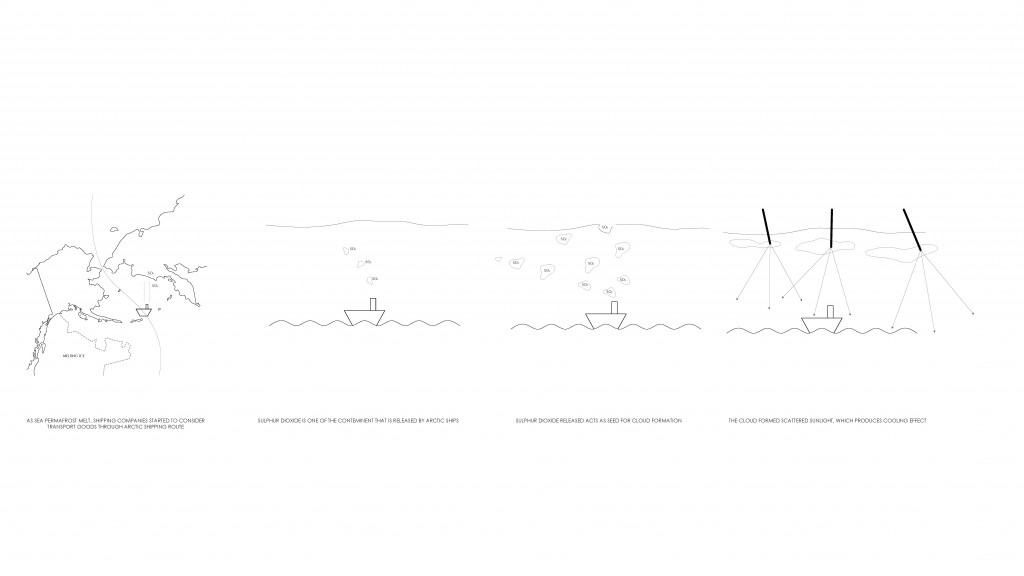

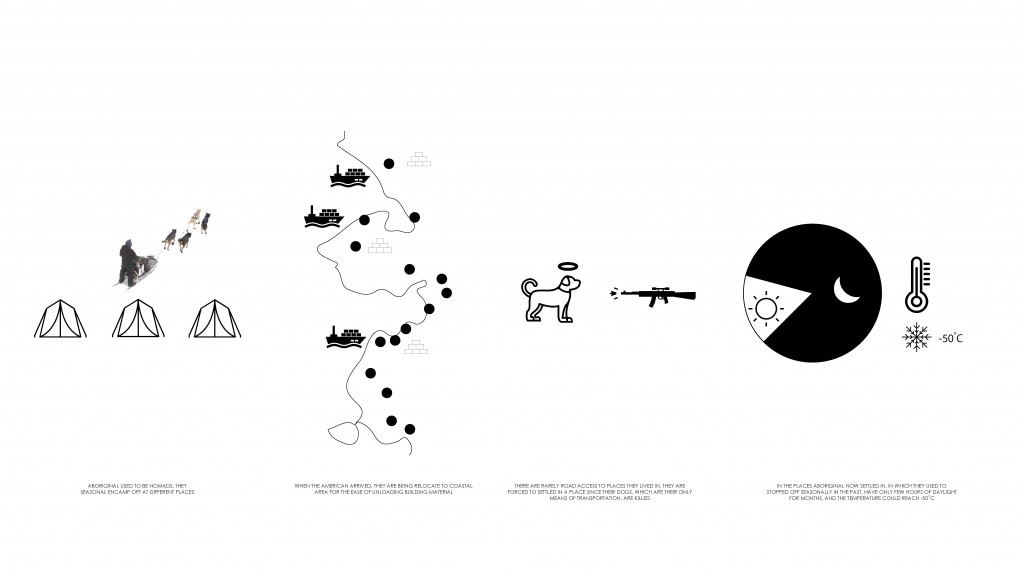

The project is a step towards designing self-sufficient building(s) that manipulate particles in the atmosphere at the end of the third term. The project located in the region where permafrost exist in continuous or partial continuous form.

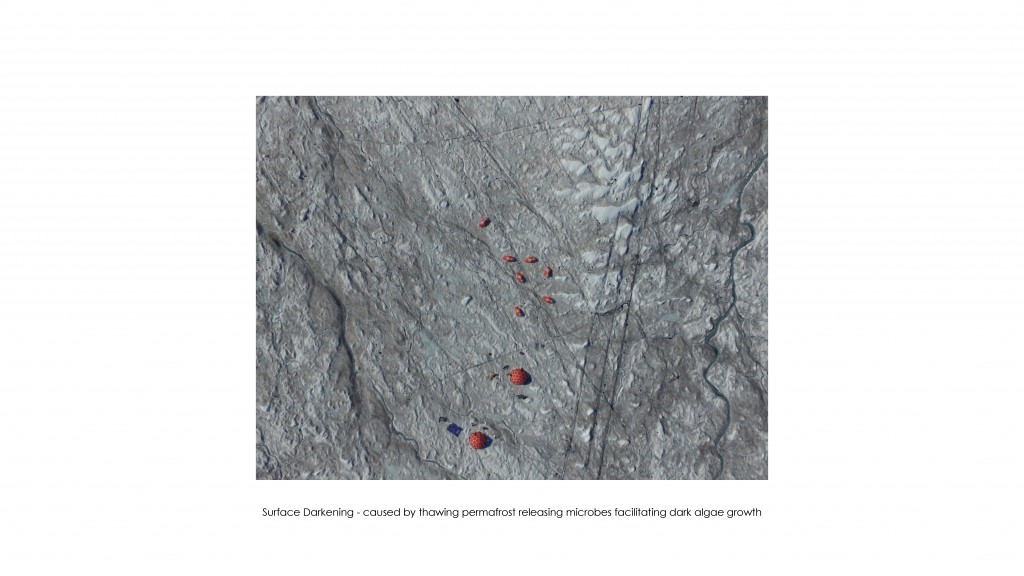

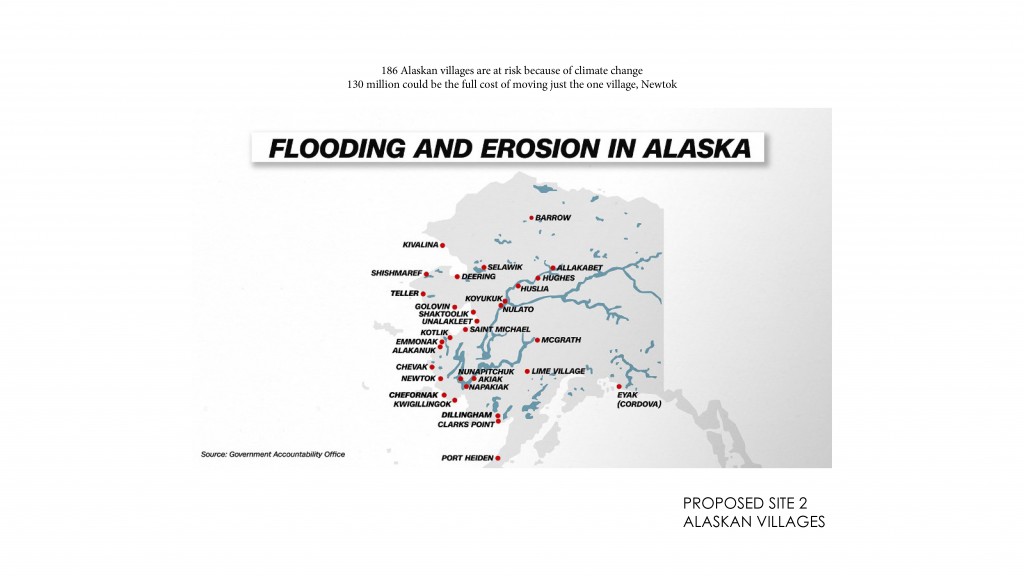

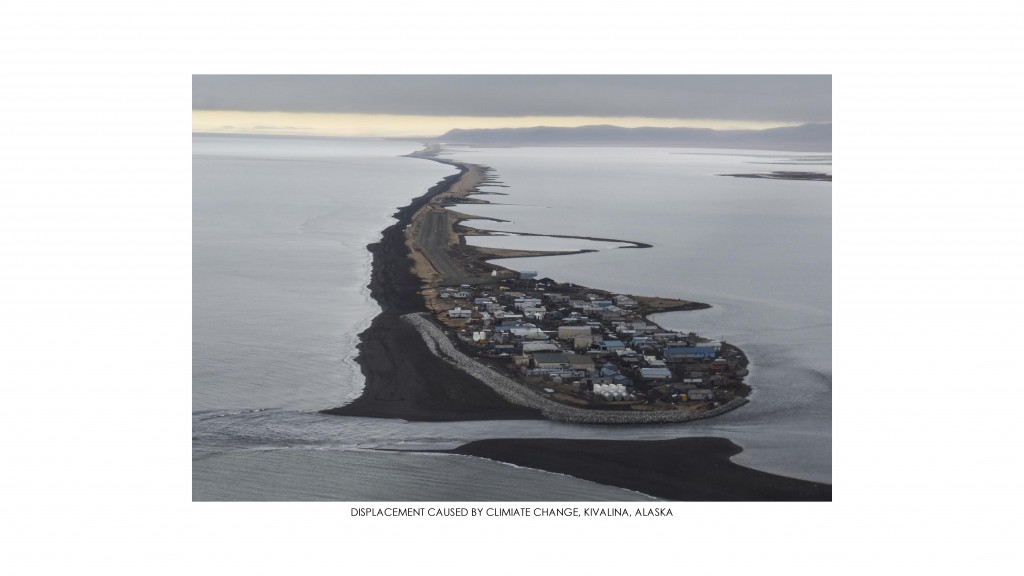

With our studio closely linked to the climate change agenda, the site selection process begins with looking at the certain climatic triggered events such as drought and wildfire together with the source of all these events which is the melting of permanently frozen matter in the arctic circle.

