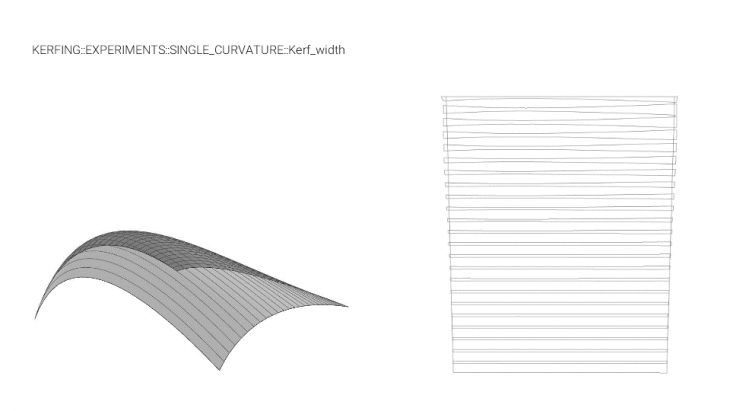

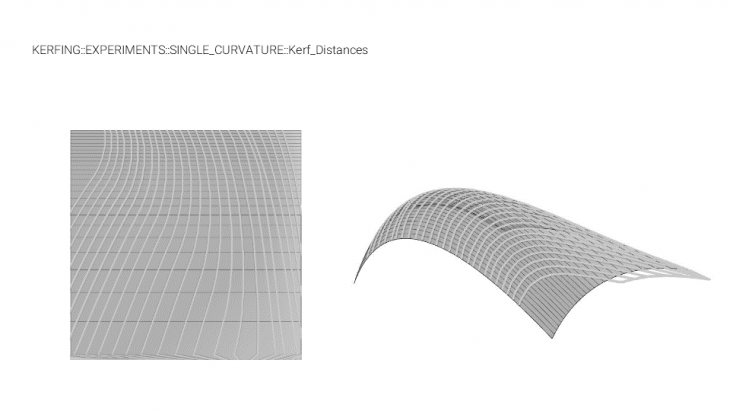

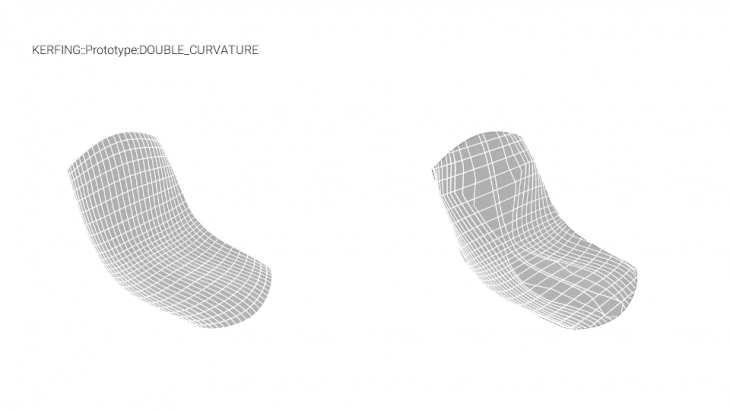

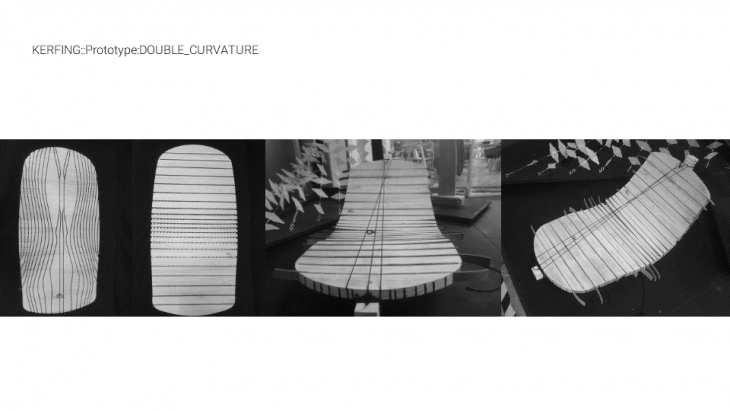

Is it possible to fabricate a lightweight DOUBLE-CURVED wooden structural panel by LAMINATING wood?

