The aim of this second phase of the digital fabrication class is to deepen the understanding and explore the capabilities and limitations of the three manufacturing processes introduced in the crash course, and to develop an integrated approach to design and production. The students will alternate every two weeks between each of the three fabrication machinery to further their knowledge according to select research performances. The common framework of the biweekly exercises is the task of developing modular components at various scales of architecture elements: a tile, a surface, a panel, which will then be collectively assembled to construct architectonic structures: a lamp, a partition, a wall.

First two weeks:

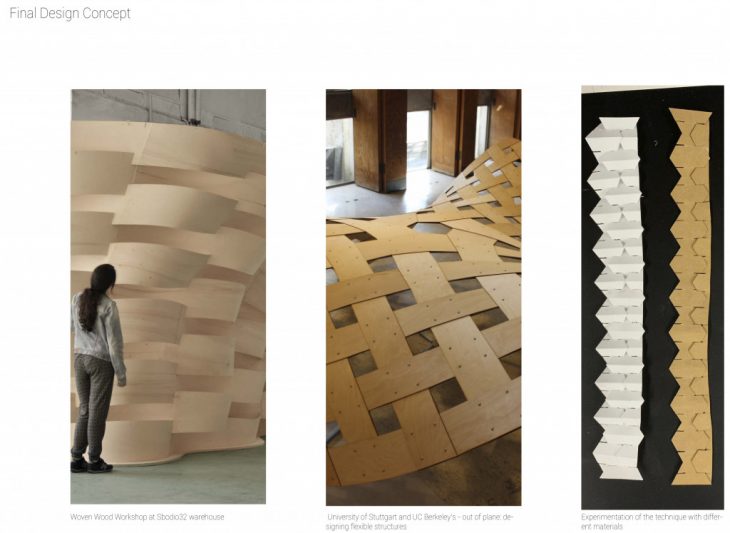

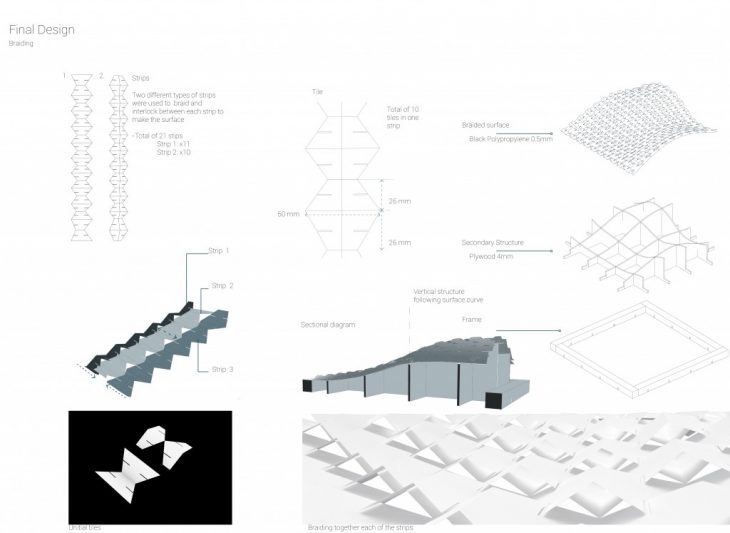

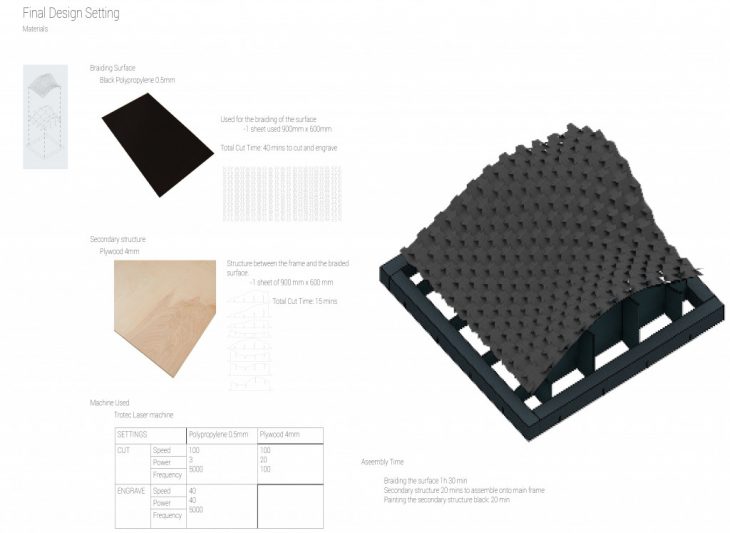

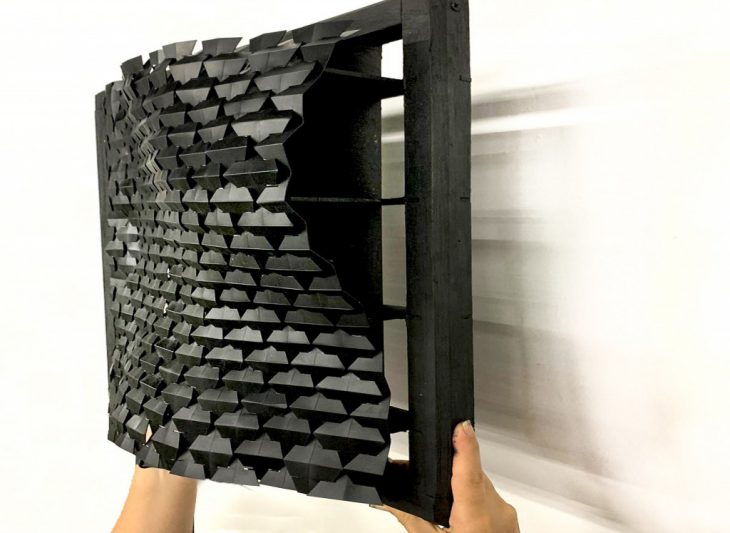

Laser cutting/Braiding

Second two weeks:

