ABSTRACT

Developing nations like India have long struggled with the slumification of urban cities. On the other hand, concrete 3d-printing has reached a certain maturity in other countries in terms of technology and the materials involved. In this study, it is found that some form of semi-automation can directly benefit the construction process in terms of economics. However, major policy reforms are still needed to alleviate the problem of urban housing in Indian metropolitan cities like Mumbai, Delhi. These reforms can accelerate construction times but create environmental issues as bricks are the primary source of construction material. A major technological shift in terms of materiality could possibly ease the environmental burden of this policy-propelled construction drive. A push is needed for the adoption of these sustainable materials, which could be difficult to implement in an established, competitive environment.

HYPOTHESIS

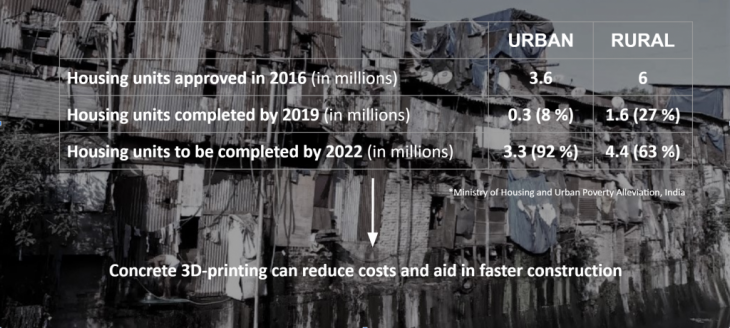

Dubai recently announced its plans to 3d-print quarter of its homes by 2025, postulating a 90% reduction in costs due to this automated approach. Most of this reduction in cost comes from two sources: a 10-20% decrease in materials used, and the rest 70% from reduced labor costs. However, this advantage quickly vanishes once the technology transcends into developing nations like India with labor costs an order of magnitude lower than other countries. In this scenario, what is the advantage of 3D-printing in these developing countries? India is home to the world’s largest slums and the housing problems are only going to exacerbate becomes the most populous country by 2024. More than half the population (52.5%) lives in extremely unorganized neighborhoods without proper sewage, water or electricity in Mumbai, the economic powerhouse of India. Thus, advancement towards sustainability and automation seems necessary. Concrete 3D-Printing might be able to alleviate these issues but the adoption of new technologies relies heavily on its profitability and sustainability in the market, especially in a highly competitive industry such as construction. The following image represents the housing projects approved by the housing board in India in 2016 to be completed by 2022. This was to ease the inertia in constructing houses to democratize housing in urban areas. However, less than 20% of the houses have been completed by 2019, halfway through the intended course of 6 years.

We continue to depend on manpower intensive traditional construction practices, which are slow and highly dependent on skilled labor input – a category already scarce in availability. Therefore, in order to be able to meet the huge housing shortage, we need to adopt partially or fully mechanized methodologies, which primarily need some unskilled labor inputs. A macro-economic viewpoint is essential is undertaken to evaluate the effect of concrete 3d-printing in particular. These mechanized approaches usually involve a fixed capital investment with high returns based on economies of scale, which is the need of the hour in the Indian housing ecosystem to alleviate the living conditions like sanitation, electricity and water supply and the overall quality of life in urban cities of developing nations.

RESEARCH FRAMEWORK

3D-Printing, in general, can be seen as an amalgamation of innovation in the process (for example, using a 6-axis robot instead of a traditional 3-axis gantry system. Beginning from casting to desktop 3D-printers to contour crafting to the 3d-printed bridge in Madrid portray an advancement in the process. On similar lines, from clay to reinforced concrete to green concrete signify innovation on the material end. There are many factors dictating the benefits of concrete 3DP to traditional methods like structural integrity, economics, environmental sustainability, regulations, and societal implications. All of these factors dictate the public adoption of any technology. A literature review of the advancements in the field of concrete 3DP is made with their implications on the technologies considering these factors.