Glue-laminated timbers, steam-bent wooden structures, and many other methods of wood-forming has their own potentials and limitations, however, fabricating a double curved wooden panel has always been a matter of milling the shape out of a blank piece of wood and achieving such a shape through wood-forming has not been extensively explored.

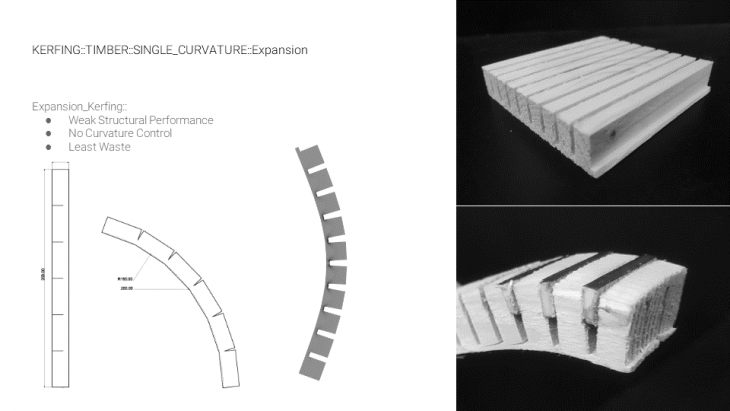

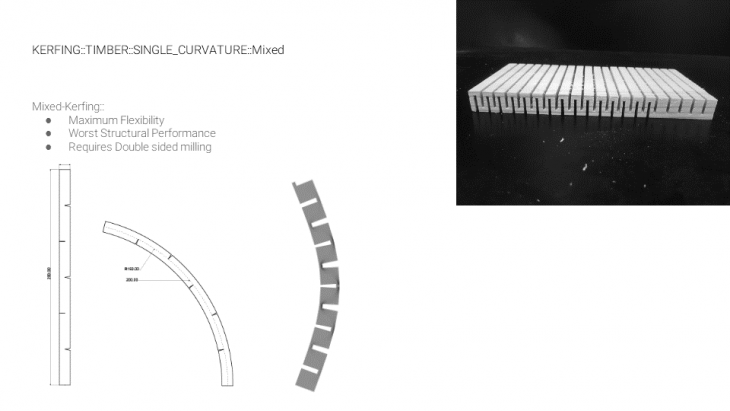

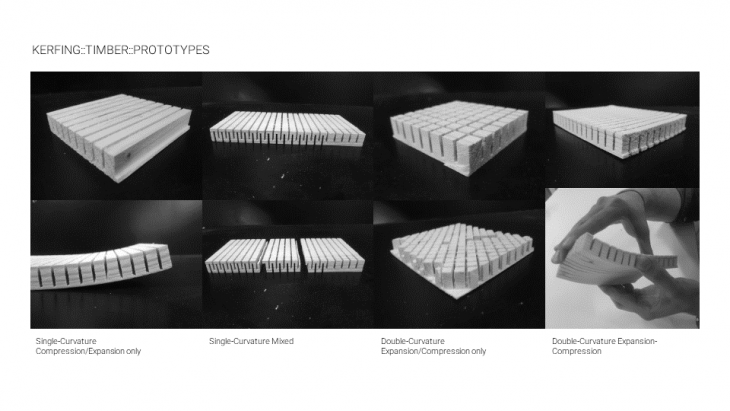

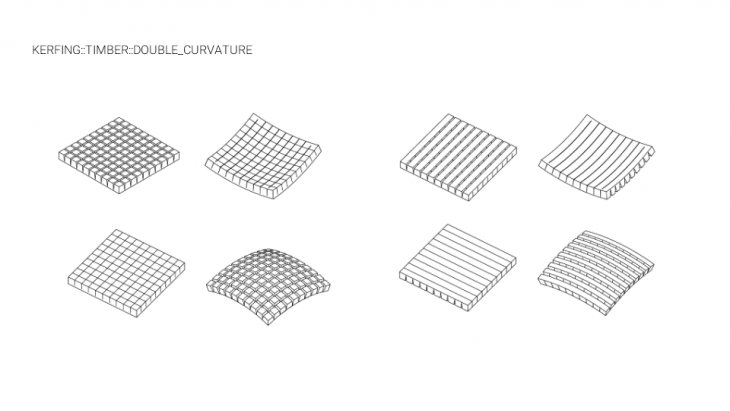

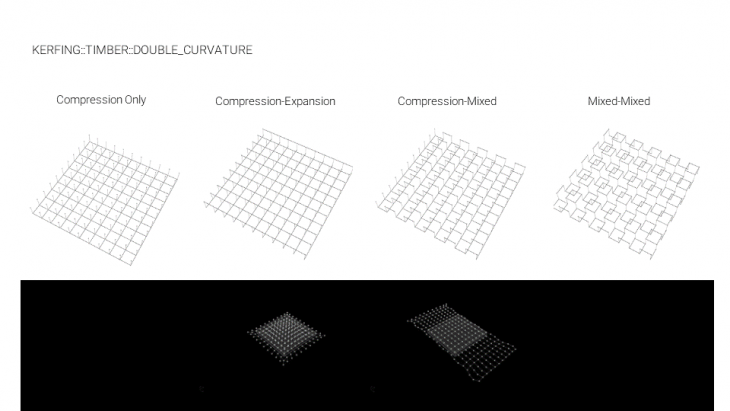

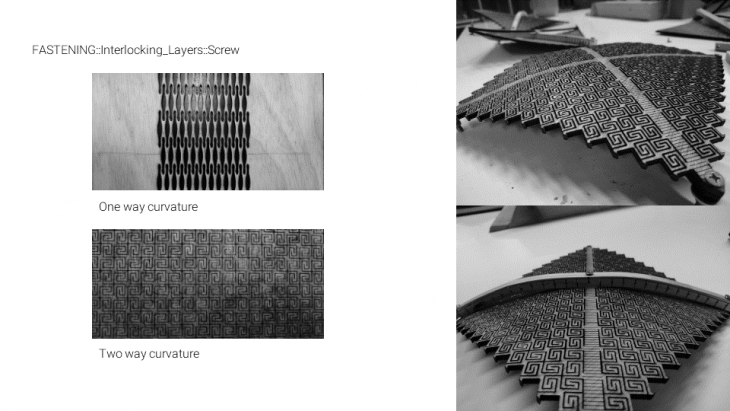

