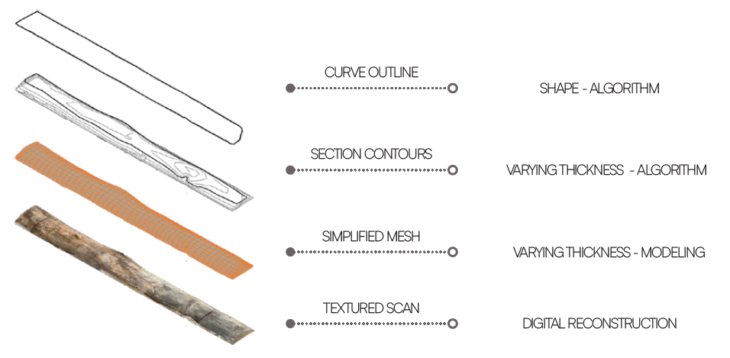

3D Scanning:

In this research 3D scanning data collection had following goals:

1. To obtain three-dimentional geometric data to reconstruct the offcut components as a mesh in a 3d software and to learn about their dimensions (primarily varying thickness

and lengths).

2. To obtain two-dimensional curve outline data to allow it to be used in the algorithm

Scanning Set-up (Source: Autor)

Geometrical Deconstruction:

Geometrical Deconstruction was conducted to input the information about the offcut components into the algorithm, with an additional goal of optimizing it for the best possible performance

of the script. This process resulted in firstly, converting the point cloud information into a Textured detailed Model, then simplifying it creating a Simplified Mesh Geometry and finally slicing it horizontally to extract Cross Section Contours. Lastly a polyline outline based on the bottom Cross Section Contours was extracted to serve as the main input for the algorithm, representing the irregular shape of the component.

Geometrical Deconstruction (Source: Author)

Algorithm:

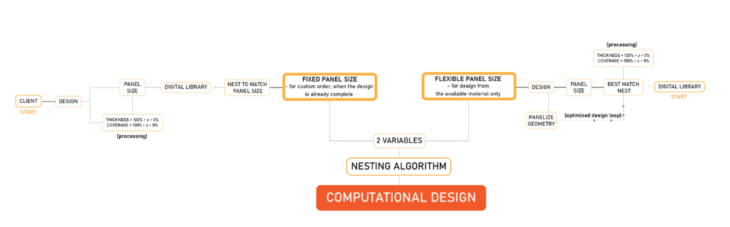

The role of the algorithm as a tool for CLT Offcut panels fabrication is to have greater control over the irregular geometries of the material and to minimize the waste produced during carpentry processing needed to use the waste components as a high value use product. The architecture of the script allows for panel design which relates to its future purpose and design strategy.

Nesting Algorithm architecture (Source: Author)

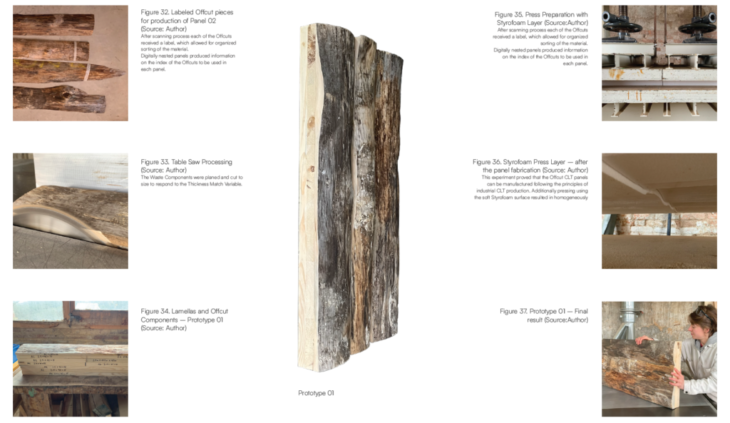

Prototype:

The main goals of taking a step into physical prototypes were:

1. To demonstrate the feasibility of use of irregularly shaped sawmill offcuts on the outer layer in the production of CLT panels.

Fabrication process (Source: Author)

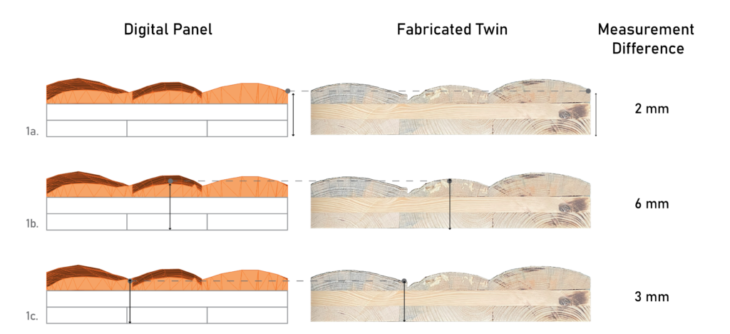

2. To test the results of the scan resolution in relation to measurements from reality.

Measuring the Results (Source: Author)

