Overview

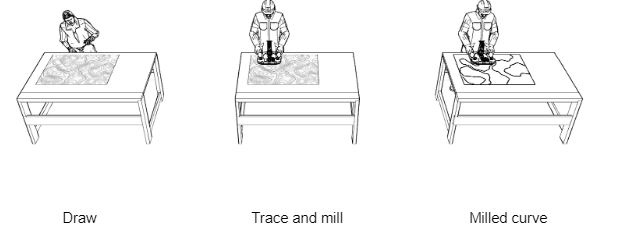

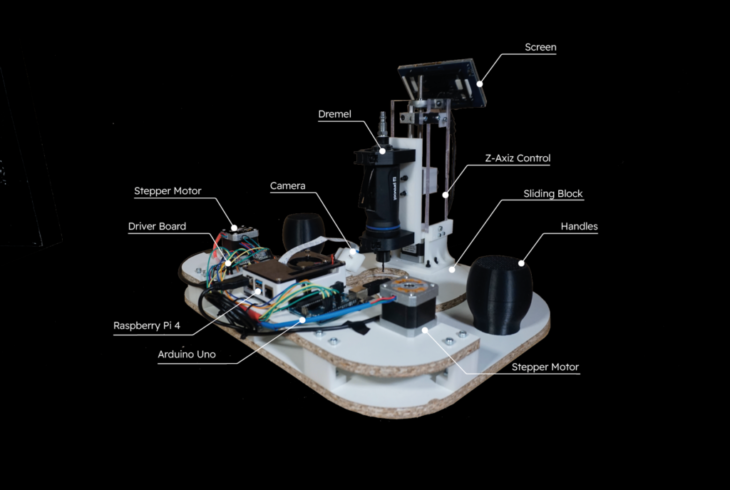

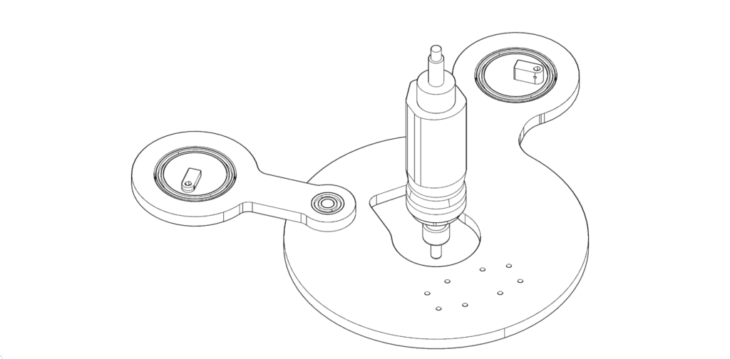

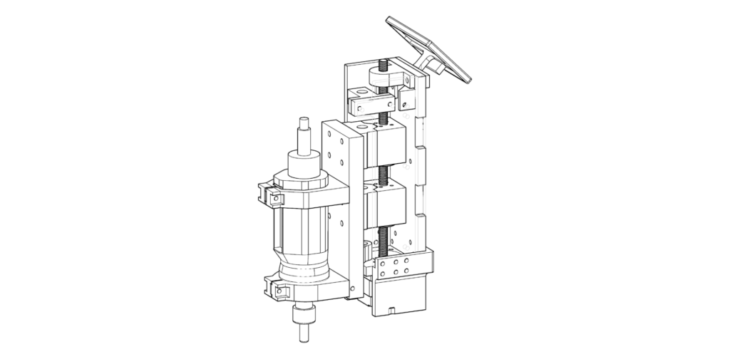

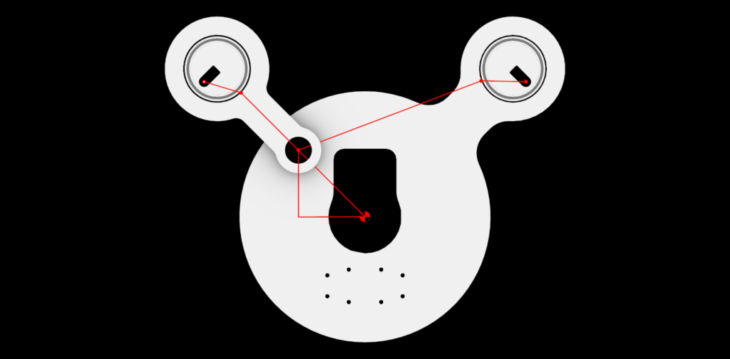

The project aim is to develop a handheld CNC router which could be used for milling and inscribing into planar sheets of material. The router will be hand-guided by the user while motors which control the position of the mill bit will activate to correct for the error made by the user between the actual and target position of the bit.