Through process of wood cold-forming, the wood is considered as a linear element as it can be only bend along one direction. On the other hand, kerf-bending of wooden panels has been widely explored in a furniture scale. The goal of this research is to explore the possibility of combining these two methods to achieve a double curved wooden panel.

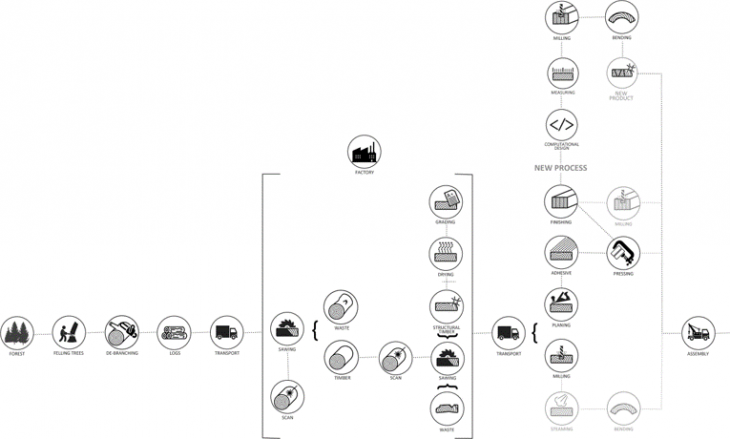

WOOD_BENDING :: State_Of_The_Art::Diagram

Curve is always GOOD – Shajay Booshan

EVIL comes in round shapes -Bad Lip Reading

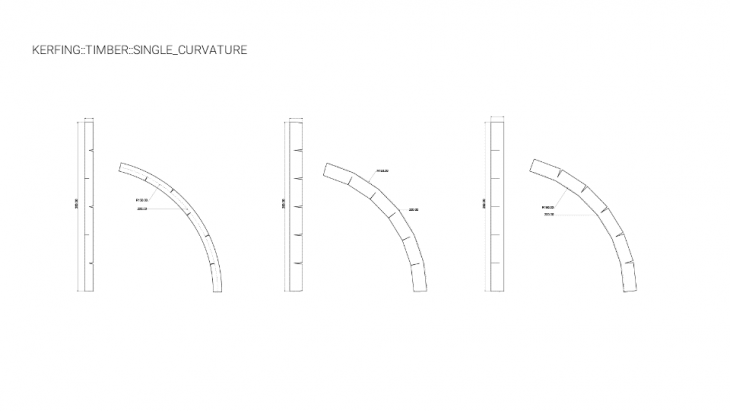

KERFING :: State_Of_The_Art :

