INTRODUCTION

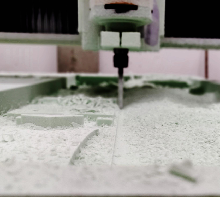

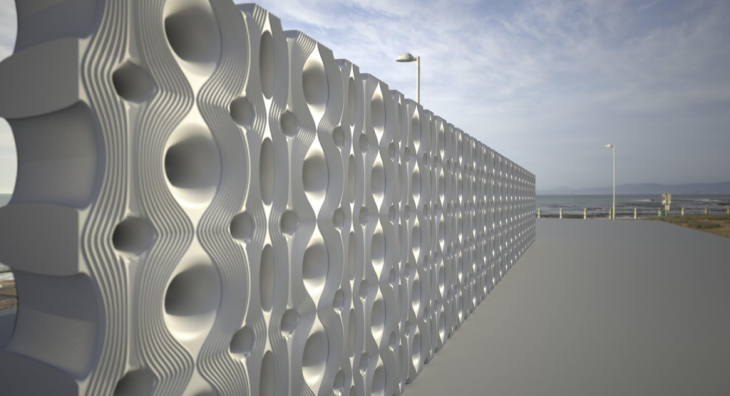

Machine: CNC milling;

Density: 80%;

Topic: Structure performance;

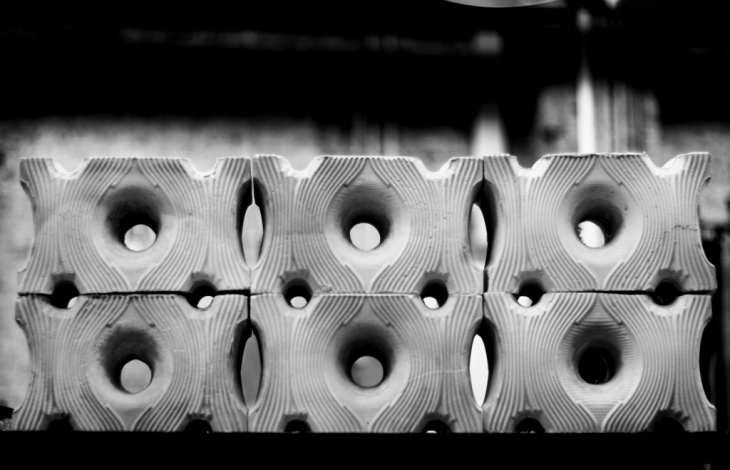

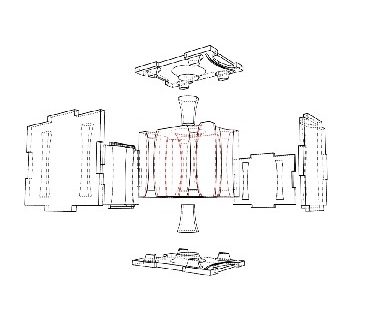

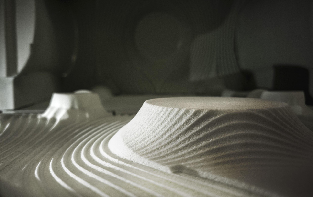

The mission of digital fabrication phase2 is finish 6 plaster bricks. The moulds are manufactured by CNC milling. Our group chose high density foam as the mould material, which has a easy milling processing. In this project, we tried to built a relationship between force analysis and texture, meanwhile we explored how to generate different texture with milling bits.

