INTRODUCTION

Digital Fabrication is an introductory course on new production techniques through the relation between computer data and machine-oriented fabrication. The aim of the course is to explore the design opportunities arising from three common digital fabrication processes: Laser Cutting, CNC milling and 3D Printing. The group aimed at understanding and exploring the capabilities and limitations of the three manufacturing processes and to develop an integrated approach to design and production.

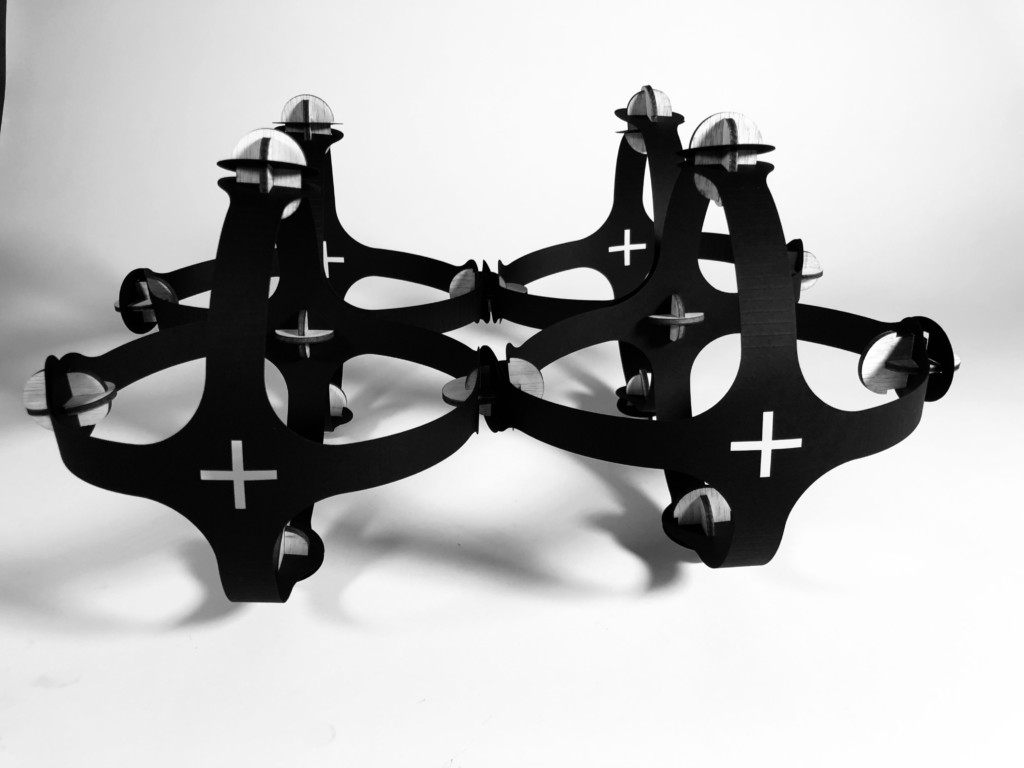

EXERCISE 1 // LASER CUTTING // STAR BALL

Minimizing the amounts of cuts while testing the bending properties of different materials. Original intenstions to create the structure in 0.4 mm plywood. Each Star Ball have 6 connection point, the design intesion was to differenciate the joint from the star structure, through it’s material and thickness? Exploring the different incuts possible to make the structure more maleable and bendable. For this prototype as the chosen material was card simple engravings suffised to achieve a bendable surface.

