Circular Design in the Built Environment

Project: Jonas

Architects: Orange Architects

Construction: 2017

Location: Amsterdam, The Netherlands

Jonas is an iconic, sustainable and attractive structure that stands out from the surrounding buildings. The building shapes themes that matter here: water, quayside and maritime craft. At the same time, by embracing the ‘soul of the site’ and rendering it visible, Jonas looks like it belongs here.

‘The name Jonas is a reference to ‘Jonas and the Whale’, a tale about adventure and intimacy, and about shelter, security and homeliness inside a ‘big body’.’ – Orange Architects

The irregular composition of window openings gives the impression that they undulate gently across the facade. That makes Jonas just a little bit different: slightly distorted, slightly strange. The grid is not regular but distorted. The facade does not touch the ground but is raised. The building is not orthogonal but lozenge-shaped. That makes the building both familiar and alienating, sculptural yet rational, recognizable yet innovative.

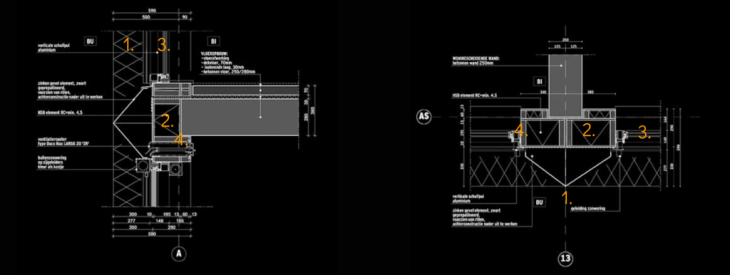

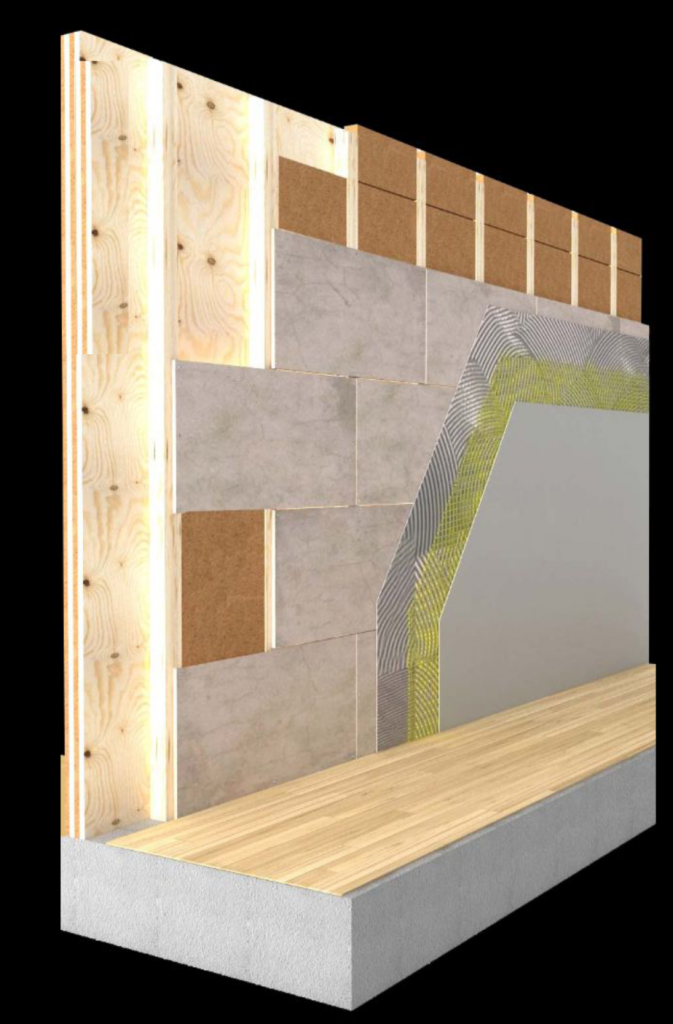

ASSEMBLY PRODUCTS

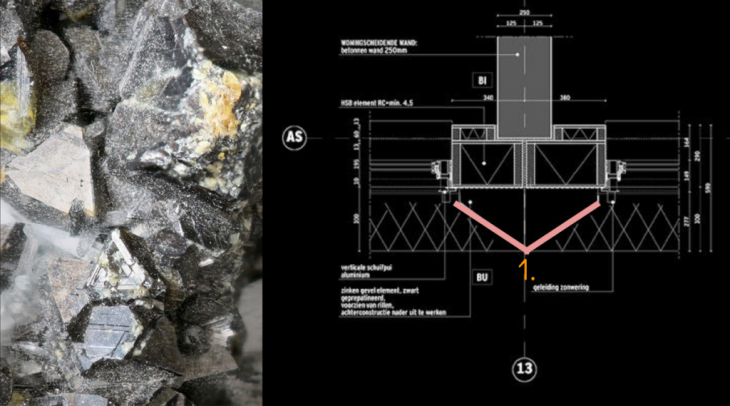

- ZINC ELEMENT: Zinc exterior panel in black pre-painted & pre-painted from WVH Gevelprojecten

