HARDWARE I // SHAPEWEAVER (SW)

During this seminar, MRAC 01 students Shahar Abelson and Helena Homsi designed an end effector for the IRB 140.

MRAC Faculty Angel Muñoz lead this seminar assisted by Matthew Gordon (MRAC 02).

A short extract of the syllabus showcases the guidelines of this seminar:

“In this seminar the students will be introduced on how to develop hardware projects covering the whole process including research, prototyping and documentation. During the first term we will focus on actuators like different types of motors, solenoid valves, pneumatics, relays, electromagnets and how to control them from a microcontroller. After the first intensive week the class will spend the rest of the first term working on a project to create an end-effector tool using the actuators previously taught and to be installed on the ABB robot.”

The end effector designed here is still ongoing further tests and is not fully optimized yet.

Stay tuned on the blog for future updates!

Concept & Inspiration

Nowadays, robotic weaving is not only limited to textile and product design. The aim and material of the process are slowly growing to adapt in the construction industry. We would like to test the ability of our hardware, attached to the ABB, to weave shapes out of metal wire on a wooden base with columns. The project is inspired by radial braiding machines and the aim is to create our small scale interpretation of a similar process.

Initial Explorations

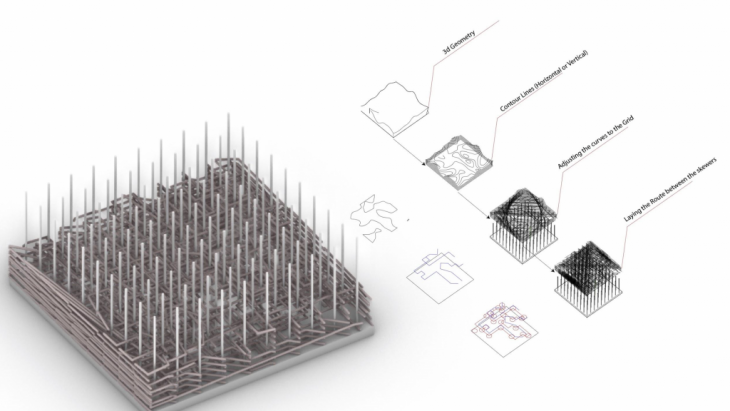

Design Strategy & Goal Refocused

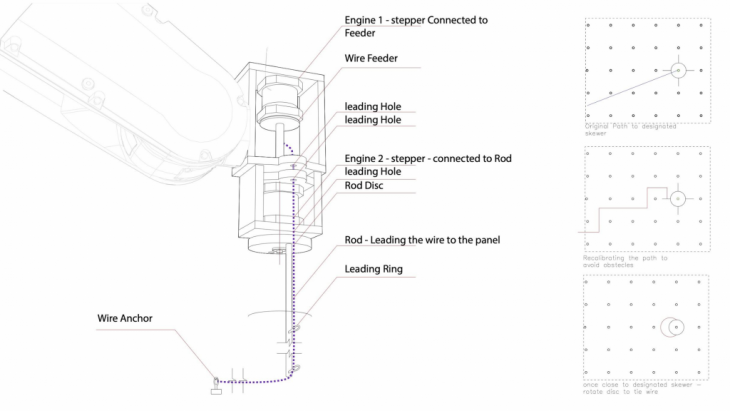

The design strategy was simplified from this point and onwards to a metal weaving design onto a base. The wire would start by being attached at an achor point and then unwravel itself as it moves through the grid to create shapes through linear motions in x, y and z.