Concept

Imagine a tool that does what CNC does but it fits in your hand. That exactly is the idea behind the prototype but without any complications of generating a g-code. The prototype is designed with the intelligence that enables the user to hover over the drawing to cut or engrave a surface. The prototype neutralizes the irregular movement of the hand by using computer vision to keep the mill bit on the drawing line.

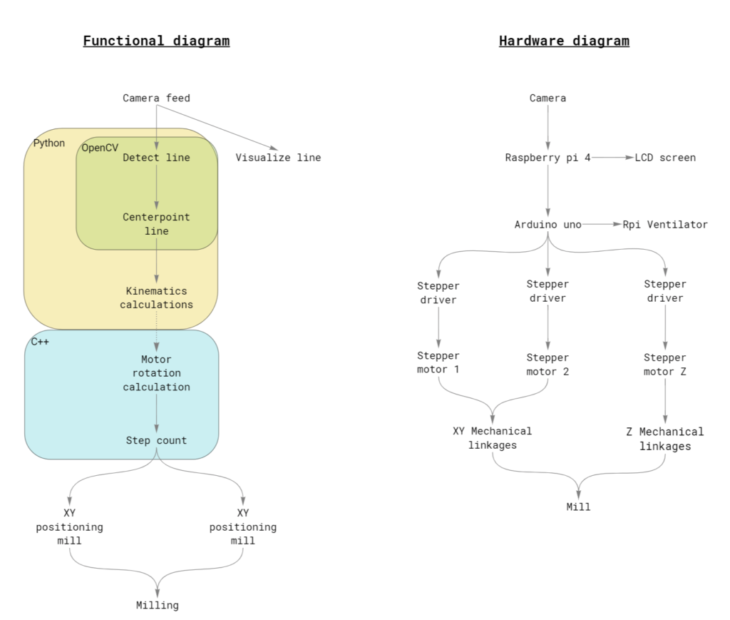

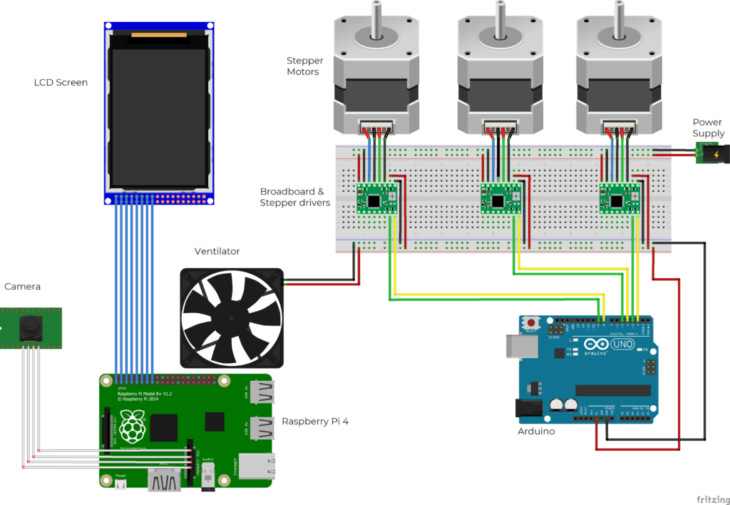

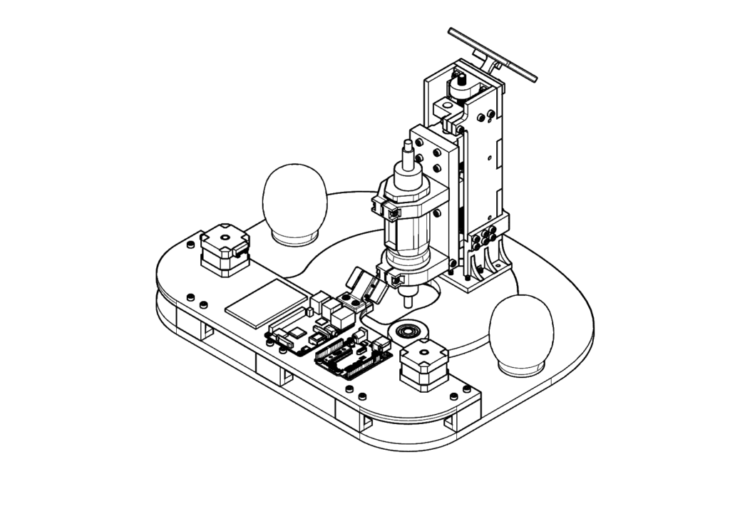

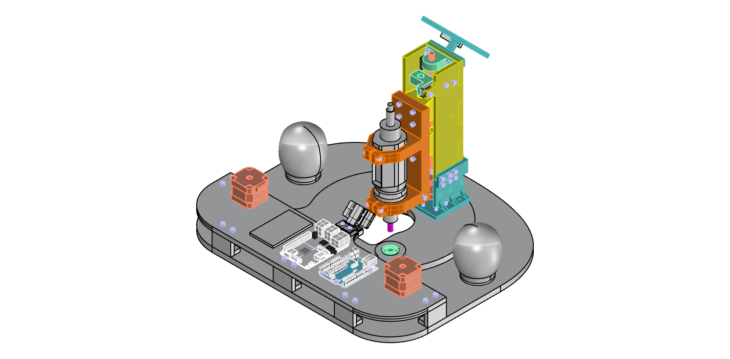

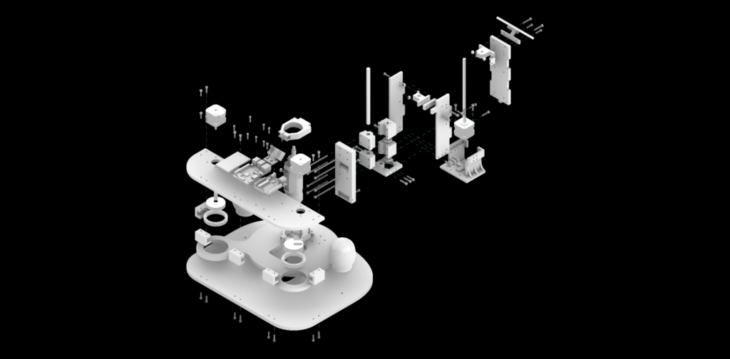

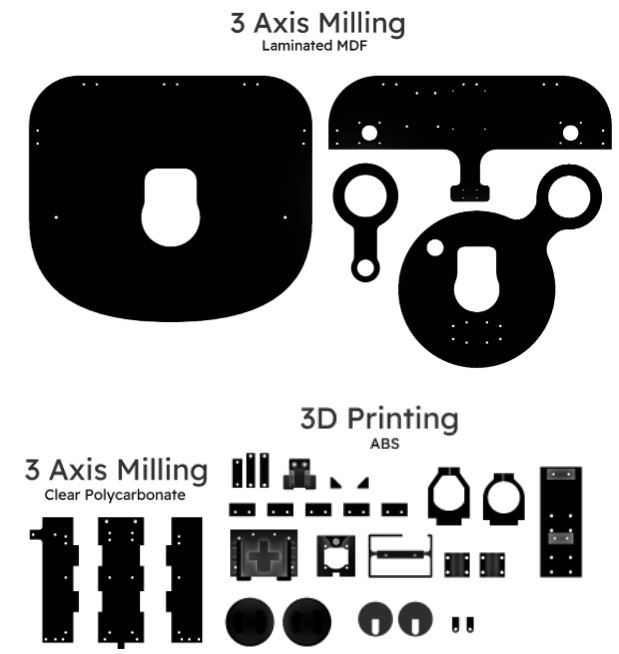

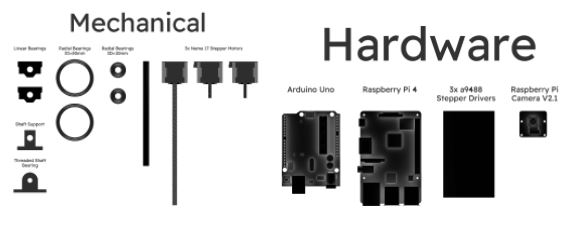

Designing the tool we started by looking at what functions the tool would need. From here we made a hardware diagram as a base of designing the product.