One part of the world is burning and at the same time another part is melting

Some species that extinct ages ago come back to live while some existing species is facing permanent extinction

Part I (Group work collaborated with Karisma Heman Bhagnani and Gayathry Mohan)

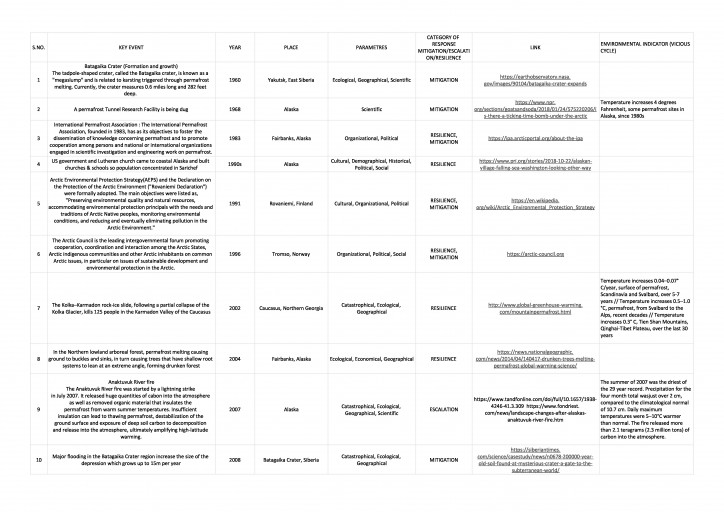

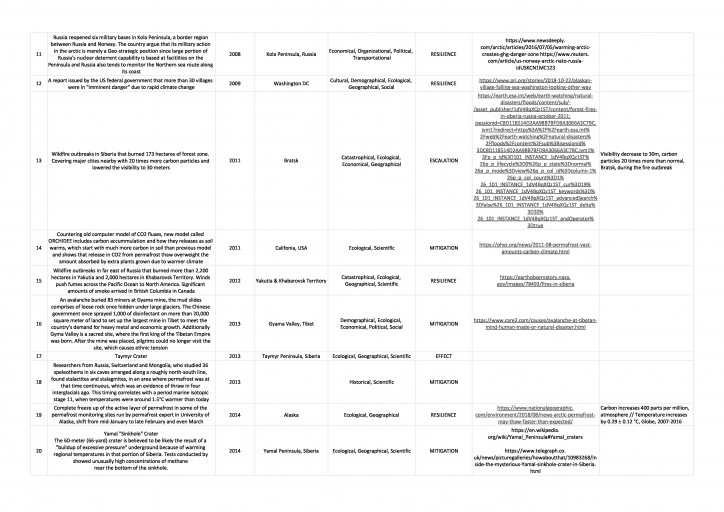

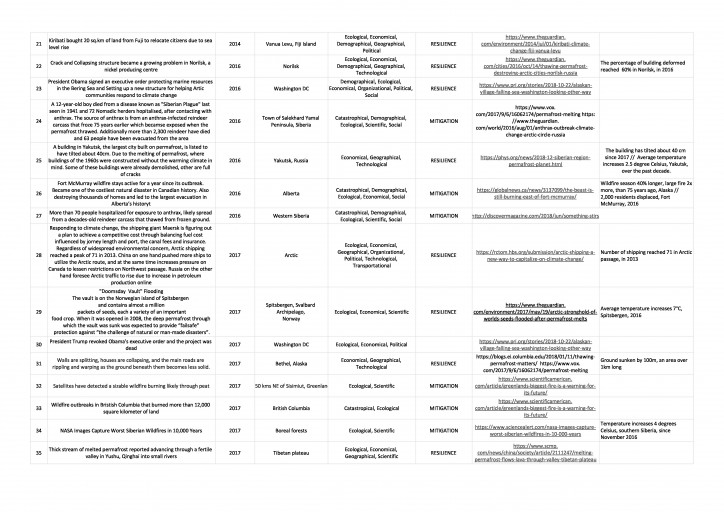

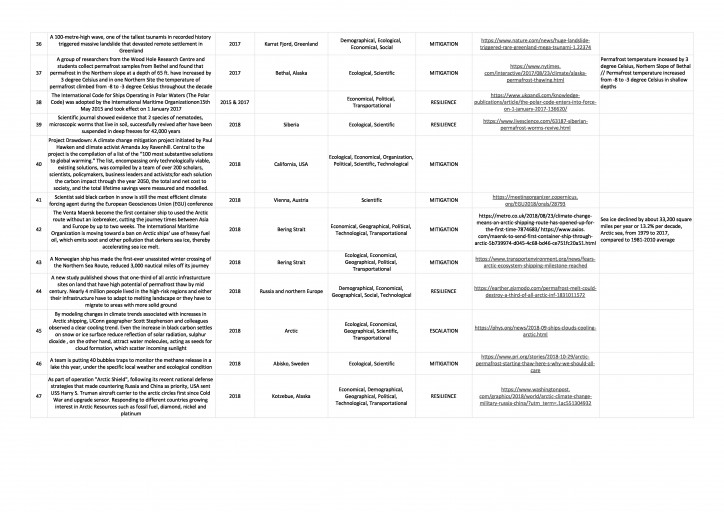

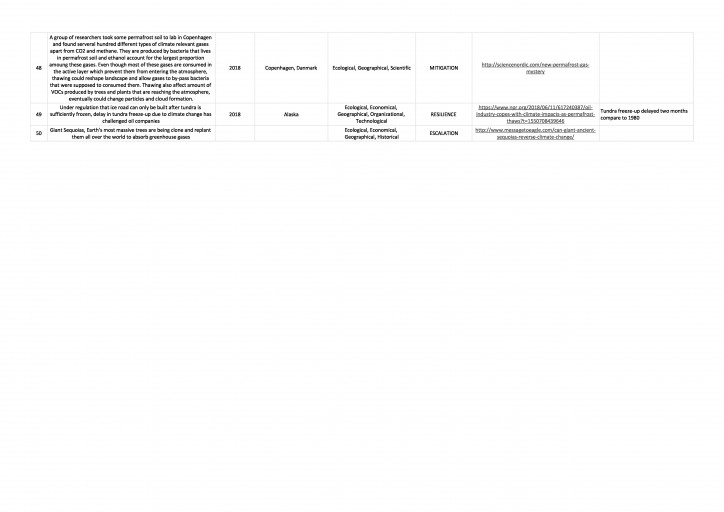

