HUMANITY’S CRISIS

It’s hard to believe now that these were inescapable norms 30 years ago, before COVID, but they were. The poor indoor air quality was knowingly killing us through disease, with so many employees often sick and unfocused. Feeling purpose at a job wasn’t always an occurrence, as it was for many, a means to make money. At that time, buildings were still ruthlessly being constructed with materials extracted from raw resources. There was a plastic island twice the size of Texas floating in the middle of the ocean. We were all actors watching these tragedies.

It was beyond clear that we needed to fight for a circular economy, for cities to be more regenerative and waste-free.

Our impact and the importance of health was particularly highlighted during the pandemic. As many worked from home, loneliness and our innate need to collaborate became apparent, and the required balance between individual and collective thinking grew stronger.

In this pause, we understood more about the air we breathe; about the symbiotic relationship between us, and nature, and the impact that we have. This is now the new inescapable norm.

THE COMPANY OF CHANGE

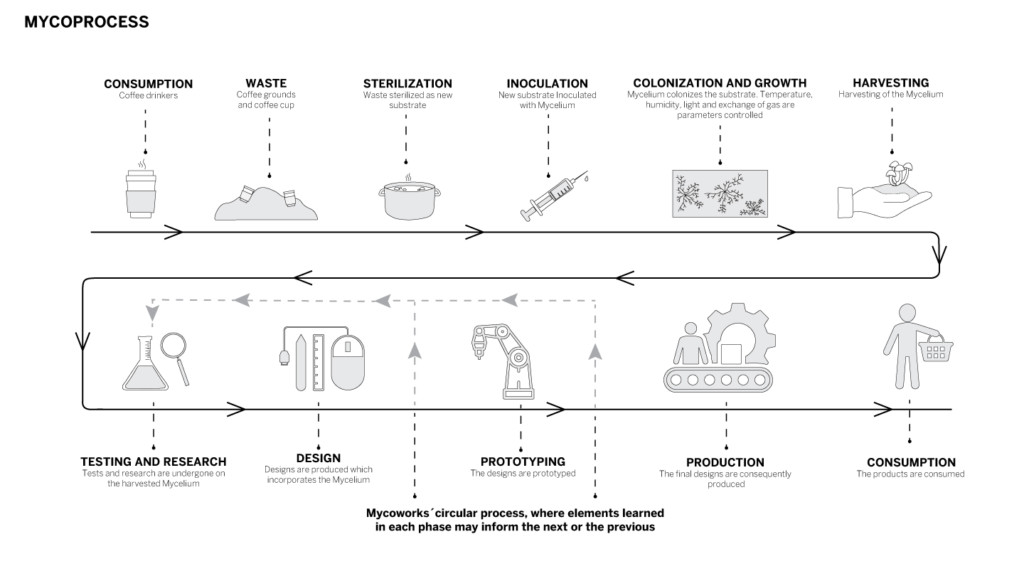

Mycoworks´ is a biotechnology company that began with an artist and chef, Phil Ross. The company is now a team of master leather tanners, biochemists, mycologists, production specialists, and engineers. Phil´s early material research opened the field of and coined the term ‘mycotecture’ which describes the art of designing and building with mycelium. Mycoworks is currently able to manipulate the mycelium to grow in certain ways by controlling its environmental parameters and giving the mushroom types of food that it might like or dislike. Fasteners can also be grown directly into the leather, without having to use glue necessarily, or even seaming.

It takes merely 2 weeks (and substantially less resources) to grow a piece of mushroom leather in comparison to 2 years for cow hide.

THE FUTURE WORKSPACE

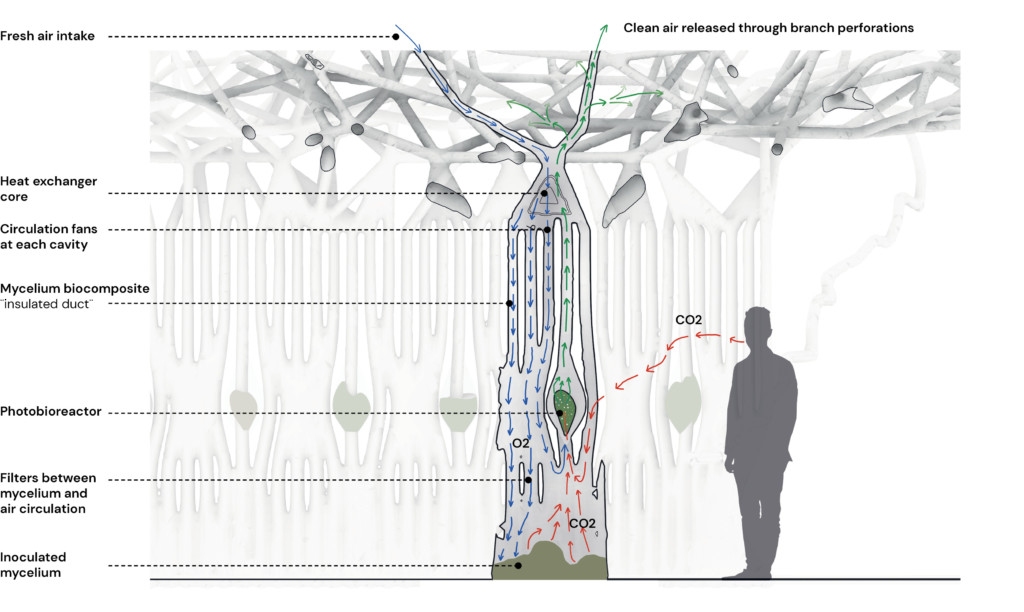

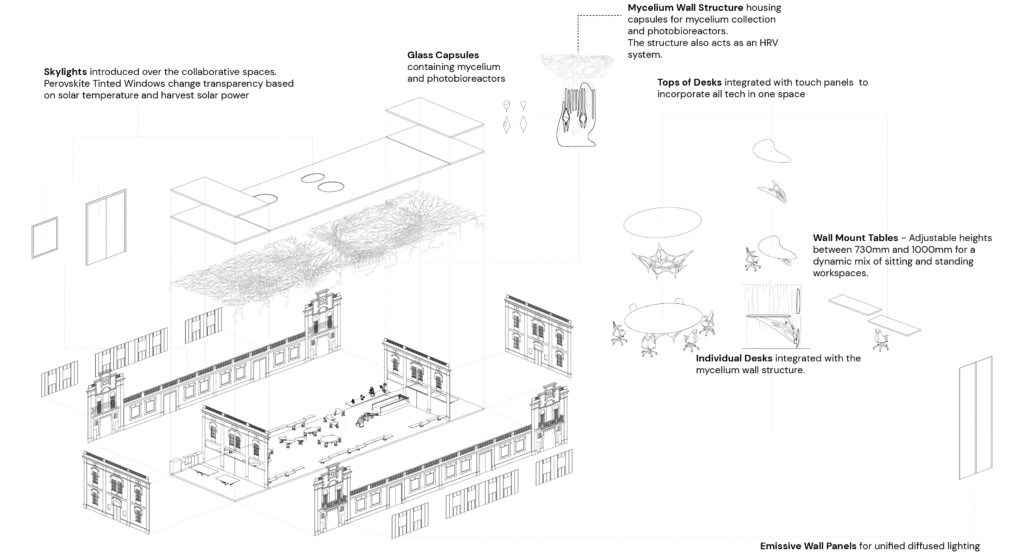

The place we work now breathes new life into us as soon as we walk in. The branching structures are constantly cycling fresh air and recovering all of the heat generated in the space. The mycelium growing is fed with oxygen and moisture as well as the photobioreactors with C02 from this process and the air we breathe out. The cleanest air is released throughout the space. We´re all part of this symbiotic system. 30 years ago it would have been made using plastic pipes or metal ducts, but now mycelium biocomposites commonly resist moisture, yet if triggered could biodegrade.

This is a place of meaningful research, creating hybrid materials from different waste streams, and experimenting with mycogenomics, growth patterns, and fabrication.

Spanish Pavilion at Expo Dubai, External Reference and Onion Lab. Photo: Adrià Goula

”Phytoremediation” involves using plants or in this case microalgae to remove toxins from air. It begins with a mix of algae and water with added carbon dioxide, phosphorus and nitrogen. Artificial lighting can be used either instead or in addition to sunlight.

Creating an agile working environment that is supported by hotdesking.

An organizational system where desks and workstations are first come, first served with no assigned places. The office space may be divided into zones giving the user freedom circulate their positions. Desks themselves are also changed to accommodate modern needs. Furniture design incorporate agile working trends; screens and digital whiteboards will plaster walls and be built into the desks, connecting seamlessly to devices.

