DIGITAL WOODCRAFT

Materially intelligent/informed timber fabrication strategies

Seminar Faculty: Tom Svilans

Faculty Assistant: Shyam Zonca

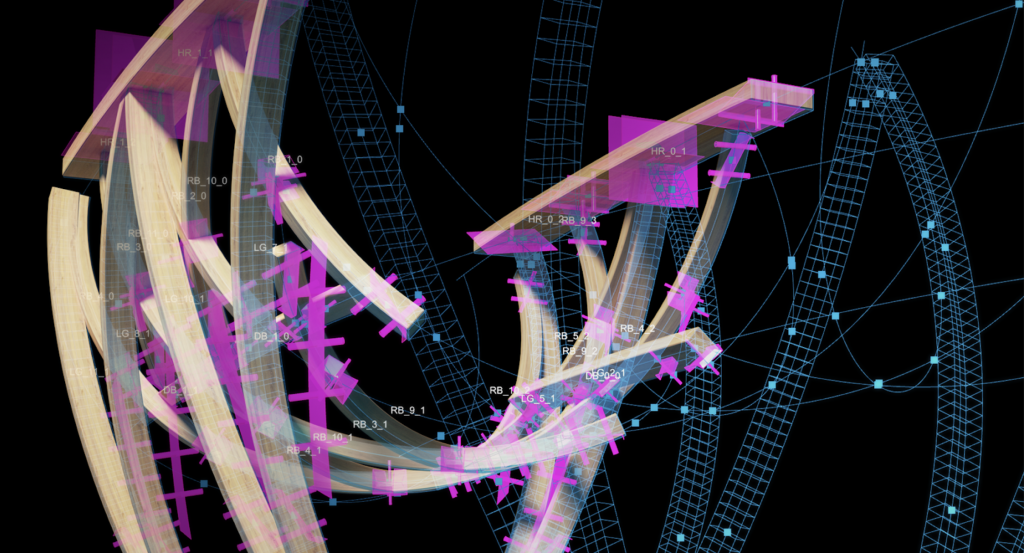

Figure 1 MBridge (Tom Svilans)

Figure 1 MBridge (Tom Svilans)

How have digital tools changed age-old practices of wood craft and timber construction?

This seemingly simple question has been asked and answered in many different ways since the introduction of numerical control and automation in timber manufacturing, and has led to the design and construction of entirely novel timber morphologies and dramatic new architectures.

The capacity of digital modelling tools to represent forms is enormous; however, the affordances of timber and timber manufacturing are more tempered. By engaging with the processes of fabrication directly, and experiencing the consequences of our design decisions, we can better understand how to navigate these affordances with our design ambitions intact. The tools and contexts of craftsmanship have changed, however the central principles remain the same: a deep understanding of the capacities, constraints, and inclinations of both tool and material, guided by a learned knowledge of the specific consequences of specific decisions.

Figure 2 Robotic free-form glulam (Tom Svilans, Johnny Martin)

Figure 2 Robotic free-form glulam (Tom Svilans, Johnny Martin)

So what new languages can we impart to our constructions? How can we appropriate the mechanical movements of a CNC router and turn them into a choreography that traces out our design ambitions? In this seminar, we will design and rationalize a curved glue-laminated timber structure, choreograph its digital production, and thus explore the language of digitally designed and fabricated timber. Through this effort, we will begin to form the beginnings of our own material practice – operating in the fertile space between digital drawing and physical making.

Figure 3 Fabrication-led design modelling (Tom Svilans)

Figure 3 Fabrication-led design modelling (Tom Svilans)

Learning Objectives

At course completion the student will:

- understand the basics of wood behaviour and glue-laminated assemblies

- understand the basics of the production constraints of glulam beams

- be capable of designing and making architectural assemblies that recognize these constraints and how to mitigate them

- be capable of moving from a schematic design proposal of a timber assembly to a fabrication-ready proposition.

Faculty

Dr. Tom Svilans is an architectural designer, researcher, and consultant based in Copenhagen. His research focuses on the design and manufacture of large-scale timber structures, the timber value chain, and emerging technologies. He has a particular interest in the translation of the architectural concept into the fabricated artefact, and all the intermediary translations that this implies. Tom has presented and published his work internationally. He has taught, presented, or been a guest critic at, among others, the Bartlett School of Architecture, UCL; the Architectural Association (AA); the Institute for Advanced Architecture of Catalonia (IAAC); and the Royal Danish Academy.

Links:

www.tomsvilans.com

Twitter: @spilans

LinkedIn: www.linkedin.com/in/tom-svilans/

Faculty Assistant

Shyam Francesco Zonca is a product designer, who focuses on creating truly durable and richly detailed goods within the creative process. He holds a Bachelor’s degree in Industrial Design from Politecnico di Milano and with two academic experiences in Brazil and Portugal, and a Master of Science in Product Design for Innovation. Since he moved to Spain in 2017 he has been working with digital manufacturing in the academic area, IED and IAAC; and in projects that integrate digital technologies with handcrafted finishes. In Milan and Rio de Janeiro he worked as Creative and Project Manager in different areas of design, including products, furniture, digital fabrication, events and visual merchandising. Following this line, he has executed not only creation works, but also collaborated with craftsman and production control.