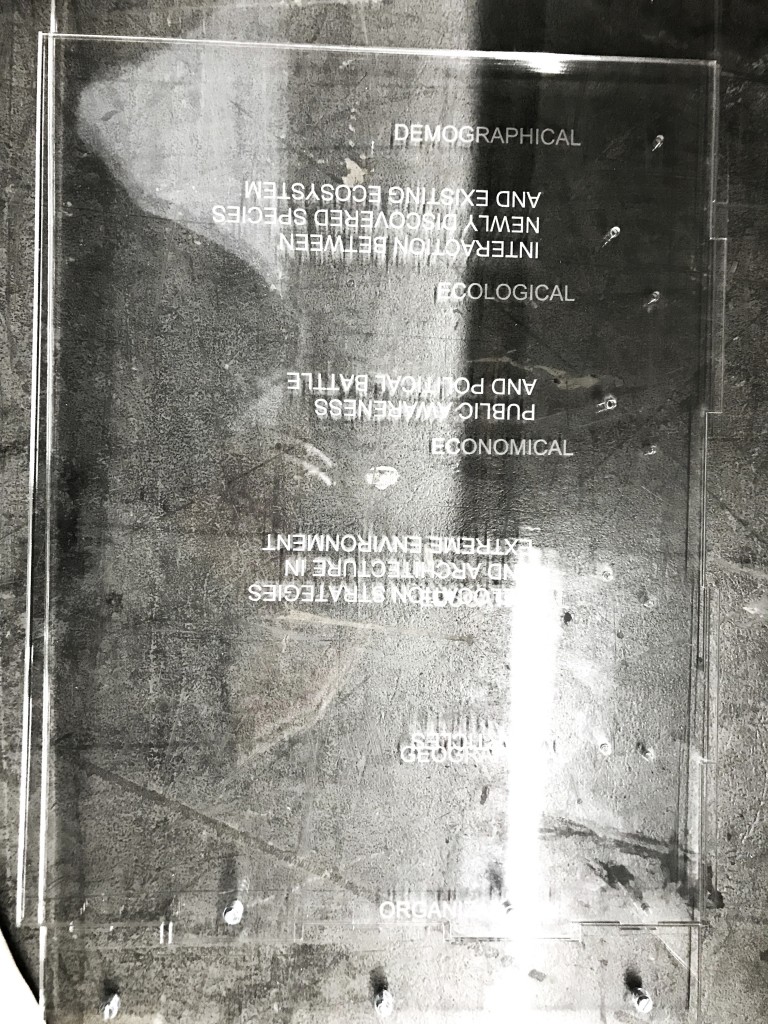

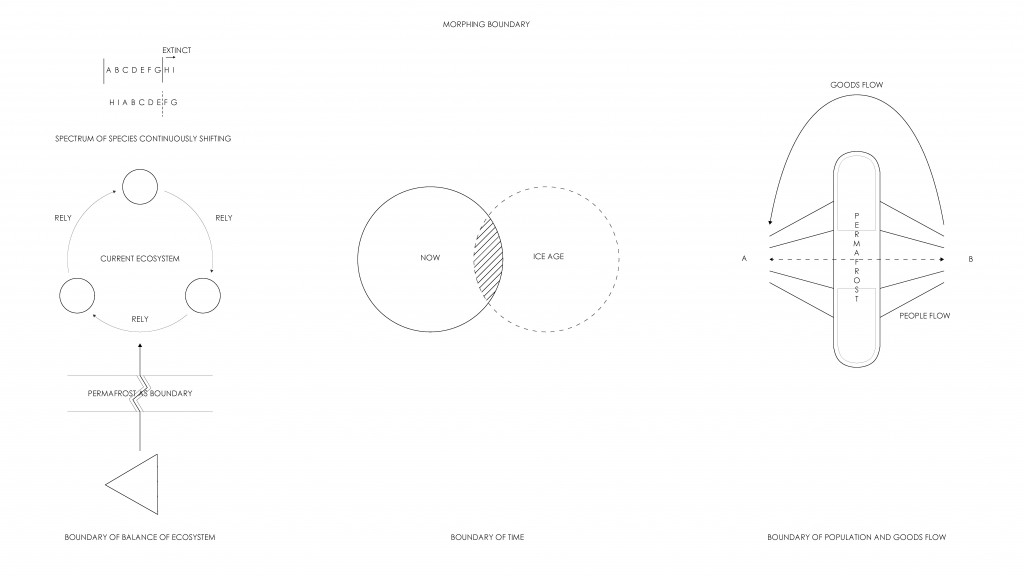

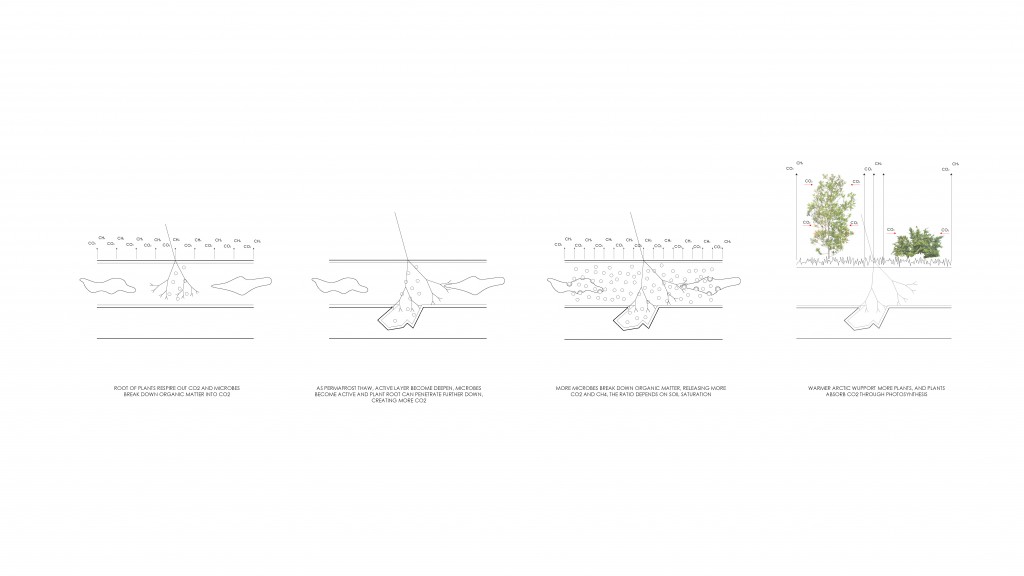

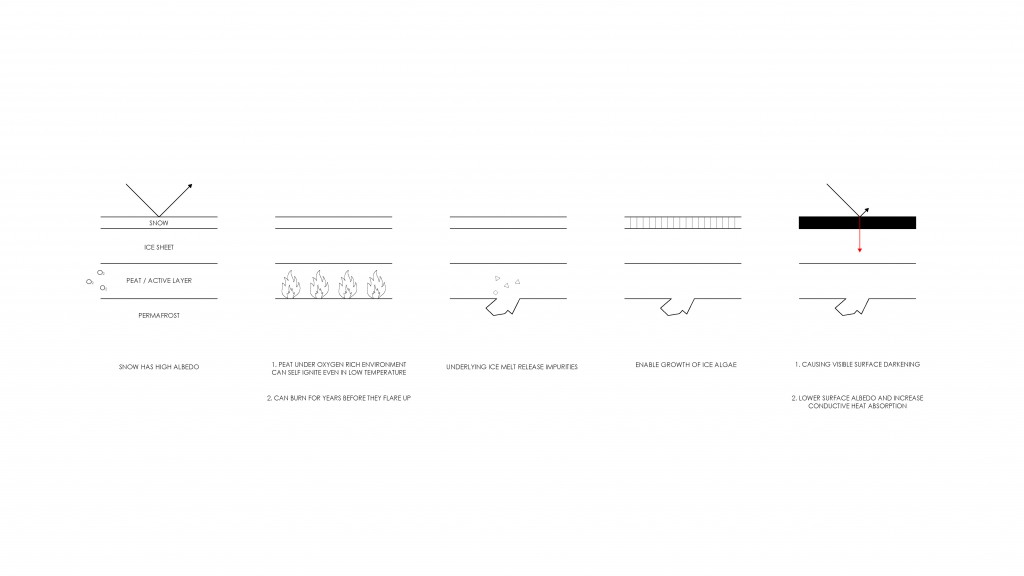

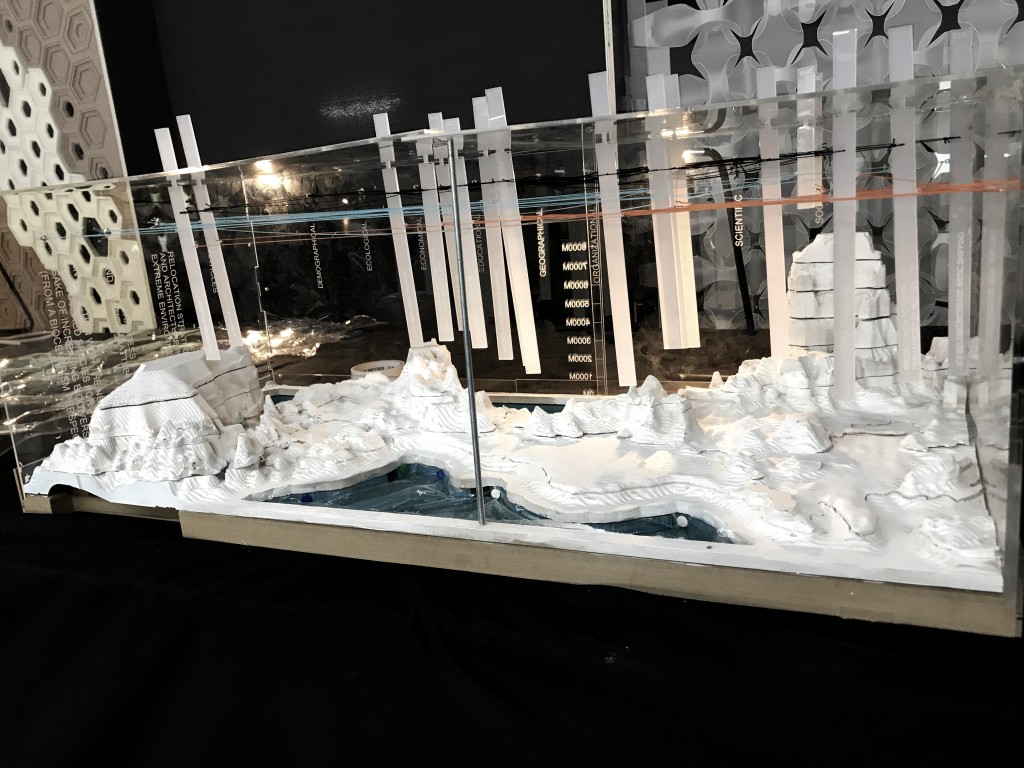

Events related to the topic of permafrost is being researched into and categorized according to aspects that are involved in a certain event and the implied strategies of that event. To map the particles through an animation, all the events are represented in numerical data using the same protocol.