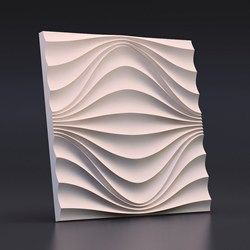

REFERENCE

CONCEPT

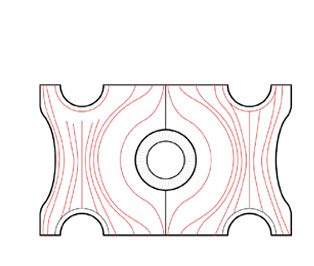

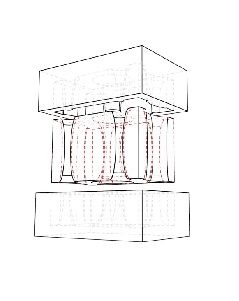

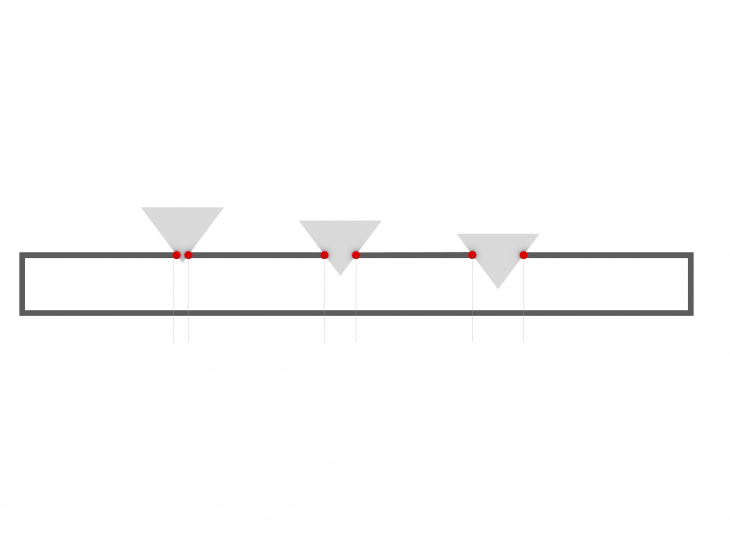

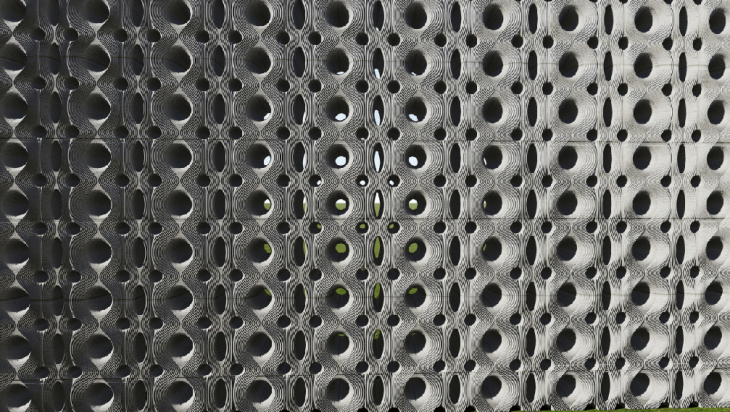

The idea is to establish the structural stability through deformation of force lines caused by the voids at specific locations in the module.

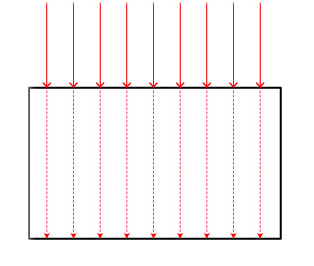

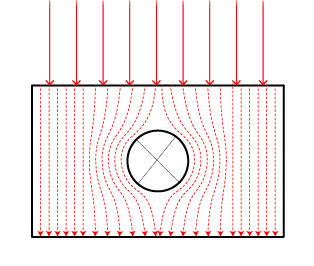

1.Taking the Forces from the above bricks

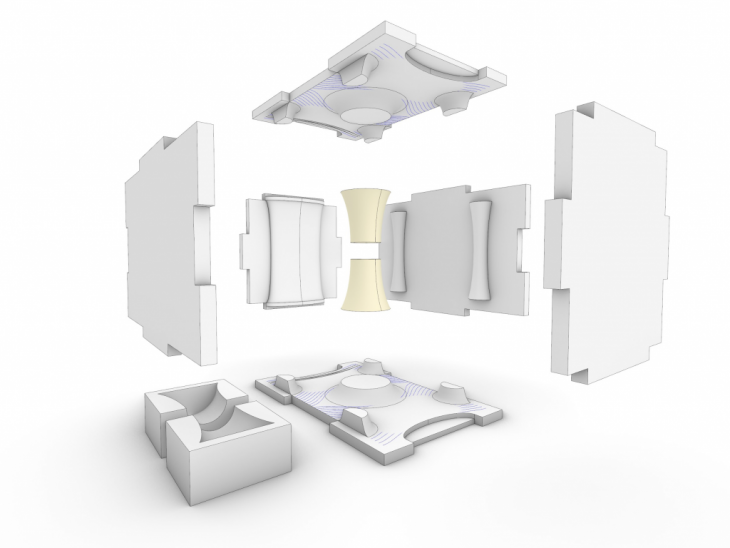

2.Placing a void in the centre (hyperbolic shape) has a non uniformly distributed stress.