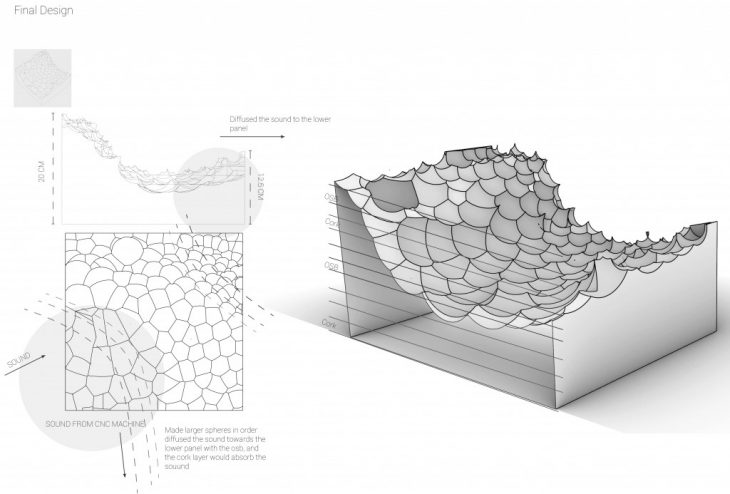

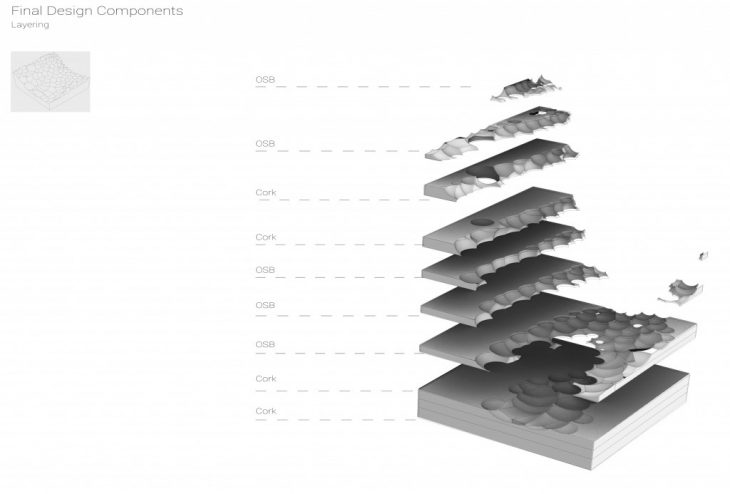

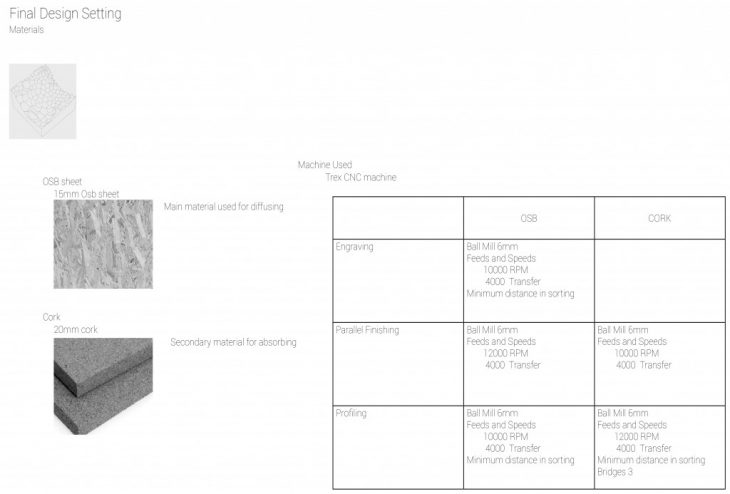

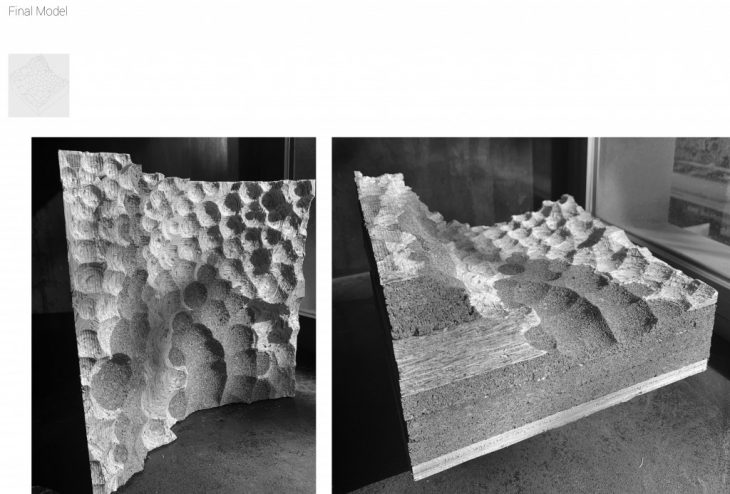

