F2F

field to facade

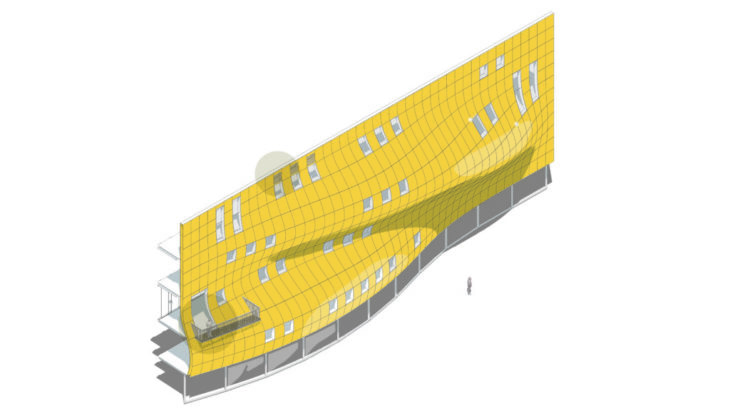

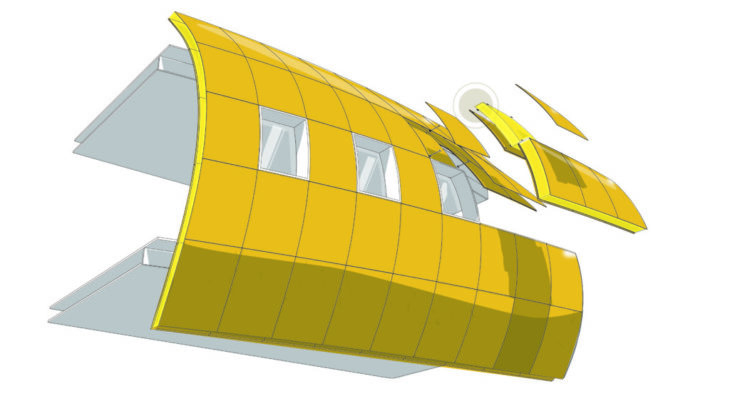

This research project examines potentials of re-purposing barley straw as a construction material. Current straw construction techniques have many advantages. However, the design limitations and inability to create geometric variation has resulted in negligible acknowledgment by big urban projects. Additionally in order to scale up and achieve multiple stories a wooden structure is required which is not ideal. In light of all of this, the project sought to design a double curved self-standing insinuative skin that would not require any extra wooden sub-structure.

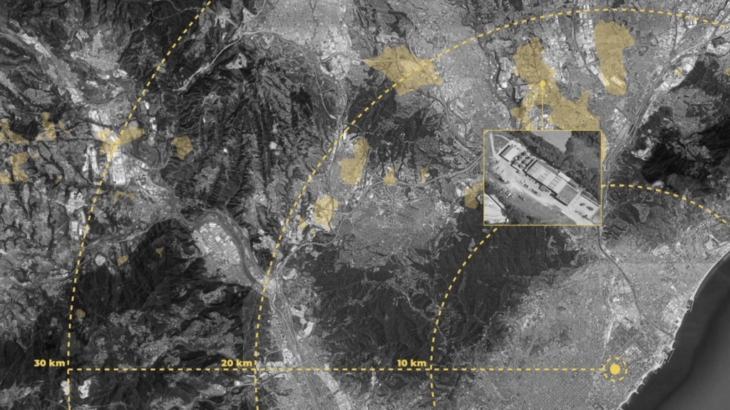

sourcing

http://www.laperpetuenca.com/cat/index.cfm

video

Methodology

Current straw construction techniques as mentioned in the video before have many advantages. However, the design limitations and inability to create geometric variation has resulted in negligible acknowledgment by big urban projects. Additionally in order to scale up and achieve multiple stories a wooden structure is required which is not ideal. In light of all of this, the project sought to design a double curved self-standing insulative skin that would not require any extra wooden sub-structure.

