Introduction

The aim of the course was to explore three digital fabrication techniques. The seminar structured in the form of a workshop included, for each manufacturing technique, an introductory lesson to the method and to the machine in which we were able to actively experiment, with trials and tests, the limits and potential of each machine. After that, the second phase involved a week of development of a specific concept for each machine whose common denomination was that of designing discrete elements that can be aggregated in a recursive geometry. The form of the seminar allowed us to quickly and effectively understand the pros and cons of each method as well as the limits and potential of the machinery, giving us the bases and the skills to understand which fabrication technique is suitable for a specific project rather than to another.

3d printing

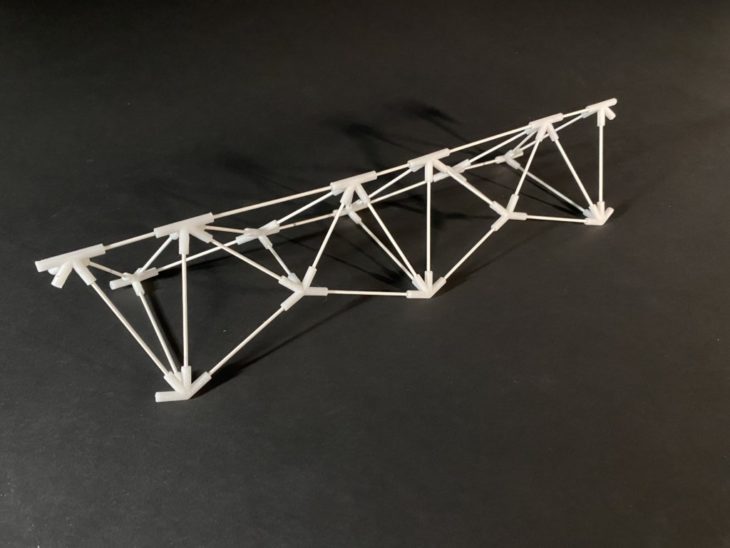

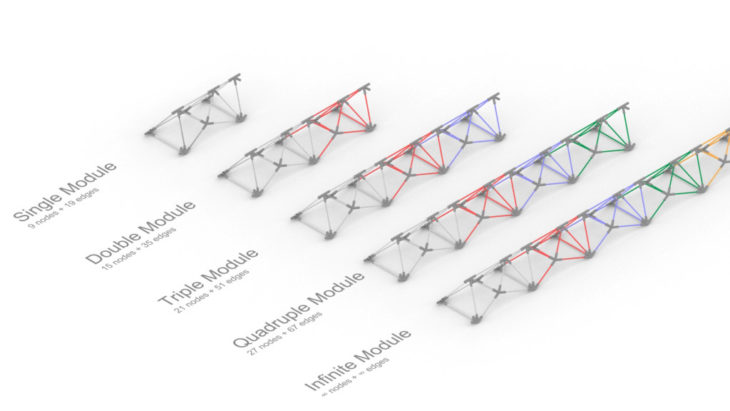

The first fabrication method explored during the seminar was the 3d printing. Preliminary stages of our design began with sketches of a pyramid shape to resemble a truss module. This idea was further developed into two connected and symmetrical pyramids. These pyramids were connected by a rod in order to become a recursive geometry that could be stretched infinitely. The final geometries that were designed are symmetrical and recursive for two directions, it allows for infinite stretching of the shape. The form is modeled out of a simple truss system with 6 triangle modules.

Technical information

Material: Z-ABS

Machine: Zotrax M200

Total number of nodes: 16

Total print time: 4h 04m

Total material quantity: 19g

Layer thickness: 0,19mm

Support type, angles and specifications: Automatic, 31°

Infill type, percentage, & pattern: Normal, 30%, Patt. 2 (honeycomb)

Seam: Normal

Mesh errors and fixes: No errors

Recursive geometry

Digital exploration

CNC Milling

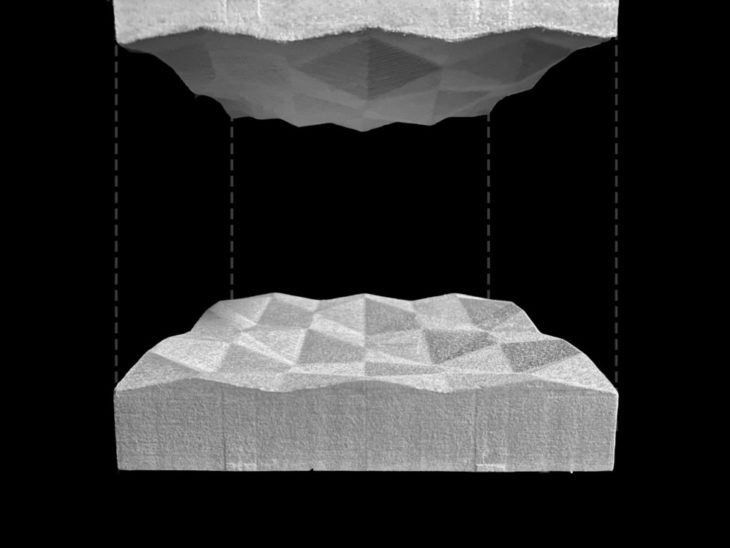

For the CNC milling fabrication technique we were inspired by the honeycomb shape and the pattern resulting from the sectioning action of beekeeping boxes that generate an interesting play of solids and voids. We wanted to combine these two elements in our project, also taking into account the possible variations generated by the pattern and for this reason the result consists of two tiles, one concave and one convex, therefore different in shape, but perfectly overlapping.

Technical information

Material: MDF

Machine: Raptor

Workpiece volume: 150x150x30mm

Total mill time: 23 mins

Engraving & profiling

Upcut Mill 6mm

Spindle Speed: 12000

Cut Direction: Upcut

Horizontal Roughing

Upcut Mill 6mm

Spindle Speed: 18000

Cut Direction: Upcut

Step-down Control (dZ):50%

Stepover Distance: 40%

Parallel Finishing

Ball Mill 6mm

Spindle Speed: 18000

Cut Direction: Mixed

Stepover Control: 20%

Recursive geometry

Digital exploration

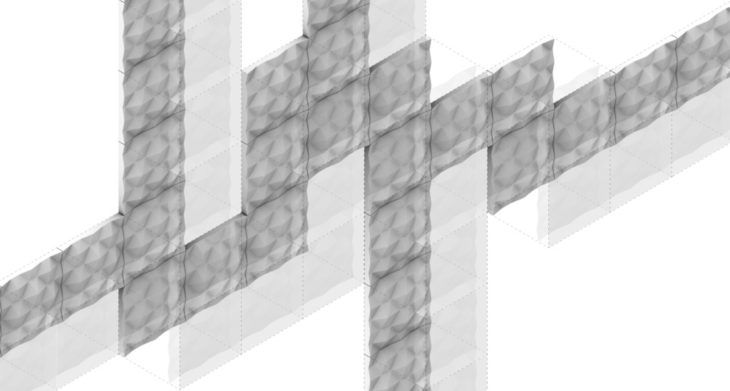

Laser Cutting

Technical information

Material: Polypropylane 1.2 mm

Machine: Rayjet 500

Total cutting time: 23 mins

Total number of pieces: 111

Joinery type: halved

Recursive geometry

Digital exploration

Introduction to Digital Fabrication G21 is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in (2021) by:

Students: Emily Bishop, Angelo Desole, Sarjak Rakholiya

Faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca