// PROJECT DESCRIPTION

/project visualization/

/project visualization/

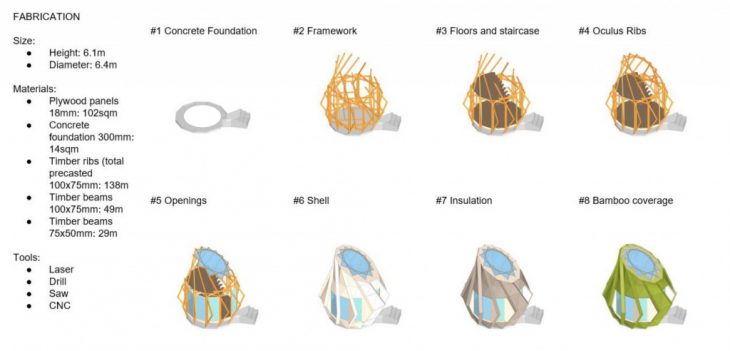

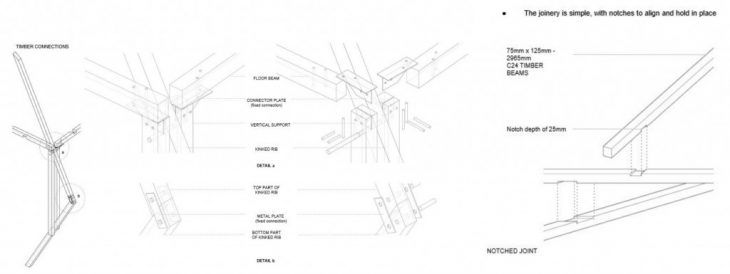

This structure is a light-weight prefabricated and modular yurt, that aims to be a semi-portable structure capable to be assembled and disassembled in the simplest way possible. Trying to avoid as much as possible heavy materials as concrete in the structural elements, and used only for the foundation of the same. 51.6% of the complete structure is timber and plywood, to reduce the cost and weight of the structure, the joints of the kinks in the ribs were designed in a way that can be connected only with the use of metal plates and screws for an easy assembly and disassembly. The floors and oculus were design by an notched connection system. A glass material was added for the natural illumination in the interior.