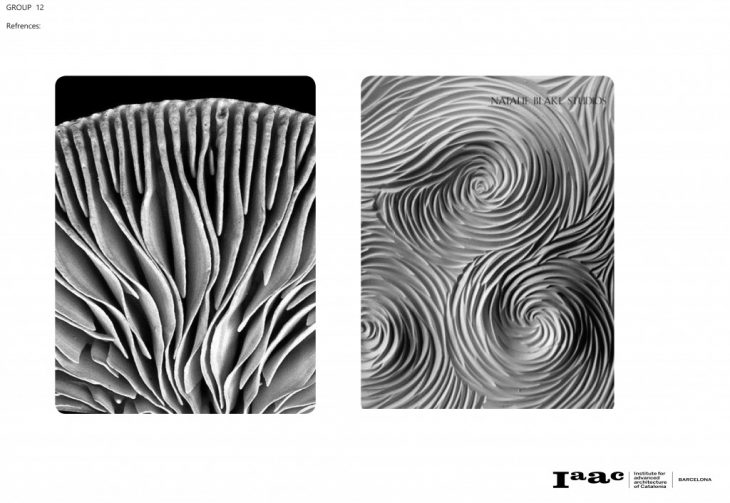

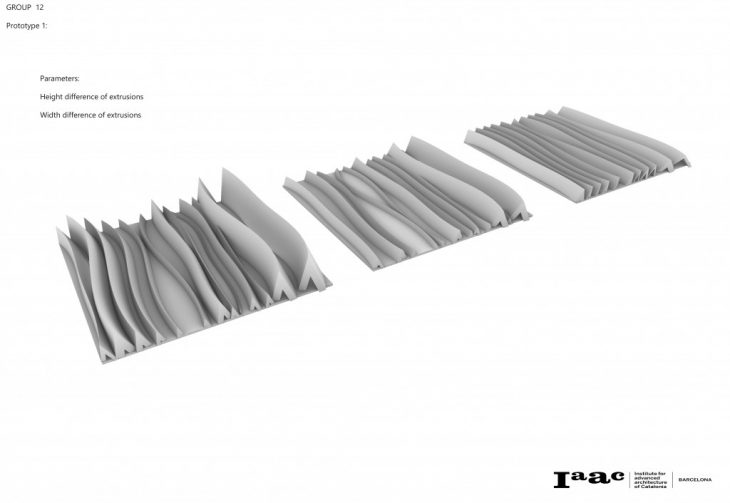

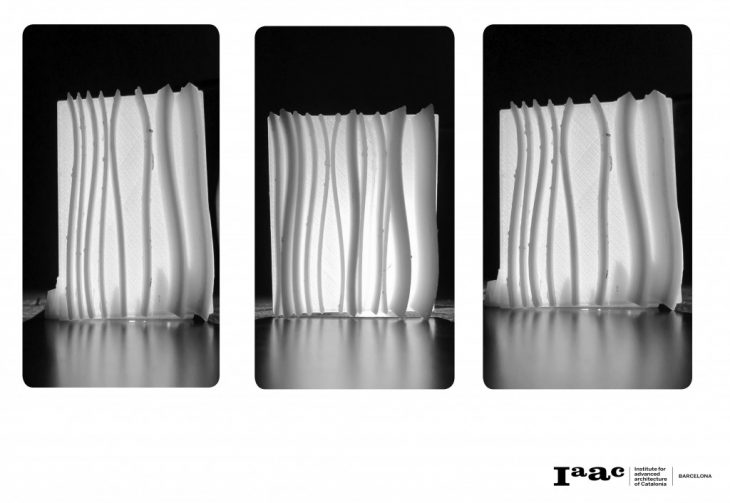

