THE PROCESS OF MAKING A BRICK USING A PLASTER :

ABSTRACT:

Machine : Laser Cutter

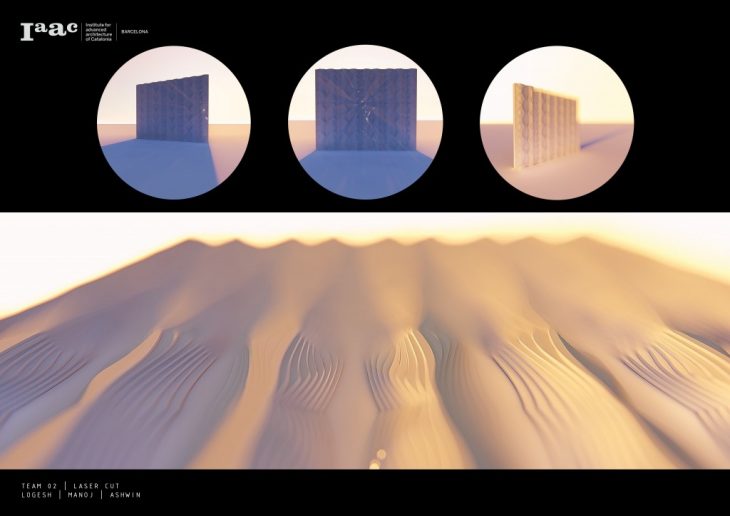

Density : 70% solid and 30% Openings

Performance : Structural Stability

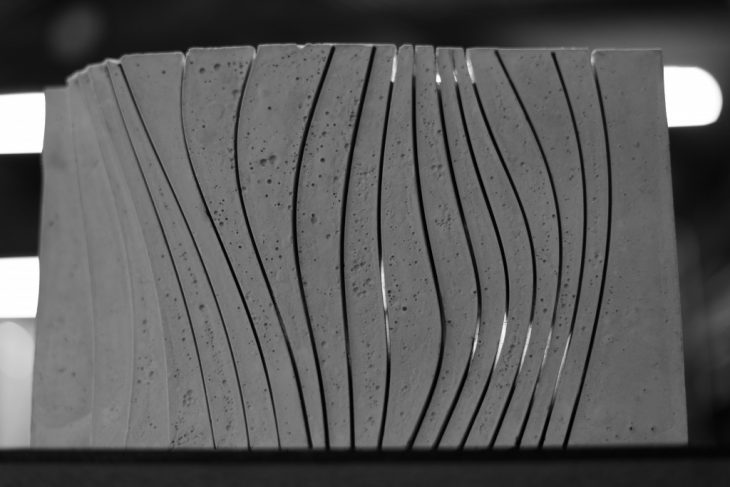

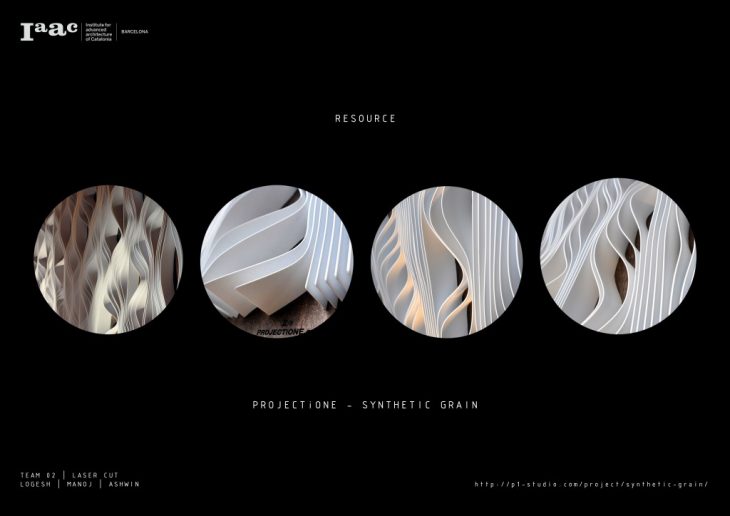

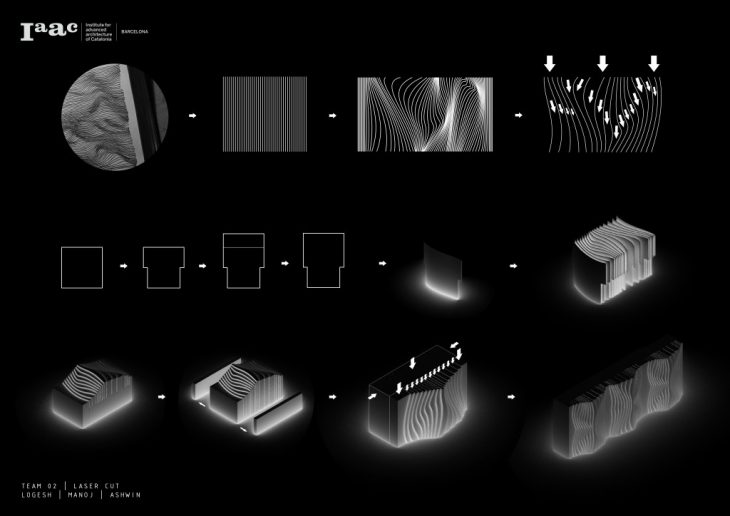

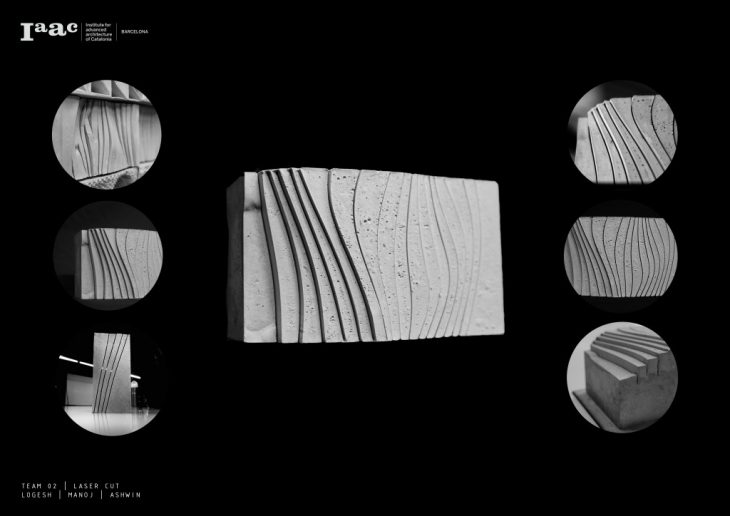

Our task was to create a plaster brick mold where structural stability was an important parameter. We created a concept of lines that run vertically in the brick through which the openings were achieved. These lines were curved, thus we were able to test the plaster’s stability by slicing in various thickness in various levels.

The structural stability was achieved to a certain level by creating a beam in the bottom of the brick to a certain height on the top and bottom. The parameters of the beams were achieved by testing the beam height and width from smaller in size till it transfers the load equally in both sides. This