Studio 3 | MRAC 2018-2019 Faculty: Aldo Sollazzo, Alexandre Dubor Project by: Stefano Meloni, Riccardo Mura, Luis Pacheco

“Construction sites are complex environments.

We decided to develop a Robotic assistant

able to cooperate with workers and designers

to better handle practical tasks”.

CRA – Construction Robotic Assistant

Introduction

It’s well known that the construction industry is one of the less automated ones, and one of the biggest reasons is that robots work well in repetitive tasks and in supervised environments, which the construction sector could not be more distant from. The world of construction is so messy and unpredictable, in fact some companies started directly 3D printing on the construction site, this is an approach that exploits existing robots -largely used for other industries adapted to perform all sorts of fabrication tasks, although this type of machines hardly fits into a construction site, mostly because it’s just not what they were designed for. For this project, we tried to deviate from the actual state-of-art in robotics in the AEC industry and tried to rethink a whole new process.

For these reasons we didn’t use any robotic arm (which is what people are mostly relying upon their researches and experiments) instead, we tried to develop, an affordable Assistant that can help workers avoid repetitive tasks on site. The technology we built up so far is not advanced enough to achieve a fully automated construction site any time soon, the project has been developed as a PROOF OF CONCEPT in order to understand the technology behind and the feasibility of its parts working in synergy. Once understood this point, we started our experiments on an existing type of robot, in order to provide a tool that can be scaled to many different sizes and, depending on the task, can be applied in many different ways.

The main point was to provide workers an easy and affordable tool that could improve their workflows and their life on construction sites, increasing safety and accuracy. For this matter, we achieve to develop only a few features around this concept, but what we envisioned is a goal still far to achieve in terms of full functionality and precision. We strongly believe ” the right tool for the job” as we try to apply this philosophy mostly in every aspect of this project, we developed our own tool instead, using mostly parts you can find in any digital fabrication toolbox.

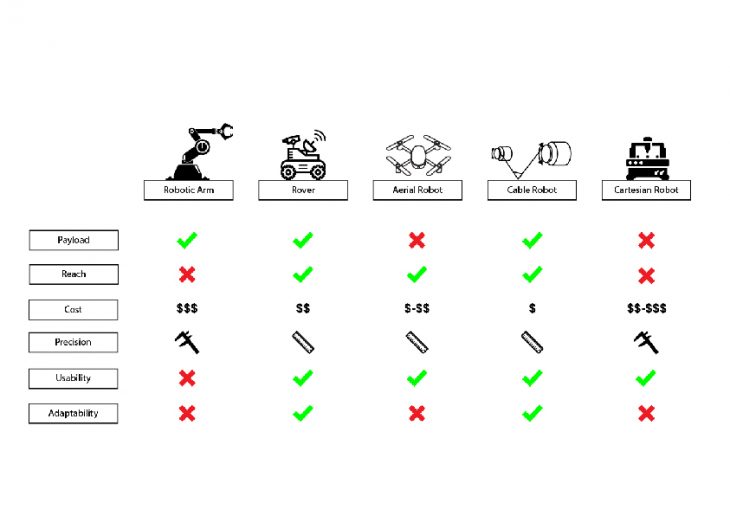

Robot Comparison

As most people know, there are many different types of robots, which are now starting to be introduced and experimented and implemented in the construction world. For this research we needed a specific type of robot that had very specific characteristics, so we started to analyze machines under different aspects and points of view. Due to our needs, we decided to use six main parameters: Payload, Reach, Cost, Precision, Usability, and Adaptability.

First, we analyzed the payload feature, we know that most of the robots can bear and operate medium and heavy loads, but for what we needed it wasn’t so necessary to work with too much loading capacity, but not even to have limitations for just a few grams. After this first analysis, we discarded drones, mainly for the little payload they can carry compared to their size, but also because they are not so reliable to work around humans.

The second aspect we took in consideration was the reach since we needed a very adaptable robot, we also needed a very extensive reach which could be achieved only by rovers and drones (the last one already discarded), but not with robotic arms, so we opted to get rid of this option.