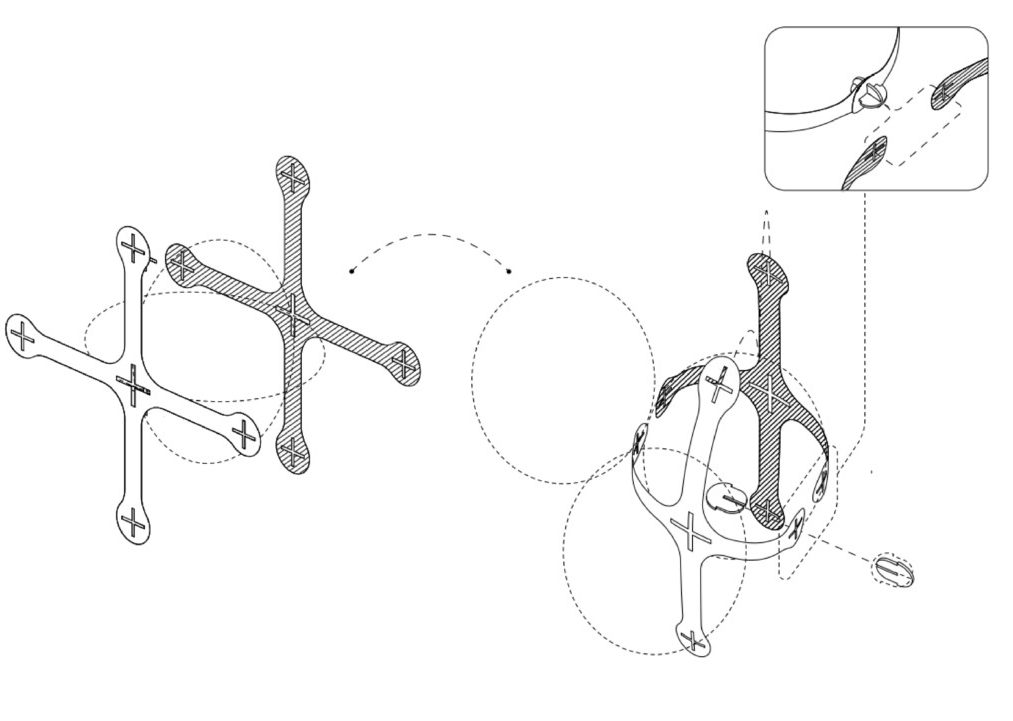

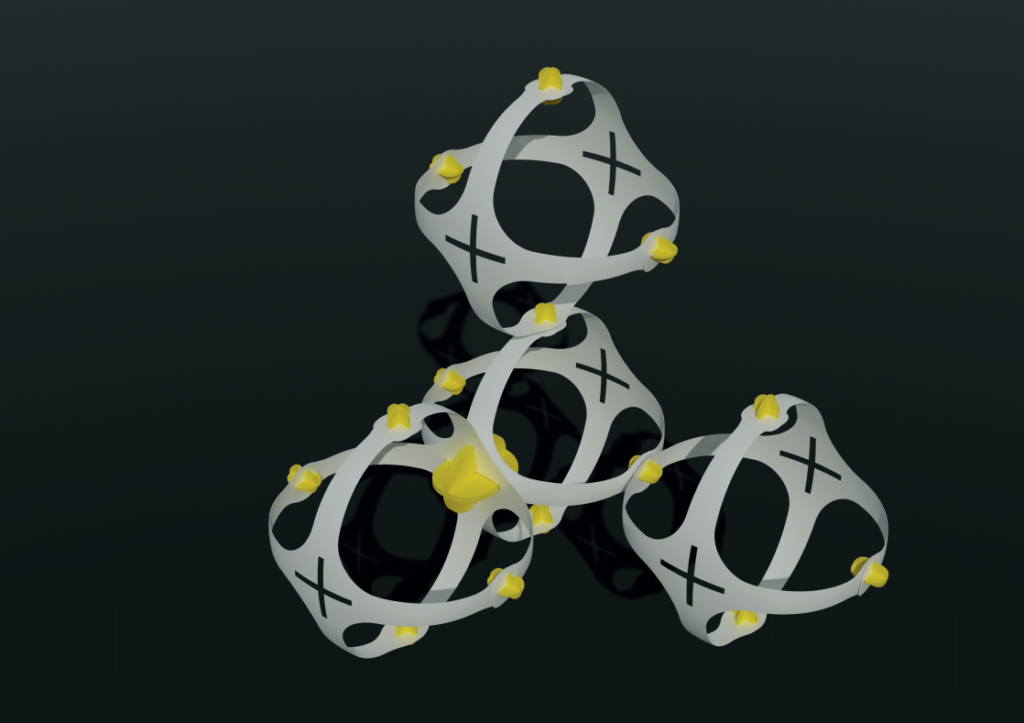

DIGITAL EXPLORATION OF AGGREGATION STRATEGY

DIGITAL EXPLORATION OF AGGREGATION STRATEGY

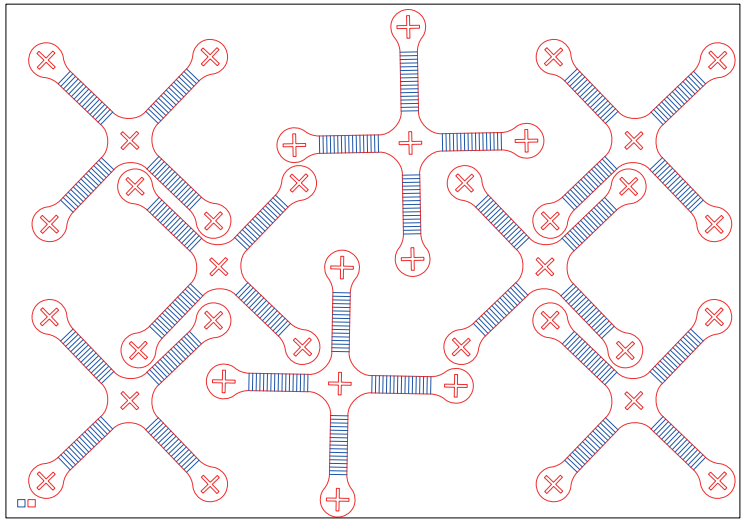

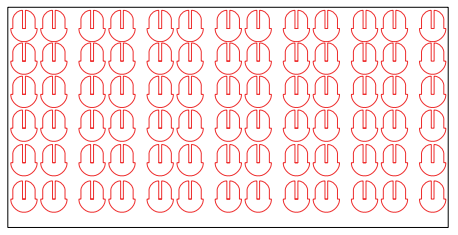

TECHNICAL//SETTINGS & PIECES

TECHNICAL//SETTINGS & PIECES

Machine: Rayjet 500

Joint type: Interlocking

Material: Card Board

Cut:

Speed: 3.00

Power: 20

Engrave:

Speed: 55.00

Power: 15

Total prints: 8 units

Material: Plywood 4mm

Speed: 2.00

Power: 50

Total prints: 78 units

For practical and structural reason a thin cardboard ( cartalina) was choosen – 0.1mm, the laser was set to cut fast. The engravings in blue were placed and soften and direct the card to achieve better bending.

