Bio-reactive facade – 3D printed wall system – Extrusion

The aim of the exercise is to explore the design potential of 3D printing technology in architecture. A 3D printed monoblock wall (extrusion), to be built onsite, without cantilevers and bridge is created, and its stability for 3D printing is studied.

Students :

James Nurtanio

Lili Tayefi

Prajakta Panchal

Tutors :

Alexandre Dubor

Djordje Stanojevic

With help from :

Ricardo Valbuena

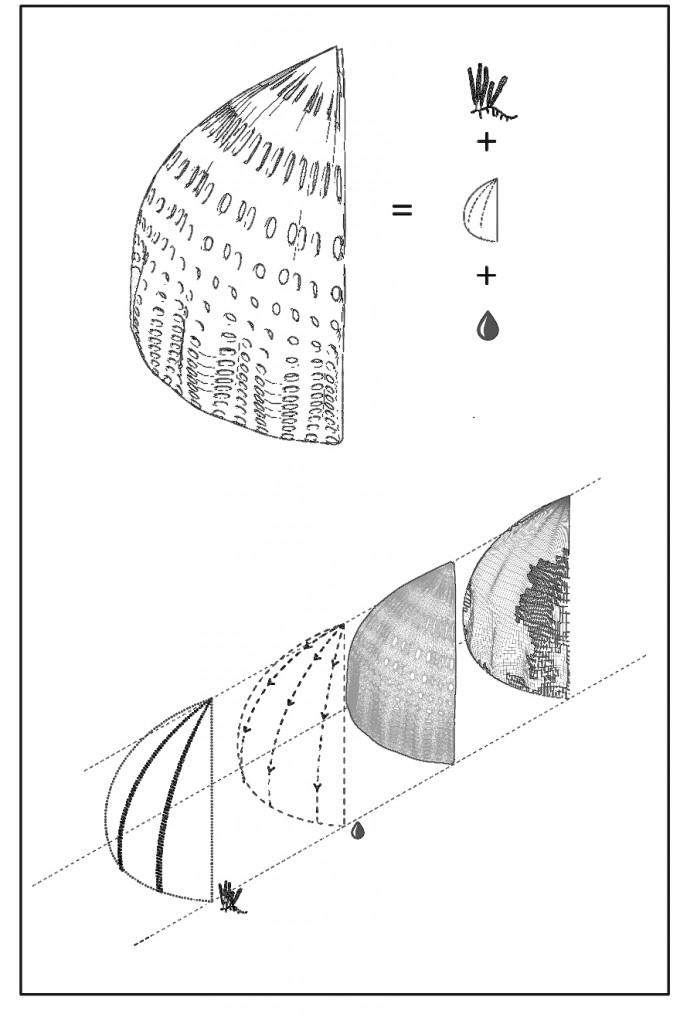

Diagram

Concept :

The façade consists of 3 components – water channel, algae channels and air insulation. Micro – algae in facades store thermal energy and could be used to generate power, act as bio – reactive shading systems and help in improving the surrounding air. The water channels would be used for rainwater harvesting as well as to feed the algae. The air pockets (formed by the internal structural grid within the wall thickness) will create insulation while the openings create ventilation.

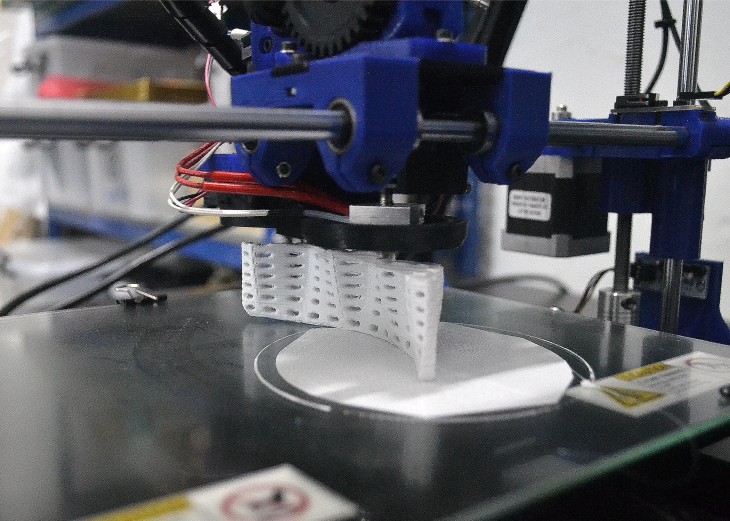

Process

Process :

A 3D printer is used to create the prototype. Punctures in design are provided to obtain 20% openings in the facade. These opening locations can be controlled to create the water channels for rain-water harvesting. The design of the shape and texture as well as the placement of the openings is chosen to avoid fabrication and structural issues. This has been resolved through the use of Slic3r, a software for understanding the 3D printing of a particular design.

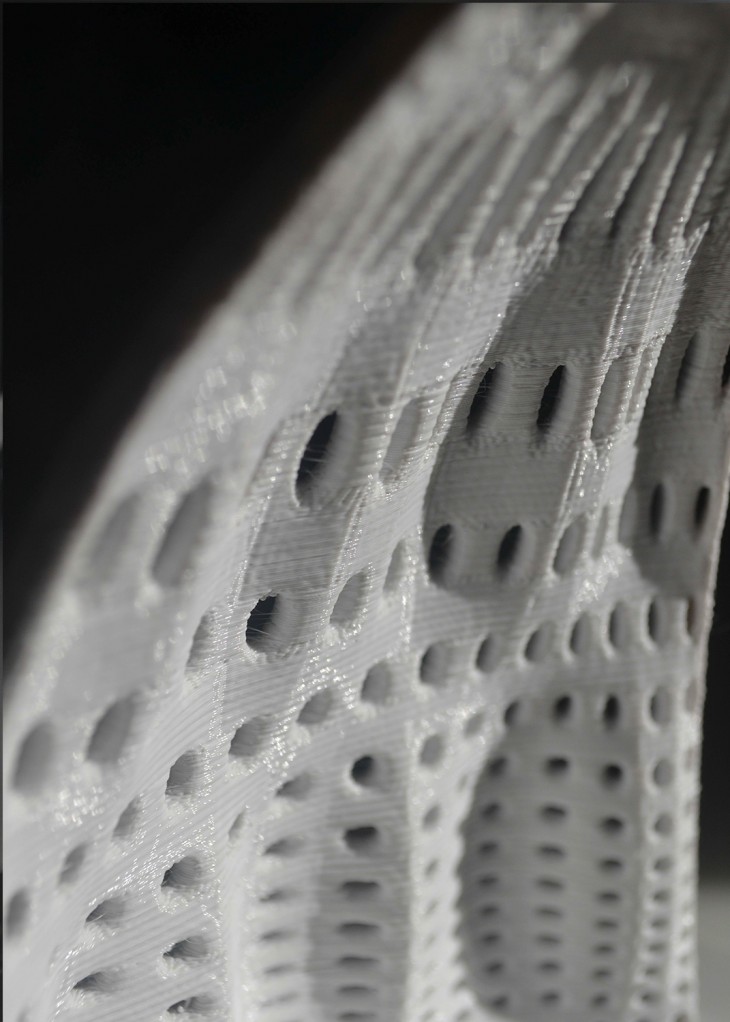

Detail

Facade