- INSULATION ELEMENT: Soft insulation e.g Mineral Wool 300 mm from Logrotex Isolgreen Insulation

- GLAZING ELEMENT: Triple glazing unit with anodized aluminium frame in dark colour from Metaglas Facade Systems

- TIMBER FRAME ELEMENT: HSB RC: min. 4.5 from Kingspan/Knauf Insulation

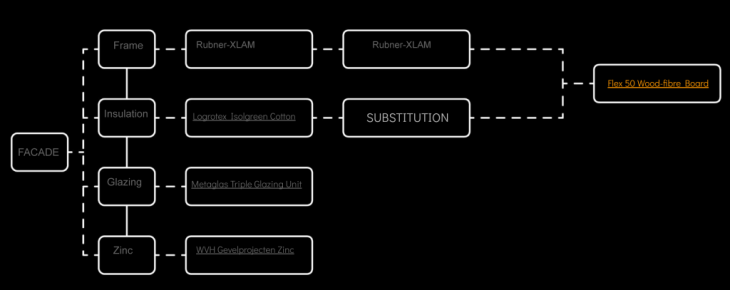

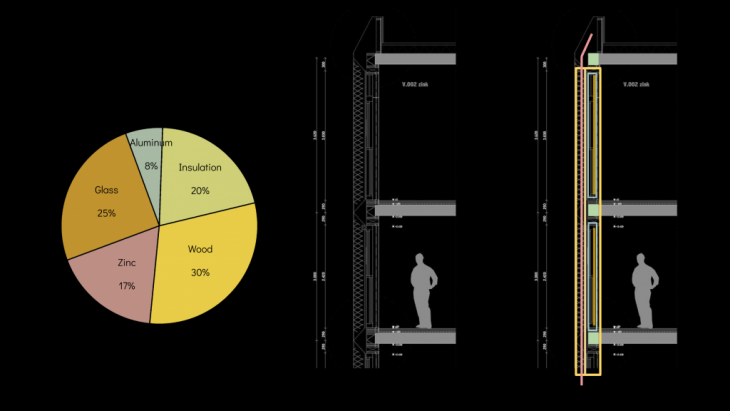

Flow Chart of Materials

Pie Chart of Material Distribution

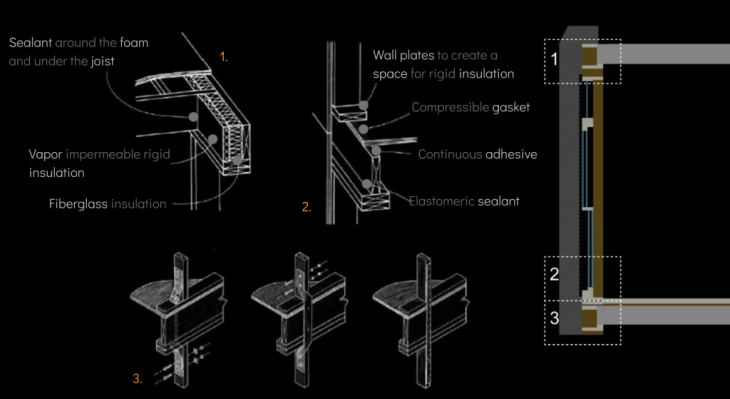

Connection Properties

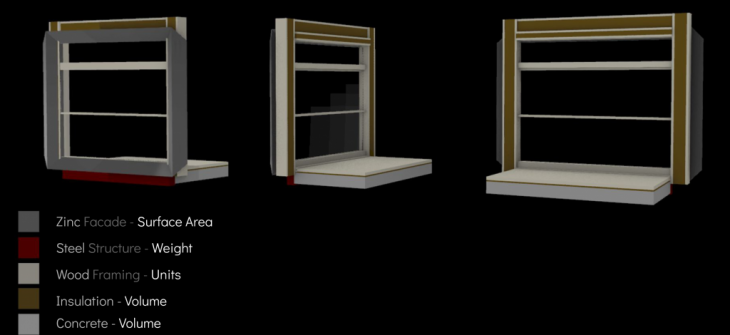

Prefabricated Assembly

- A prefabricated timber frame can be erected on site faster than a comparable brick and block construction.