For the joint a thicker material – 4mm plywood

FINAL RESULTS

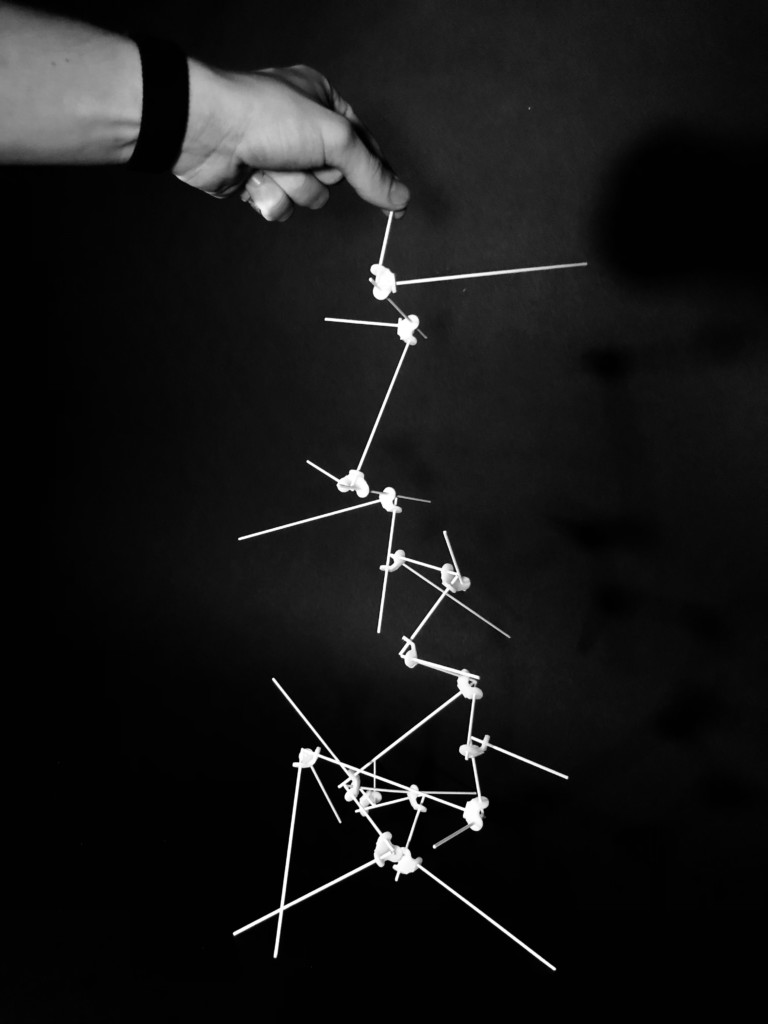

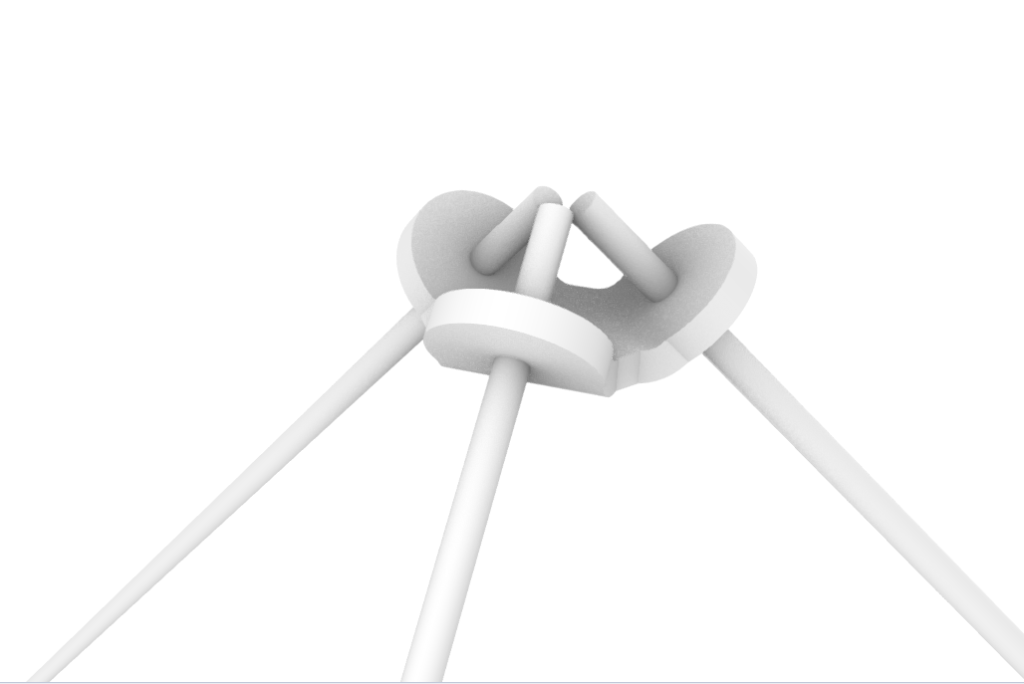

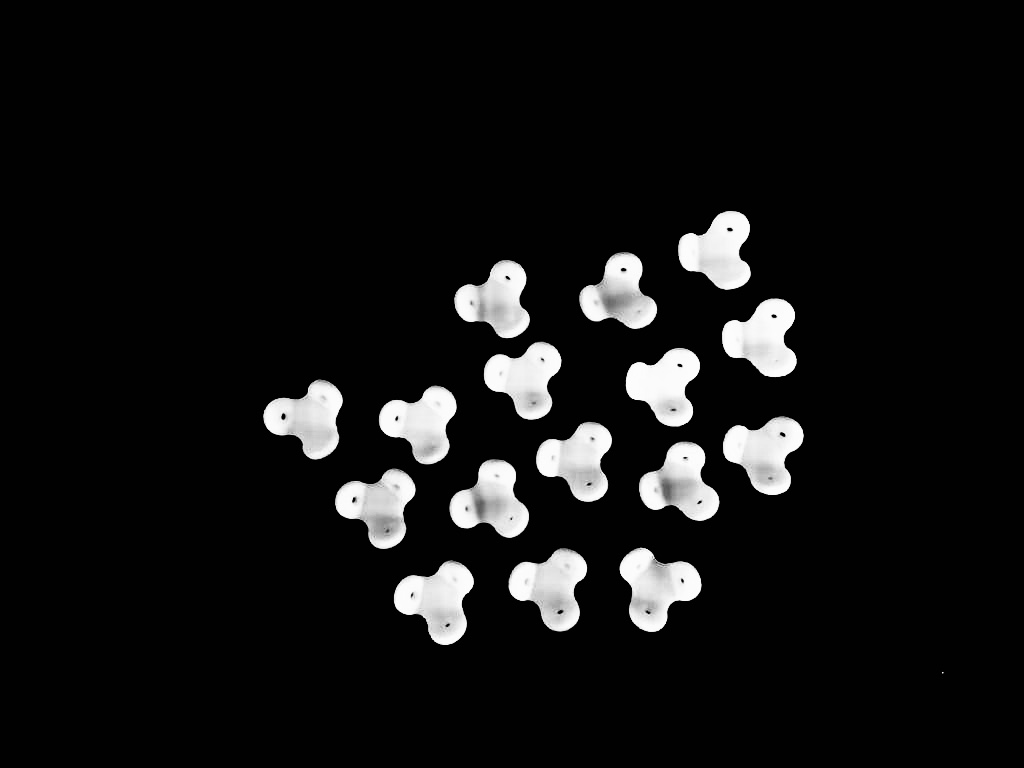

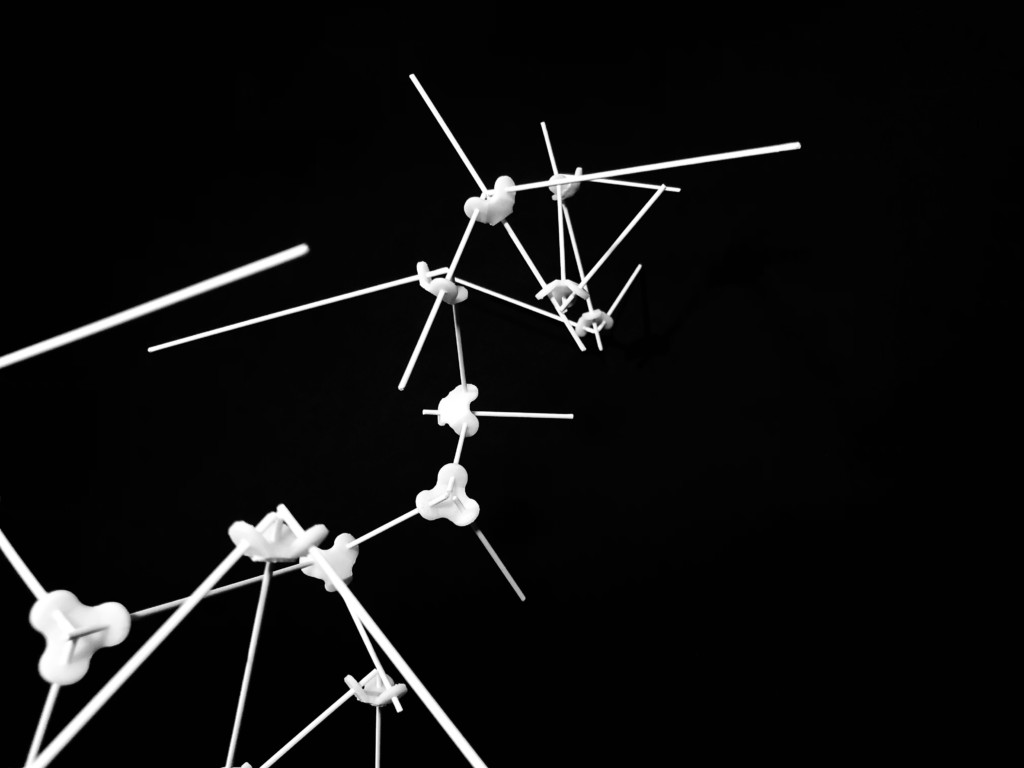

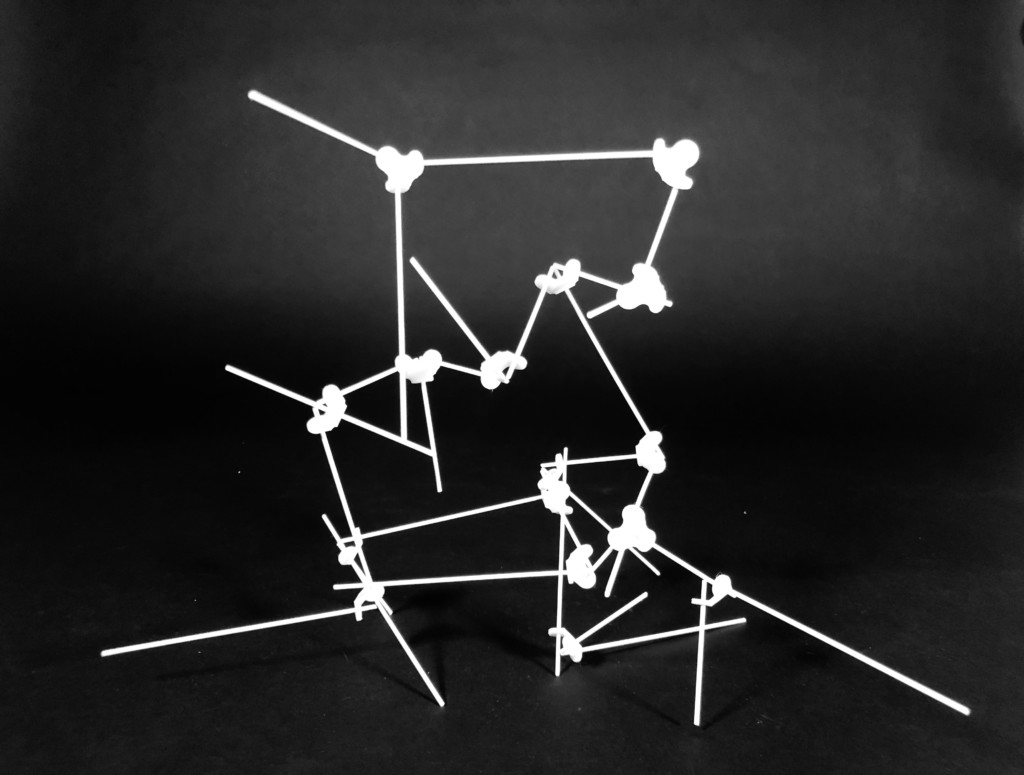

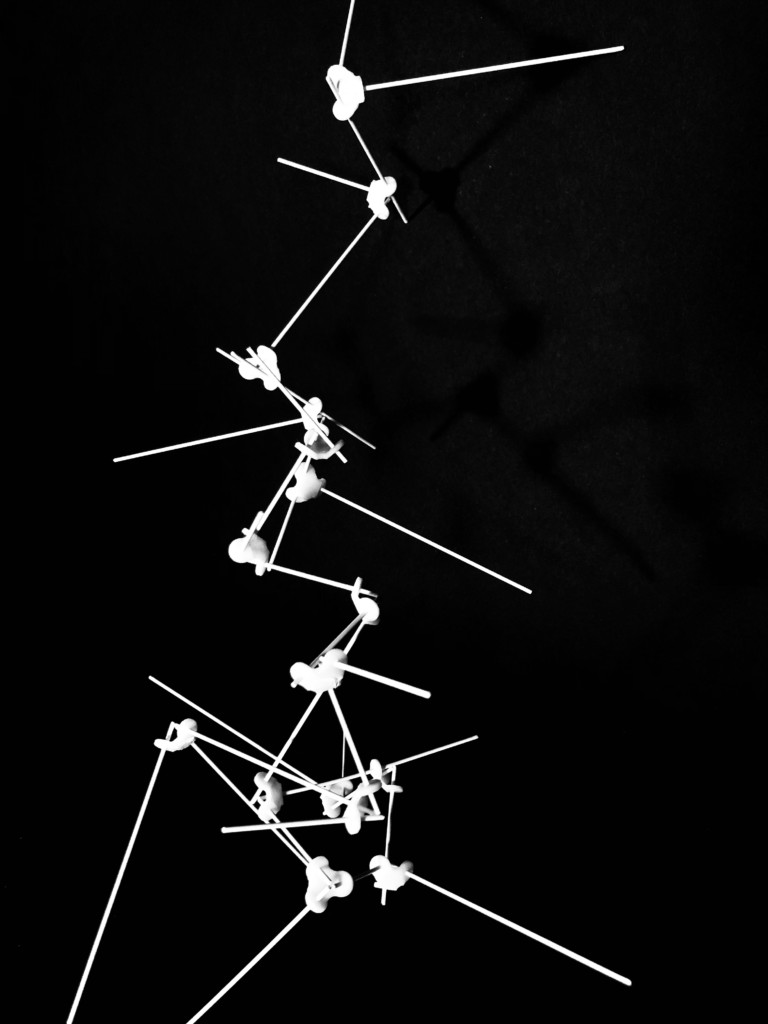