METHODOLOGY

In this study, the economic factor is considered to approach the problem since it drives the adoption of any new technology. A macro-economical standpoint, in particular, gives insight as to how concrete 3d-printing can impact the housing ecosystem in India. Houses have always been built ‘additively’ but concrete 3d-printing promises an automated approach for faster cycle times. In any automation based economic study, a pertinent topic is the study of fixed costs as well as the variable costs. This study pinpoints the economies of scale required to achieve, for any new technology to breakeven with the conventional methods.

RESULTS

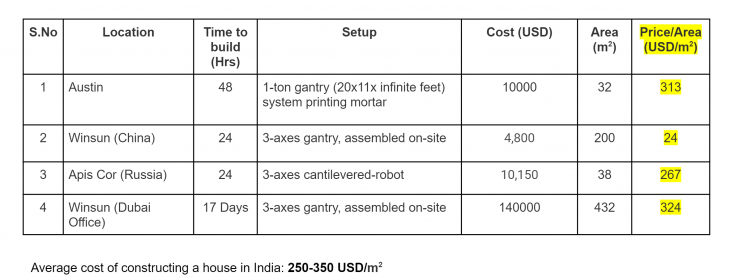

Variable costs as reported by various startups across the world have reported a cost of about 300 USD/m2. However, the costs associated with the procurement of the machines or materials aren’t reported. Do these costs include amenities like plumbing, electricity or interior decoration? This makes any economic estimates on the variable costs difficult.

During the readings, however, a recurrent topic in the context of India, in particular, was the outdated policy structure regarding the low Floor Space Index (FSI), land prices and analog land records. These factors play a major role than construction times or cost. Another problem pertains to environmental sustainability. Brick and concrete are carbon-intensive industries. The effect of these policy reforms could solve the housing problem but could add millions of tons of CO2 every year to the environment.

SUSTAINABILITY

It is a matter of great concern that the traditional burnt clay bricks continue to be the primary raw material for housing activity all over India. Brick making consumes fertile topsoil from agricultural fields making these unfit for cultivation for many years. Moreover, baking of bricks consumes energy and burning coal emits unhealthy smoke and carbon dioxide into the atmosphere.

It would be worthwhile to note, that the land wasted in the production of the current annual requirement of 170 billion bricks deprives the country of food production that could feed 30 Lakh Indians for the whole year. Moreover, the production of these bricks consumes around 24 million tonnes of coal and the process emits 61.3 million tonnes of CO2 into the atmosphere. We, as a nation need to continuously increase our food production to feed our growing millions. Therefore, we can ill afford to waste our precious agricultural land for brick making, since it is against our national interests. This amounts to meeting one basic need of shelter while sacrificing the other basic requirement of food.

It is therefore imperative that we must look for and develop alternative materials, which are energy efficient and more environment–friendly. Fly Ash Clay Bricks, Fly Ash lime Sand bricks are some of the alternatives being promoted by CBRI, NTPC, Fly Ash Mission, but with limited success. Fly Ash-based Autoclaved Aerated Concrete (AAC) blocks, produced in big plants or more efficient and economical alternative of the site produced Cellular Lightweight Concrete (CLC) blocks are gaining increased usage. The latter produced in an environment–friendly process need least intrinsic energy, offer superior thermal efficiency and lower water absorption than clay bricks, need lower raw material inputs and make productive use of fly ash – a waste industrial output. This seems to be one of the ideal futuristic material.

CONCLUSIONS

Large scale application must be encouraged for semi-mechanized and mechanized systems. These would provide faster, durable, economical dwellings deploying limited unskilled inputs. Use of prefabrication technology or ready-made building components in traditional constructions can also help. However, there is a major policy shift necessary to accelerate the construction of homes in metropolitan cities like Delhi, Mumbai, etc. Digitalization of land-records, tax exemptions, reduced registration fees and adoption of modern FSI standards should be emphasized, starting with urban cities. These policy reforms when implemented can enable more efficient, cheaper and faster construction. This brings along new problems with it, however. Traditional construction methods involve dated technology using clay-bricks which have detrimental environmental effects. Hence, innovation in the domain of environmental sustainability in terms of the material itself is crucial in the coming decade.