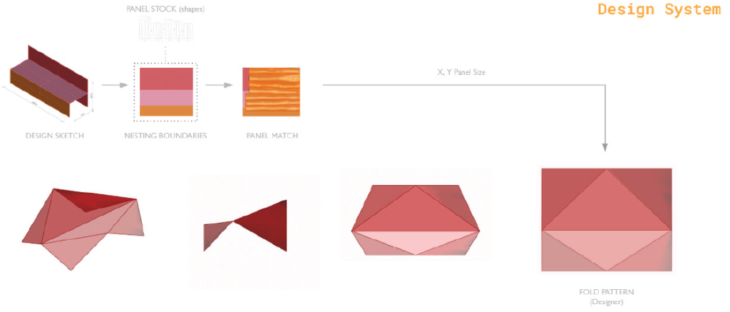

Design System:

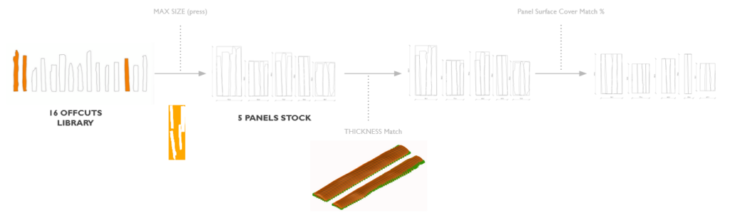

To take advantage of the the nesting algorithm and the Digital Library of 16 Items collected and scanned for the purpose of this research the first step was to propose a smaller furniture scale structure, which could be supplied from the Digital Library of 16 items.

Digital Library Stock to Panel Design Workflow (Source: Autor)

The Furniture is a teaching tool, with a gradient of results for solving emerging design and fabrication challenges. This architectural experiment puts an emphasis on the Flexible Panel Size Algorithm Variable and explores the way how this type of structure could be addressed by the Digital Library and the available Material Stock. In other words – it explores how an architectural

form could be found on the basis of the characteristics (in this case dimensional) of the material available and at the same time find a design which can benefit from the embedded material qualities. The Panel Size X (Width) and Y (Length) are the inputs for the Dimension available for the form.

Design System (Source: Author)

Fabrication Method and Joinery:

In order to verify physical feasibility of the ‘’fold’’ and the proposed workflow the design was taken into 1:1 scale prototype. This experiment puts special focus on testing the joinery proposed for maintaining a continuous folded surface and the fabrication strategy for merging material geometrical individuality and design efficiency. Additionally, a conclusion on material behavior during fabrication is drawn.

CNC Milling (Source: Author)

In the attempt to optimize the fabrication process 3-axis CNC milling is applied in order to produce the joinery. The fabrication process aimed to result with a smooth finish of the milling, for the two panels being able to connect tight. In order to do that two different strategies of milling were applied for rough and finish effect. During that process varying material behavior was observed, which provoked a constant settings adjustment for finding the most accurate result and discovering a process which could overcome the obstacles set by the material difficulties.

Prototype 02 Fabrication (Source: Author)

Drawing from experience from Prototype 01, which explored the method of Offcut CLT panels production steps, two panels resulting from the Flexible Panel Size Variable (Figure 43) were produced for a second phase of experiments, this time exploring the Furniture fold design. Previously observed fabrication difficulties opened a new research question on how to address the recognized material difficulties and provide a responsive fabrication workflow. Two connections, both of different angles were tested for achieving more results related to material

loss during fabrication and for further surface continuity and angle fitness tests. Each of the joints received a different cutting strategy.

Fabricated Panels (Source:Author)

Another step into improving the material – customized fabrication settings was to recognize that the layer of the offcut is the one more sensitive to the milling process. To address that the Strategy was extended into a 3 processes, where the first 4 cm of cut-to size lamellas were milled following Roughing Strategy (5 mm cut depth) in order to speed up the processing and beginning the Re- Roughing Strategy was introduced at the height of the Offcut Layer. This Strategy allowed for a major improvement in results.

Final Prototype – Folding system (Source: Author)

Architectural Application:

The objectives of the research were to investigate the synergies between the recognized qualities of the waste material and architectural application to develop a building component in a form of a CLT panel, with a goal to extend their life-span and provide new high-quality purpose which could benefit the Timber Value Chain for carbon storage. Through the Final Prototype the research covered the material testing for fabrication methods and achieved a method for producing Offcut CLT panels. To adopt those findings and apply to a scalable design a shading structure is proposed.

