INTRODUCTION

The aim of the digital fabrication introductory course was to utilize three fabrication methods – 3D printing, laser cutting and CNC milling – in order to explore different recursive geometry and aggregation methods. The group’s aim for the three exercises was to analyze the properties of curved geometries the behavior of the materials under bending stress.

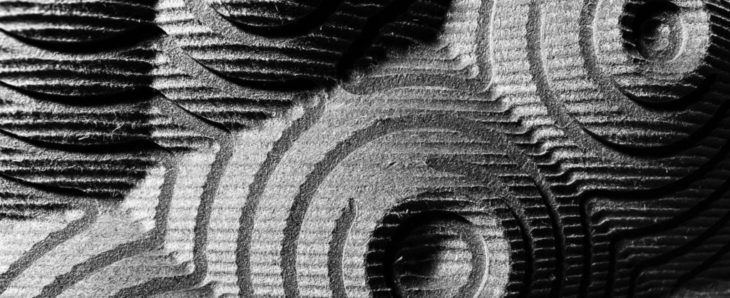

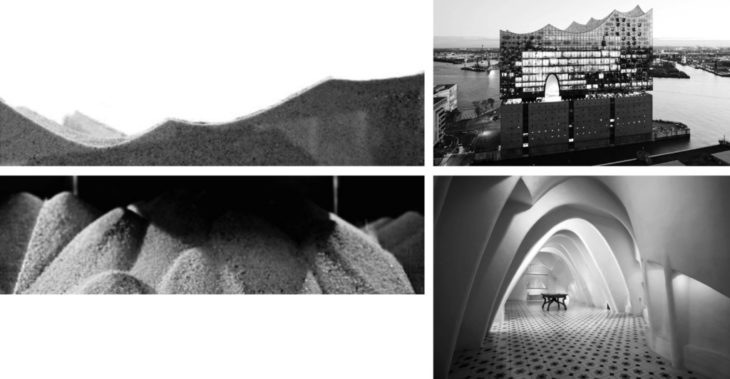

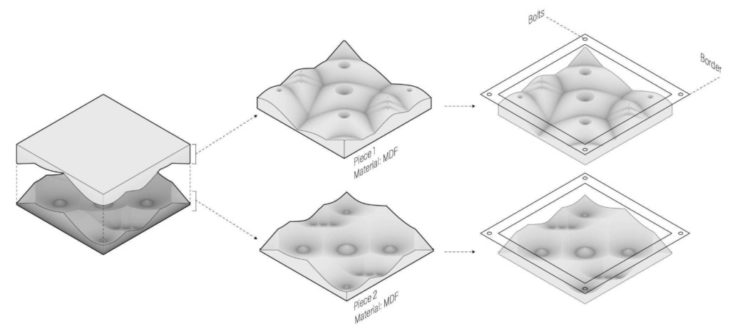

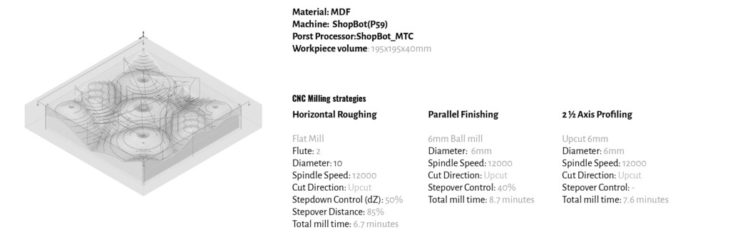

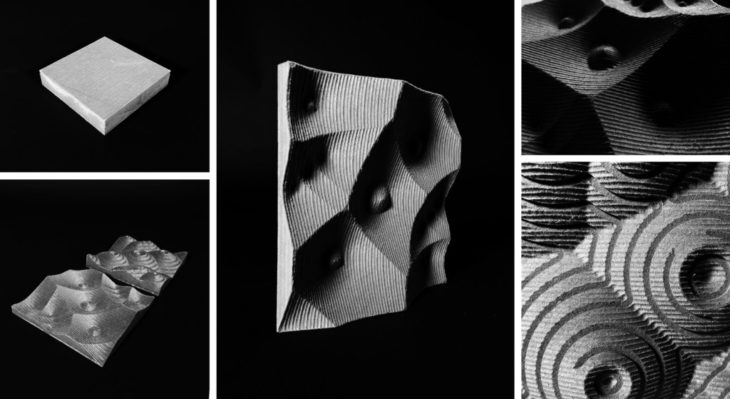

EXERCISE 1 // CNC MILLING // DUNES

“Dunes” was inspired by sand-form finding experiments and the concept developed aimed at creating complementary surfaces which could interlock upon placement on each other.