Illustration by Jia Lin

Use of glass is replaced by “Perovskite tinted windows” which are made of a mix of elements with a particular crystalline structure. Beating solar cells in manufacturing price, perovskite tinted windows not only provide a greater opportunity to harvest solar power but by changing the elemental components of the material the glass like material becomes responsive to the sun and adjusts the translucency in accordance with the solar radiation index.

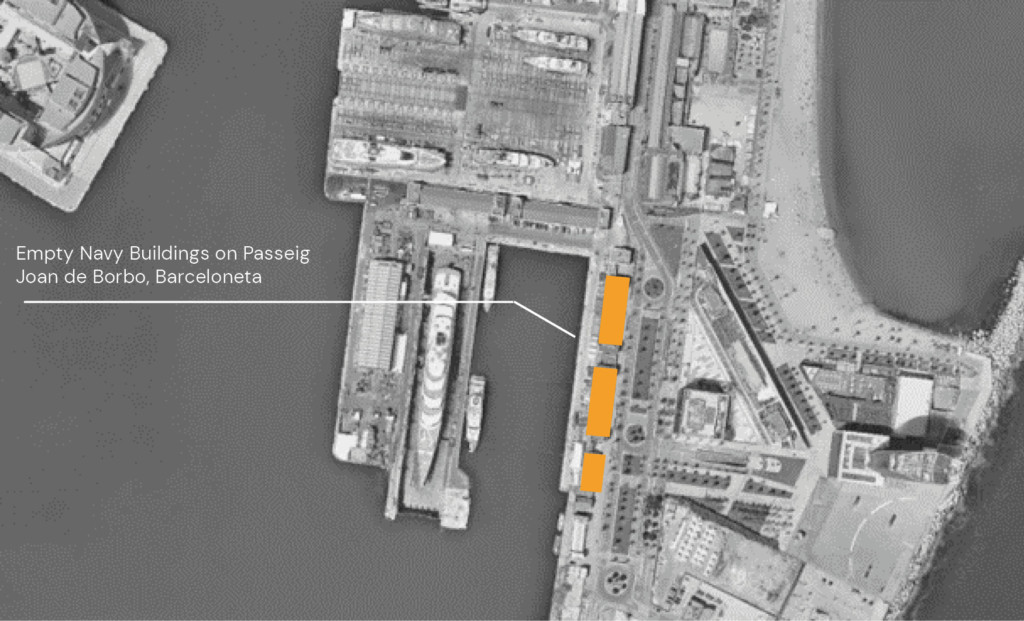

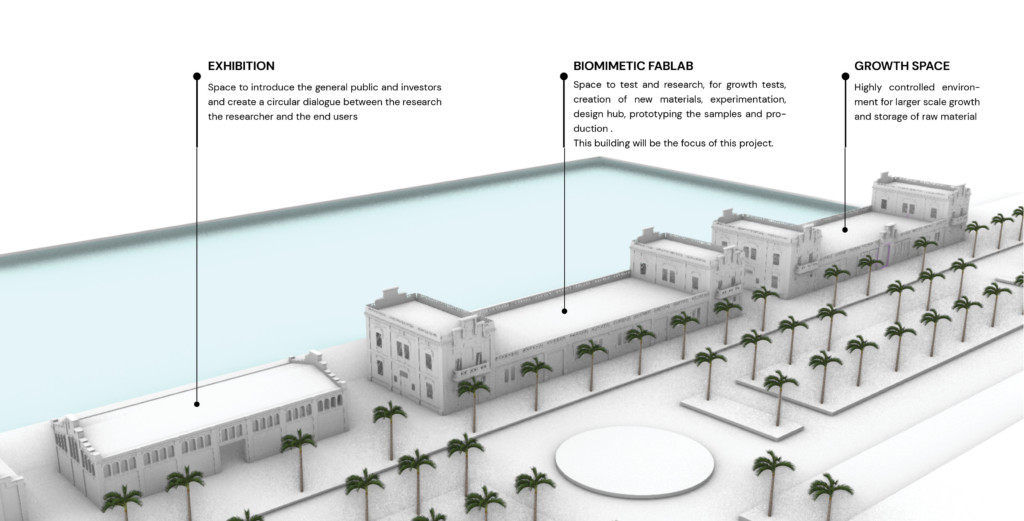

THE SITE

The site is located along Passeig Joan de Borbó in Nova Bocana, the relatively new leisure area and marina of Barcelona’s port near Barceloneta beach. The buildings date back to 1900-1904 and functioned as warehouses on the Barceloneta wharf for decades until the 1992 olympics where they were relocated and have lied empty since. They currently face the water and the streetscape, and have strong potential for adaptive reuse.