The hardware diagram is translated in the following overview:

The hardware diagram is translated in the following overview:

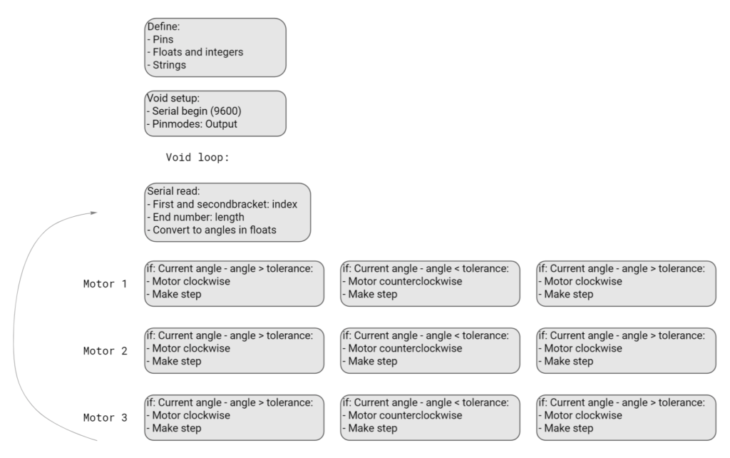

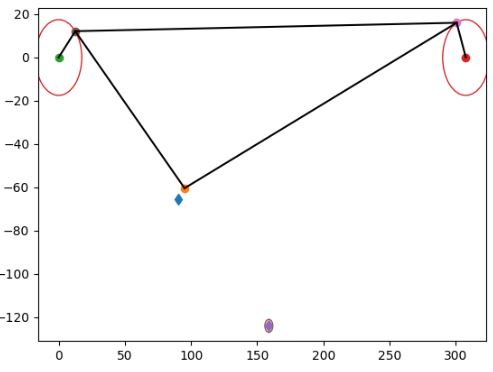

This overview is to understand how the stepper motors are controlled by the Arduino. The code would be easier with servo motors since they are controlled by giving them a certain position. The choice of stepper motors is made because with micro stepping the motors can move very precise angles which is needed for the position of the drill.

Prototype

How does it all work?

Computer Vision

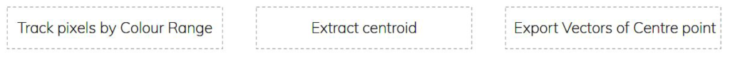

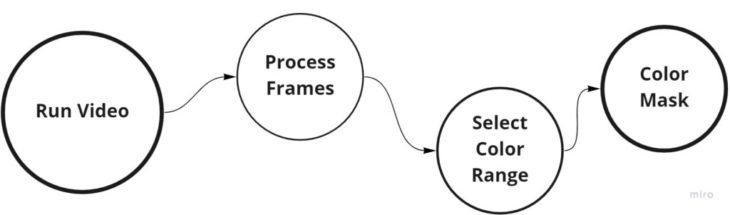

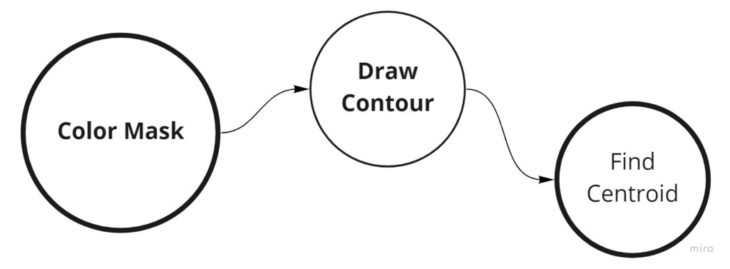

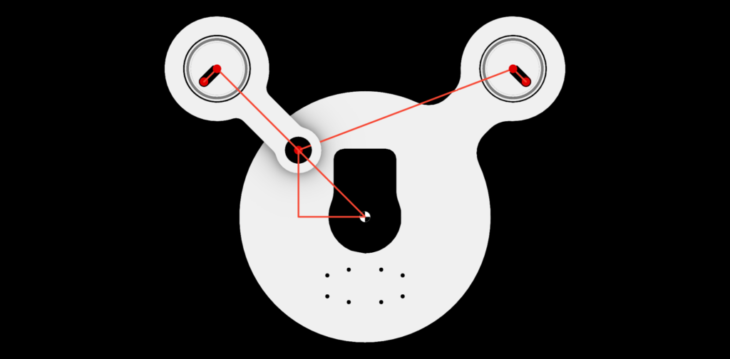

Computer vision provides necessary intelligence to the hardware setup to autonomously track and adjust the mill bit to keep it on the cutting course. Computer vision follows a three step process as mentioned below. It is further explained in detail in the blog.