PROJECT INSPIRATION // Sand form-finding & References

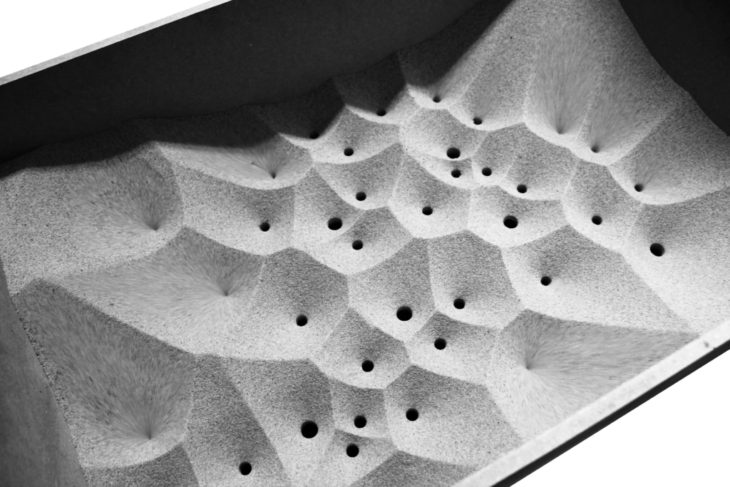

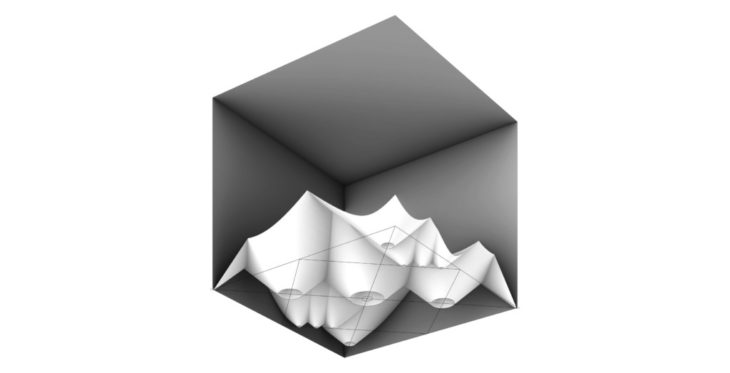

DIGITAL EXPLORATION OF AGGREGATION STRATEGY // GH script

PROJECT DIAGRAMS / TECHNICAL DRAWING // Positive and negative pieces

PRODUCTION CALCULATIONS // RhinoCAM setup

PROJECT // Final results

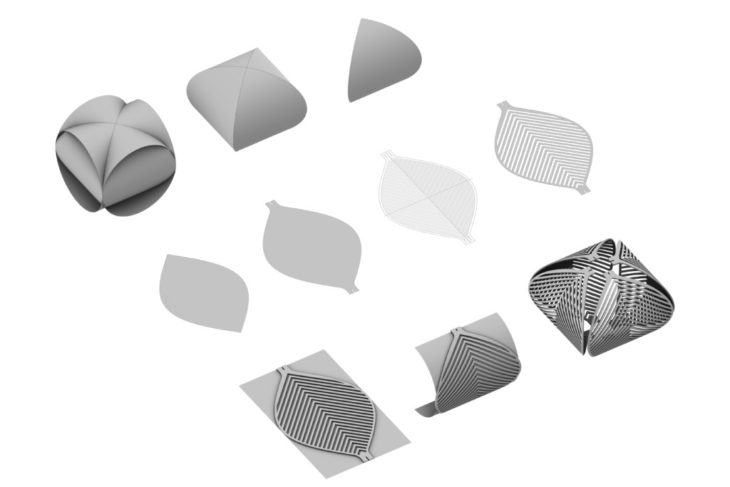