Kerf (def)::A slit made by cutting with a saw. -Oxford_Dictionay

Kerf refers to the width of cut a saw blade makes when it’s cut through wood. When you’re cutting a board you have to allow for the width of the sawblade and its teeth when you’re cutting. Kerf cutting is making many kerf cuts (cuts the width of your saw blade) along a piece of wood.

References :

Temporary Timber Pavilion – AA EmTech & ETH Zurich Double Curvature Plywood – CHRISTIAN BEHLING KERF CUTTING TIMBER – NICK POLANSKY Kerf-Based Complex Wood Systems -Achim Menges, Brad Crane, Andrew McGee, Marshall Prado, Yang Zhao

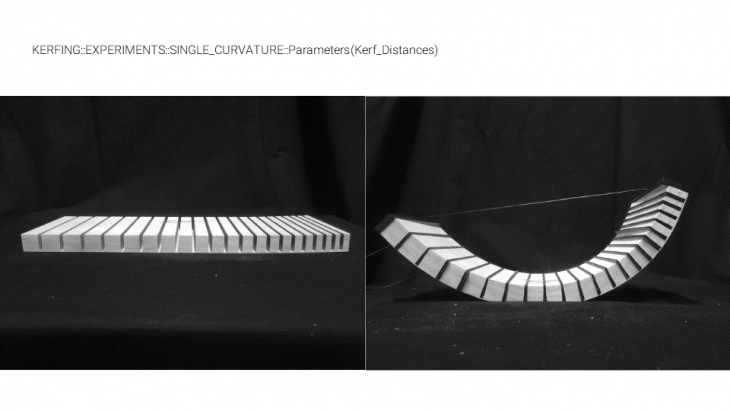

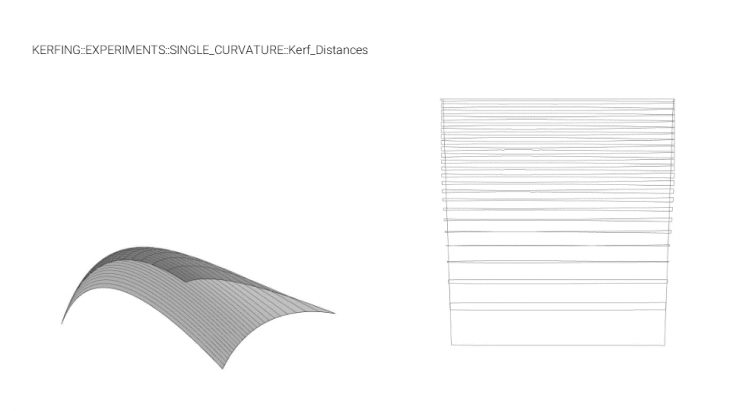

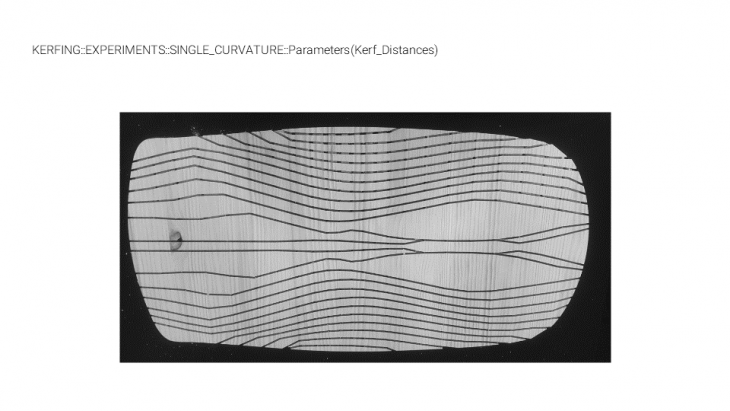

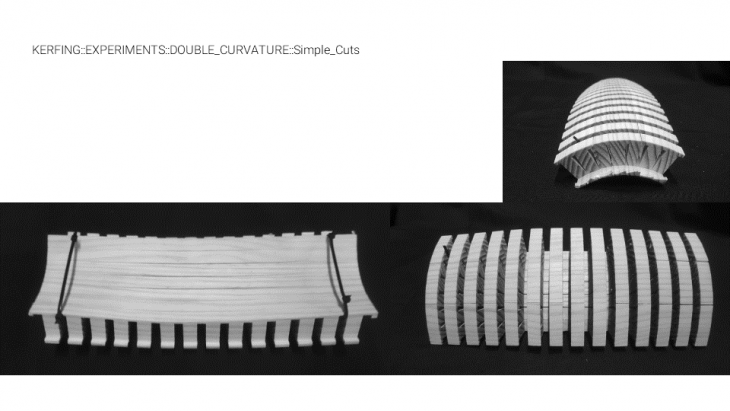

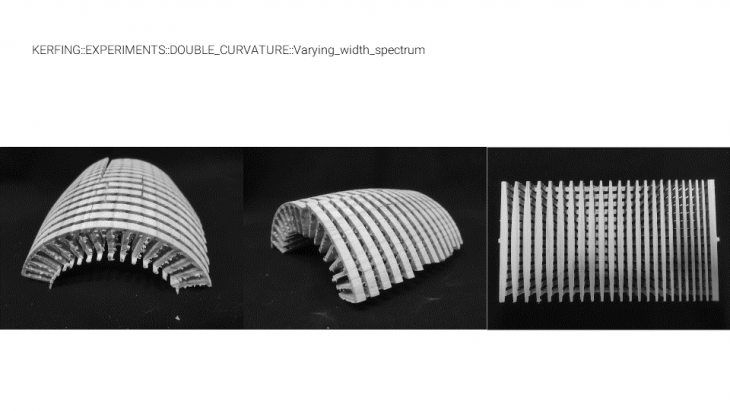

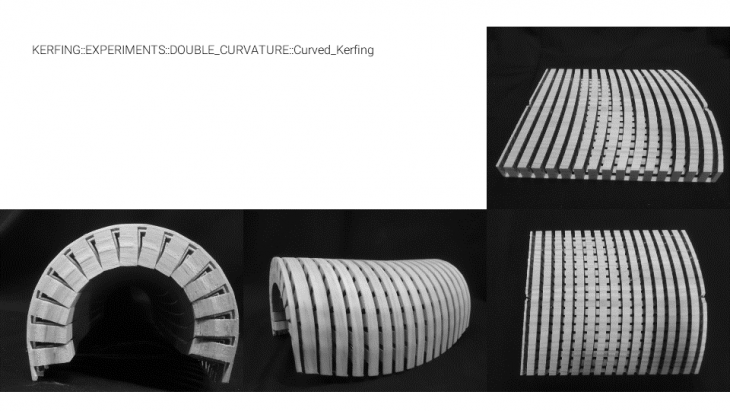

KERFING : EXPERIMENTS

KERFING::EXPERIMENTS::CONCLUSIONS

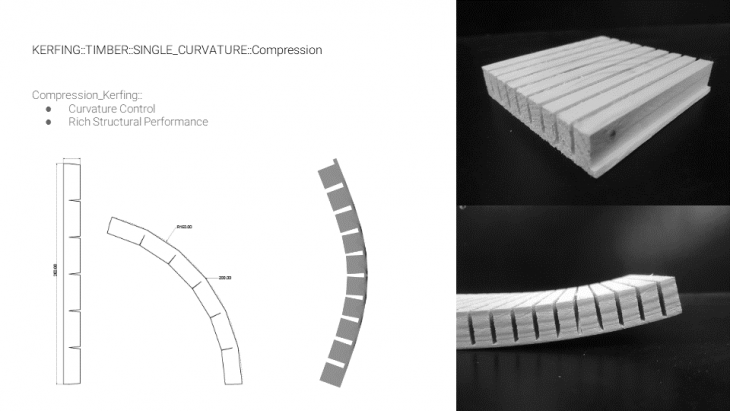

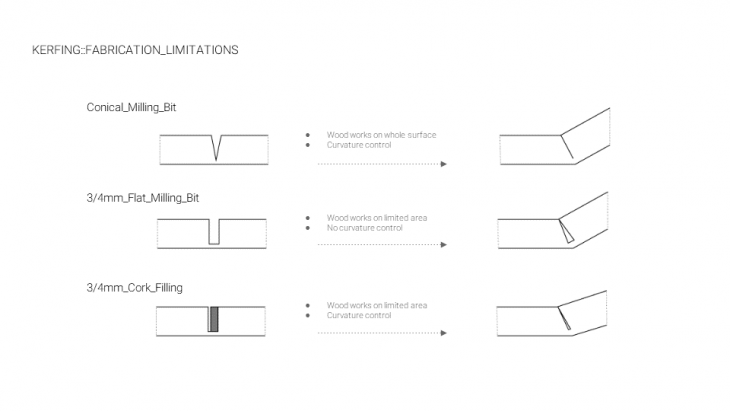

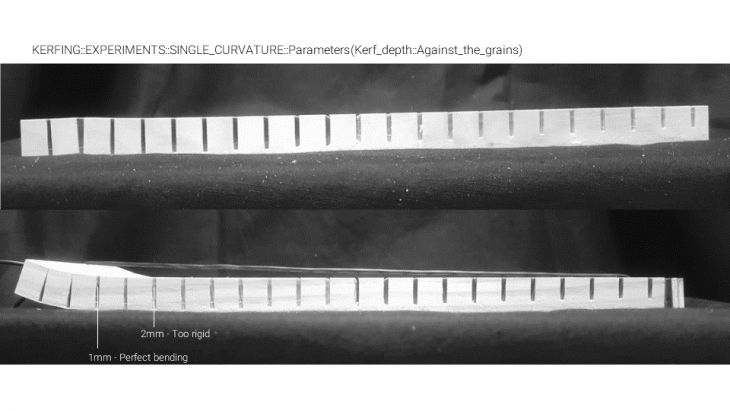