/fabrication strategies/

/fabrication strategies/

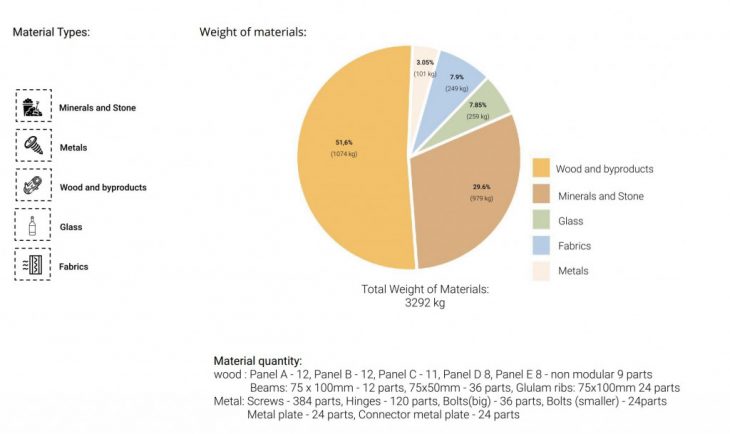

// MATERIALITY

/material quantities/

/material quantities/

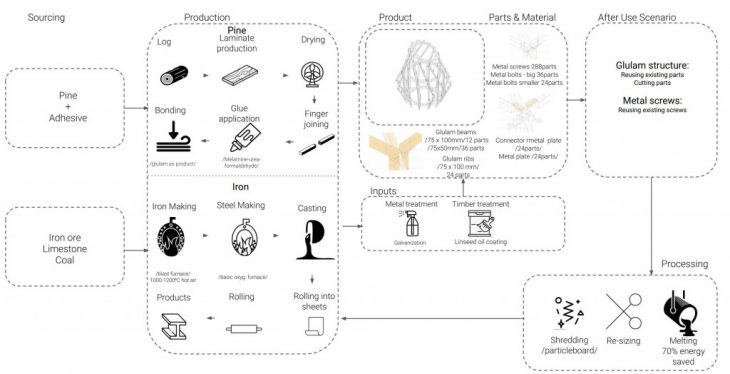

// PRODUCT JOURNEY MAPPING AND DESIGN FOR DISASSEMBLY

MAIN STRUCTURE

/material passport/

/material passport/

/design for disassembly proposition/

/design for disassembly proposition/

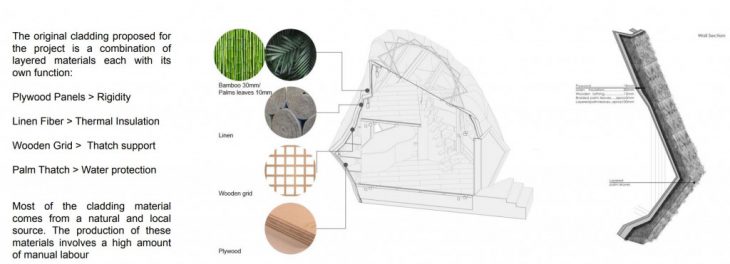

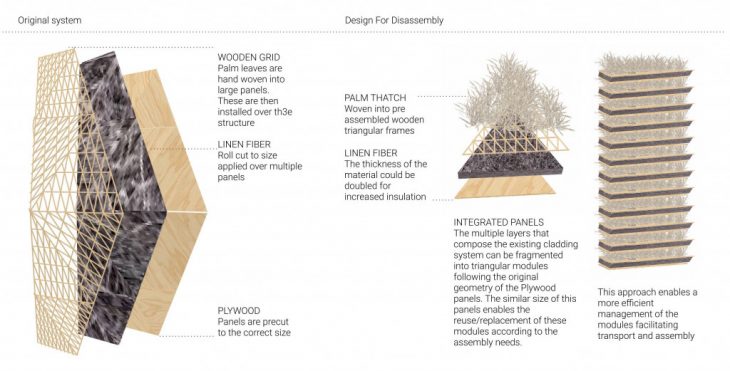

CLADDING SYSTEM

/cladding system/

/cladding system/

/material passport/

/design for disassembly proposition/

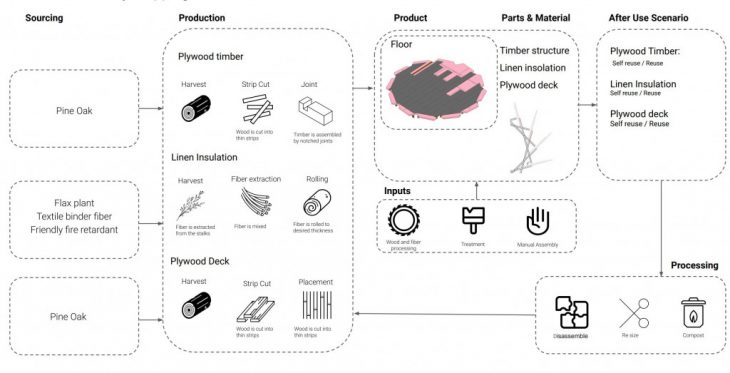

FLOOR

/material passport/

/material passport/

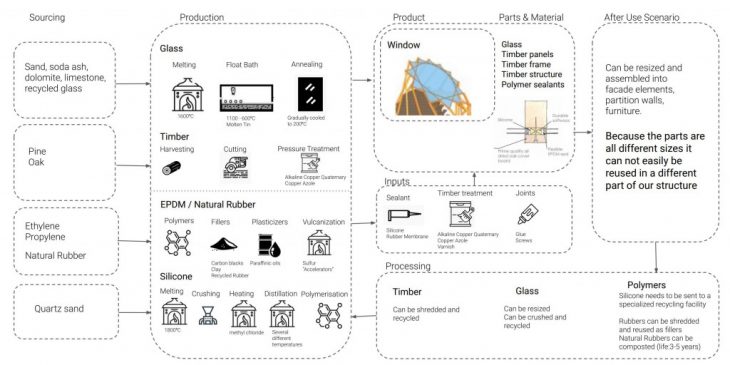

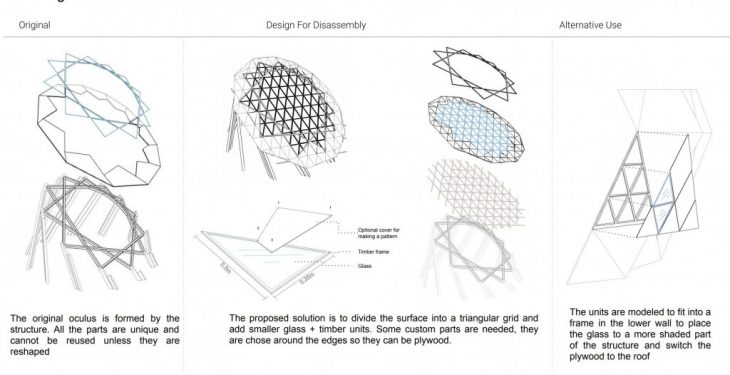

OCULUS

/material passport/

/design for disassembly proposal/

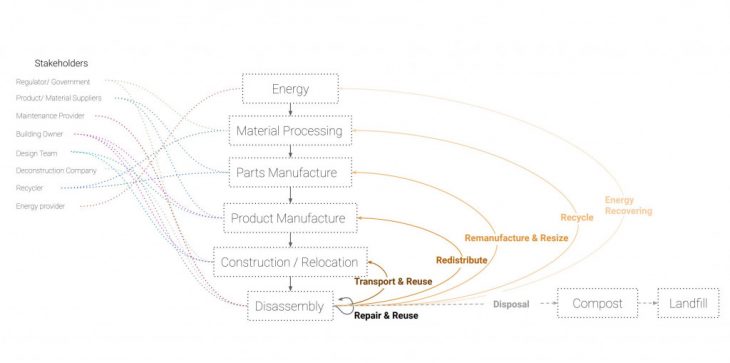

Most of our structure is made from timber, which will need to be treated to withstand moisture, rot and termites. Therefore, our strategy should first be to reuse elements in their initial form, before resizing to reuse or finally shredding to recycle them into particle boards. We have redesigned parts into changeable modules that be easier to disassemble when the structure is moved or repaired and will need less resizing when parts are reused and redistributed.