The third attribute we examined was, of course, the cost, fundamental when we talk business in any industry. We actually found out that, despite the typologies, prices can escalate pretty quickly, but with our solution cable robots could be built in a cheaply, maintaining a good level of accuracy, plus, the simplicity of the mechanics and kinematics helped us to develop more than one prototype in order to experiment more; in total, the whole project cost us, for a working prototype, less than a hundred fifty euros.

The fourth aspect we investigated was the Precision, as we all know robots can be very precise or not, depending on a lot of factors. As we can see from the diagram some robots fit this characteristic but don’t fit others, plus a very important question we asked ourselves was:” how much precision do we nee in the construction site?”. The answer was: not a lot.

The fifth parameter was Usability,. Some machines are more user-friendly some machines are very complicated, looking at our market we acknowledged that workers can be technical on their own fields, which rarely is robotics, and we wanted a tool that was ready to use. So we decided to exclude this robot that required a high level of expertise to operate.

The last aspect we took into consideration was adaptability, and again the comparison makes it very clear. Most used robots are not adaptable at all, they have ranges, very specific feature that allow them to work in controlled and limited environments, that doesn’t match with the construction site description.

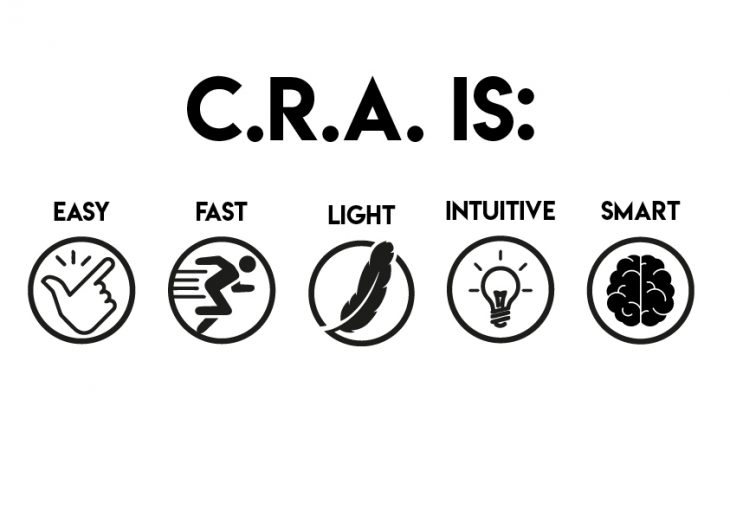

For all of these reasons, we decided to work on a cable robot, which gave us most of the features we were requiring. Even though the work to develop our own tool is still long, this base is the best where to start from. Our goal is, through this, to make a robot with 5 main characteristics: Easy to command, Fast installable, Light weighted, Intuitive and Smart.

