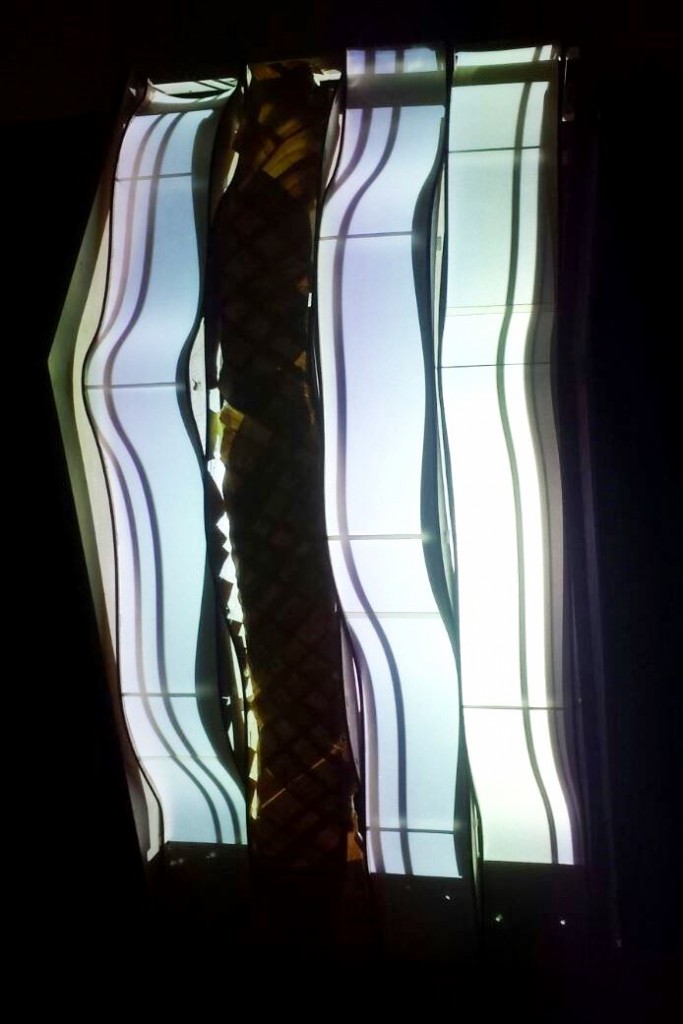

A digital facade is developed with 95% polypropylene combined with 5% laminated wood to obtain maximum translucency as part of the design brief.

Students :

Borislava Lyubenova

Justyna Brzakala

Nour Mezher

Prajakta Panchal

Tutors :

Alexandre Dubor

Djordje Stanojevic

With help from :

Ricardo Valbuena

CONCEPT (100 words)

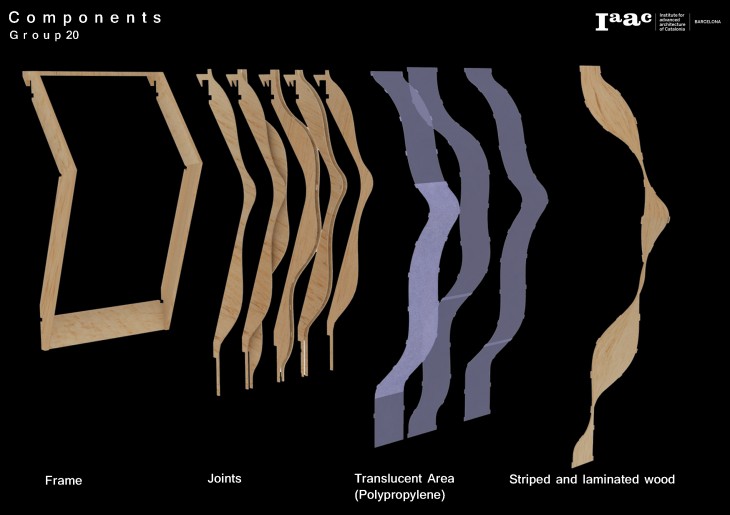

Laminated wood, bent in calculated curvatures can tolerate more forces. The idea is to play with this concept of laminated – bent wooden stripes that goes well with the bending properties of polypropylene. The frame of the façade is divided into four sub-frames.