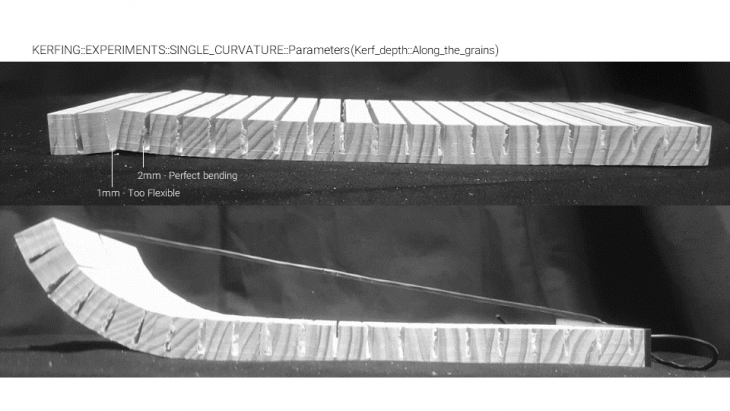

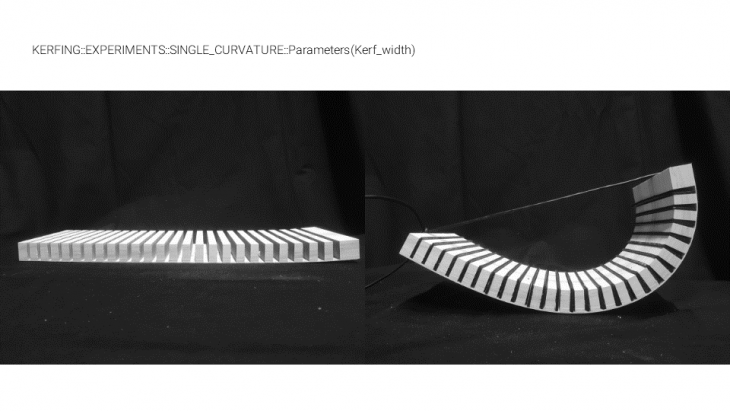

Throughout the experiments we have established wide roster of parameters that affect the final curvature:

- Cut depth

- Cut width

- Cut density

- Cut width variation

- Cut curvature

The wood does not feature homogeneous behaviour. It’s properties differ depending on the direction of grain. To counter that behaviour we incorporate into our process the industry-standard technique of cross-laminating panels.