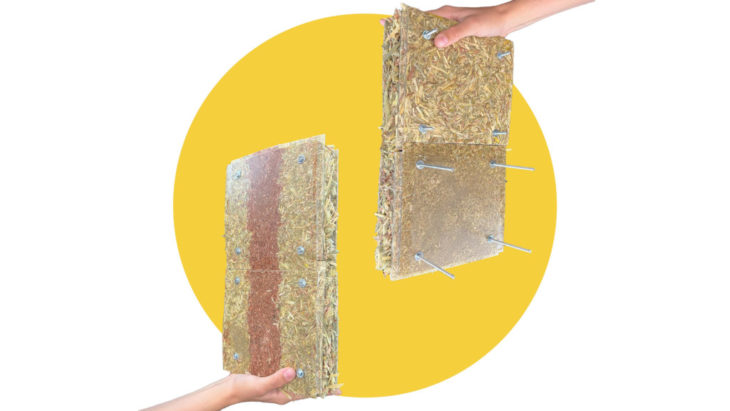

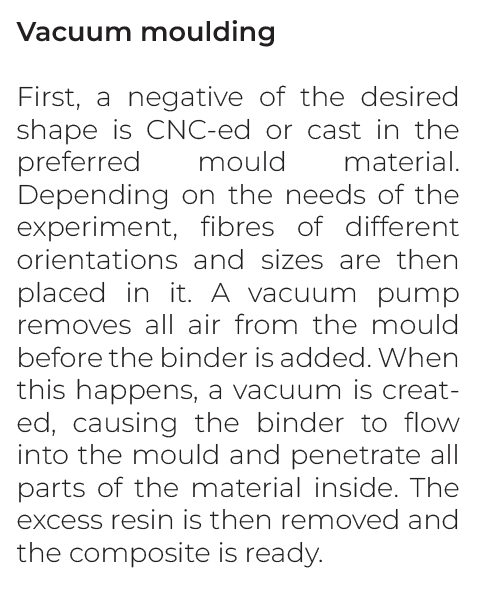

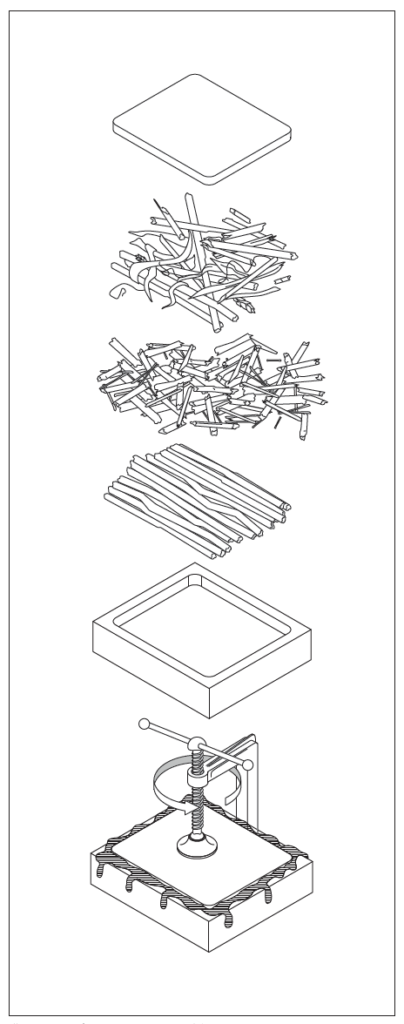

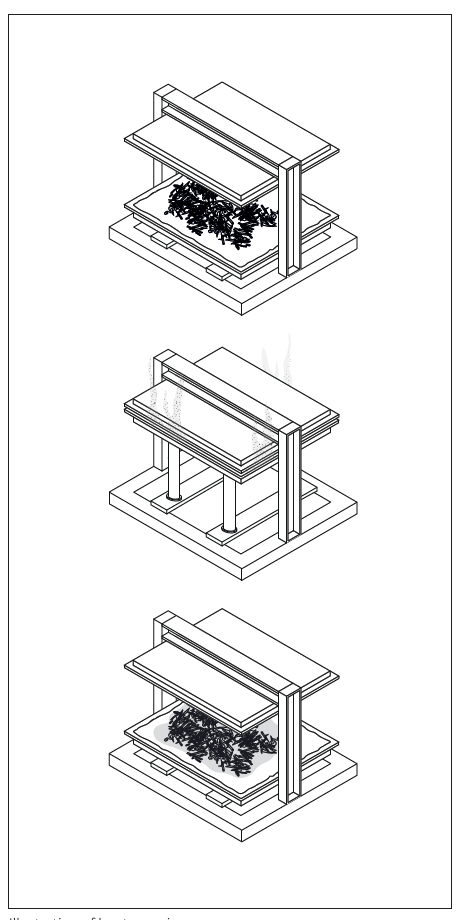

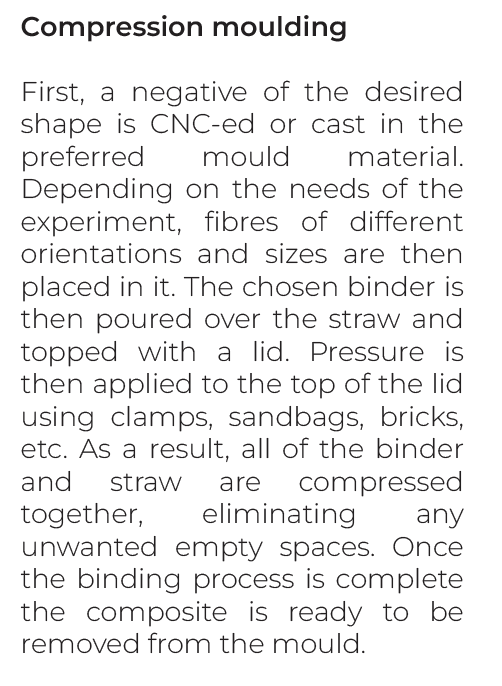

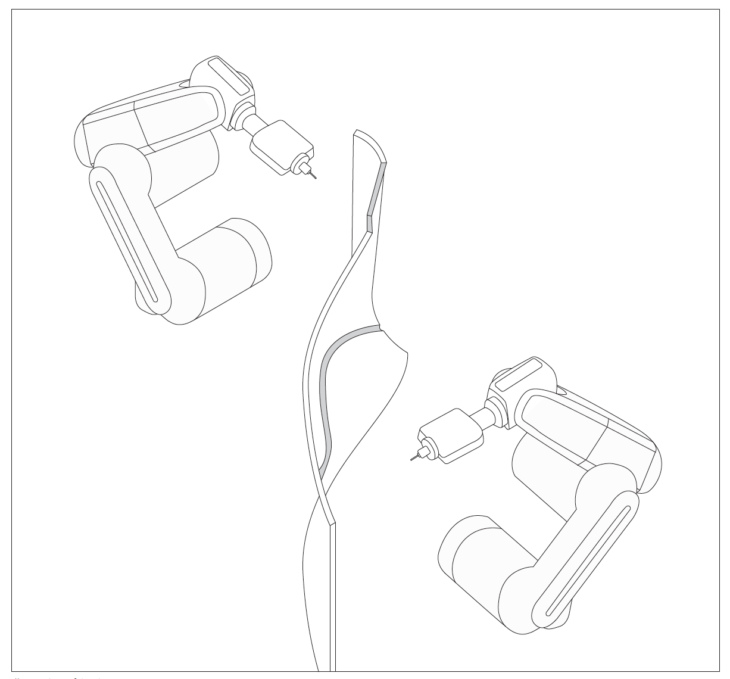

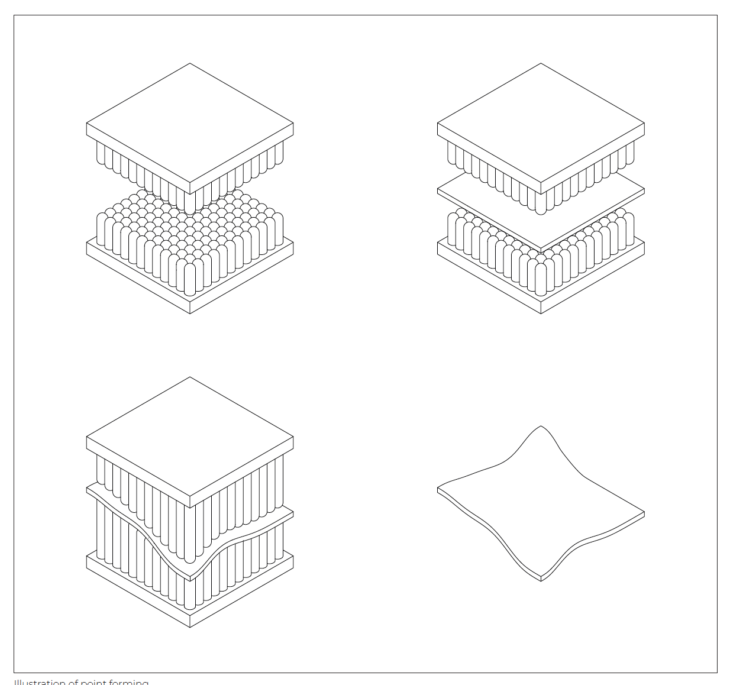

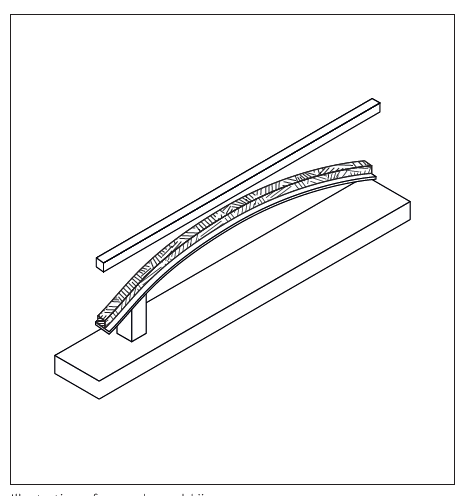

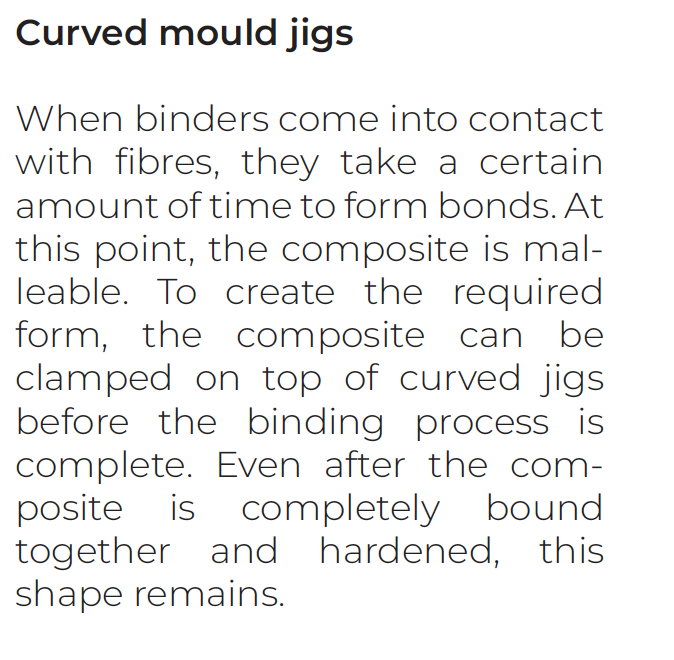

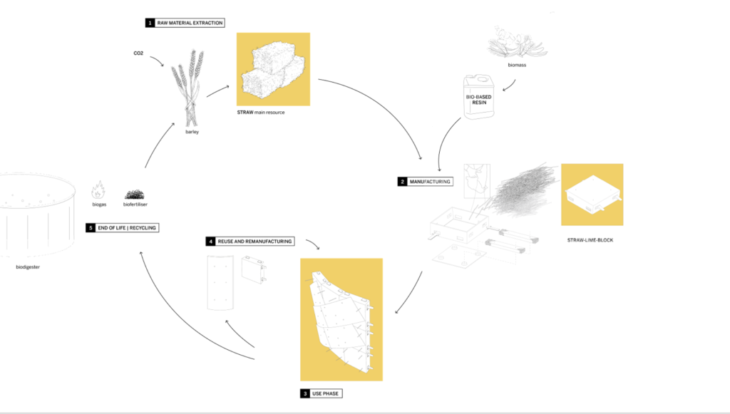

To achieve this, fibrous mater composites were assessed. A combination of carbon fibre with resin (as used in the automobile industry) was found to be the most promising composite as the fibre behaved