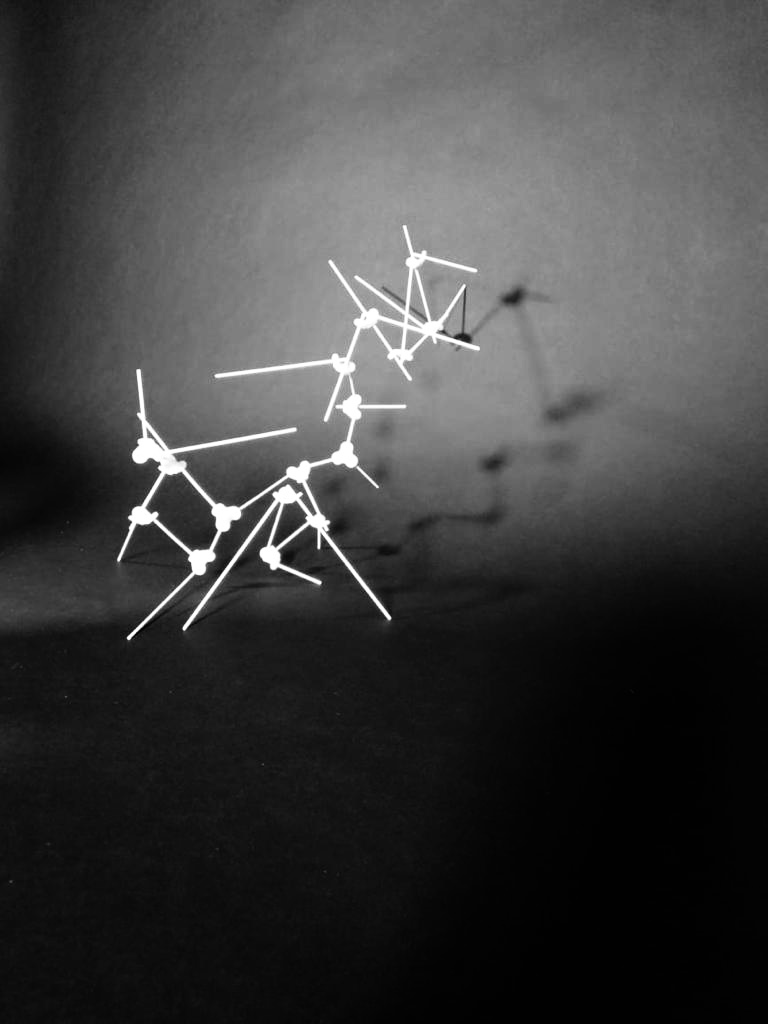

EXERCISE 2 // 3D PRINTING // TRANSFORMERS

The intent was to design an efficient joint system to connect angled members of different sizes.The joints can be flipped and rotated to form multiple permutations and combinations, that could combine to make