3.They are again deformed by arches on the top and bottom.

4.The stress lines are engraved on the brick which forms the texture on its own.

PHYSICAL TEST

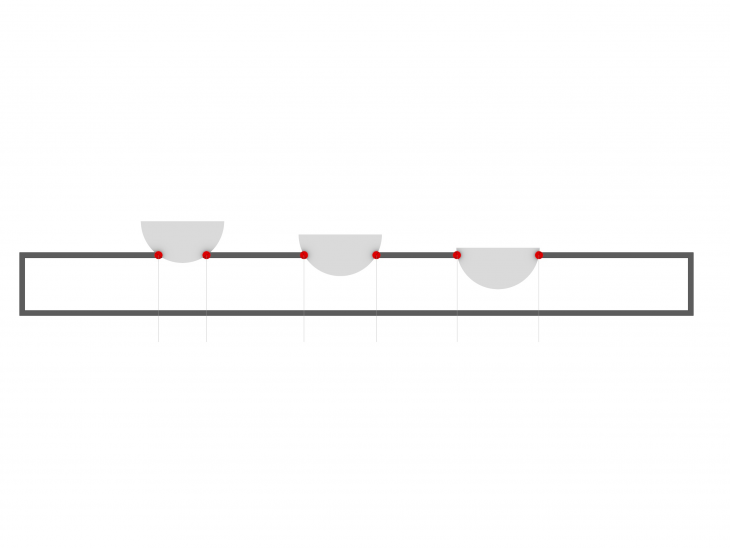

Horizontal roughing Parallel finishing: 120 mins Hard Demolging Tools hits Edges

Horizontal roughing Parallel finishing Horizontal Finishing Engraving: 120 mins Tools hits Edges Complicated Milling Process (Double-Side Milling)

Horizontal Roughing Parallel Finishing Engraving 2 1/2 Axis Profiling: 100 mins Better Graving Quality Material Saved Easy Demolding

STRATEGY

Milling Tool Test

RHINOCAM

Horizontal Roughing Flatmill: 12 25 mins

Parallel Finishing Ballmill: 8 40 mins

Engraving V-shaped Bit: 15 mins 2 1/2

Axis Profiling Ballmill: 8 20mins

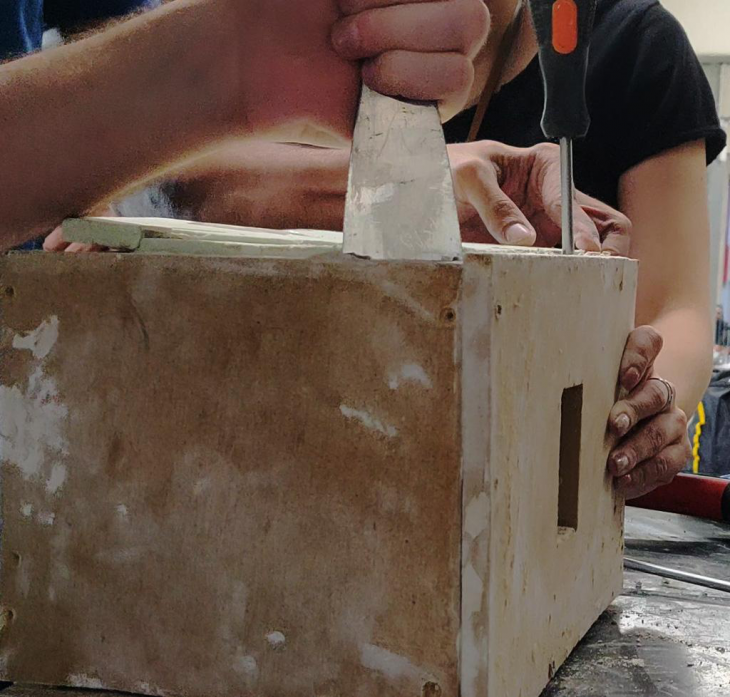

PHYSICAL BUILT

Fixed Wood

Casting: Plaster : Water = 7000 : 2800 40 mins;

PROCESS

RENDER

Developed by students: deepark.mudikondan, jingwen.chiou, alaa.aldin.al.baroudi, hongyu.wang from iaac at Master in Advanced Architecture, in 2018-2019.

Faculty: Alexandre Dubor, Ricardo Valbuena, Ricardo Mayor, Lana Awad, Sujal Kodamadanchirayil Surech