HRC in Preliminary Design – Research methods

Research Statement

FIELD

The study model is a valuable practice. It invokes the designer to participate intuitively and freely in the design process.

As a critical tool it helps to manifest a design vision prior to its verbalization. As a self reflective tool it communicates the idea between the designer’s logic , skill and vision. And in a design community it informs the partners and stakeholders.

GAP

Physical Models are becoming obsolete due to their low value – for – money measure. The process takes time and skill, And the outcome has to be manual digitized in order be used in the continuous design process.

Digital fabrication processes such as CNC and 3D prototyping , although helping to maintain the tangibility of a design, do not replace the haptic design process as they are direct result of a symbolic modeling process.

OPPERTUNITY

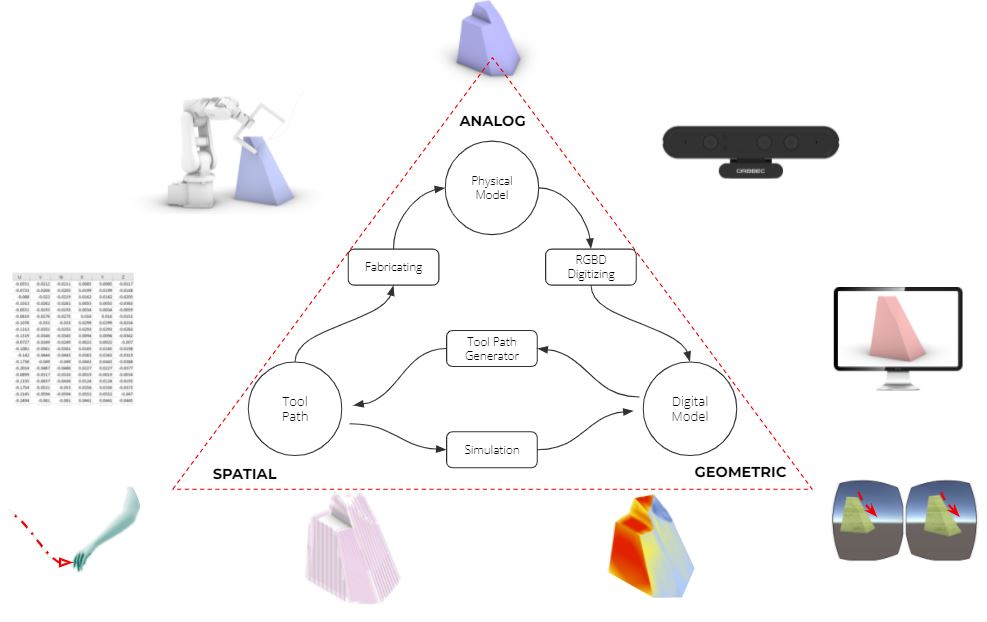

In this gap, emerges the possibility of integrating the creation of physical model while producing its digital twin. By merging the digital and physical modeling ,one can open the process new possibilities such as informing the design, integrate more participants, or create a physical facsimile. In addition, the integration could lead to a new tangible design process.

PROJECT

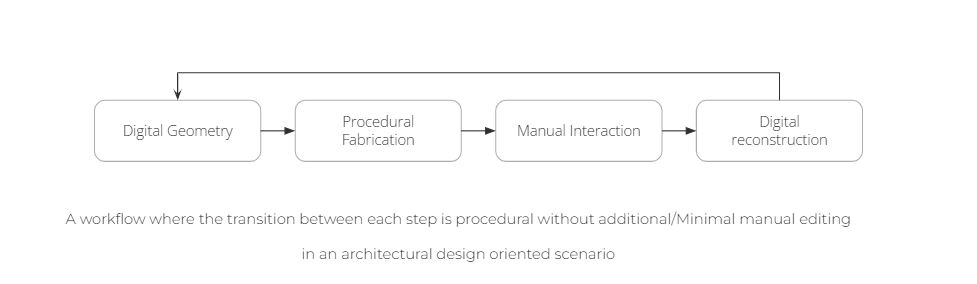

In this project, I aim to lay the groundwork for an integrated design exploration workflow, where the design exploration occurs simultaneously in a digital and a physical environment. By creating a digital/physical craft procedure, the study models could be reintegrated to the general design workflow, and can emerge as a new digital craft skill.

Framework

DOCUMENT 1

Neil Leach and Philip F. Yuan Architectural Intelligence Selected Papers from the 1st International Conference on Computational Design and Robotic Fabrication (CDRF 2019) -Introduction

Robotic fabrication, then, can be understood within the logic of the cyborg as a form of cyborg intelligence .With industrial robots as the revolutionary construction platform in the digital era, the architectural profession is experiencing a significant paradigm shift from traditional crafts and industrial reproduction to a new human– machine collaboration. Indeed, all robotic fabrication tools are an extension of the operations of the fabricator. As such, it is not as though we should make a distinction between manual craftsmanship and digital fabrication. Rather the whole of robotic fabrication can be understood as a form of cyborg craftsmanship. If, as Alberti claimed, “The workman is a tool in the hand of the architect,” so too the robotic arm is a tool in the hand of the architect, a cyborg-like extension to the architectural imagination. We could therefore refer to the intelligent use of robotic fabrication technologies as robotic intelligence.

The architectural academic world is looking for ways to implement novel “intelligences” to promote novel design procedures. One of the prominent ones is the connection between a human mind to a robotic application.