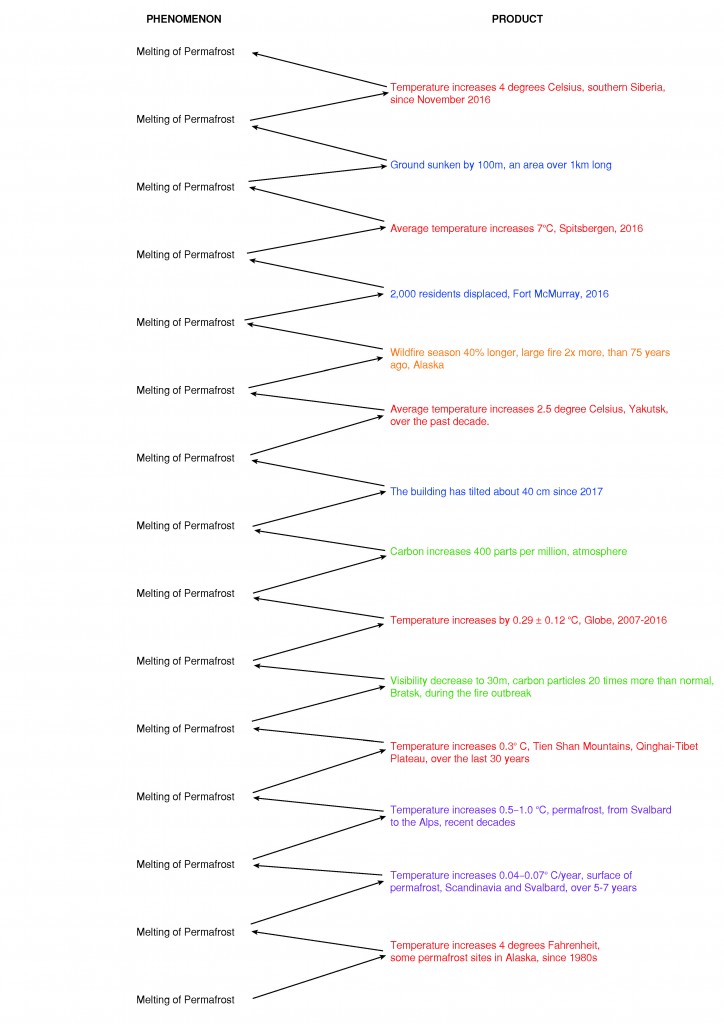

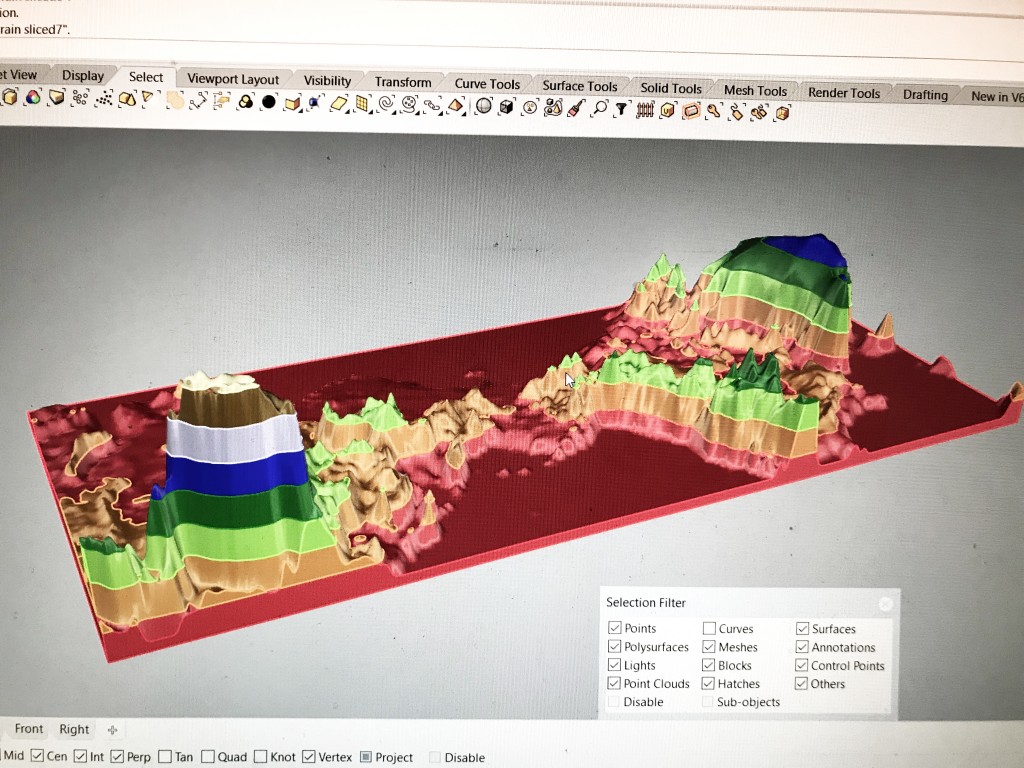

In the cosmogram, the arctic circle of 9000 km where permafrost exist is being the base model where all the information overlay on. Due to the large area included, the height is of the topography is represented in a different scale.

Part II (Individual work)