different recursive geometries. A flat based node with 3 angled anchor points was modelled.

The intent was to design an efficient joint system to connect angled members of different sizes.The joints can be flipped and rotated to form multiple permutations and combinations, that could combine to make different recursive geometries. A flat based node with 3 angled anchor points was modelled.

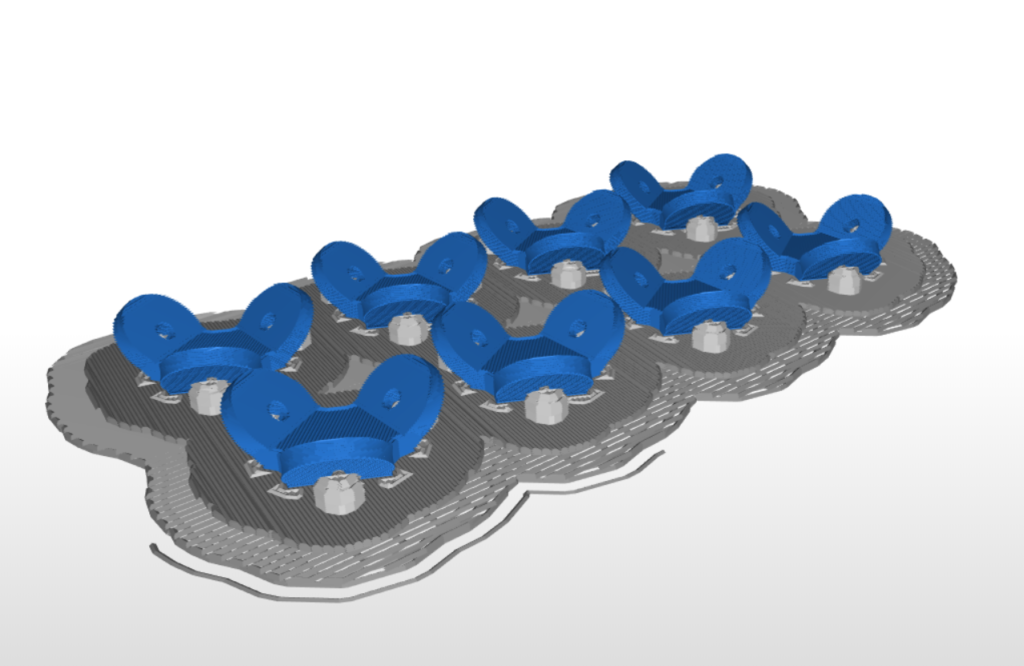

TOLERANCE TESTS

- Tolerance test 1: Hole of size 2mm

The rod fit, but was too resistant. the rods were getting deformed due to pressure put while connections were made.

