This project seeks to explore, discover and ultimately present an effective and efficient avenue to producing, in cast materials, particularly concrete, one specific type of complex geometry, that typically would have been prohibitively complicated to produce, and with some degree of control over a set of architectural parameters.

Vision

Objective 1 – Biodiversity, Health and Wellbeing

Identify appropriate aggregate geometry and material that allows for a stable interior formwork which also is removable, and less harmful to the environment.

Objective 2 – Preserve human society, Health and Wellbeing

Identify appropriate use case with parameters which could benefit from optimization controlled by porosity control, creating architectural elements that can enhance quality of life for human, and/ or the environment.

Objective 3 – Preserve human society, Health and Wellbeing

Develop a robotic pick n’ place process appropriate for the material that adds a measurement of precision, control, intelligence (feedback), and/or speed. A human center fabrication process requiring less labor for more complexity and allowing for flexibility in the design outcome.

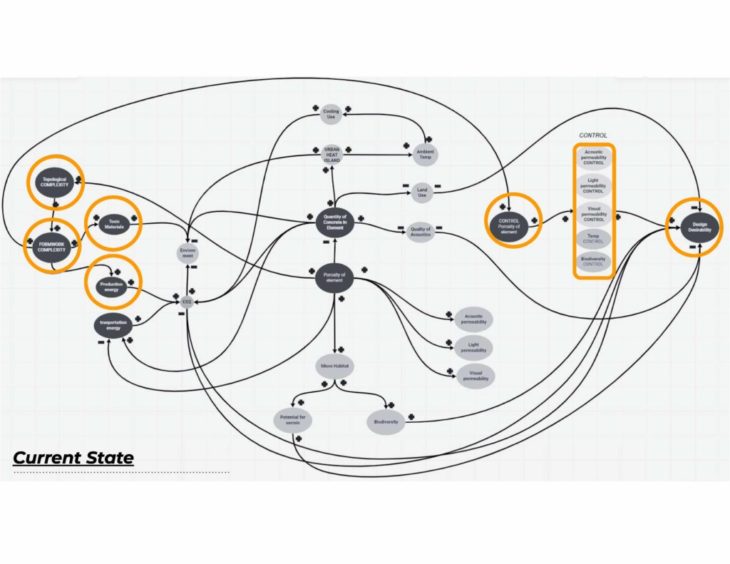

Current state of connectivity and relationships existing between concrete implementation in the building sector, concrete formwork and supporting material construct and consumption, complex topologies in the design space, biodiversity and CO2 emissions, and control over architectural parameters.

Current state of connectivity and relationships existing between concrete implementation in the building sector, concrete formwork and supporting material construct and consumption, complex topologies in the design space, biodiversity and CO2 emissions, and control over architectural parameters.

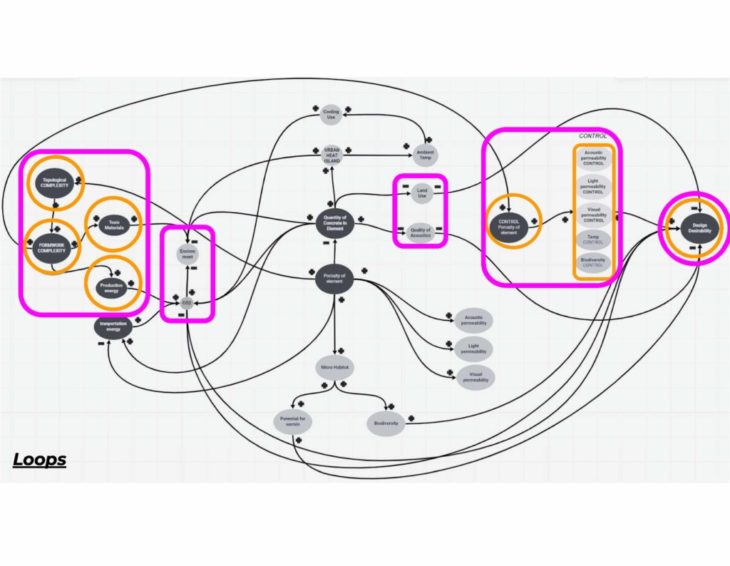

Reinforcing loops in the system.