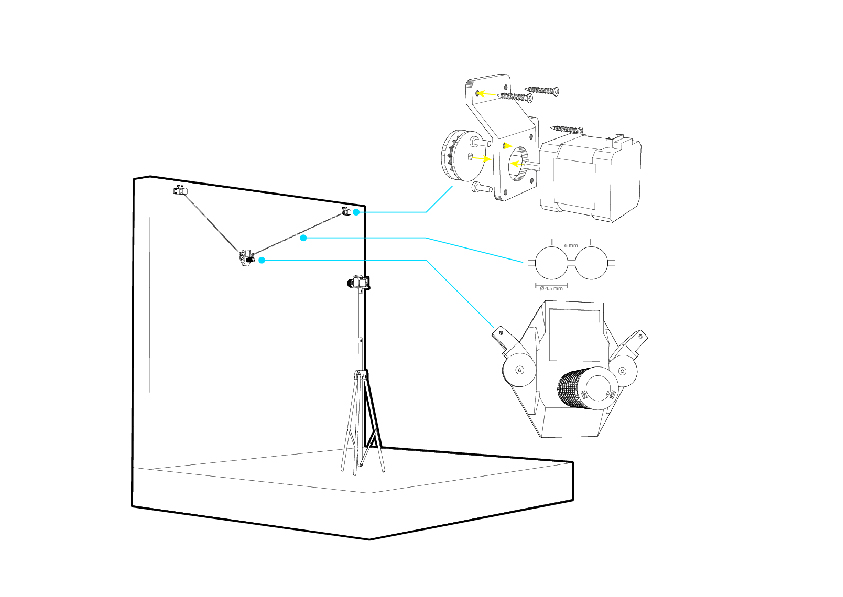

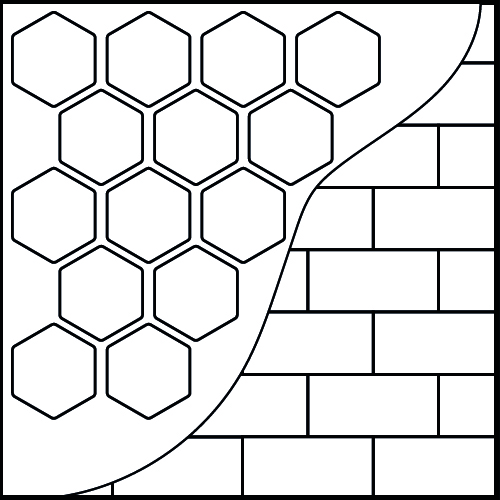

Why cable robots?

We decided to develop a prototype of a cable robot because of five main reasons, this system is: Fast, Cheap, Adaptable, Easily fixable and Easily programmable.

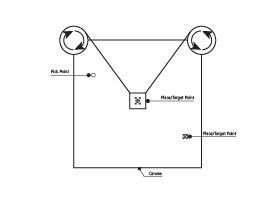

This type of robot can move rapidly, of course, is not the most precise compared to most of the different kinds of a robot on the market, considering we are aiming to the construction site world, we didn’t need an industrial level of accuracy, other aspects were still more important. Cable robots are extremely affordable, our functioning prototype, fully assembled, cost us around a hundred euros.

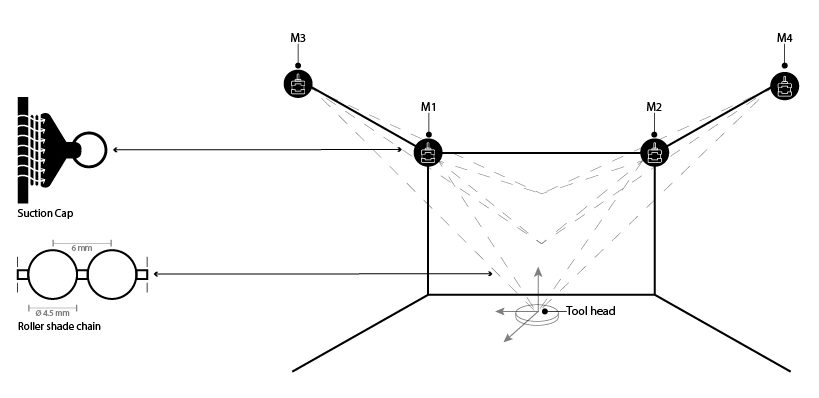

This specific kind of robot is also versatile, indeed, one of the most important aspects we wanted to achieve on our robot was the adaptability, since not all the construction sites are equal to each other, we wanted to obtain a tool with which we could be able to fit to any size, shape or surface. Due to the very simple typology and the very limited number of pieces, cable robots are also easily fixable or replaceable. Lastly, the relative simplicity of this tool, just by programming two stepper motors we could achieve a fully automated action, helped us to obtain quick results that can be applied to a bigger and more complex machine.

Vision

The vision is to have a portable, flexible tool that every construction site worker could use for different purposes. The long term goal is to have a construction assistant that can relieve and facilitate some repetitive tasks which don’t require decision making. This tool could speed up some jobs reducing the number of workers and increasing accuracy meanwhile.

Opportunities

The opportunities are endless, indeed achieving to go move from the 2D to the 3D space could open up even more perspectives. This could be used not only on normal construction sites but also in places hard to operate by humans or hard to reach places.