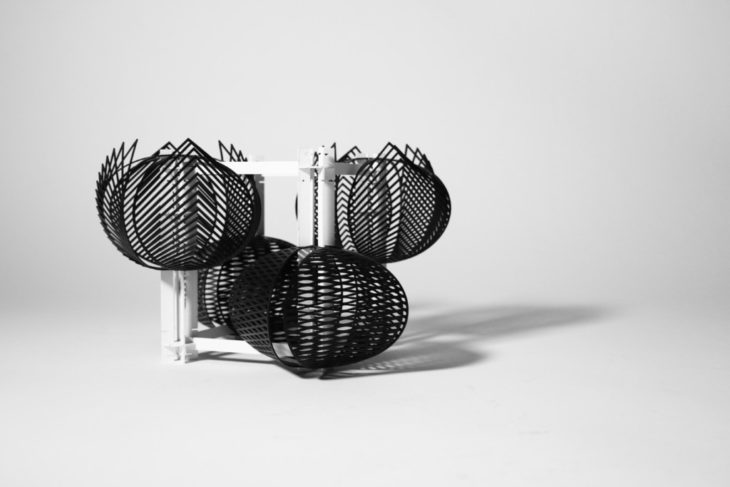

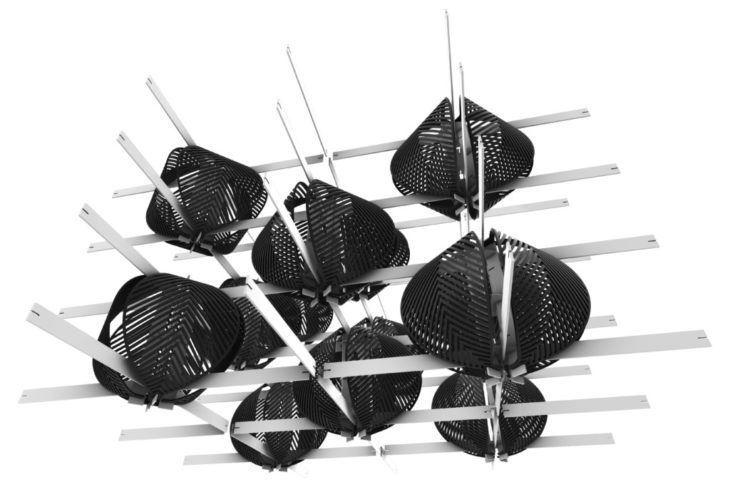

EXERCISE 2 // LASER CUTTING // BLACK ROSES

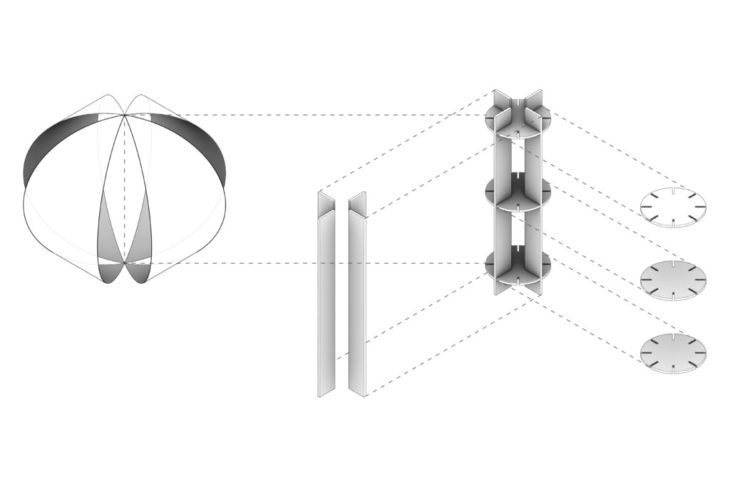

Inspired by the bending properties of leafs and petals, “Black Roses” aimed at creating leaf like structures that could be aggregated using various joinery strategies. The design involved cutting strategies such as kerfing and interlocking.