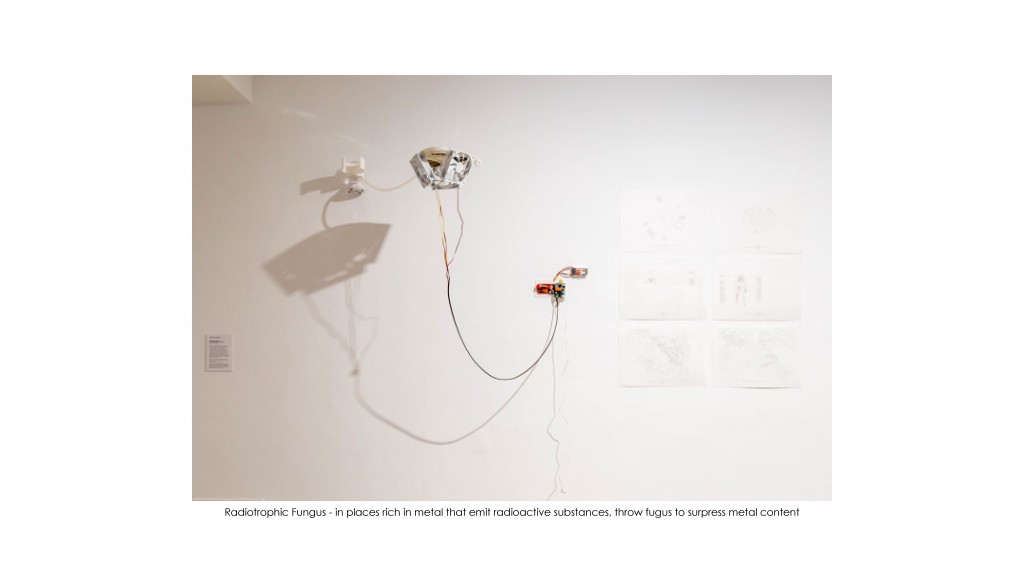

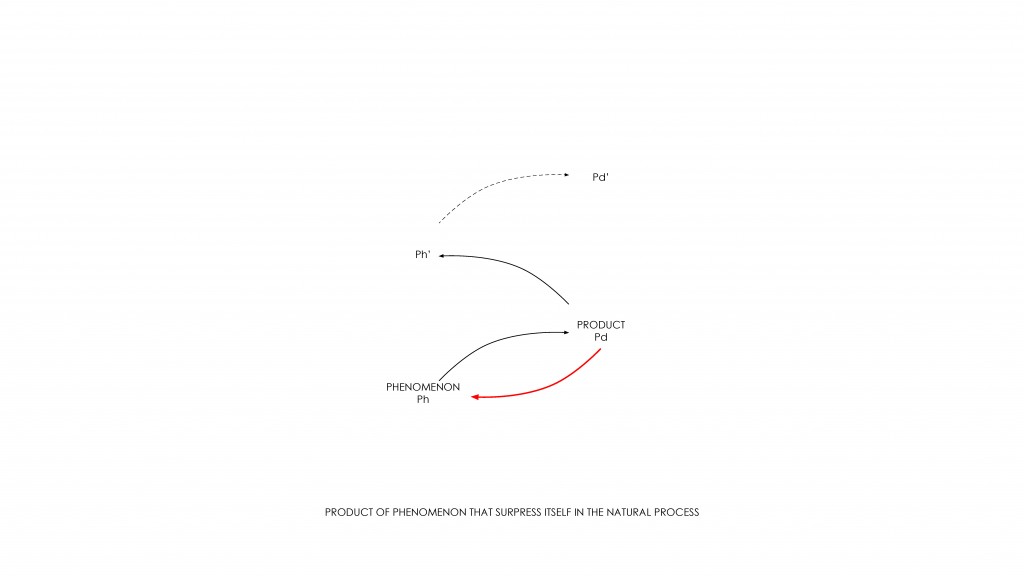

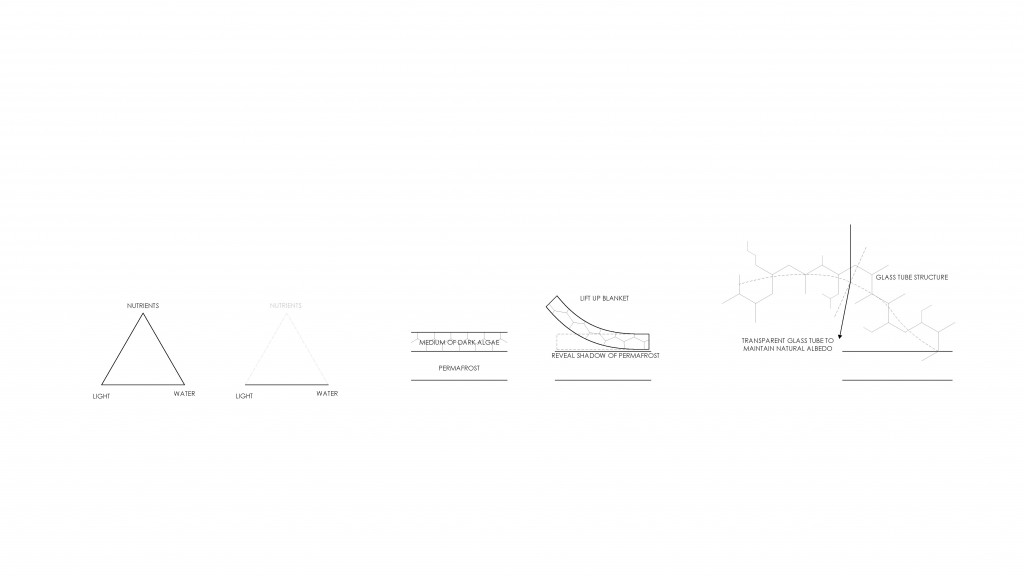

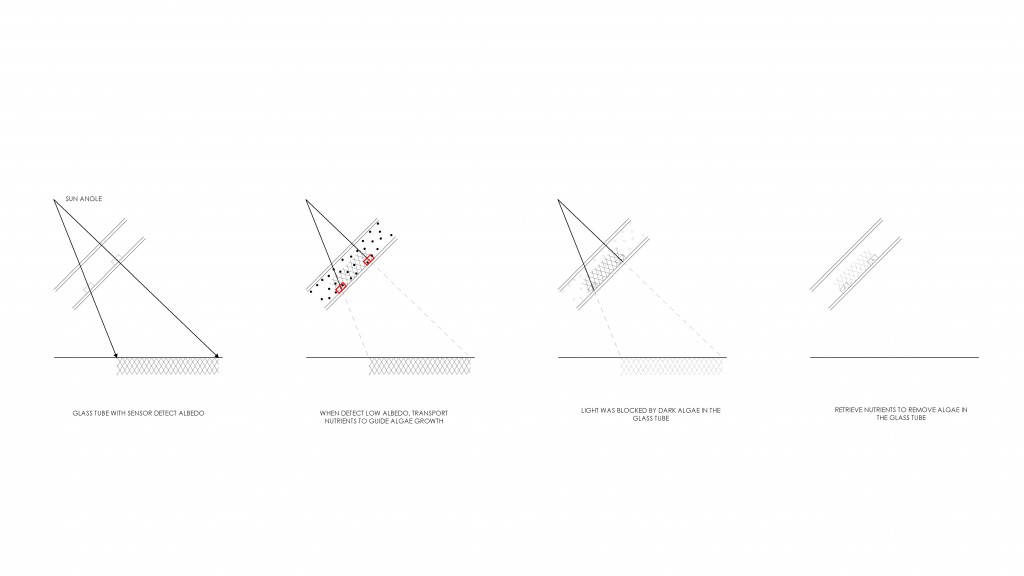

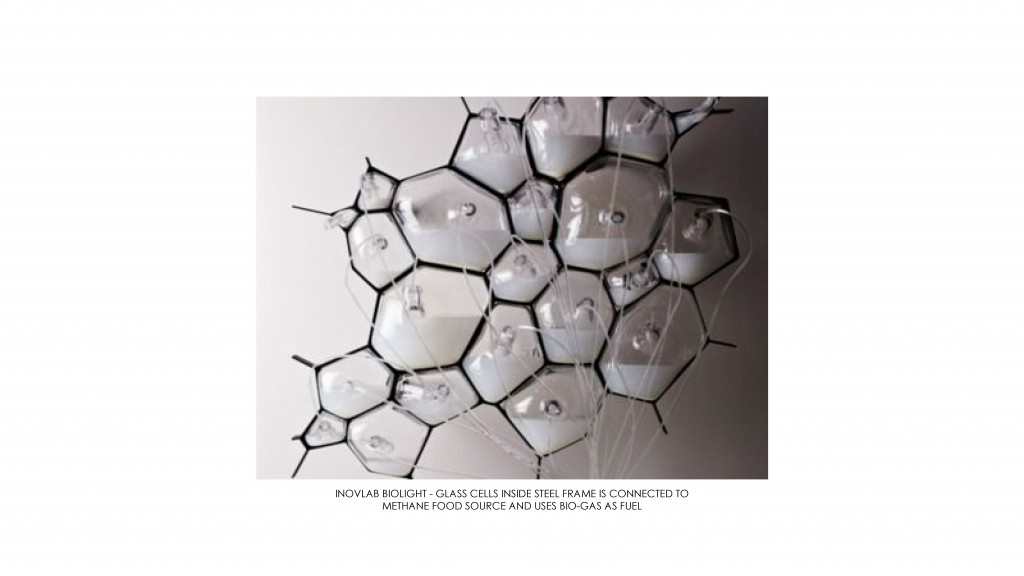

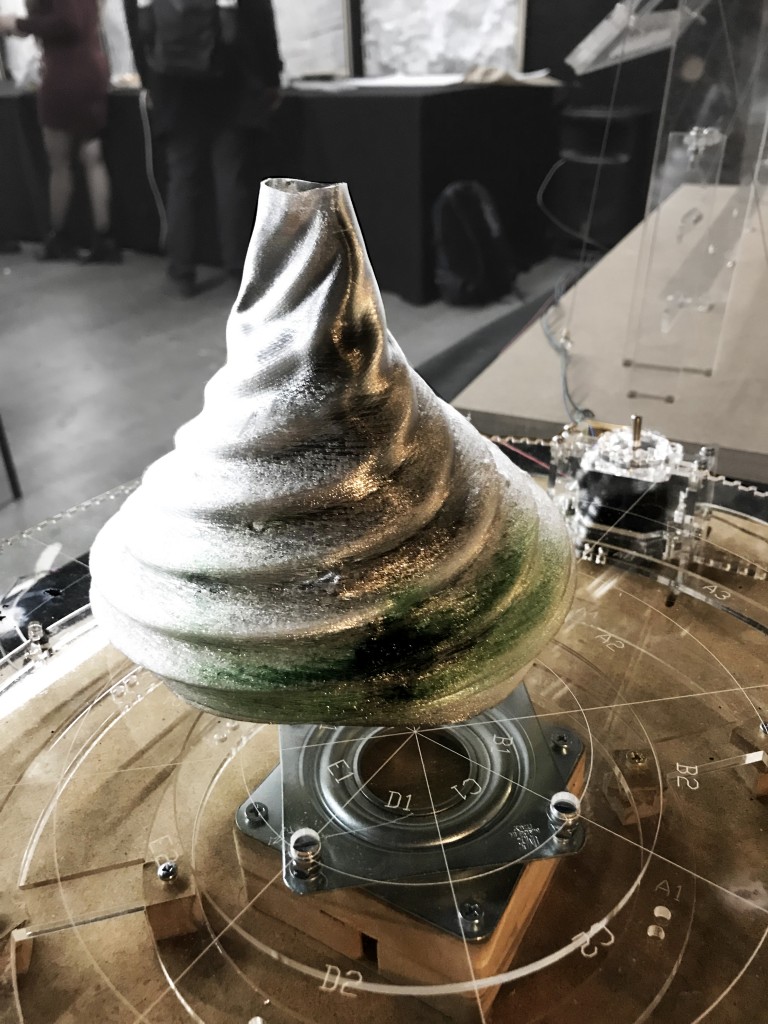

In the second stage, a device is being considered. The device made for the permafrost area is one that dealt with methane gas since it is one of the upper surface gas that first release into the atmosphere when the permafrost melt. Secondly, despite having a shorter life, methane is 4 times more powerful in terms of heat trapping ability. Since the biggest worry about permafrost melting is that when this substance melt to a certain point, the process of warming of the earth can be automated without human actively polluting the environment, the main goal of the device is to keep the process in the controlled manner. To achieve this, certain natural process are being learnt from, in which the product of the phenomenon suppressed instead of escalating the phenomenon to form a vicious cycle.

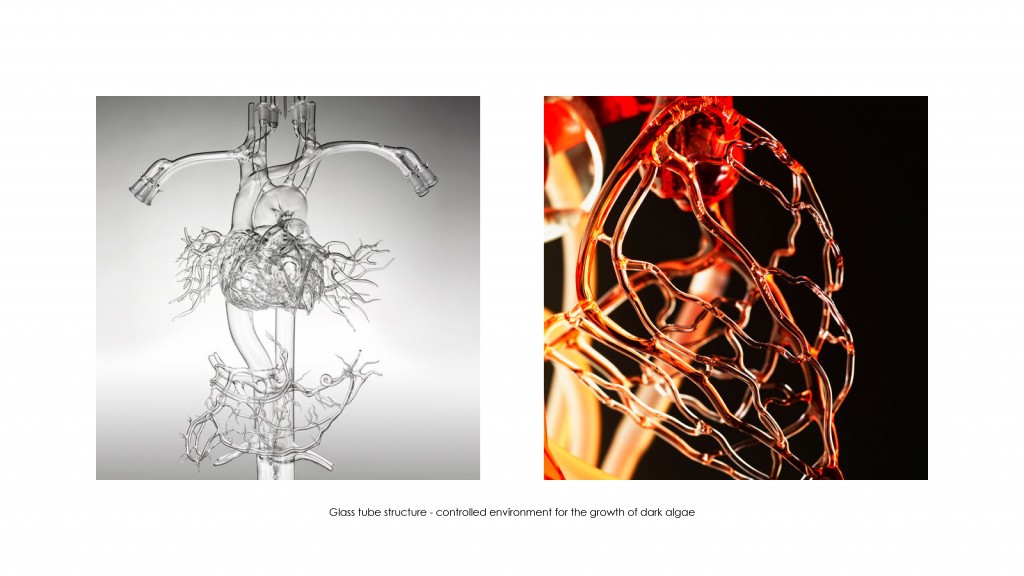

To proceed with the idea of using algae pigment to shield off a certain amount of light to limit the overgrowing of such species is tested.