Conclusions

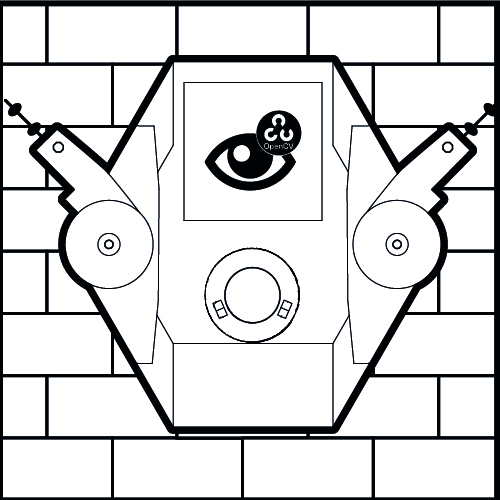

Mounting process

We developed a system which easily mountable by everyone, even and especially people who are not used to work with robots. To achieve this we developed a step mounting system, first of all, motors need to be placed, depending by the surface, the anchor system obviously changes.

Once the motors are placed (doesn’t really matter the alignment or their actual position), cables need to be passed through the nodes and then when the board is connected to electricity and the motors the Construction Robotic Assistant is ready to go. As we saw the process requires only a few very simple steps, unplugging it from the wall is as easy as plugging it. This System doesn’t only allow everyone to use it, but it’s also very fast and adaptable to be moved inside the construction site.