- Prefabricated Timber is classified as a renewable material, as the principle holds that if a tree is felled another is planted in its place.

• Prefabricated Timber construction requires less CO2 to process and produce it than, for example, steel.

1] Material: Zinc Panel Properties

Approximately 30% of all zinc produced is from recycled sources. The total amount of zinc scrap is rising around world and is estimated at about 3 million tons.

- When in contact with humidity, zinc panels generate a self-protecting layer that isolates heat from indoor spaces during the summer.

- Rain and snow, slide easily over its surfaces.

- Its modular panels can wrap curved shapes or be perforated according to the architectural design.

- The panels can be combined in facades and/or ceilings through different shades, brightness, and colors.

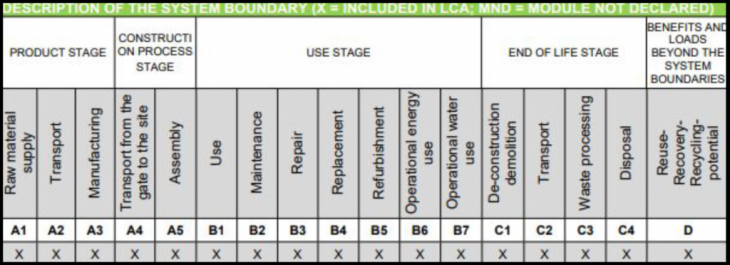

A] Technical Sheet: WVH Gevelprojecten Zinc Composite

Composite Zinc is a multilayered panel made up of two sheets of zinc that are 0.5 mm thick and thermo-glued on either side of a mineral-rich polyethylene core for optimum reaction to fire.