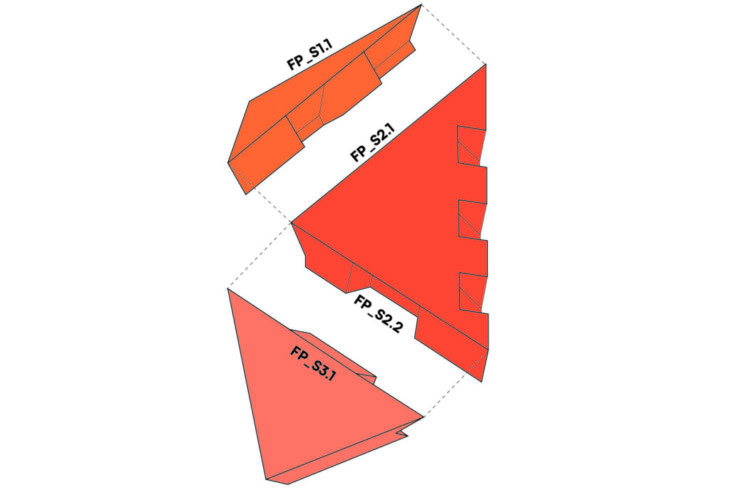

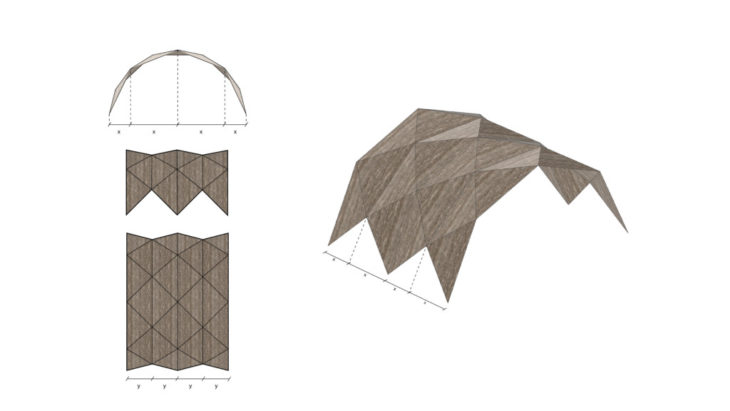

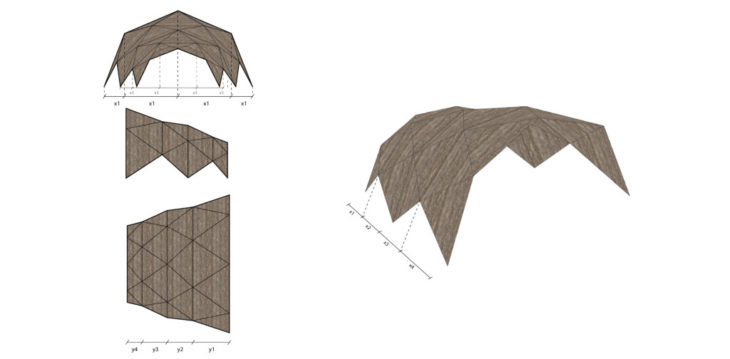

Folded Structure exploration (Source: Author)

CLT construction is mainly represented by orthogonal grid designs, which refer to the material as a final supply for an already detailed design. Folded structures are less explored, specifically using mass timber elements. The staring point is a simple algorithmic folded structure design, where the folded geometry gives possibility for self-supporting large span structure, which simultaneously

serves as a skin layer. Through the ‘’fold’’ this proposal investigates the potential of a ‘’waterproof timber’’ where the Offcut Components serve as the exterior layer and placing panels in an angle allows the exterior water flow. Previously explored Thickness Matching and Surface Continuity is crucial for this type of design. Beyond that the Flexible Panel Size Variable continues to be the design driver, therefore the proposal aims to be a result of the available material stock.

Folded Structure Material Stock Design exploration (Source:Author)

Learning from the results of the fabrication which indicated various material quality issues, which might be caused by not proper way of storing the waste components – the offcuts collected were laying around sawmilling station at Valldaura Labs, exposed to direct sun and rain. The Offcut Shelter is used as a roofing structure for storing waste components for future use, with the goal to create an efficient drying environment. For wood to dry evenly, avoiding drying-caused defects like cracks, certain weather conditions are to be favored and some to be avoided. Through various climatic analysis the structure finds the best position to create protection from direct sun and to open itself to winds coming mostly from the north.

Conclusion:

This research proposed a strategy for grading and exploring discarded qualities and ‘’waste leaks’’ of timber coming from various streams of Timber Value Chain. From theoretical point of view the experiments aimed to underline the importance of mindful surveying material studies focused on previously disregarded qualities. Resulting from the grading system specifically established for this study, it focuses on repurposing sawmilling offcut waste from its usual low value purpose – chipping for biofuel and designs a workflow for converting them into high value mass timber building component. The findings of this study suggest that through the process of using digital technologies like photogrammetry and algorithmic design a material stock based design method for the reuse of sawmilling waste can be applied to serve as a mass timber building component for folding timber structures. Lastly through various physical prototypes it explores the fabrication challenges and limitations for this material and sets direction for future development of the recognized Offcut waste qualities.