process was challenging as we are slicing the brick at various levels which makes the plaster’s structural limit is far beyond through this. The extreme stress loads were transferred through these curves at various levels which tests the structure whether it can be achieved or not.

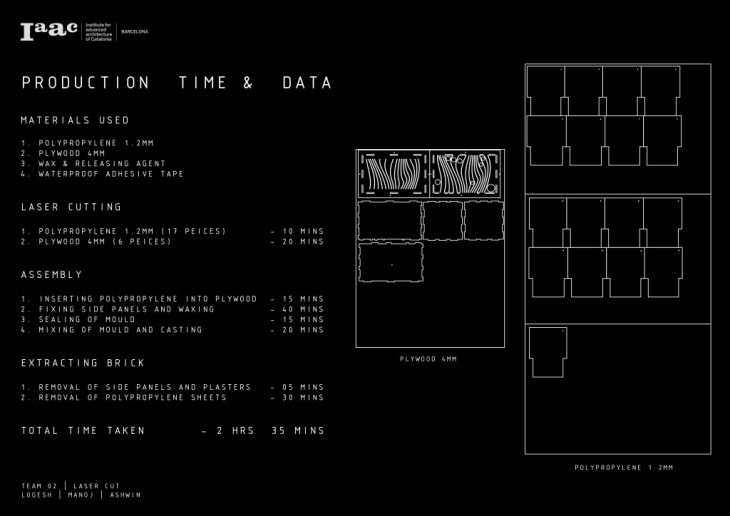

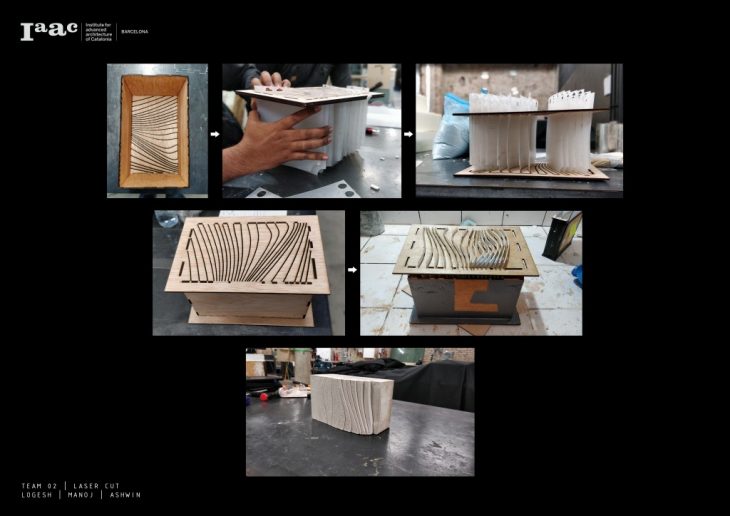

We started testing using various materials with different thickness to achieves these lines in the brick. The Wood with kerfing, Acrylic with Kerfing and Polypropylene were used to create these curved lines. Finally we used 1.2 mm Polypropylene sheet which is more flexible and removable without damaging the brick’s stability.

Removal of the Mold :

“Structural Stability” is a project of IaaC,

Institute for Advanced Architecture of Catalonia

Developed at Master in Advanced Architecture in 2018 by:

Students: ManojRaj Manachanallur Raju Periyasamy, Logesh Mahalingam, Ashwin Varma Dandu

Faculty: Alexandre Dubor, Ricardo Mayor