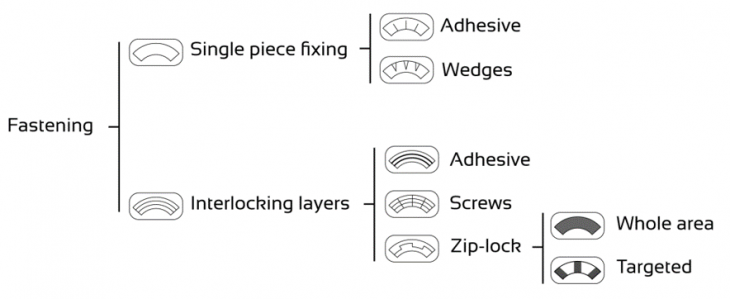

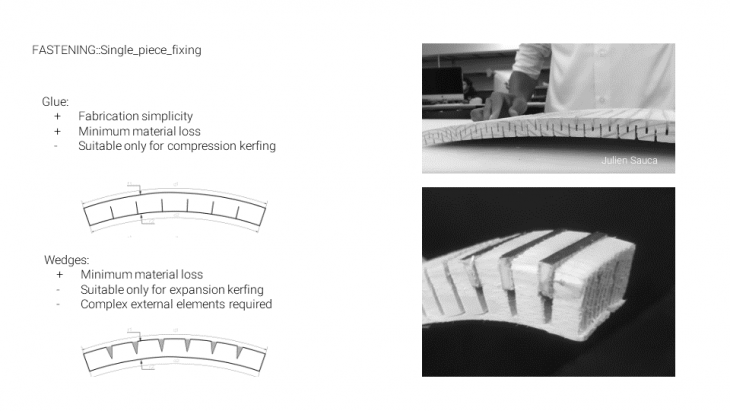

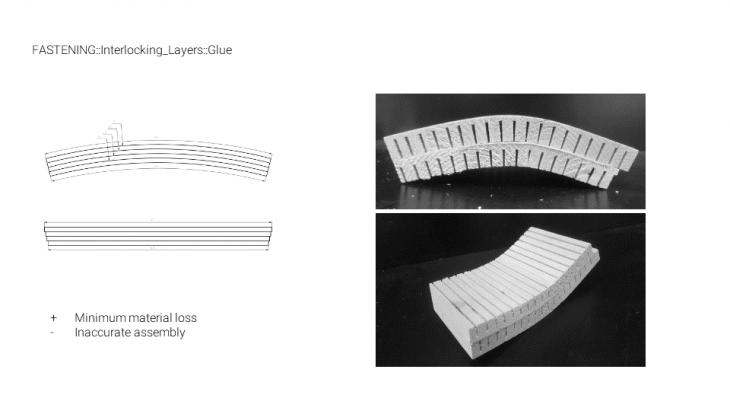

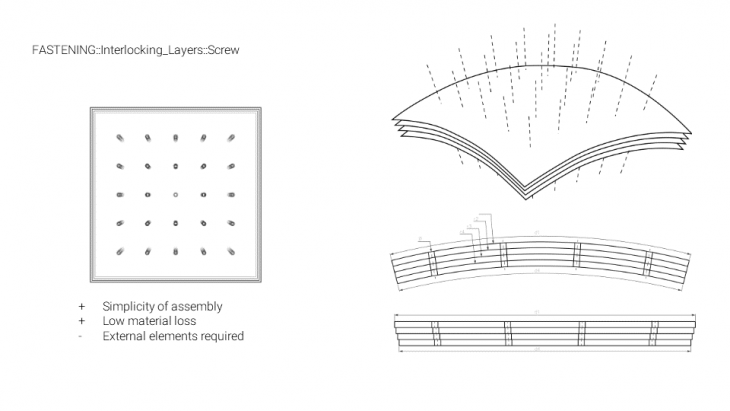

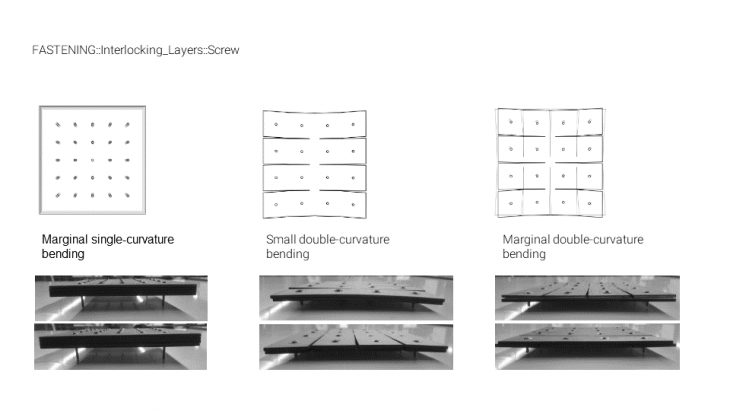

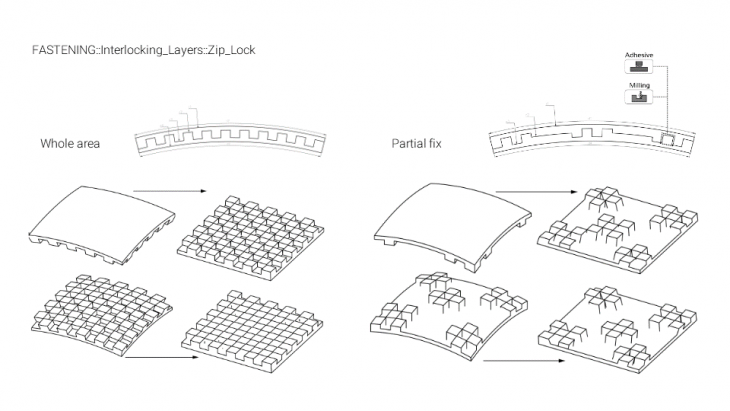

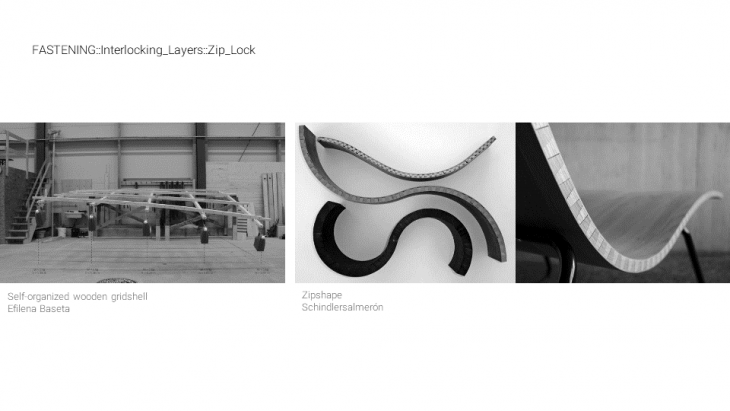

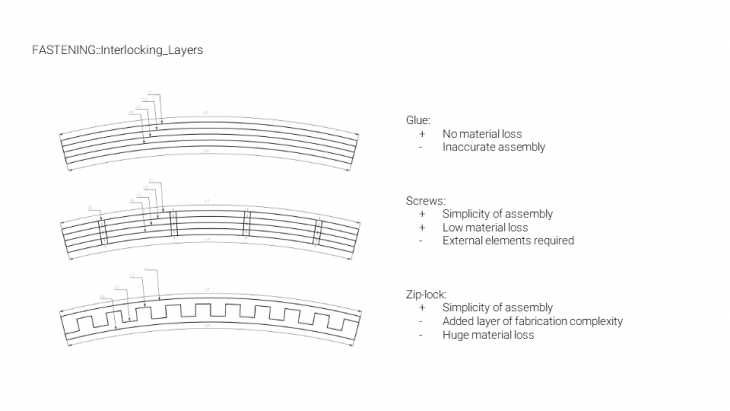

FASTENING :: Classification

An Exploration on Possibility of Double-Curved Wooden Panels Fabrication is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

Students: Andrzej_Foltman/ Ardeshir_Talaei/ Luis_Arturo_Pacheco_Alcalá/ Subhash_Prajapat

Faculty: Dir. Alexandre Dubor, Raimund Krenmuller, Kunaljit Singh Chadha