MASTER IN ROBOTICS AND ADVANCED CONSTRUCTION 2018-19

THEORY & CONTEXT

Faculty: Ricardo Devesa

Student: Apoorv Vaish

BIBLIOGRAPHY

[1] R. A. Buswell, W. R. Leal de Silva, S. Z. Jones, and J. Dirrenberger, “3D printing using concrete extrusion: A roadmap for research,” Cem. Concr. Res., vol. 112, no. October 2017, pp. 37–49, 2018.

[2] D. Asprone, C. Menna, F. P. Bos, T. A. M. Salet, J. Mata-Falcón, and W. Kaufmann, “Rethinking reinforcement for digital fabrication with concrete,” Cem. Concr. Res., vol. 112, no. January, pp. 111–121, 2018.

[3] A. L. M. Tobi, S. A. Omar, Z. Yehia, S. Al-Ojaili, A. Hashim, and O. Orhan, “Cost viability of 3D printed house in the UK,” IOP Conf. Ser. Mater. Sci. Eng., vol. 319, no. 1, 2018.

[4] S. Lim et al., “Fabricating Construction Components Using Layered Manufacturing Technology,” Glob. Innov. Constr. Conf. 2009, pp. 512–520, 2018.

[5] H. Van Damme, “Concrete material science: Past, present, and future innovations,” Cem. Concr. Res., vol. 112, no. January, pp. 5–24, 2018.

[6] T. Anjum, P. Dongre, F. Misbah, and V. P. S. N. Nanyam, “Purview of 3DP in the Indian Built Environment Sector,” Procedia Eng., vol. 196, no. November, pp. 228–235, 2017.

[7] S. Verma, A. Kumar, and B. Rai, “Green Concrete – An Emerging Trend in India,” Cem. Concr. Res., no. June 2012, 2017.

[8] P. Wu, J. Wang, and X. Wang, “A critical review of the use of 3-D printing in the construction industry,” Autom. Constr., vol. 68, pp. 21–31, 2016.

[9] I. Hager, A. Golonka, and R. Putanowicz, “3D Printing of Buildings and Building Components as the Future of Sustainable Construction?,” Procedia Eng., vol. 151, pp. 292–299, 2016.

[10] C. Gosselin, R. Duballet, P. Roux, N. Gaudillière, J. Dirrenberger, and P. Morel, “Large-scale 3D printing of ultra-high performance concrete – a new processing route for architects and builders,” Mater. Des., vol. 100, pp. 102–109, 2016.

[11] Z. Malaeb, H. Hachem, A. Tourbah, T. Maalouf, N. El Zarwi, and F. Hamzeh, “3D Concrete Printing?: Machine and Mix Design,” Int. J. Civ. Eng. Technol., vol. 6, no. 6, pp. 14–22, 2015.

[12] M. Youssef and A. Chen, “Applicability and Limitations of 3D Printing for Civil Structures,” Civil, Constr. Environ. Eng. Conf. Present. Proc., vol. 35, no. June, pp. 1–25, 2015.

[13] J.-C. Kucharek, “3D-printed concrete components,” 2015.

[14] L. Feng and L. Yuhong, “Study on the Status Quo and Problems of 3D Printed Buildings in China,” Glob. J. Human-Social Sci. H Interdiscip., vol. 14, no. 5, 2014.

[15] C. Balaguer and M. Abderrahim, “Trends in Robotics and Automation in Construction,” Robot. Autom. Constr., 2012.

[16] S. Lim, R. A. Buswell, T. T. Le, S. A. Austin, A. G. F. Gibb, and T. Thorpe, “Developments in construction-scale additive manufacturing processes,” Autom. Constr., vol. 21, no. 1, pp. 262–268, 2012.

[17] T. T. Le et al., “Hardened properties of high-performance printing concrete,” Cem. Concr. Res., vol. 42, no. 3, pp. 558–566, 2012.

[18] M. S. Imbabi, C. Carrigan, and S. McKenna, “Trends and developments in green cement and concrete technology,” Int. J. Sustain. Built Environ., vol. 1, no. 2, pp. 194–216, 2012.