Carbon Footprint

Total whole life cycle: ——- kg CO2 eq / functional unit

Product stage: 3.99 kg CO2 eq / functional unit

End of life stage: 0.00285 kg CO2 eq / functional unit

Location: Germany

Period of Use: 75 years

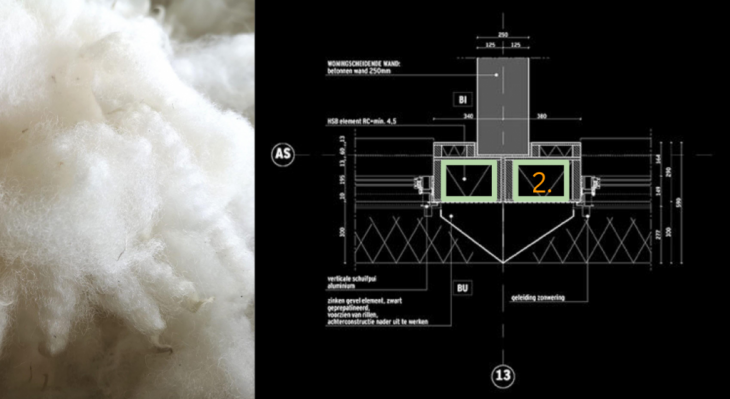

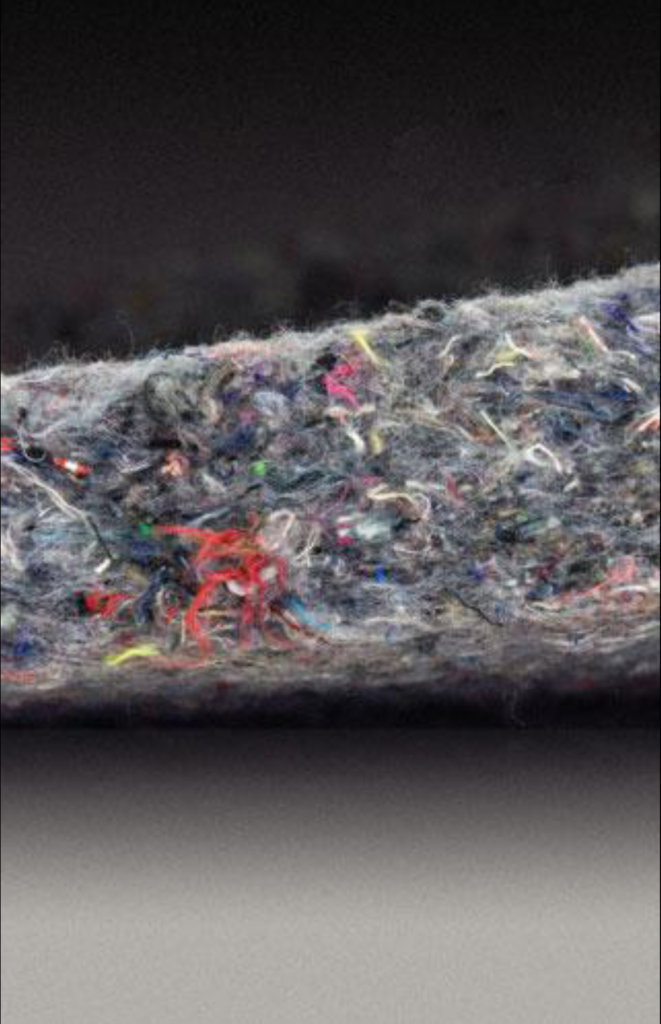

2] Material: Façade Insulation Properties

While primarily used as building envelope insulation, cellulose insulation uses a large percentage of recycled materials; reportedly in the 80 to 85% range.

- Used for thermal purposes, but it also provides solutions for acoustic, fire, and impact concerns.

- After proper air sealing, insulation is the most important building feature for comfort and energy efficiency.

- Due to the high degree of insulation and the large windows in the facade, the risk of overheating is considerable.

B] Technical Sheet: Logrotex Isolgreen Cotton

The cotton range comprise spongy nappas of virgin or recycled cotton in insulate ceilings, walls, etc., facilitating breathability and providing a feeling of freshness.

Carbon Footprint

Total whole life cycle: 0.4 kg CO2 eq / functional unit

Product stage: —- kg CO2 eq / functional unit

End of life stage: —- kg CO2 eq / functional unit

Location: La Rioja, España

Period of Use: 25 years

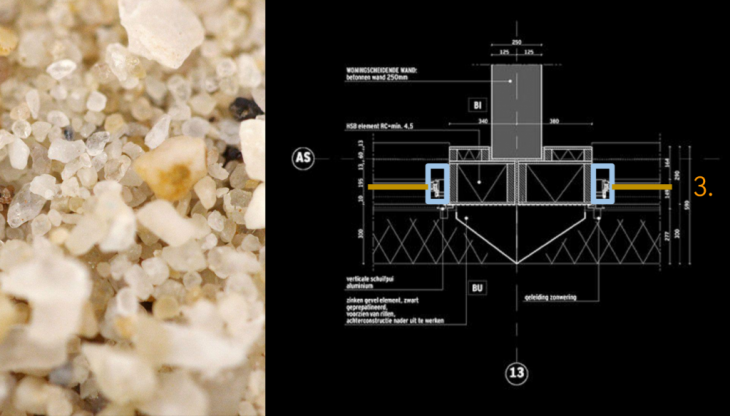

3] Material: Façade Glazing Properties

According to industry experts, only about 27% of manufactured glass is eventually recycled at municipal solid waste or at construction and demolition facilities.

- Allowing daylight into the interior of the building, enabling views into and out of a building and at the same time providing protection against the weather.

- The perception depending on factors such as transmission, absorption, reflection, scattering of light, brightness adaptation, glare.

- Instead of infill material, glass is sometimes used to carry loads that exceed the actions per unit area due to self-weight, temperature fluctuations, wind and snow.

C] Technical Sheet: Metaglas Triple Glazing Unit

This design underlines a style which is often requested for residential architecture. Ideal for new building and for energetic renovations alike.