Reinforcing loops in the system.

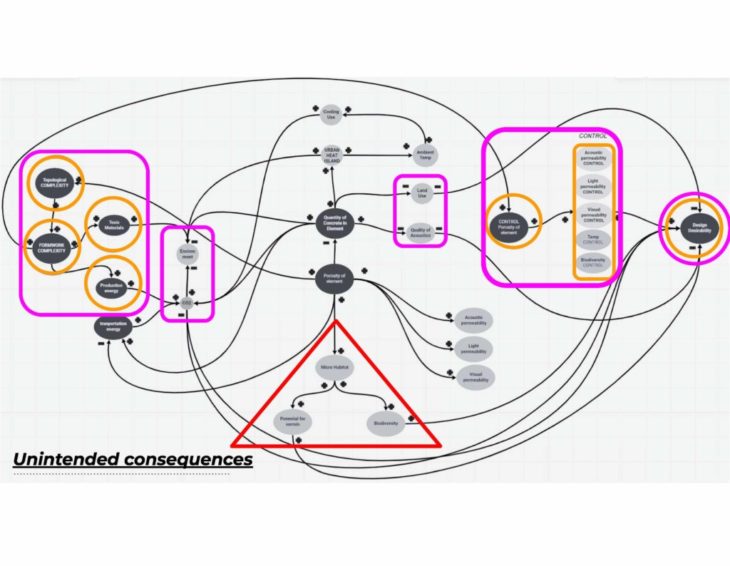

Unintended consequences, in the red triangle, could be an uncontrolled or unplanned proliferation of biodiversity in the porous building elements due to the increased surface area, protected crevasses, and potential for trapping or collecting sediment. This could be both good or bad depending on context, in some cases this good support a vermin problem while on the other hand this could solve certain habitat loss problems and actually help keep balance in an ecosystem.

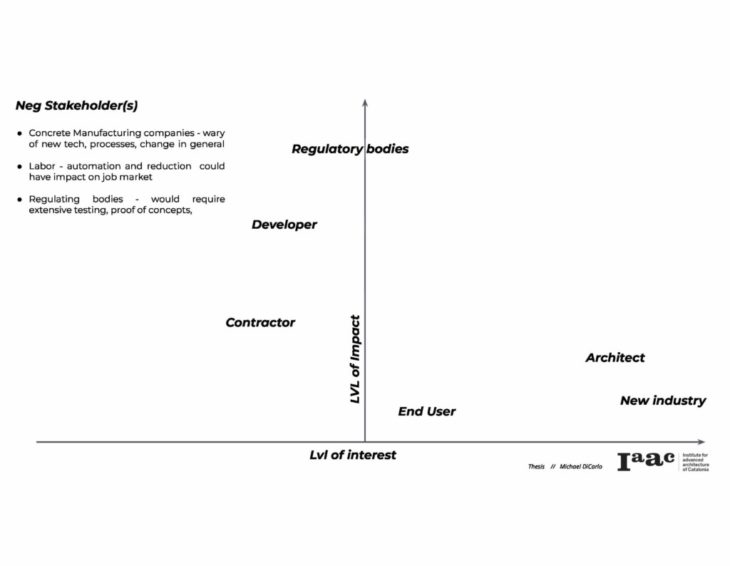

Target Market(s)

- Luxury design and and architecture firms interested in innovative and novel technology or aesthetics.

- Landscape designers or public works organizations interested in the habitat regeneration and preservation potential.

- Structural engineers interested in novel solutions for low waste and light-weight concrete systems.

According to the AIA Firm Survey 2020, architecture firms with a commercial/industrial specialization reported the highest profitability at 14.8%

First users

Mid to large scale architecture firms working on large budget projects and a dedicated fabrication R&D department

- ZHA (UK)

- MAD (China)

- SHoP (USA)

- Thomas Heatherwick Studio (UK)

- Roth Architecture (Mex)

- Situ Studio (USA)

Implementation plan

- Produce working prototypes that:

- Achieved desired functionality

- Are cost effective

- Reduce waste involved in concrete casting and use

- Partner or collaborate with firm for real world implementation

- Use resources to finance research in further development and potential markets