in tension similar to straw and the resin acted as a binding agent. Together the system performs well structurally. To develop a zero waste circular system, we had to look for a bio-based binder. This exploration led us to experiment with pine resin, beeswax, carnauba wax, gelatine, glycerine, xanthan gum, collagen and lime. The composites were then subjected to heat and pressure tests to determine if they would be able to function as a layer of the building skin. Additionally, various fibre orientations and straw sizes were tested, to examine possible differences in structural qualities. In terms of fabrication, techniques such as heat pressing, compression moulding, and vaccum moulding, were studied to combine the straw with the resin. Curved mould jigs and point forming were investigated in order to achieve multiple panels with different shapes and curves. Furthermore, cnc machines were explored to create joints and textures.

fabrication

material exploration

Material systems

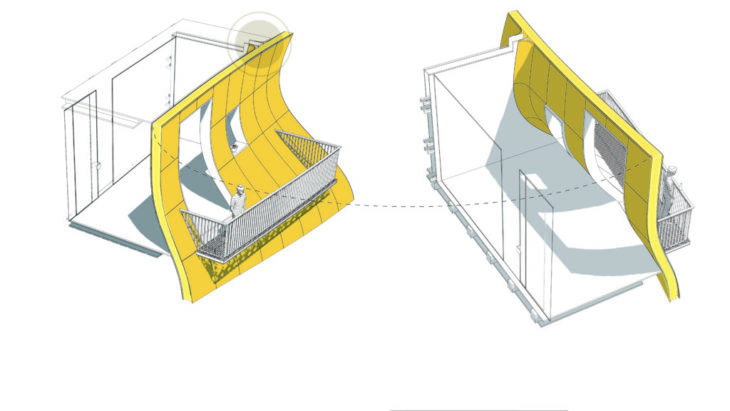

To produce a performative building skin that is double-curved, self-standing, and has minimal/ no substructure a few requirements were outlined.

- Thermal and acoustic insulation

- Waterproof