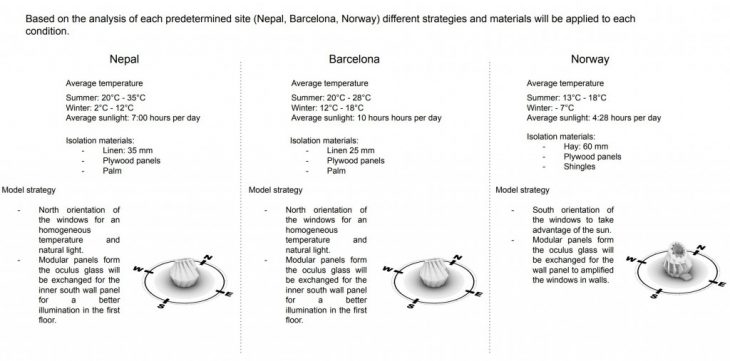

// LOCATION

/climate analysis/

/climate analysis/

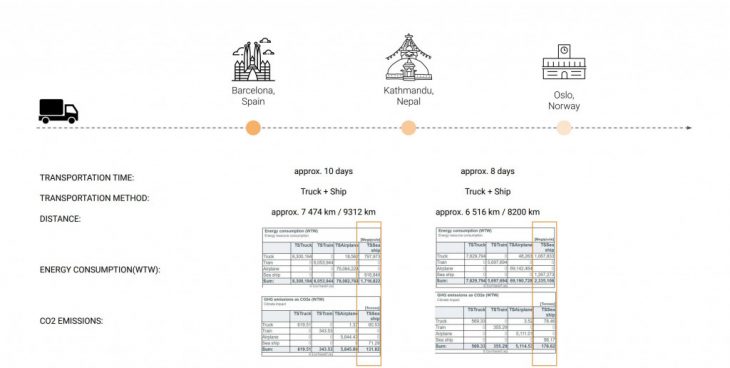

/transportation analysis/

// BUTTERFLY DIAGRAM

/butterfly diagram/

/butterfly diagram/

The building owner becomes an important stakeholder in this type of design. Ownership becomes more complicated, and could have conflicting interests with other stakeholders when recycling and redistributing parts. Alternative business models, like leasing of parts, could shift reliability to other agencies to resolve such issues.

Since the NEST is designed to be relocated around the world, several governments and regulators will need to be taken into consideration. One might need to consider if transporting emissions and costs of parts will be higher than producing them locally. Depending on the climate and legislation in the new location, more modifications to the structure and envelope materials might also be needed.

Design for Disassembly: Nest 2.0 is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2019/20 by:

Students: Hanna Lepperød, Ines Cavar, Michel l’eglise, Mauricio Casian

Faculty: Ignasi Cubiña, Cristina Sendra, Gemma Canals Flix

Faculty Assistant: Mahsa Nikoufar