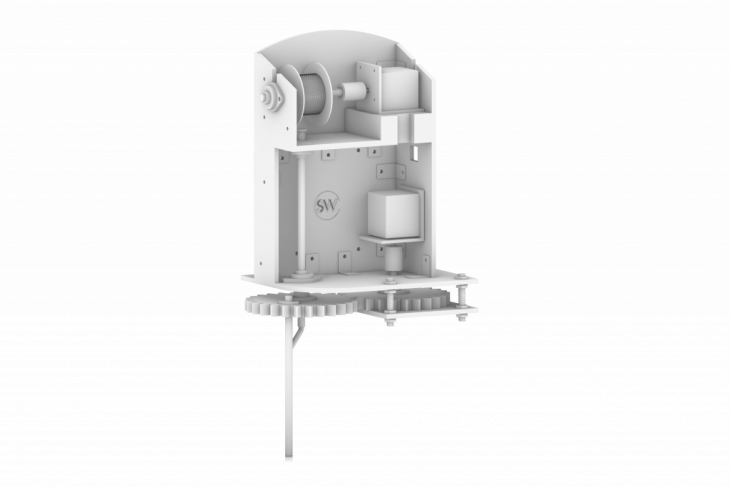

The very first conceptual sketch was like so. Many improvements needed to be made:

- use the correct measurements of parts

- spindle thickness & rigidity

- arduino placement

- cable placements

- connection to ABB

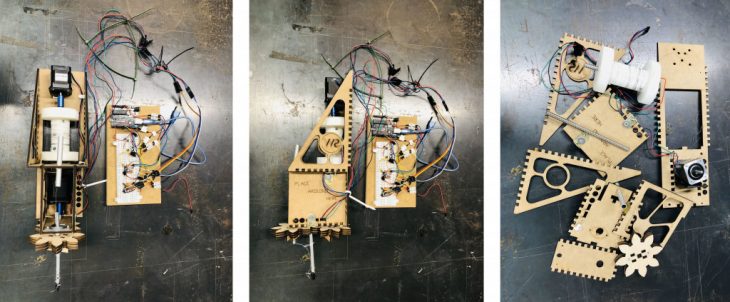

The very first prototype followed and also needed some adjustments:

- lower rod too long

- motors should not be superimposed

- need gears to enable axis rotation (wire to rotate around rod of base)

- spindle is too thich and heavy

- use thinner wire (0.3 mm)

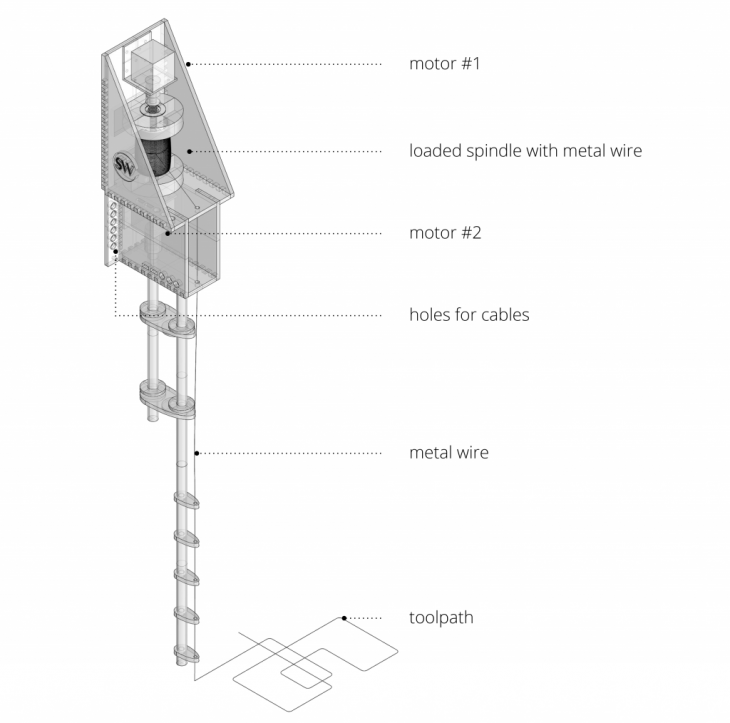

Simulation

Simulation of the toolpath of the IRb 140 with the newest SW prototype as the end effector.

