Waste-based Materials Experiment

This research aims to develop and understand the manufacturing of bio-materials from coffee grounds.

Continue Coffee Freak project from last semester, this project aims to understand how biodegradable materials are transformed into hybrid 3D printing filaments.

Some of the lessons learned from previous experiments, the coffee powder bio-plastic was hydrophobic. The higher percentage of coffee I used in the material, the stronger the result would be. The input of Sodium Alginate or Glycerol would trigger the output of a self-assembly behavior of the form.

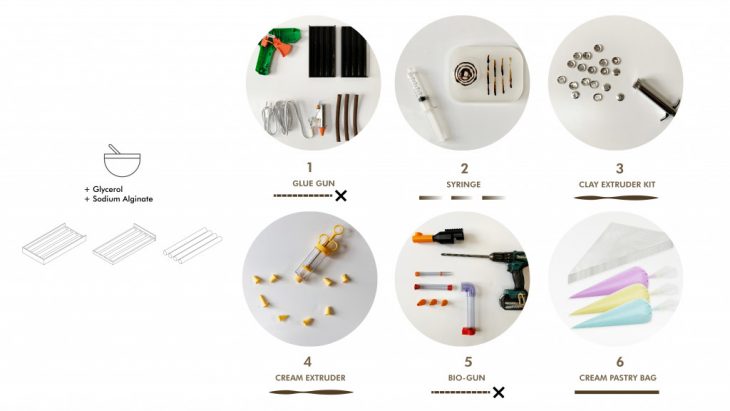

Before the printing process, there are 2 main points that have to be achieved, First of all, at Valldaura Labs, there is no printing machine for material tests so searching for the right tool for the manual extrusion is the first priority.

[6 Experiments with Manual Extrusion]

After experimenting with 6 tools, the size of the nozzle head and the air pressure are necessary for extruding process. Manual extrusion can guide all basic ideas of printing production.

Used Coffee grounds for Mold [Left] / Used Coffee grounds for Extruding [Right]

Compared to making Bioplastic by mold, the recipe for coffee-based – bioplastic in the extruding process has to be adjusted. The size of the coffee grounds should be smaller to be able to pass through the nozzle head easily.

[Coffee grounds + Glycerol]

[Coffee grounds + Sisal]

[Coffee grounds + Sawdust]

previous experiment : Coffee Freak project