Digital fabrication: 3D printed wall system:

Introduction:

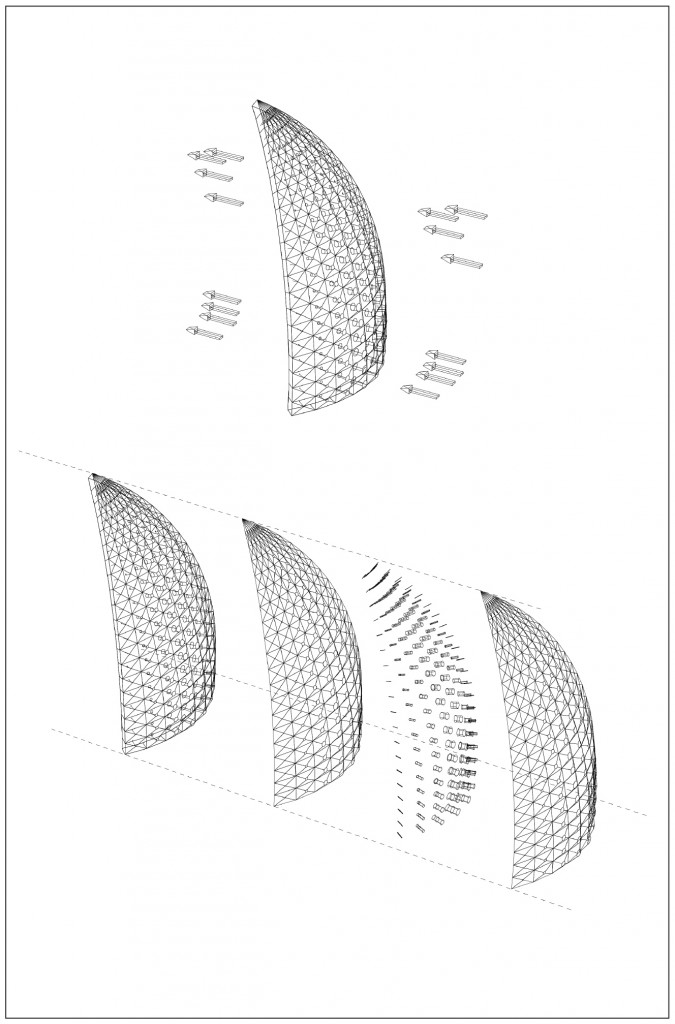

This exercise aims at exploring the design potential of 3D printing technology in architecture. We used as a test case, the detailed design of a performative wall element, with a particular attention given to the integration of opening(s) (covering 20% of the wall surface). The design of the shape and texture as well as the placement of the opening(s) needed to be cleverly chosen to avoid fabrication and structural issue. Two different Additive Manufacturing (AM) process were explored in this exercise : Extrusion and Powder Base out of which we were assigned Extrusion. Following were the conditions set for the facade using this technique:

- Suitable for onsite fabrication (one piece)

- Shape limitation (without support) : Cantilever of max. 45°, bridge length of max. : 2cm

- Material working in compression and slightly in traction.

- Anisotropic properties (better strength in the extrusion direction)

- 3D printed mono-block wall, to be built onsite, avoiding non constructible cantilevers and bridge (without the help of support)

Concept:

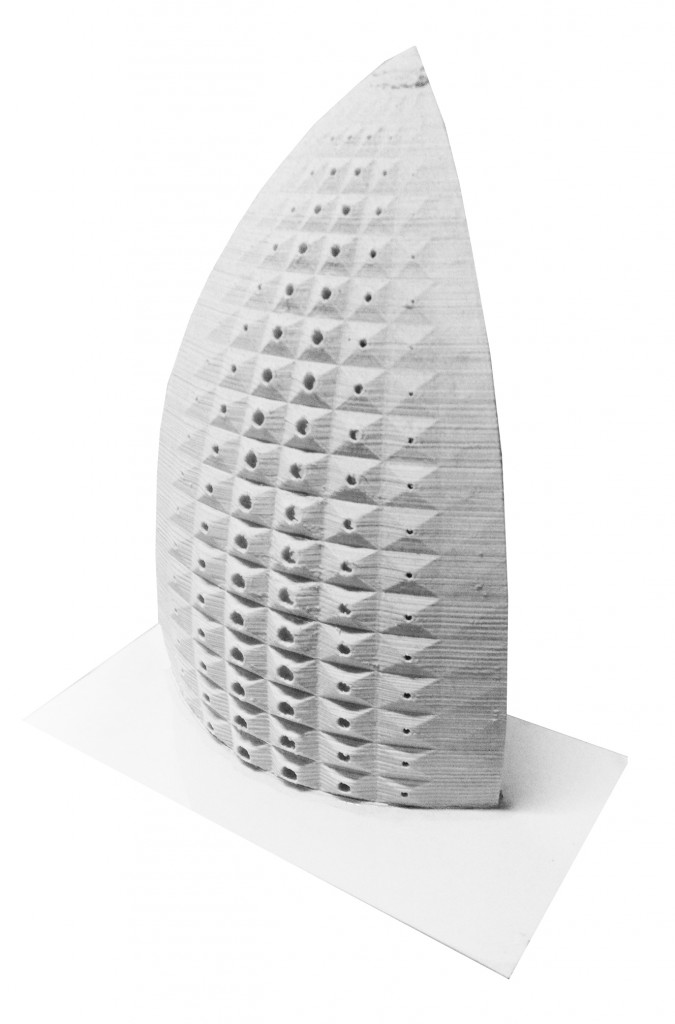

The façade was designed in order to achieve performance and aesthetics. Our idea was to have maximum number of perforations in the façade, without losing the necessary structural force and avoid fabrication issues. Hence, we positioned bigger openings in the center which

became smaller towards the end. The 20% openings were distributed calculating the amount of energy, natural light and air ventilation required on the inside. The smaller openings could house wind turbines to generate energy within the façade acting as sustainable elements. Thus, by maintaining the aperture percentage we managed to achieve a balance of the solid and void.

Outcome:

The 3D printed wall

Conclusion:

Both the technologies allowed to design the internal structure of the wall. In that case air ventilation, water collection, vertical garden and energy generation added performance and functions to the facade.

Digital fabrication: 3D printed wall system is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master of Advanced Architecture in 2015/16 by:

Students:

- Connor Stevens

- Dhairya Thakkar

- Dirk Baron van Wassenaer

- Martin Hristov

Faculty:

- Alexander Dubor

- Djordje Stanojevic