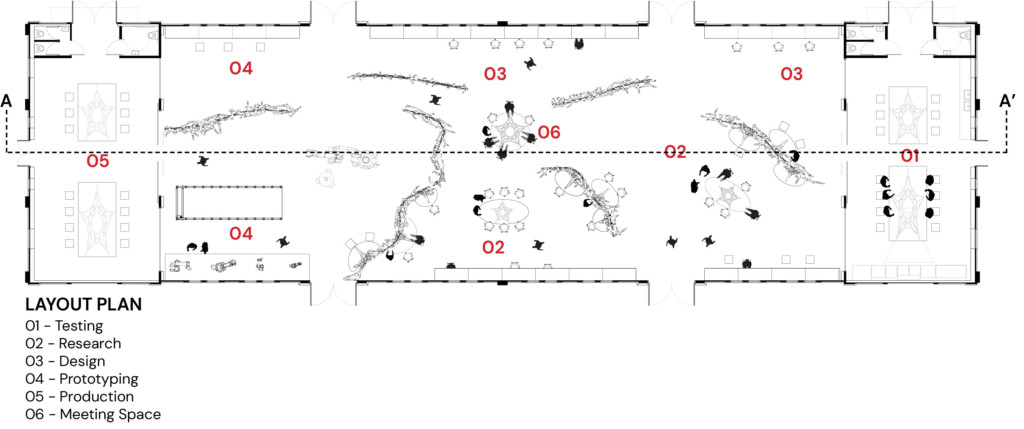

A workspace for Mycoworks that supports collaboration, health, a local circular economy, with a state of the art lab and tools to grow mycelium: To analyze, invent and prototype new materials.

