The following productions were made in IaaC Digital Fabrication class. Each of the examples are attempts to experiment with each technologies capabilities. The technologies employed are laser cutting, CNC Milling, and 3d printing. Each experiment consist of project diagrams/technical drawing, production calculations, and photo of the final output. Includes final object parameters, which are the result of many trials and optimizations.

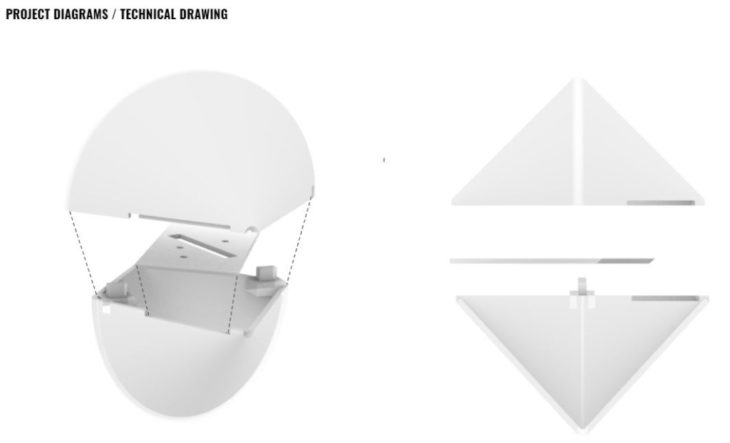

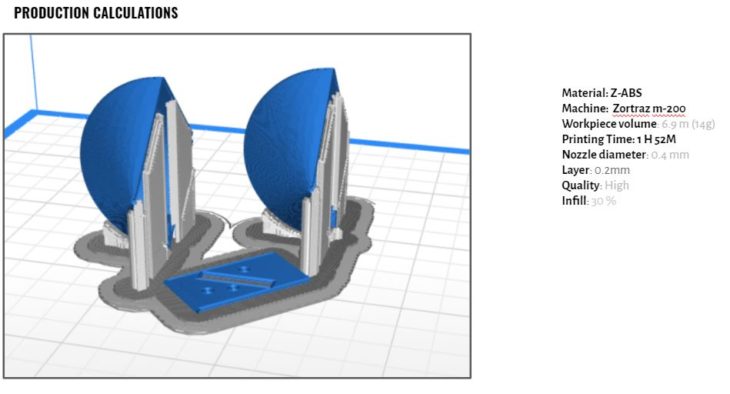

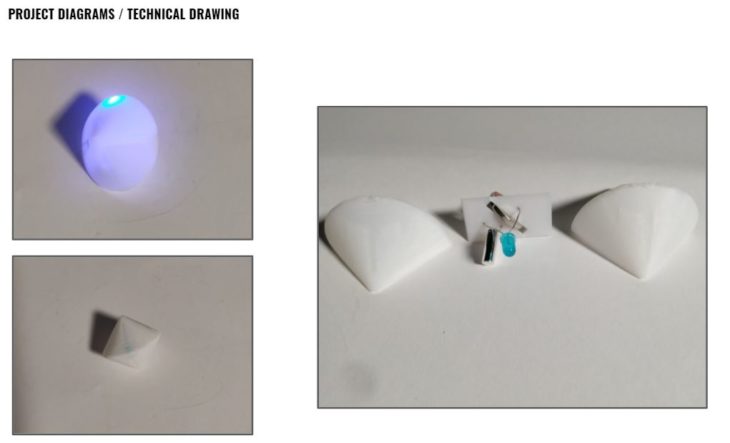

The object is a 3d rhombus which can be dissasembled into 3 parts, upper, lower, and a plastic card. The plastic card includes 4 holes to hold a motion sensor, a light and a battery. When assembled, the lights turn on and off depending on which side the rhombus lies.