- Fire resistant

- Resistant to mould

- Pre-Fabricated

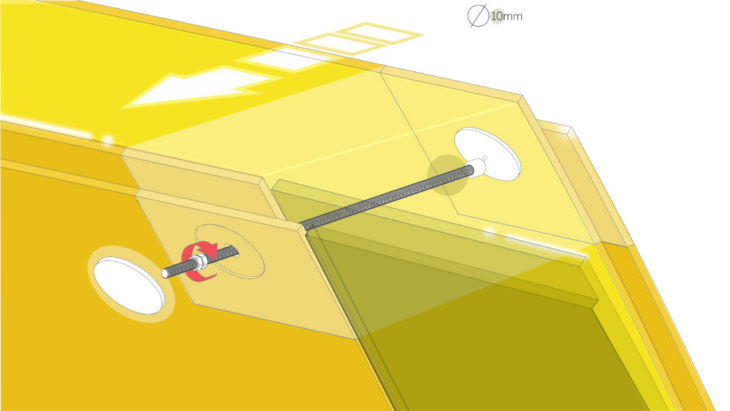

- Quick and easy assembly/disassembly

- Panelization

- Joinery

- Negligible thermal bridges

lifecycle

building skin proposal

interlocking system

F2F is a project of IAAC, the Institute for Advanced Architecture of Catalonia, developed during the Master in Advanced Architecture (MAA01) 2021/22 by students: Mira Housen, Alex Ferragu, Taimur Mian, Mara Müller-de Ahna; Faculty: Areti Markopolou, David Leon; Faculty assistant: Nikol Kirova, Eduardo Chamorro Martin; Student assistant: Alexander Dommershausen.