FROM RATIONALIZATION TO FABRICATION

</p>

The goal was to create any shape that could then be rationalized into panels using Networkx and fabricat it after generating the necessary plans and documentation.

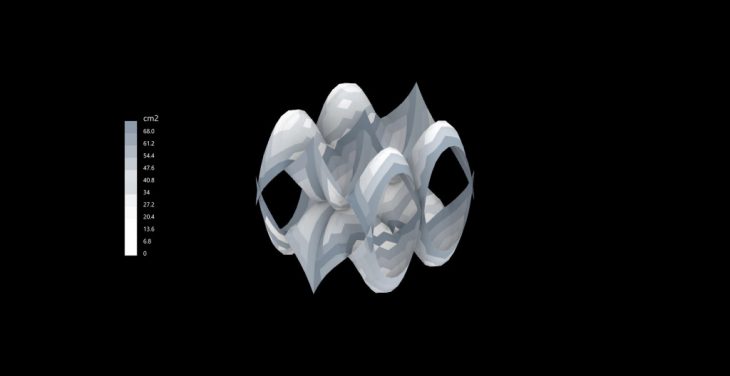

Inside a cube are inscribed two arches opposite the other, one upper and one lower. To connect the two opposite surfaces, a transition with a double curvature is proposed.

At its ends, edges are generated that play between the straight and curved lines. The surface proposes a game between its curved and straight edges, which makes for a perfect aggregation system. The challenge is to compare and choose the best method for its rationalization and stripication, for this reason the methods of all shortest path, minimum spanning trees and K-means clustering are compared, to generate in a balanced way a physical model that demonstrates the way to build it.

The rationalization process we followed used the dijkstra path. With this, we were able to get every needed stripe to then assembly them to fabricate the model.

After we got all the stripes of our model, we planarized them for generating the fabrication plans.

In these plans we also added the slabs that we would glue when fabricating our paper model.

FROM RATIONALIZATION TO FABRICATION is a project of is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Computation for Architecture & Design in 2020/21 by

Students: Jonathan Hernández López and Jaime Cordero Cerrillo

Faculty: David Andrés León and Dai Kandeel