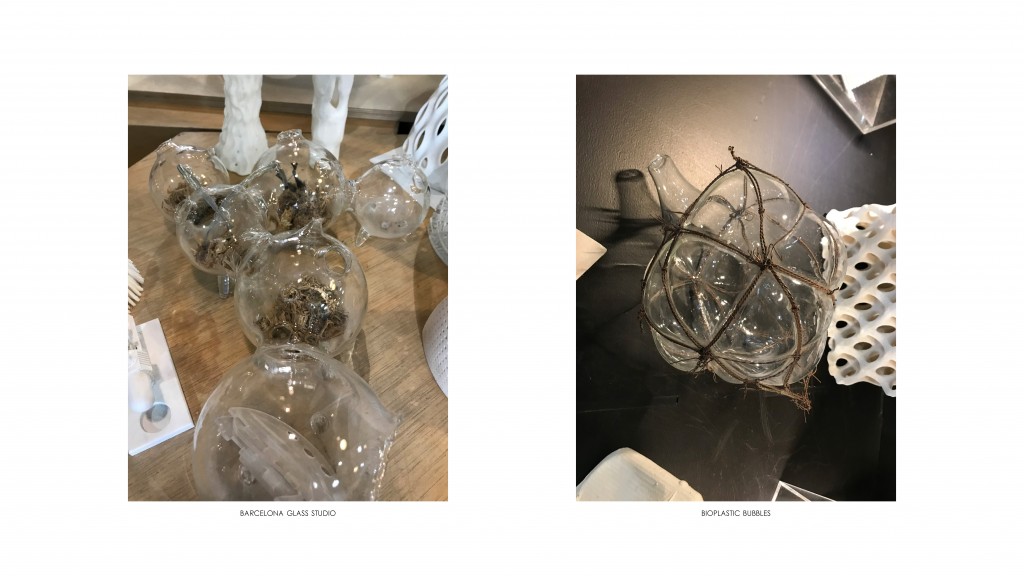

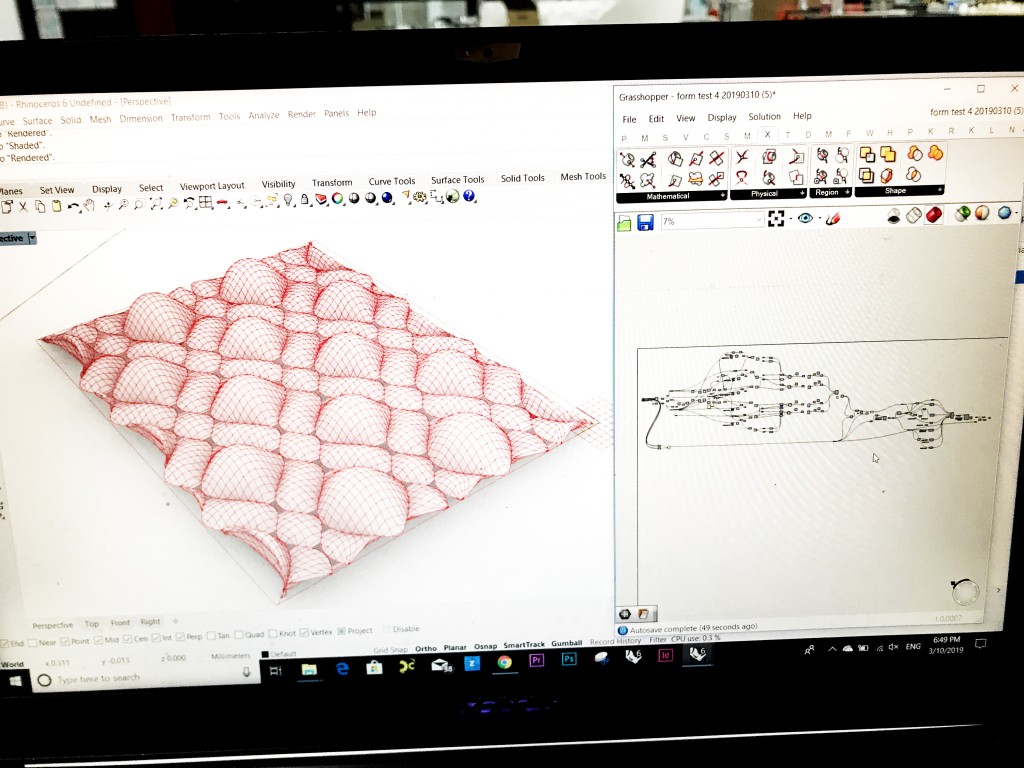

Afterwards, a geometry that create chamber of cells for smoke movement to occur within it is developed.