DOCUMENT 2

Horizon Europe – Work Program 2021-2022 Culture, creativity and inclusive society

DESTINATION: INNOVATIVE RESEARCH on the EUROPEAN CULTURAL HERITAGE and the CULTURAL and CREATIVE INDUSTRIES

“…They (the EU countries) will connect cultural heritage with the CCIs by supporting new forms of cultural and artistic expression that build on existing cultural assets and provide access to both tangible and intangible heritage. R&I will also promote the competitiveness of cultural and creative industries.

Projects should contribute to at least two of the following expected outcomes:

- Revive, valorize and foster traditional crafts techniques

- combine them with new and emerging cutting-edge technologies.

Bring together the traditional know-how with new and/or digital technologies to develop improved and new products, services and professions

There is a growing interest and government funding for projects which promote integration of traditional craftsmanship and novel technologies in the purpose of increasing the competitiveness of arts and crafts based businesses.

DOCUMENT 3

What happens if robots take the jobs? The impact of emerging technologies on employment and public policy

By Darrell M. West

Robots are expanding in magnitude around the developed world. Figure 1 shows the numbers of industrial robots in operation globally and there has been a substantial increase in the past few years. In 2013, for example, there were an estimated 1.2 million robots in use. This total rose to around 1.5 million in 2014 and is projected to increase to about 1.9 million in 2017.5 Japan has the largest number with 306,700, followed by North America (237,400), China (182,300), South Korea (175,600), and Germany (175,200). Overall, robotics is expected to rise from a $15 billion sector now to $67 billion by 2025.6

Automation industries are aiming on replacing jobs with repetitive or patterned jobs. High agency positions are more likely to be improved and augmented by technological expansion than replaced.

State Of The Art

METRICS

DEFINING PHYSICAL\\DIGITAL MERGING PROCESS

- WHERE DID THE “DESIGN” HAPPENED? (THE DEFINING SHAPE)

- HOW WAS THE DIGITAL CREATED?

- HOW WAS THE PHYSICAL CREATED?

- WHAT WAS THE ROLE OF THE DIGITAL ENVIRONMENT?

- WHAT WAS THE ROLE OF THE DESIGNER?

- WHAT WAS THE ROLE OF THE MACHINE?

Conclusion

The field of creative integration between the physical and the digital environment is a growing field of academic research. Although it did reach technical maturity –

Industrial application are still scarce and tend to stay in a comfort zone of artistic performance or capability demonstration.

Scientific Interest

The integration of physical and digital design interfaces benefit those design businesses that aspire to either improve the quality of their design processes, and want to seek leverage in a competitive and global environment.

As designers we know that while our marketability is dependent on our ability to deliver quality designs while communicating with the different consultants and professionals involved in the design and construction process. The integration of tools and workflows pushes towards closing the gap between the between the inner native design tools, which empower the designer and the outer communicative necessity.

REASEARCH AIMS

Assumption:

Manual Modeling has a high quality value as a decision making tool for architectural designers.

The cost (Time, speed and money) of the transition between the physical tools and digital tools decreases its usage.

Aim:

This researches aim is to develop a design workflow that synthesizes the manual modeling making processes with the digital to a single iterative process.

Thus increasing the qualitative values while reducing the time and effort the transition takes.

REASEARCH OBJECTIVES

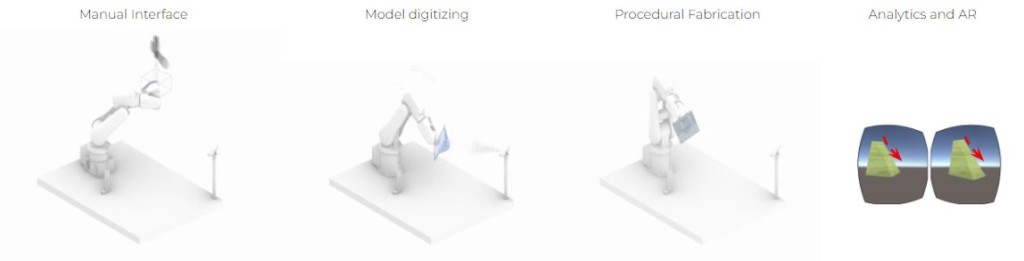

Objective 1 – Develop the ability to record manual tool movements and translate them to valid Robotic tool paths

(Given a set of recorded manual movement, The user is able send these movements as robotic instructions)

Objective 2 – Develop an automated 3d reconstruction process

(Given a predefined geometry mounted on a robotic arm, The user is able to receive a Digital mesh Generated by the system)

Objective 3 – Develop a procedural fabrication process:

(Given a digital volumetric mesh, the user is able to generate a physical fabrication process)

Objective 4 – Develop an AR analysis augmentation

(Given a digital volumetric mesh, the user is able the view data analytics of the model on the model)

RESEARCH METHODS

- Using ROS to create a unified platform and encompasses the process from start to end (geometrical Frame of reference and UI/UX )

- Using Hot Blade cutter and foam blocks to create the physical geometries.

- HTC Trackers in order to record movement in 3D space in relation to the stock material

- RGBD Camera with OPEN3D and CGAL to capture , digitize and process the physical artifact

- Using CGAL to create the procedural fabrication preparation and ROS-MOVEIT to create the tool path.

- HOLOLENS in UNITY environment to augment the model with data

- Using Grasshopper in Rhino for testing and process sketching

- Validation by experimenting in an architectural design office.