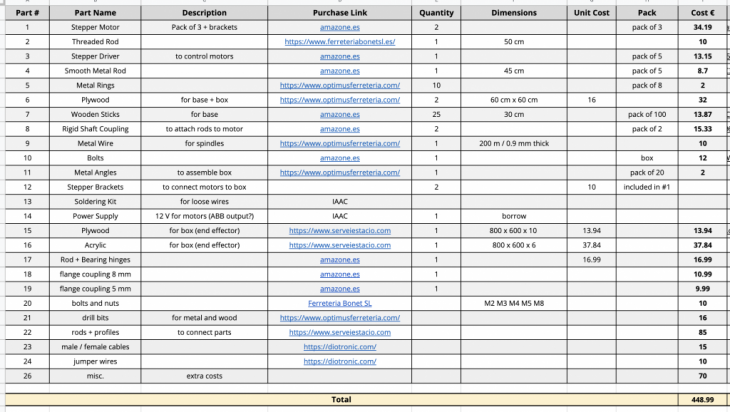

BOM (Bill of Materials)

During the fabrication process, many parts were broken, misplaced and lost, or burned (bad wiring) and had to be ordered again.

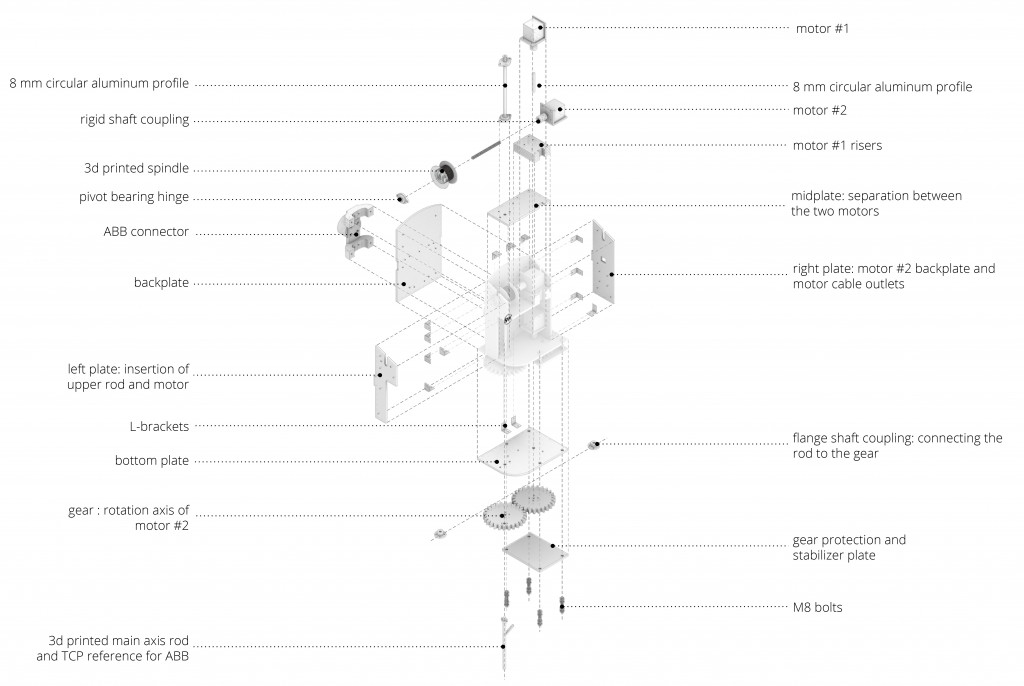

Final Prototype

The previous prototype was disassembled for parts.

The final prototype is still undergoing tests with the IRB 140 and the code and toolpaths are being optimized for a smoother run.

Arduino Schematics

IRB 140 Testing

</p>

Stay tuned on the blog for future updates!

HARDWARE I // SHAPEWEAVER (SW) is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction Workshop 1.2 in 2020/2021 by:

Team: Shahar Abelson, Helena Homsi

Faculty:Angel Muñoz

Faculty Assistant: Matthew Gordon (MRAC 02)