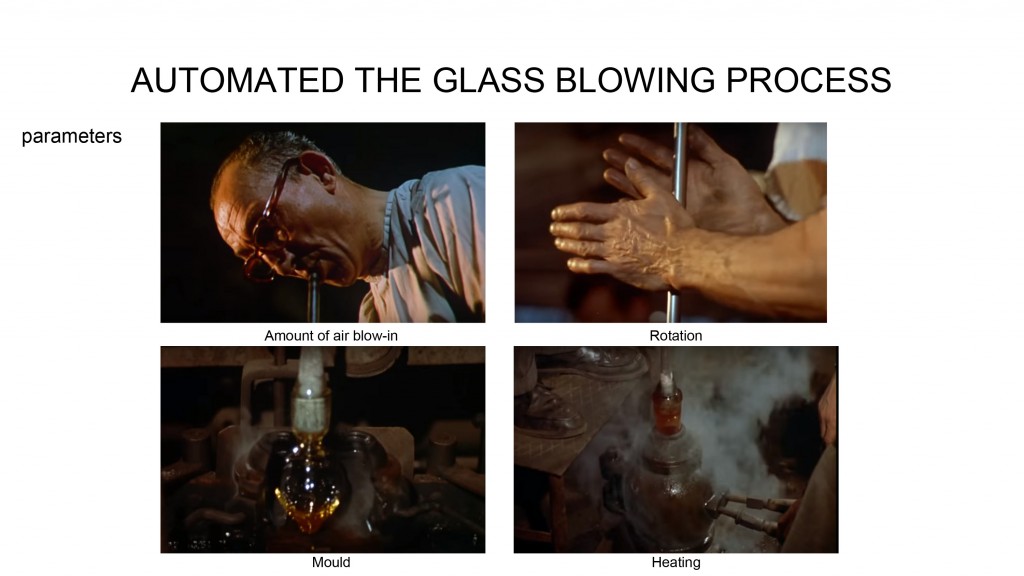

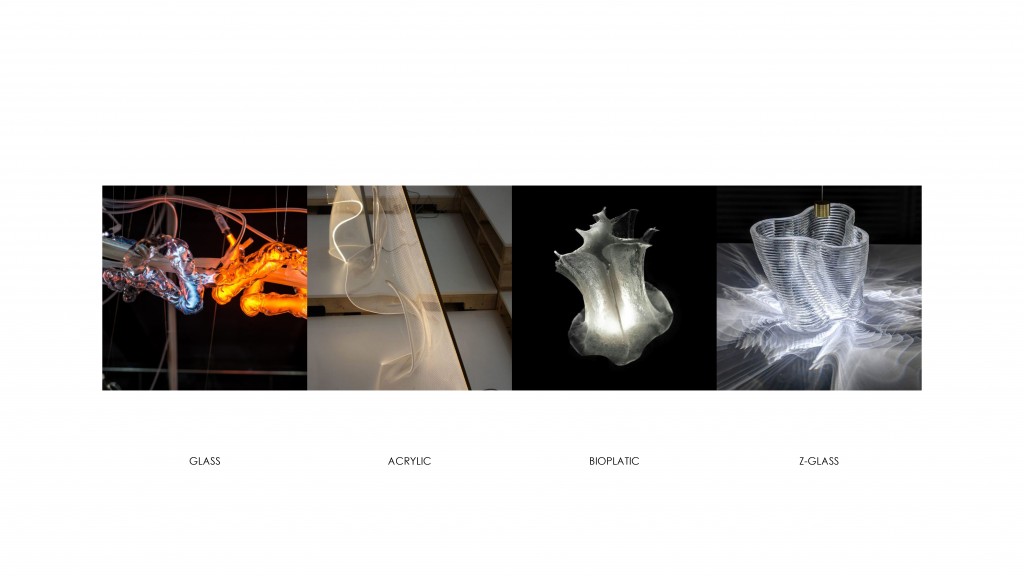

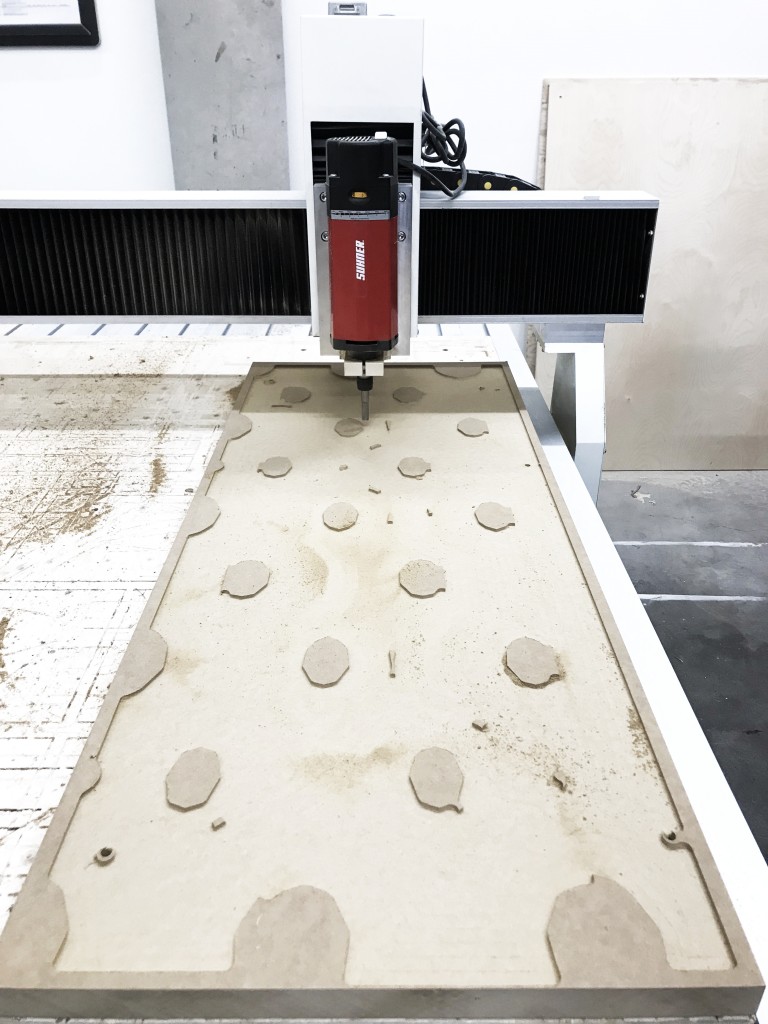

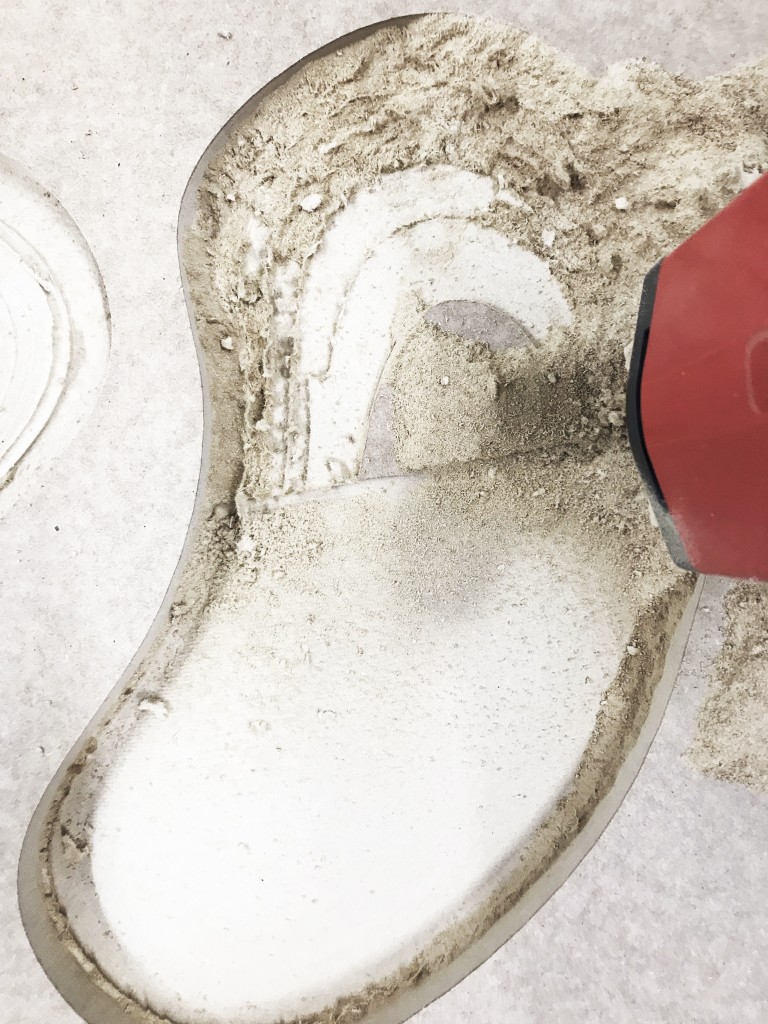

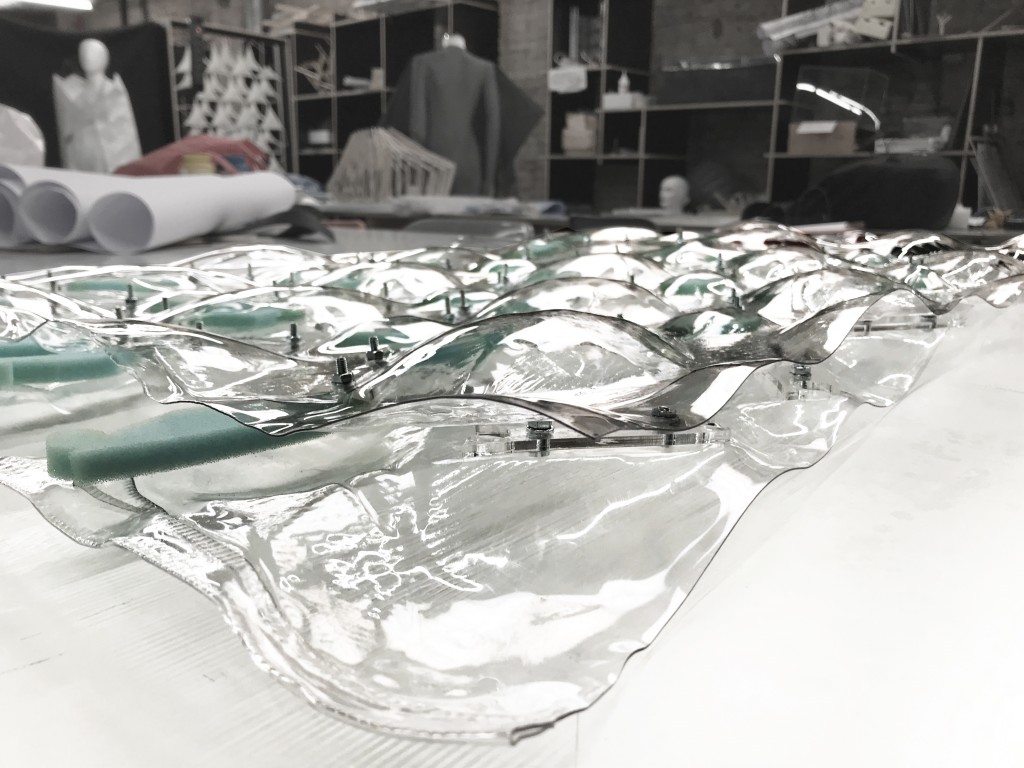

After considering the energy and large amount of heat required for glass blowing. 0.5mm PETG is used to do vacuum forming.