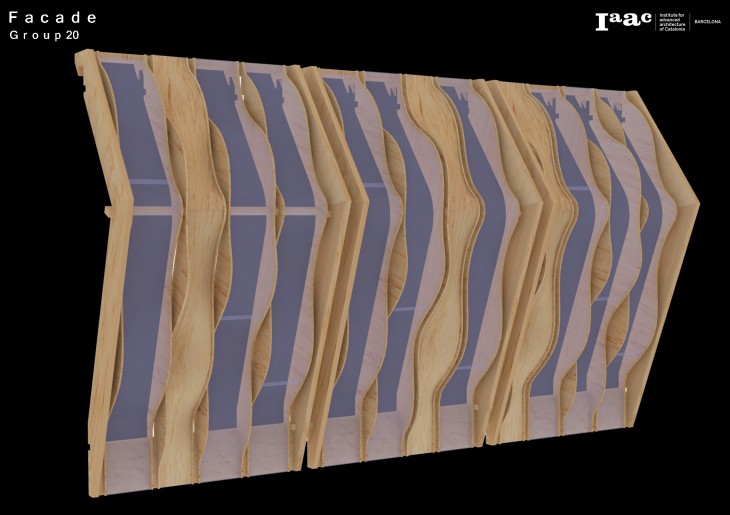

Three sub-frames have strips of polypropylene, sandwiched between two pieces of laminated wood and placed vertically to generate linearity. The forth sub-frame has a strip of bent and laminated wooden stripes sandwiched between two pieces of laminated wood to give rigidity to the façade. These sub-frames could be interchanged amongst themselves to create different configurations through the entire wikihouse façade and help in achieving certain flexibility in design.

Diagram – Component

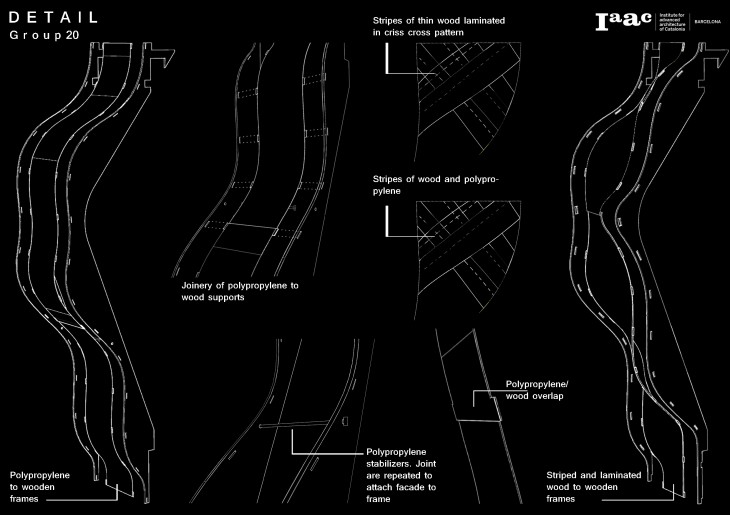

Diagram – Detail

Diagram – Facade

METHODS

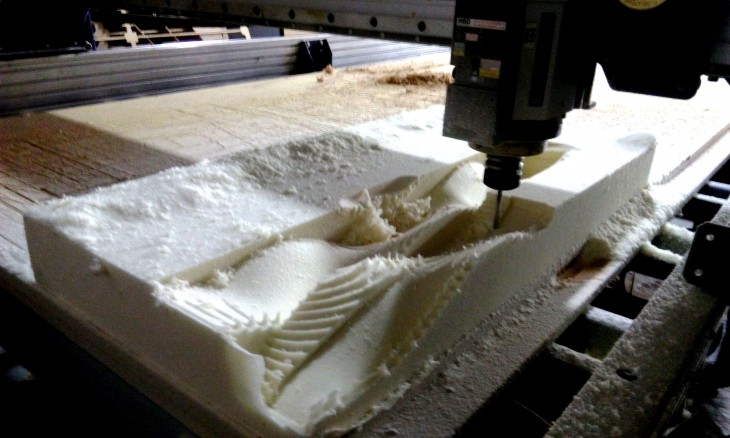

The main method used for the façade is lamination. After deciding on the design, a mould is created by milling high density foam, which is then used to create the bent laminated form with wooden stripes, using the vacuum machine. The strips of wood were laser cut and laminated in 2 criss cross layers for the same.

Process – Foam Mould

Process – Joinery

Process – Lamination

For the sub frame, polypropylene strips are laser cut and fixed along the edge of the laminated wood with a connecting polypropylene joint. Maximum translucency is created while the wooden strip provides shading. Different curvatures of the material create shading effect. The sub frames are then fixed to the frame using joinery made out of polypropylene.

Model

Model