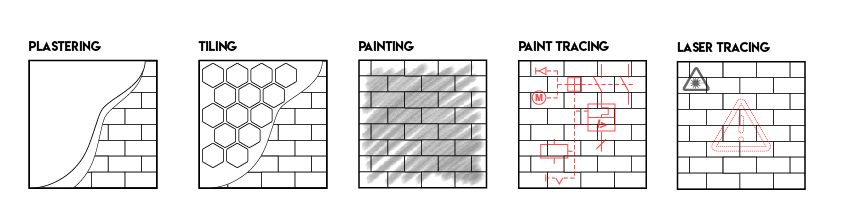

Applications

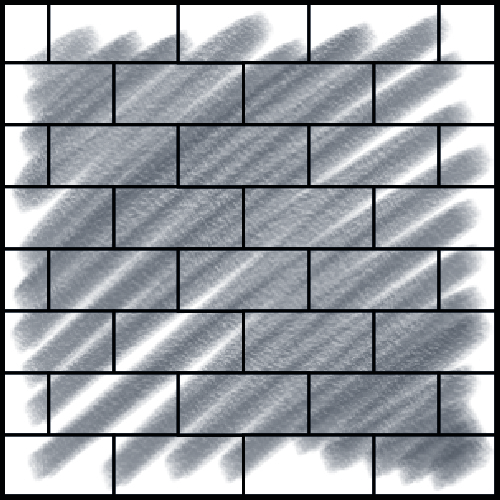

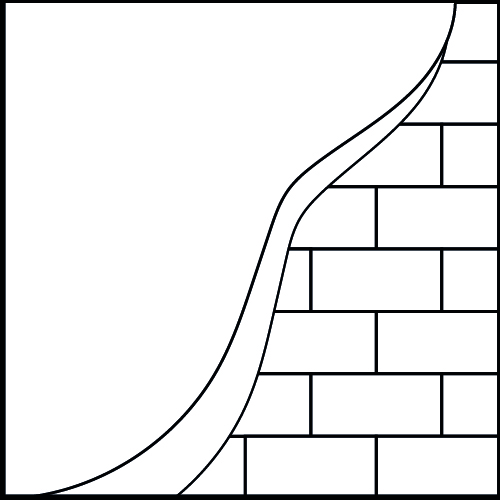

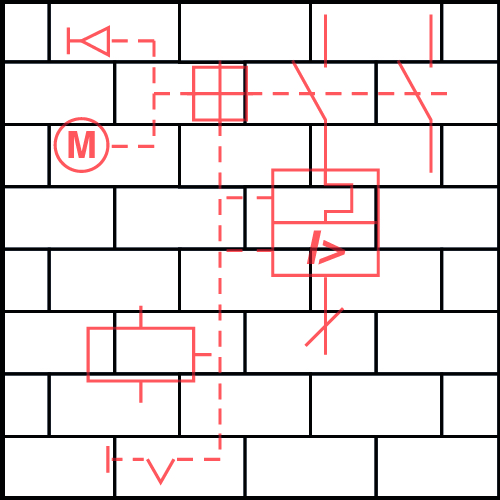

As previously said, this agent-based Robotic Construction Assistant is capable to achieve many different repetitive tasks replacing, enhancing and facilitating human labor. First and most simple is painting, indeed through the auto calibration and the BIM connection, the Assistant is able to understand the working area and to match it with the design and then hatch the area with paint through an exchangeable tool.

The same process can be applied to plastering walls, just by changing the tool the assistant can follow the same or a different type of hatch and let workers continue working on other tasks that are not so repetitive, and, that require more experience and expertise. This processes based on hatching make this kind of tasks a lot faster and a lot cheaper, allowing continuous work on the construction site without interruptions. One more job that can be completed by the assistant and that is based on hatching is tiling.

Indeed, just by feeding to the software the shape of the tiles and a pattern, the path will be calculated to finish the task, even though, not like the previous two applications, this duty will need a worker to put plaster before every tile is placed, This makes us understand that this Robotic tool is not only a completely automated system but it’s more of a real worker assistant, that should be on every construction site.

We also decided to implement the tracing of electric lines or plumbing lines, which is an implementation that is not related to hatching but it’s more related to the direct connection between the design part and the physical construction site. Indeed the electric and plumbing drawing are just gonna be delivered to the Construction Assistant and thanks to the back and forth communication, both of the world, the Physical and the Digital are going to be dependently updated.

One more tool to add to the list of features that can be embedded in the Construction Robotic Assistant is the site monitoring tool, which is a clever way to have movable monitoring systems on site, with both automated and remote control. Not only to check supplies, or workers, but also, and most importantly, to increase safety in the working areas. Indeed a lot of accidents happens because of distraction or tiredness. Having more eyes that tirelessly look for problems or dangers would be a big step on the safety topic.

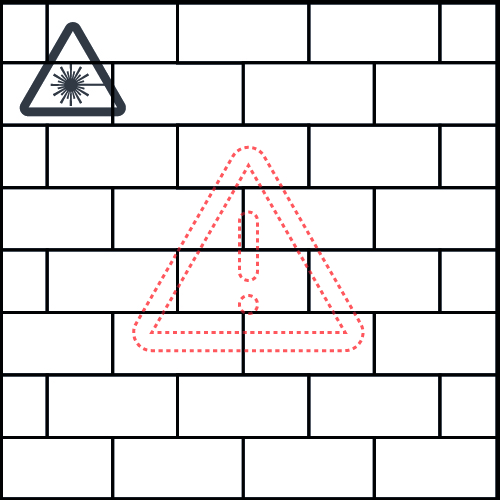

Last attainable application which could be implemented in this toolset is a laser combined with a galvanometer, that can display pictures or targets on any surface on the Construction site. This would help workers, and in general, professionals involved in the construction of the building to better understand what goes where, or where are dangerous things, even where it’s impossible to draw with a spray-can.

Roadmap

During this research, we managed to achieve half of the finished project, which means that future development is going to increase in an exponential way. Until now the focus was more on working on the basic features, achieving proper and accurate movements, creating an easily usable and universal UI. The next future steps are going to be more advanced, as in linking the system with BIM models to attain a direct connection between the digital and the physical. Furthermore – on the hardware side – the system is all going to be embedded on one single core robot which will be able to carry medium weights and to move in a 3D space, instead just surfaces.

CRA is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotic and Advanced Construction in 2019 by: Students: Stefano Meloni, Riccardo Mura, Luis Pacheco Faculty: Aldo Sollazzo, Aleaxndre Dubor