3D MODELING // Leaf

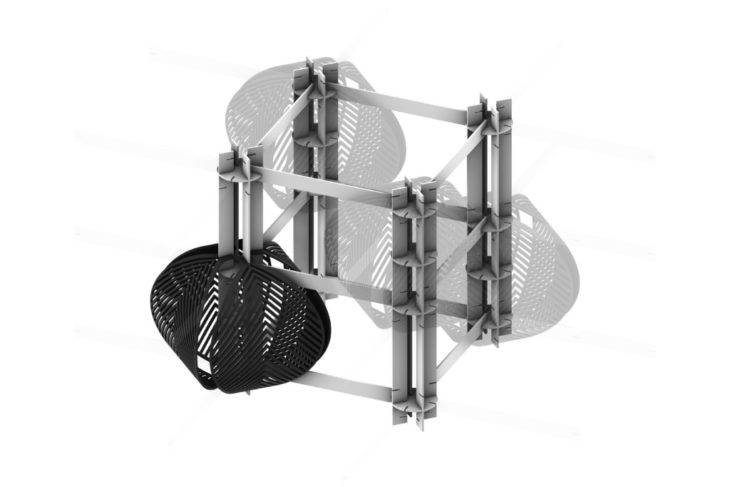

DIGITAL EXPLORATION OF AGGREGATION STRATEGY

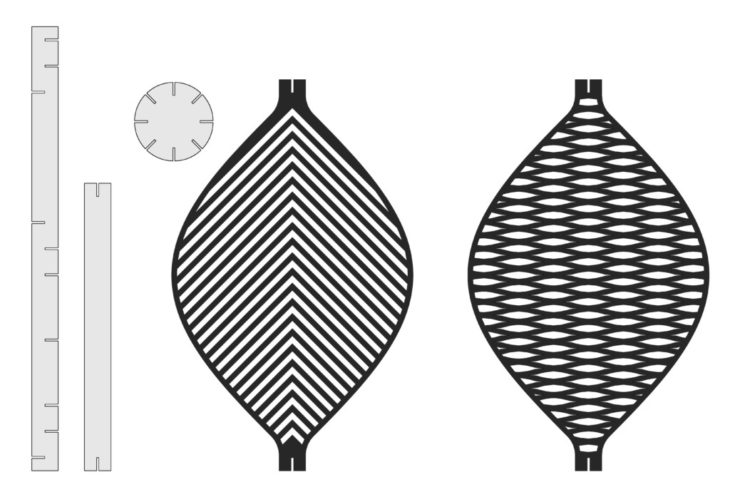

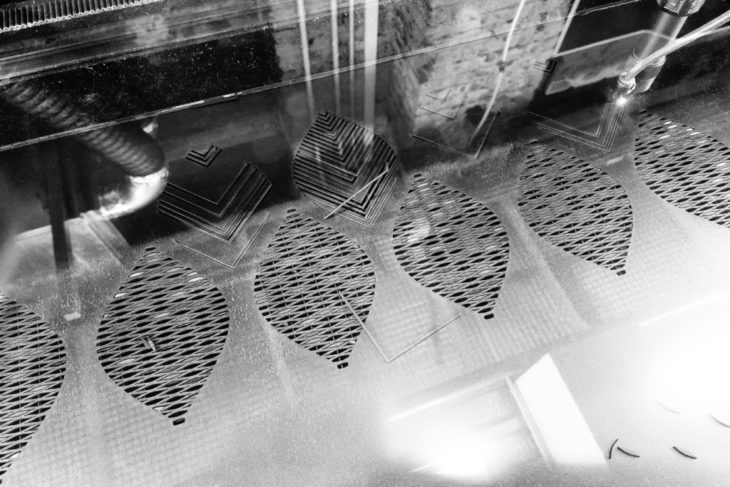

PRODUCTION CALCULATIONS // Settings & Pieces

MATERIAL – Polypropylene 1.2mm (Black & White)

