INTRODUCTION

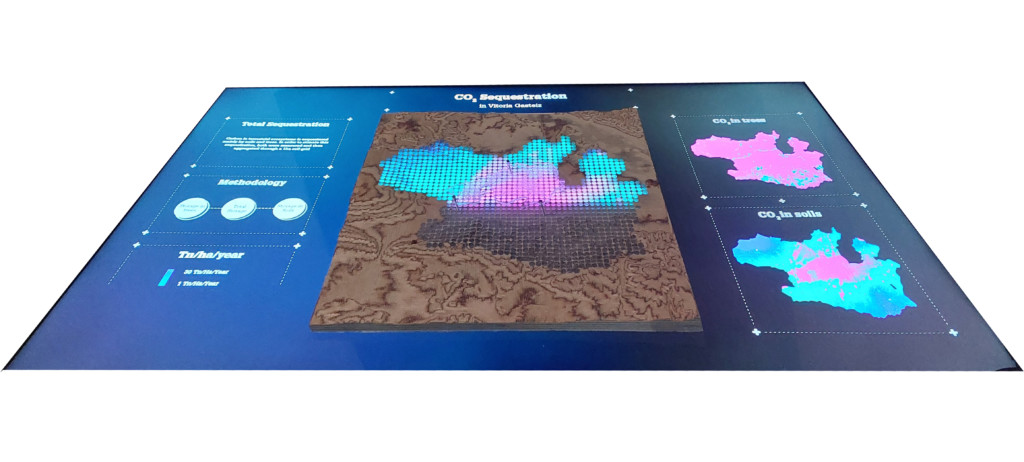

The objective of this model is to create an interactive physical interface to show LUR project, in Vitoria Gasteiz City. The physical model allocated on top of a led screen, that through different fabrication techniques filter the maps and create a 3 Dimensional image.

COMMUNICATION

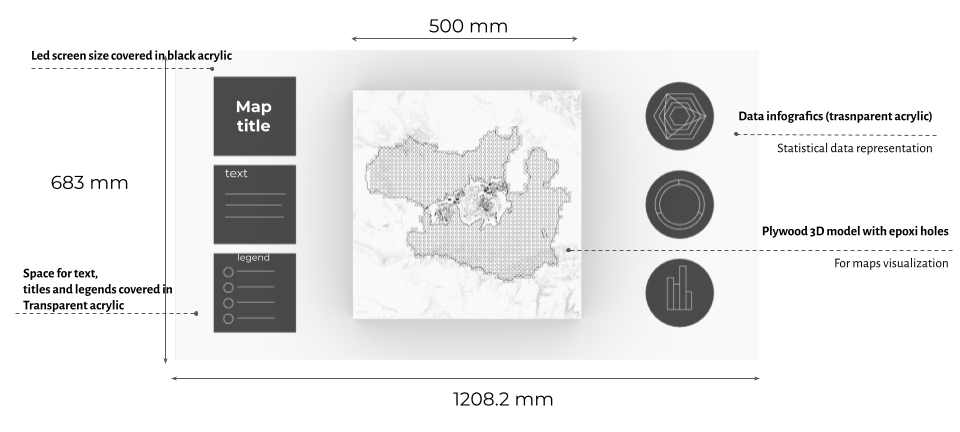

In order to create a complete table, the model is allocated on top of a LED screein in the middle. Due to the different size between the physical model and the screen, Titles, Data and legends are allocated in both sides of the Led screen.