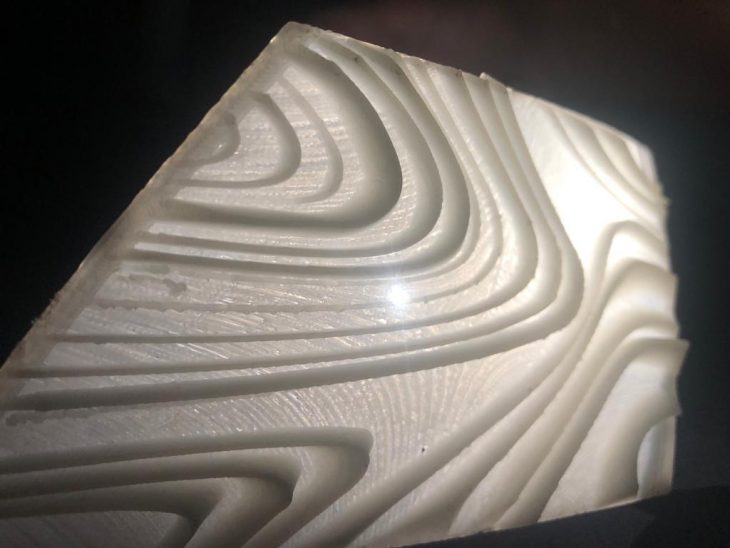

CNC milling wall

Third two weeks:

3D printed lamp:

Students:

Léa Carole Solène

Nareh Khaloian

Matin darabi