FOLDING METHOD – Kerfing

TYPE OF JOINT – Interlock

MACHINE – Rayjet 500

MACHINE SETTINGS – CUT

Black polypropylene

Power : 60

Speed : 3.00

White polypropylene

Power : 60

Speed : 2.50

WHITE

Vertical connection // 170 x 10 mm //16 pieces

Horizontal connection // 110 x 10 mm // 12 pieces

Circular node // Ø 30 mm // 16 pieces

BLACK

Leaf – Pattern A + Pattern B // 150 x 93 mm // 8 pieces + 8 pieces

FINAL RESULT

PROJECT // Aggregation strategy A – Prototyped

PROJECT // Aggregation strategy B – For the future

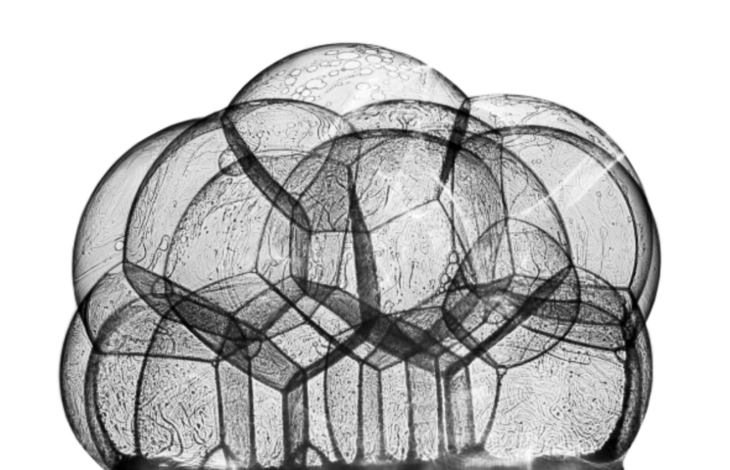

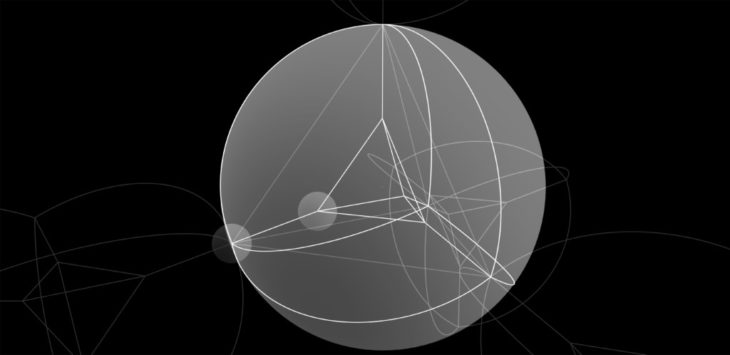

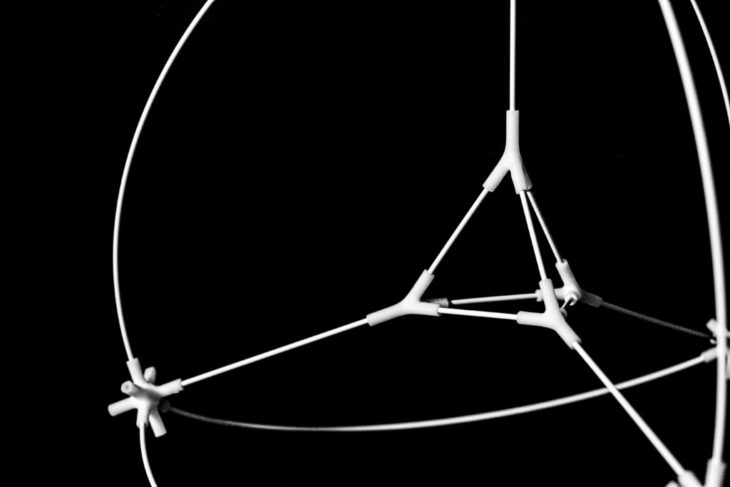