Layout

DIFFERENT FABRICATION TECHNIQUES

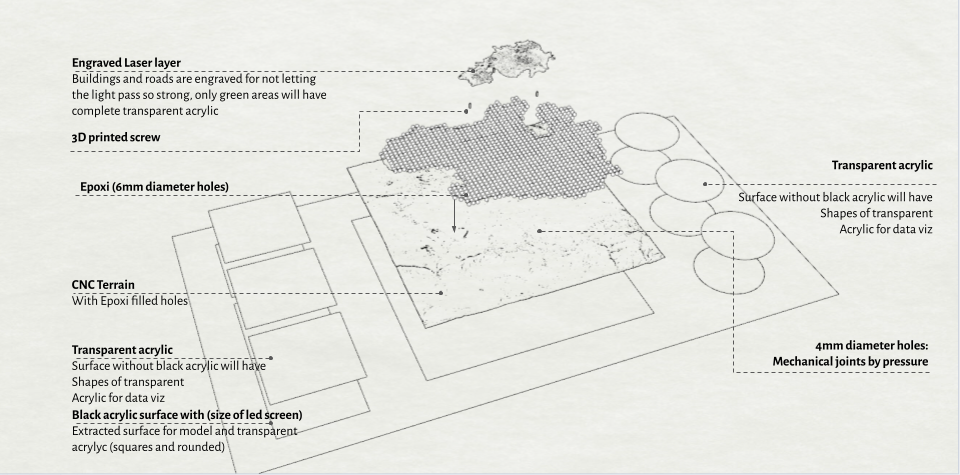

The model is created by different fabrication techniques.

- The first layer of fabrication is the layout for the model, where the central piece fits in and create the areas for the statistical data visualizations and the legend, data and texts.

- The second layer is created through CNC to recreate the topography of vitoria gasteiz, but at the same time allowing the ligh to pass through the opaque model with epoxi casting.

- The third layer is created through laser cutting and allocated on top of the model, that by engraving the residential buildings creates a transparency effect