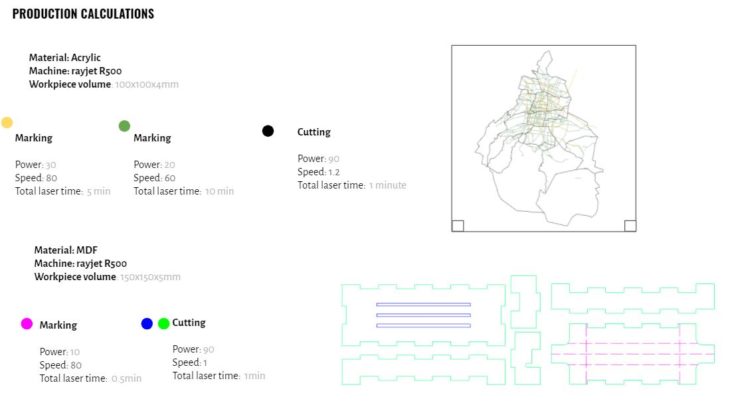

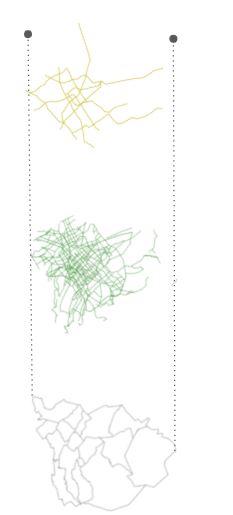

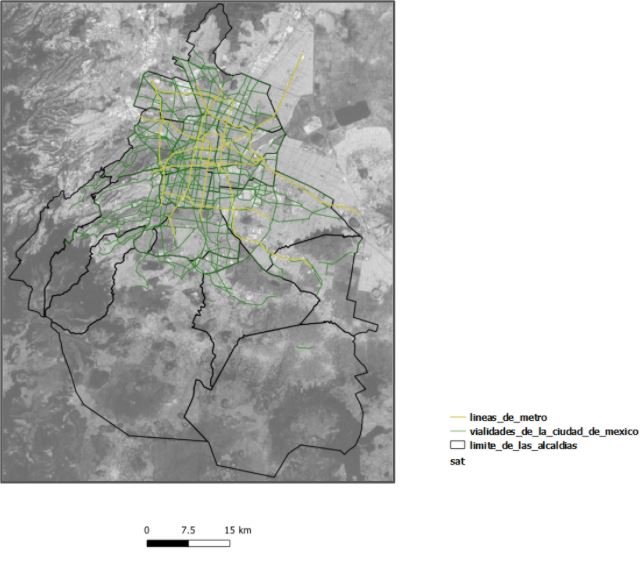

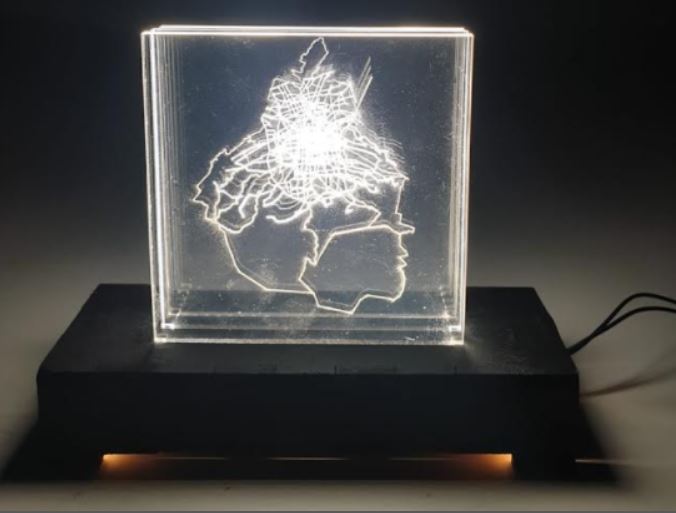

The following object is a wooden box design to hold three acrylic sheets, each with a different laser cutted engraved. In this case Mexico city administrative boundaries, subway lines and main roads. The box contains a vacuum with led lights, when on the engraving is visualized.

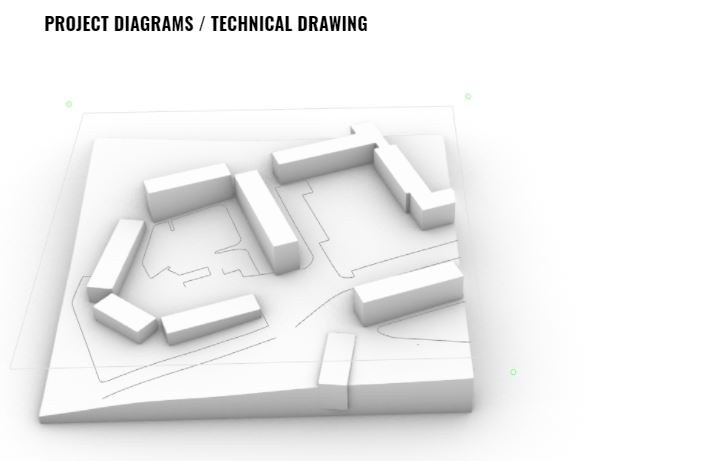

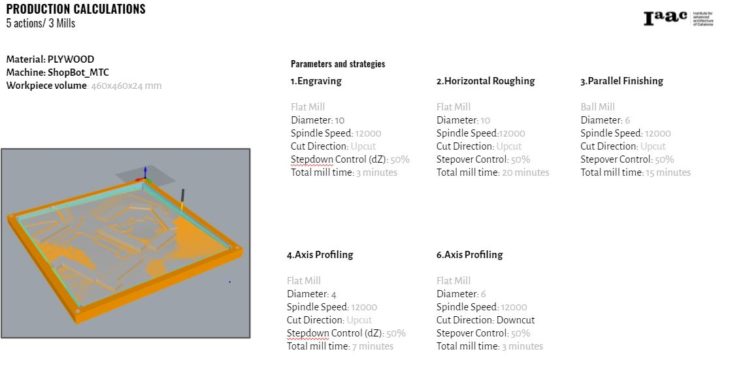

The Following simulation was made with rhino CAM (computer aided fabrication). CNC milling is functions as a subtractive manufacture, which is particularly useful to manufacture surfaces, such as topological terrains

Digital Fabrication exercises is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in City & Technology 2020/22 by Student: Juan Pablo Pintado and Faculty: Cristian Rizzuti and Shyam Zonca.