Using Supervised Learning to optimize parameters for hardwood sanding using 6 axis robot

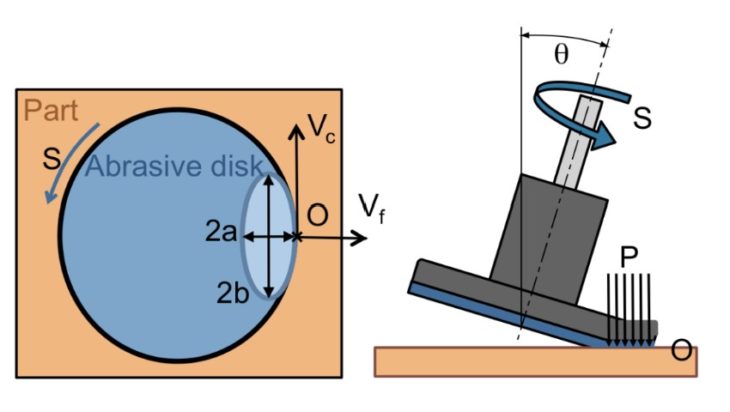

Sanding is one of the most common processes in wood manufacturing. Machine sanding involves material removal through use of sanding grit attached to a tool. The three basic types of motion for sanding tools are linear, such as belt or drum sanders, rotating, or random orbital.

While random orbital sanders are simple and efficient at fine surface smoothing, they are less suited for shaping and blending, both processes that involve higher material removal rates.

Milling is very efficient at material removal rates but less efficient at surface smoothing over larger areas. Disc sanding offers a larger smoothing surface and is ideal for surface smoothing on a large scale but is more subject to variables such as wood hardness, humidity, tool angles, feed rate, etc.. Learning Smooth studies the application of directed machine learning in optimizing the theoretical parameters involved in material removal using a rotary sanding disc.

Methodology

Manual sanding involves intuition on the part of the craftsman. In theory, material removal rates for sanding and polishing can be modeled using a model using using various equations depending on the type of mechanical process taking into consideration various parameters and a coefficient based on empirical testing known as the Preston Coefficient. For disc sanding the following parameters would be considered

-

- Feed Rate

- Tool Pressure

- Tool Speed & Torque

- Tool Grit + Smoothness

- Wood Density

- Wood Humidity

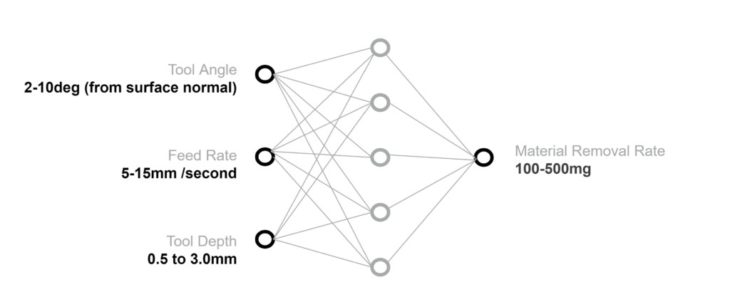

The objective of the learning network would be to work around the need for determining the preston coefficient and modeling the parameters instead of deriving the equation for optimal material removal rate mathematically.

Training Network

The supervised learning is first mocked up using mock or “false” data based on reasonable assumptions on input parameters being considered.

Data Collection

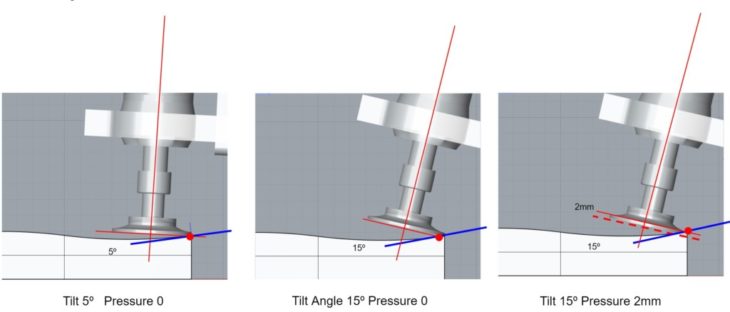

Testing for tool angle, feed rate, and tool pressure is base on a 150mm x 150mm x 30mm block with a ruled surface. Identical samples using the same material would be tested using various combinations of parameters. The basic contour is roughed using 3 axis CNC milling the shaped using a rotary sanding tool attached to a 5 or 6 axis robot.

Sanding Smooth is a project of IaaC, Institute for Advanced Architecture of Catalonia Course: Masters in Robotics and Advanced Construction (MRAC) Year: 2021-2022 Students: Christopher Booth, Tomas Quijano Faculty: Mateusz Zwierzycki Assistants/ Nikole Kirova