Three layers of fabrication

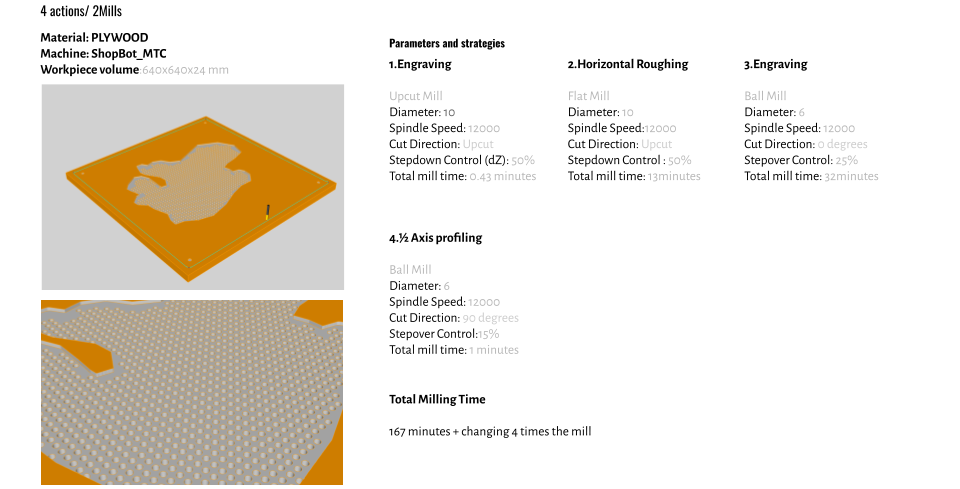

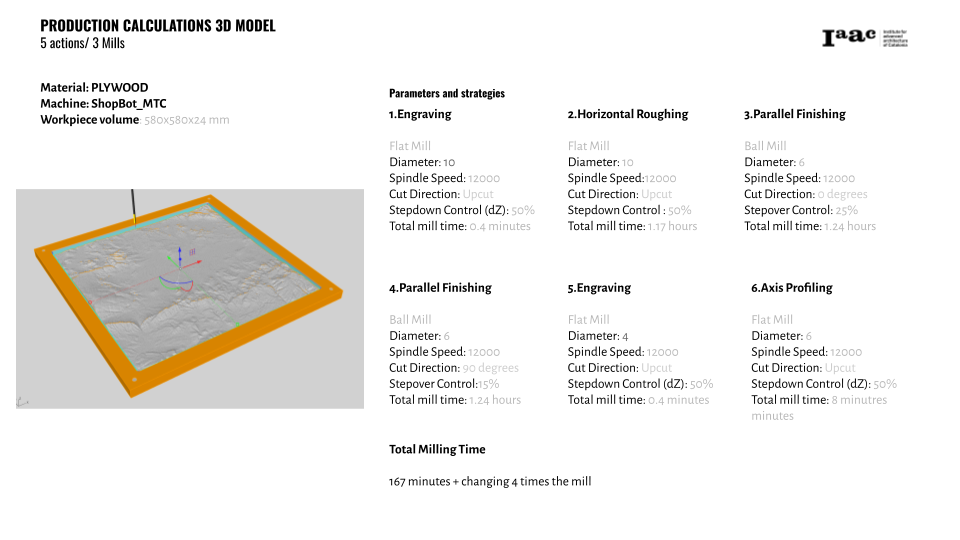

PHYSICAL MODEL: MILLING

The central piece of the model is done in plywood. Thanks to the multiple layers of the material, the topography is marked in a realistic and natural way. In order to create this piece and cast it with epoxy, there were 3 main steps to follow. The first step was to create a symmetrical image of Vitoria through rhinocam. Inside the municipality borders, a 500*500 grid was created and the centroids of this grid allowed to do the holes for the casting. The second step of the model was to fill these holes with epoxy and let it dry for 24 hours. Once the casting is finished and the material is dry, the model is flipped with now the symmetry of the symmetry of Vitoria. The model is allocated then in the same space as it was in the Shopbot and finally the territory is done. In that sense, both the plywood and the epoxy would have the topographical form. As a last step, the 3 wholes for the screws of the laser cut are done

Rhinocam Model for the firs step

Rhinocam parameters for the second step

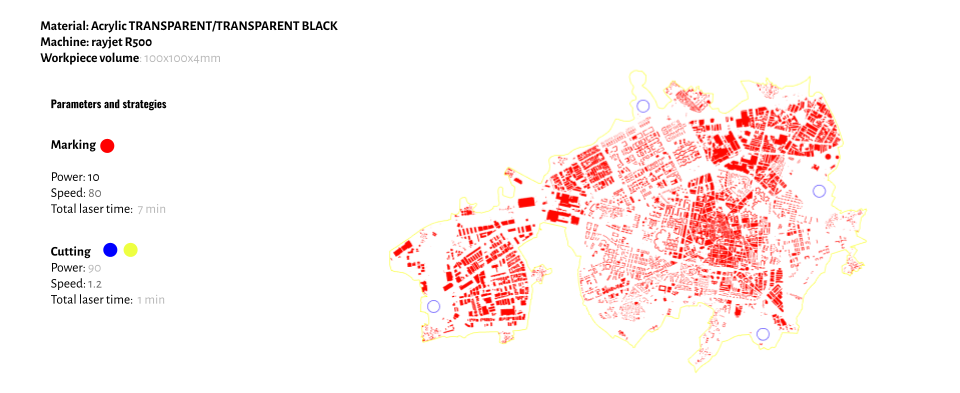

PHYSICAL MODEL: LASER CUTTING

The laser part was done in transparent acrylic in order to let the light pass through, the buildings were engraved to create a semitransparent filter.

Laser cutting parameters

DIGITAL MODEL: LAYOUT

The main objective was to create a double screen animation. In the front screen the methodology is shown with little maps. In the flat screen were the model is ubicated, the main data indicators with the explanation. The animations were created for the Carbon sequestration indicator

DIGITAL MODEL: RESULTS

Lur Interaction is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in City & Technology in 2021/22 by student: Adriana Aguirre Such and faculty: Cristian Rizzuti, Shyam Francesco Zonca.