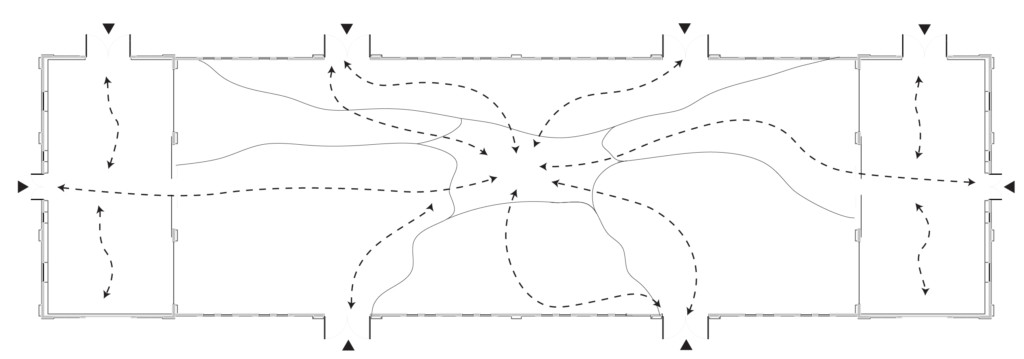

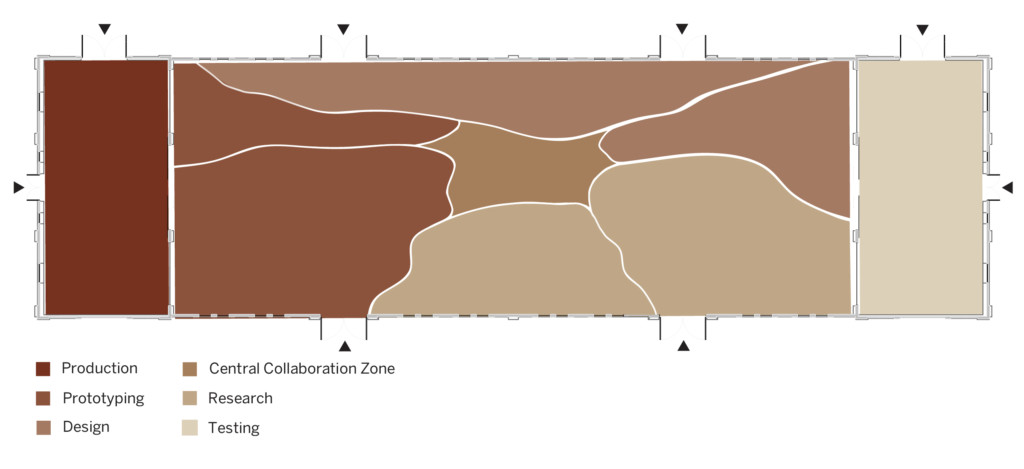

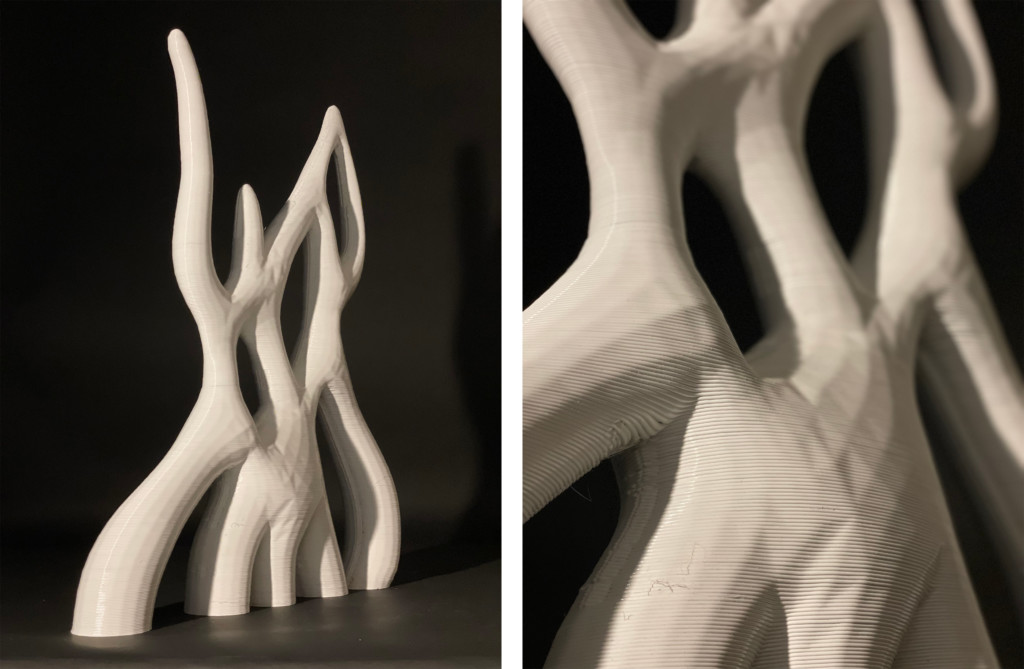

The separation of the spaces is acheived using iterations of the growth pattern of mycelium. The adjacent diagrams demonstrate a sample of the iterations that were obtained in relation to the openings of the building and the need for the central collaborative zone.

The chosen mycelium structure optimises MycoWorks´ circular working process as there is a clear center and stems organically outwards. The optimal growth pattern was simplified.

Floor Plan: Lines were chosen from the simplified optimal growth pattern in order to create the simplified optimal growth pattern in consideration with the circulation

Spatial Divisioning

Mycelium Walls: Vertical separations were created from the program and circulation, considering the location of existing windows, type of work and requirements for each space. Each separation follows a mycelium branching pattern overhead.

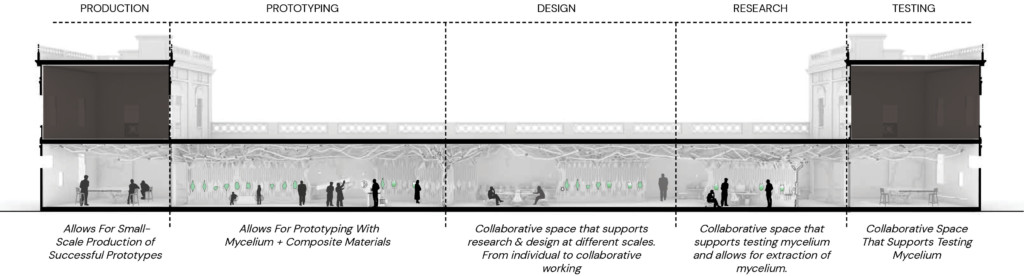

SECTION AA’

Wall System Diagram

Mycelium Wall Prototype

Mycelium Wall PrototypeBIOMIMETICS FABLAB – For Growth of Future Materials is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Master in Advanced Architecture in 2021/2022 by Students: Alessandra Weiss, Perniyal Waseem, Emily Rackstraw, Jeremiah Oonyu, and Angelina Ovsyannikova; Faculty: Carmelo Zappula; Faculty Assistant: Sebastian Amorelli, and Amin Bigdeli