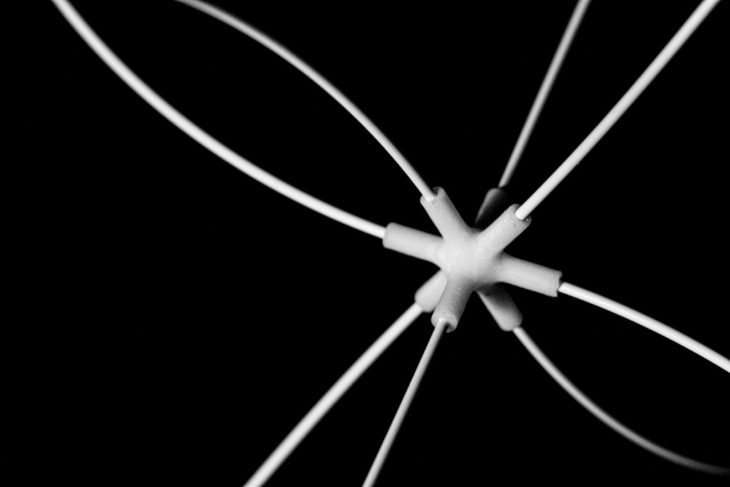

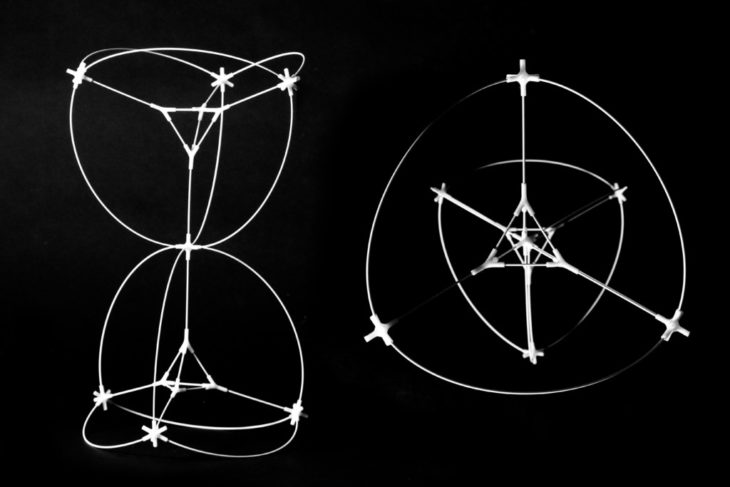

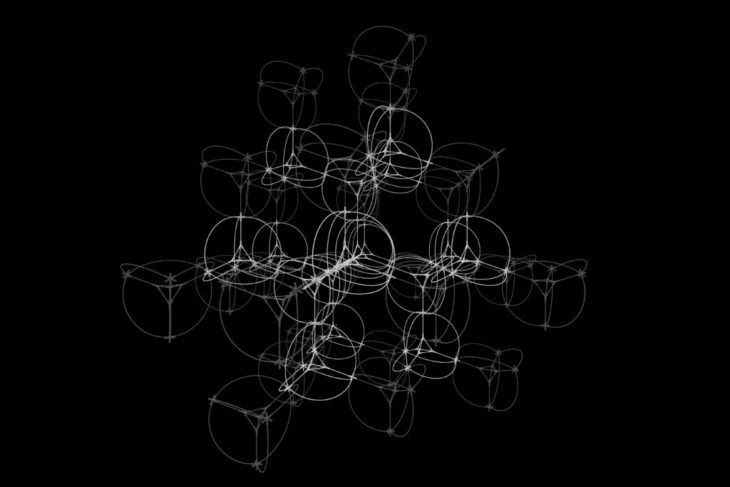

EXERCISE 3 // 3D PRINTING // LEVITATE

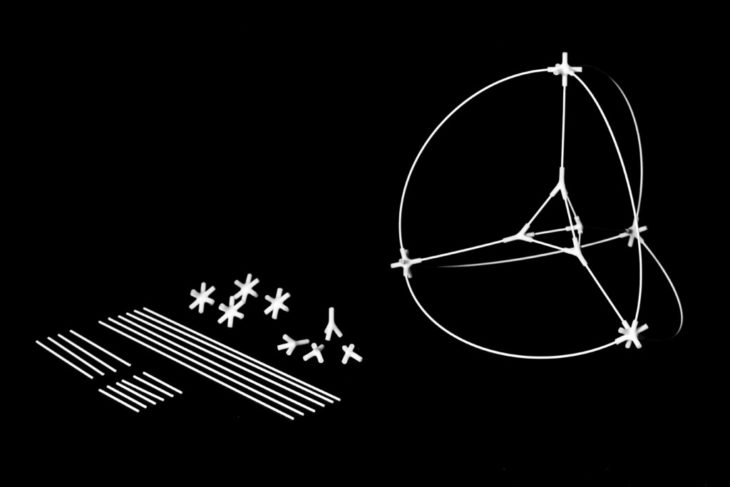

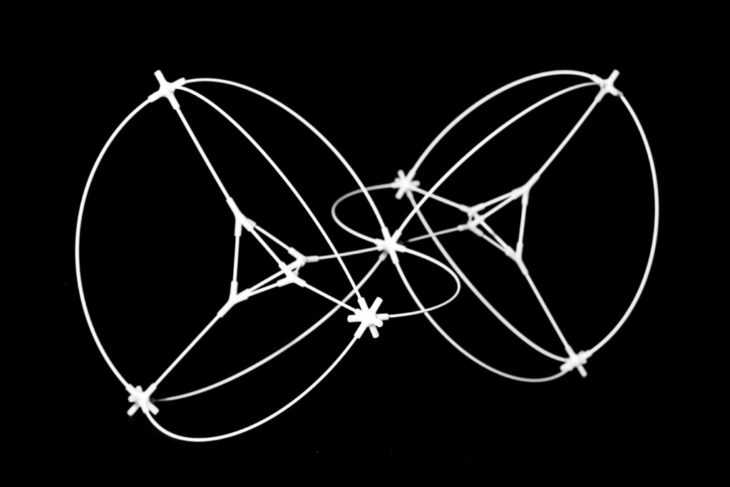

“Levitate” was inspired by the geometries of Frei Otto’s experiments with soap bubbles. The recursive geometry was created in order to analyze the behavior and strength of bent fiberglass elements and the formal possibilities of two single 3D printed nodes.

PROJECT INSPIRATION // Reference

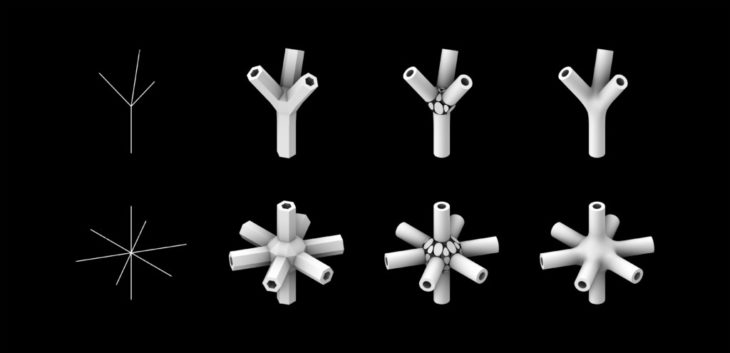

3D MODELING

DIGITAL EXPLORATION OF AGGREGATION STRATEGY

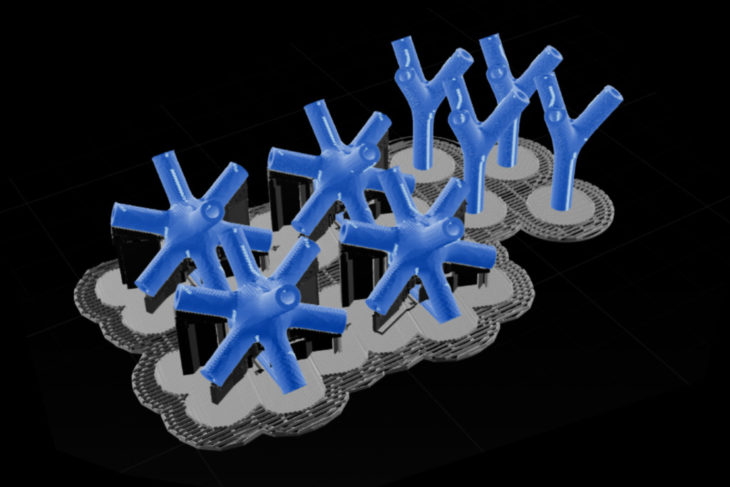

Number of Nodes : 15

Types of Nodes : 2

Estimated print time : 2h 24m

Material usage : 5.83m(14g)

Printer : Zortrax M200

Material : Z-ABS

Nozzle diameter : 0.4

Layer : 0.19

Infill : 20%

Seam : Normal

Support Lite : Yes

Smart bridges : Yes

First layer Density : 100%

First layer Print speed : 100%

First layer Flow ratio : 100%

First layer gap : 0.21mm

FINAL RESULTS

PROJECT // Aggregation strategy

Introduction to Digital Fabrication – Recursive Geometries is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021 by Students: Furio Magaraggia, Akshay Madapura, Leia Iordanou and faculty: Ricardo Mayor, Lana Awad, Shyam Francesco Zonca