Color Mask

https://drive.google.com/file/d/1X5KgEvQntMdRa8Ij427nJRVbs4Qk5ZLO/view?usp=sharing

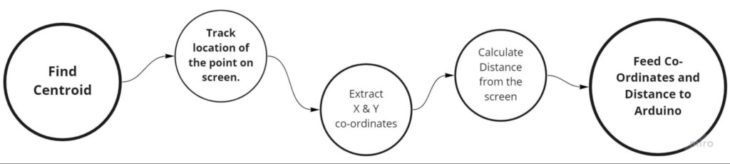

Centroid Detection

https://drive.google.com/file/d/1gan4bQeMavmGOUPj1NTpIFTwm0RwpfLW/view?usp=sharing

Vector Export

https://drive.google.com/file/d/1PO3HqeZdKnwNfsKiUiszFb5z1qn8nJGy/view?usp=sharing

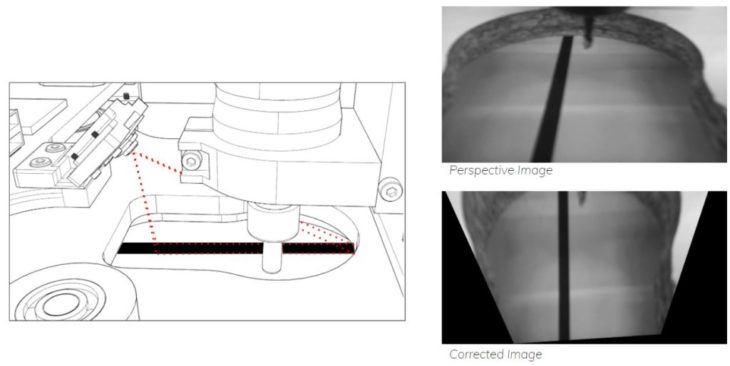

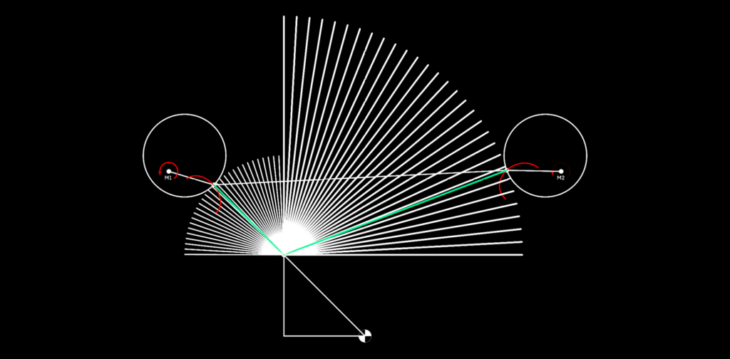

Perspective Correction Through Homography

Due to the angle of the camera the image is in perspective but a perspective image is no good to extract vectors. Therefore the image or the video stream has to be corrected for perspective for the vectors to be exported to keep the mill bit on track.

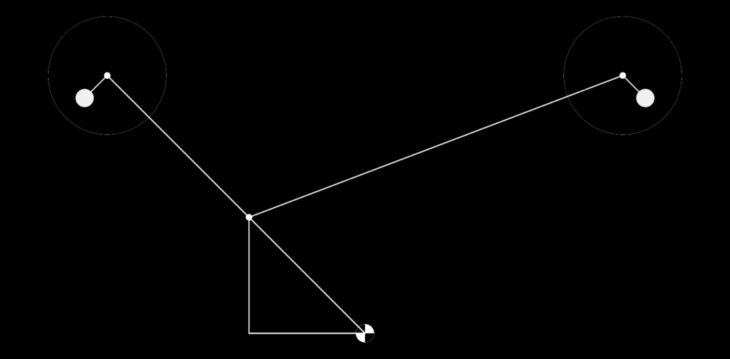

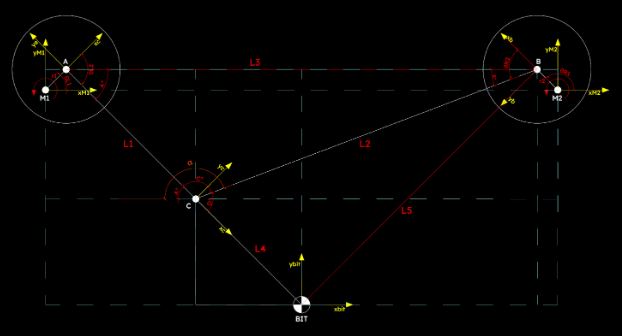

Kinematics

Kinematics Method 02

</p>

The handheld CNC router is a project developed by Alfred Bowles, Shamanth Thenkan & Vincent Verster for a 2 month hardware seminar at the Institute for Advanced Architecture of Catalonia