Carbon Footprint

Total whole life cycle: 141.2 kg CO2 eq / functional unit

Product stage: 121.4 kg CO2 eq / functional unit

End of life stage: 20.27 kg CO2 eq / functional unit

Location: Luxembourg et Allemagne

Period of Use: 50 years

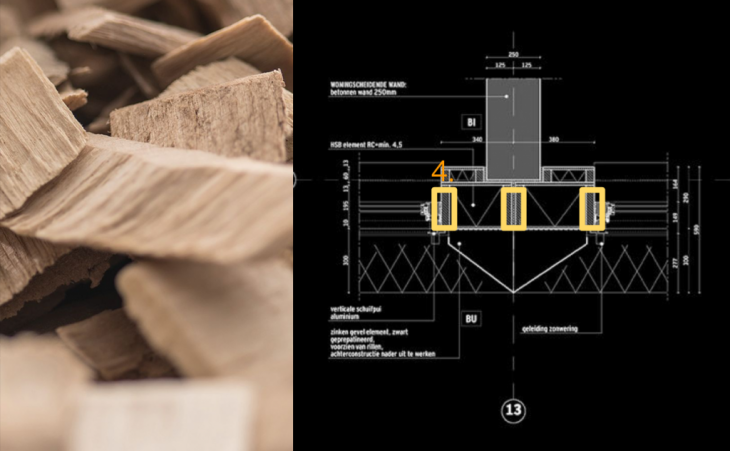

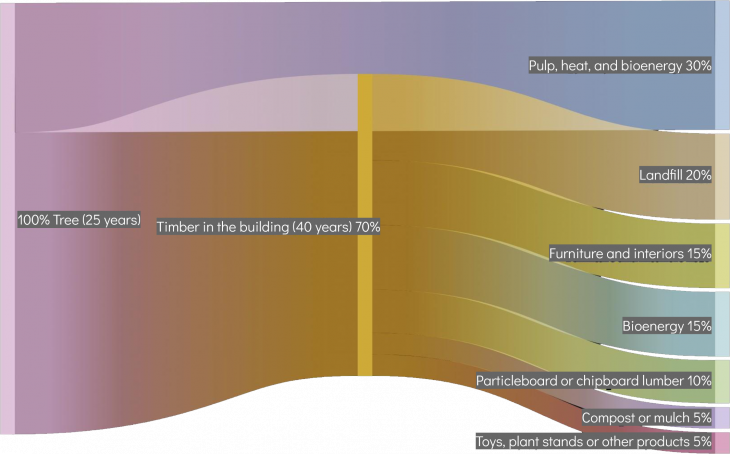

4] Material: Façade Timber Properties

Wood waste makes up about 40% of the in-feed to mixed C&D recycling facilities.

- The use of renewable and recyclable materials is maximized, which can be seen, for example, in the interior finishes and inner facades made predominantly out of wood.

- The timber frame system is the most widely used construction technique, allowing great freedom of architectural expression.

- Structural glass combined with a timber frame is a composite system that has a predisposition for good structural behavior, it is energy-efficient and cost-effective, aesthetically acceptable and has a good load-bearing characteristics.

D] Technical Sheet: Flex 50 Wood-fibre Board

The wood-fiber insulation boards FLEX 50 are panel-shaped engineered wood products made from wood fibers pursuant to / DIN EN 13171/. Small quantities of bicomponent (= bico) fibres and flame retardants that conform to the /nature plus/ requirements are added during the manufacturing process, with the boards being assembled at the end of it. It is possible to produce one-layered insulating boards with a material thickness of up to 220 mm. The energy input established in this declaration refers to a raw density of 50 kg/m3.

Carbon Footprint

Total whole life cycle: 8.53 CO2 eq / functional unit

Product stage: -82.4 kg CO2 eq / functional unit

End of life stage: 87.7 kg CO2 eq / functional unit

Location: Germany

Period of Use: 50 years

Proposed Product

Timber Sankey Diagram

Conclusion – Potential Waste Strategy

Embracing this circular economy, encouraging up-cycling rather than just recycling to help minimize waste and make the most of resources.

- Circulating economy of the waste stream and recycling in your particular area.

- Economizing circularity into the very design process.

- reduce post-manufacturing cost of up-cycled material products.

- Establish community involvement by assessing.

Conclusion – Potential Material Source

Current insulation materials in the construction market are predominantly inorganic materials.

- In this study a natural fiber material in the form of wood waste is examined experimentally to assess its suitability for use as a thermal insulation material, without the addition of any binder, within a timber frame wall construction.

- Health wise, the wood waste is from primary production sources using untreated material. Also, the humidity regulation aspect of wood fiber insulation helps the breathing system.

- Historically, we have been insulating our homes with wood for many centuries: other types of insulation are comparatively recent introductions.

Notes

1]“jonas, amsterdam,” SPS.Edu, accessed March 25, 2021,

https://www.orangearchitects.nl/projects/jonas/

2]“A unique housing development that makes sustainable living accessible and affordable to a wide audience, “ accessed on March 25, 2021, Jonas, The Netherlands – BREEAM

3] “Jonas,” accessed March 25, 2021,

https://architizer.com/projects/jonas/

Circular Design in the Built Environment is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the MAA01 2020/21 by Students: Jiaqi Sun,Jose Rigoberto Moreno,Iulia Maria Lichwar, Xingyu Zhang and Faculty: Ignasi Cubiñá, Ariane Lima, Sofía Battistino, María Colantoni