- Tolerance test 2: Hole size 2.1mm

The rod fit well, and was tight enough to form a strong joint.

Fabrication Parameters

- Number of Nodes: 16

- Rod diameter: 2mm

- Length of rod: Total 4m, in units of 60 & 120mm

- The Node plate thickness: 5mm

- Printing time: 3h 20min

- Printer: Zortrax 200+

- Material usage: 22g

- MateriaL: Z-ABS

- Layer thickness: 0.19mm

- Supports: Automatic

- Infill: 30%

- Raft Layers: 7

FINAL RESULTS

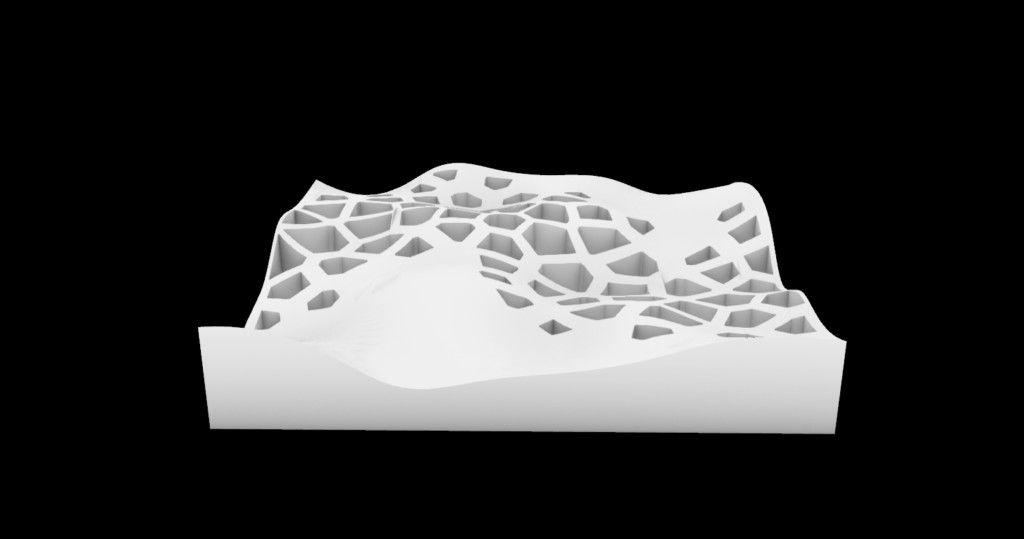

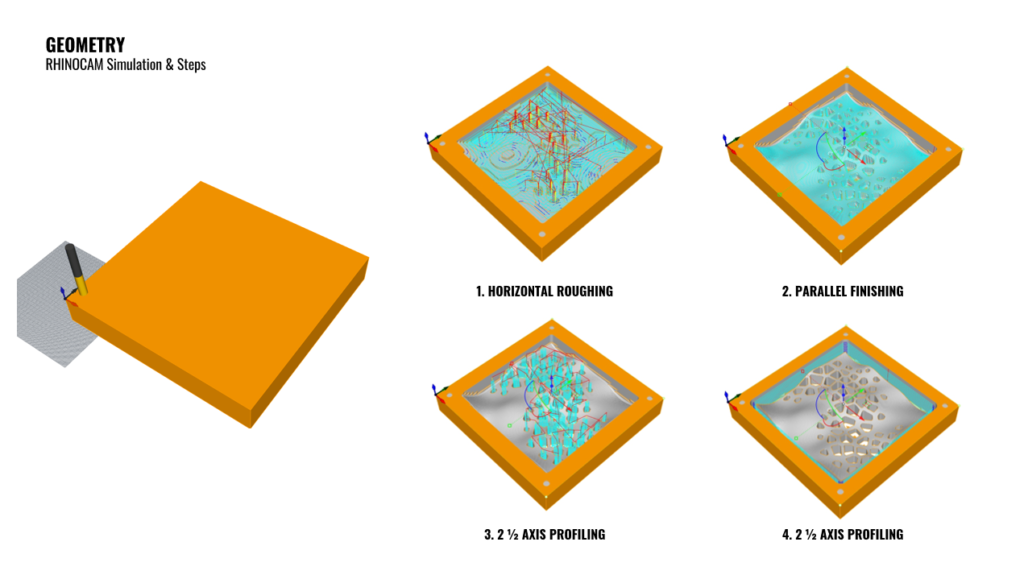

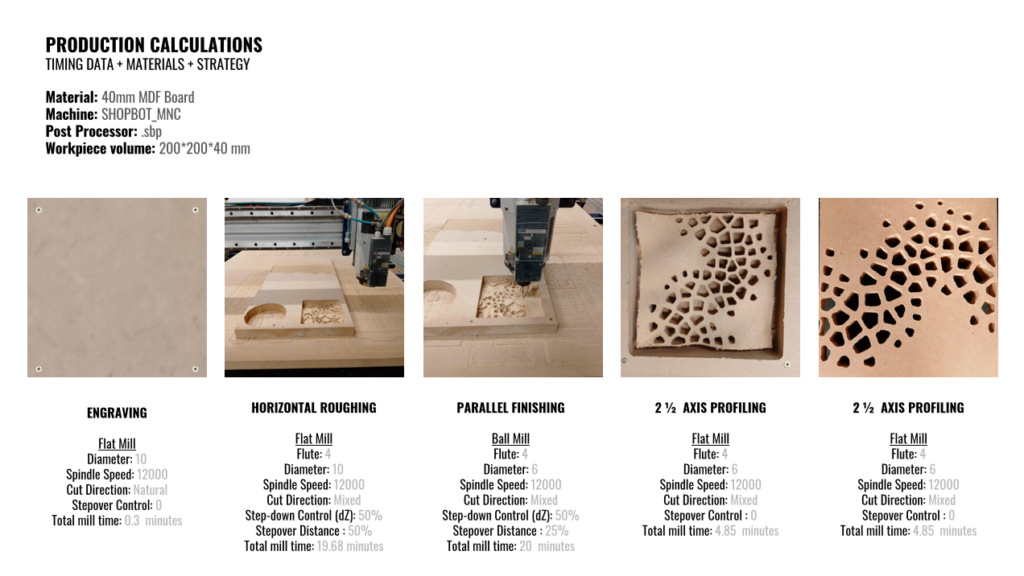

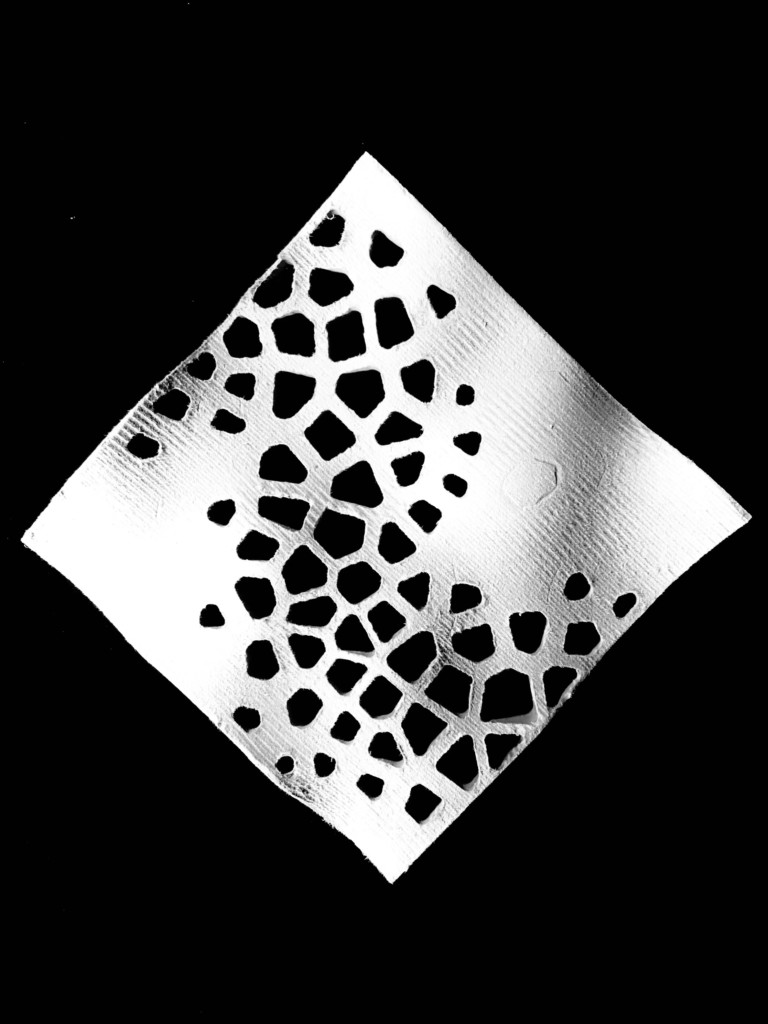

EXERCISE 3 // CNC MILLING // NEST

The initial idea was to use the basic geometry of the HONEYCOMB and morph it into an undulated surface. The perforations are continuously altering in size and location while it travels along the undulated surface creating pockets of spaces. This volume could eventually be a space within itself and aggregate into a pattern of a nested space.

FINAL RESULTS

Introduction to Digital Fabrication – is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021 by Students: Alex Ferragu, Rishad Mohammad Yusuf, Vasudha Karnani, Weihao Yin and faculty:Shyam Francesco Zonca , Lana Awad, Ricardo Mayor