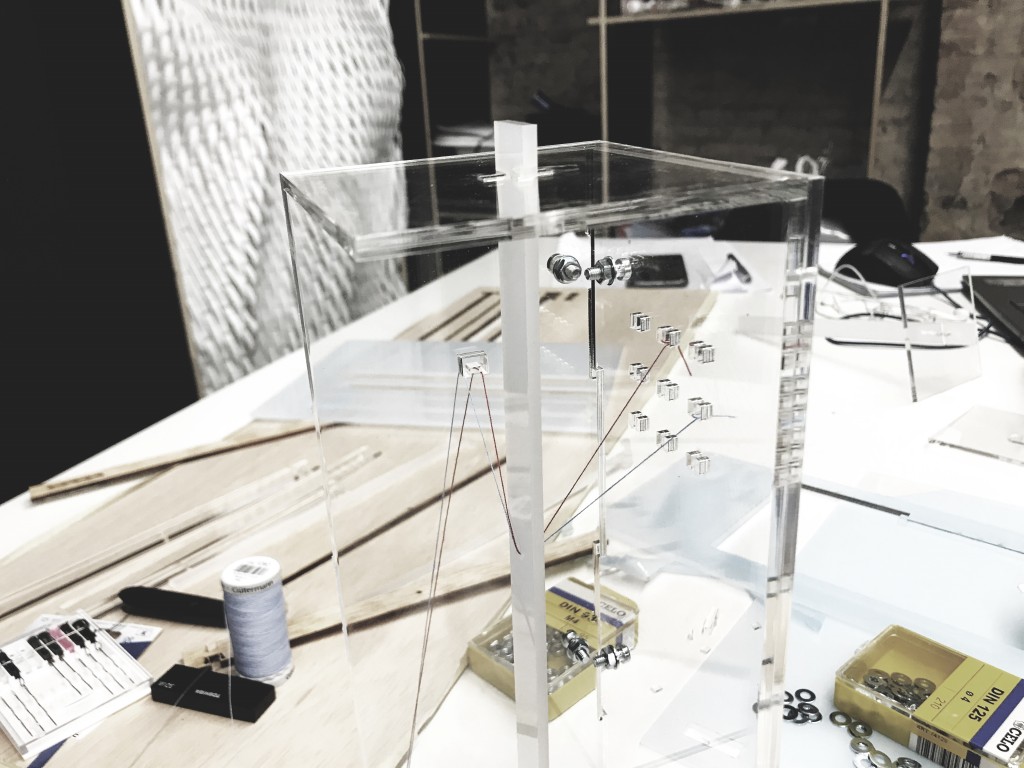

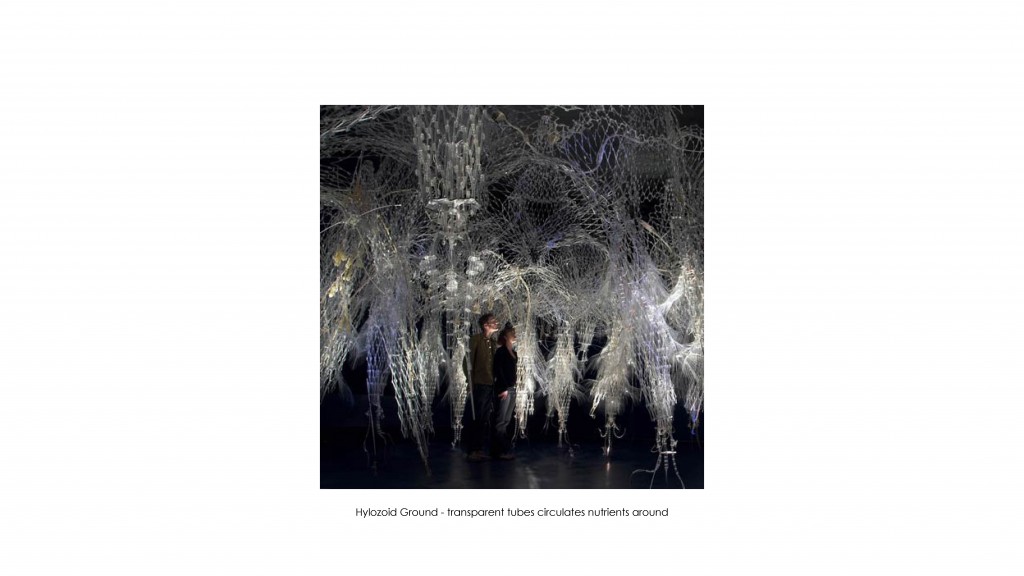

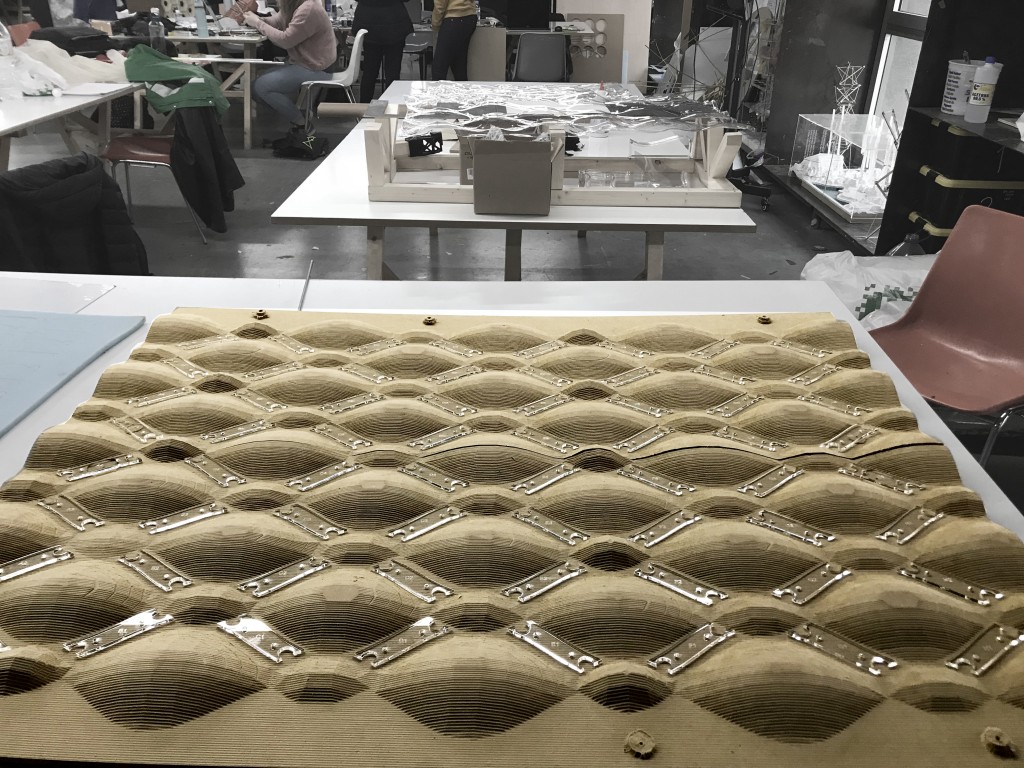

In the next step, the overall arrangement of the cells are being tested. Different options such as folding the surface to form its own rigidity, having a circular interdependent structural relationship and a tensile cable structure that is attached to a loft edges structure are being compared. The two options of shading with pigment and methane gas, whether to use chlorophyll produced by algae to dye the gas or whether to inject methane gas into insoluble viscous solution are both considered.

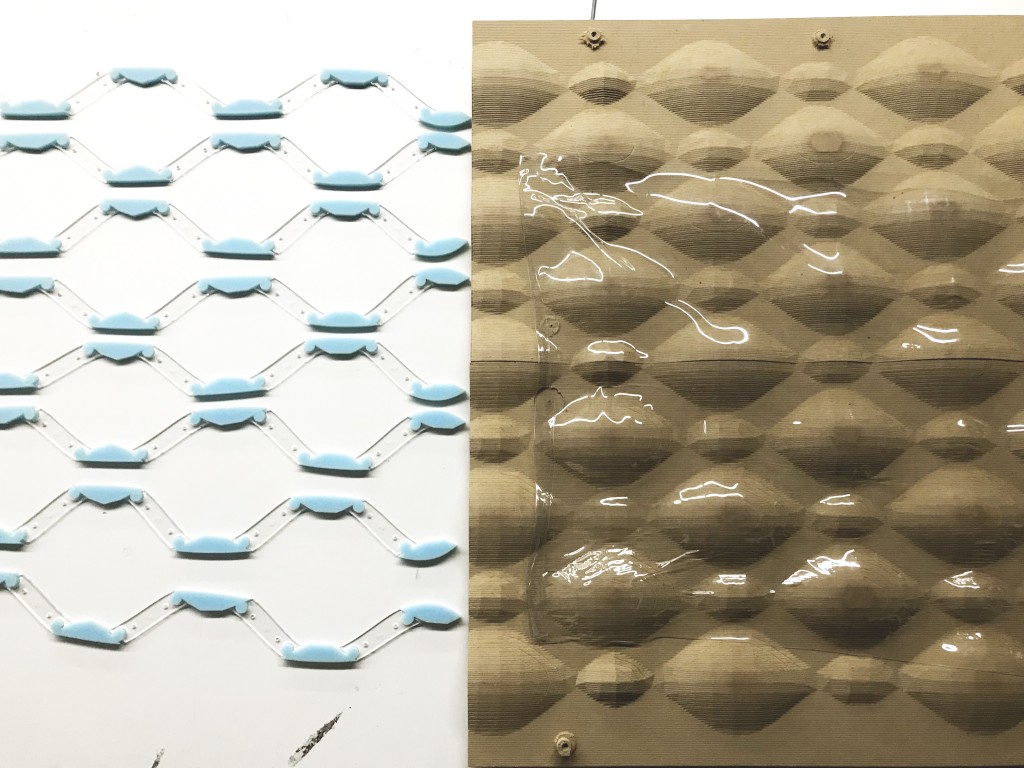

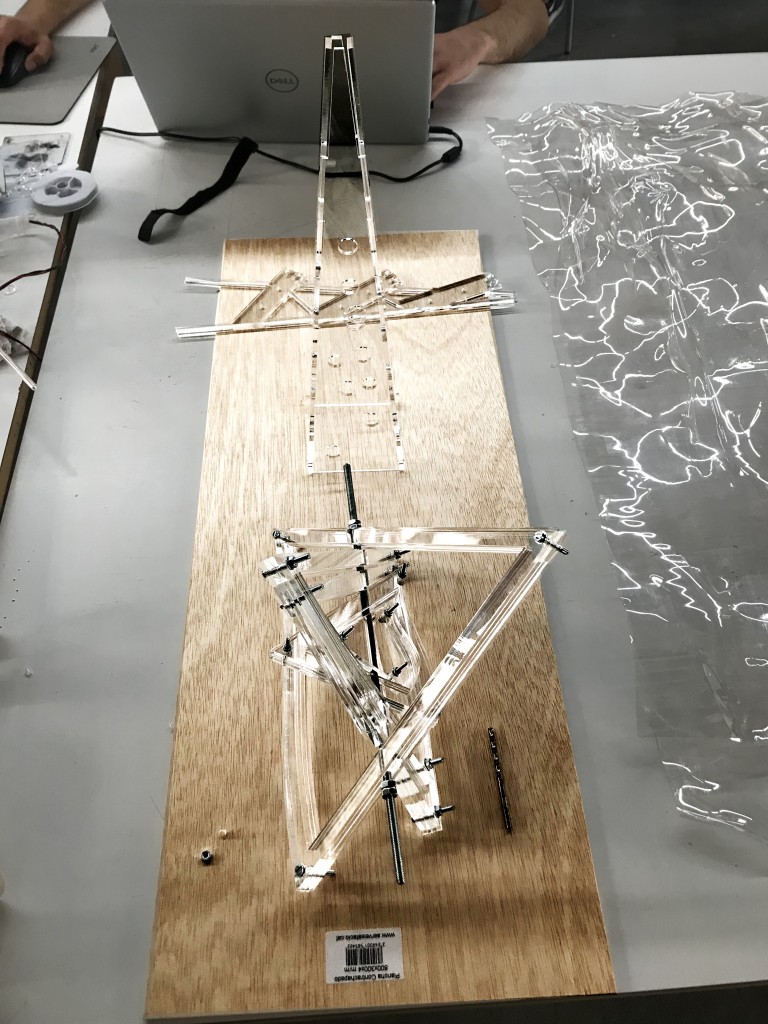

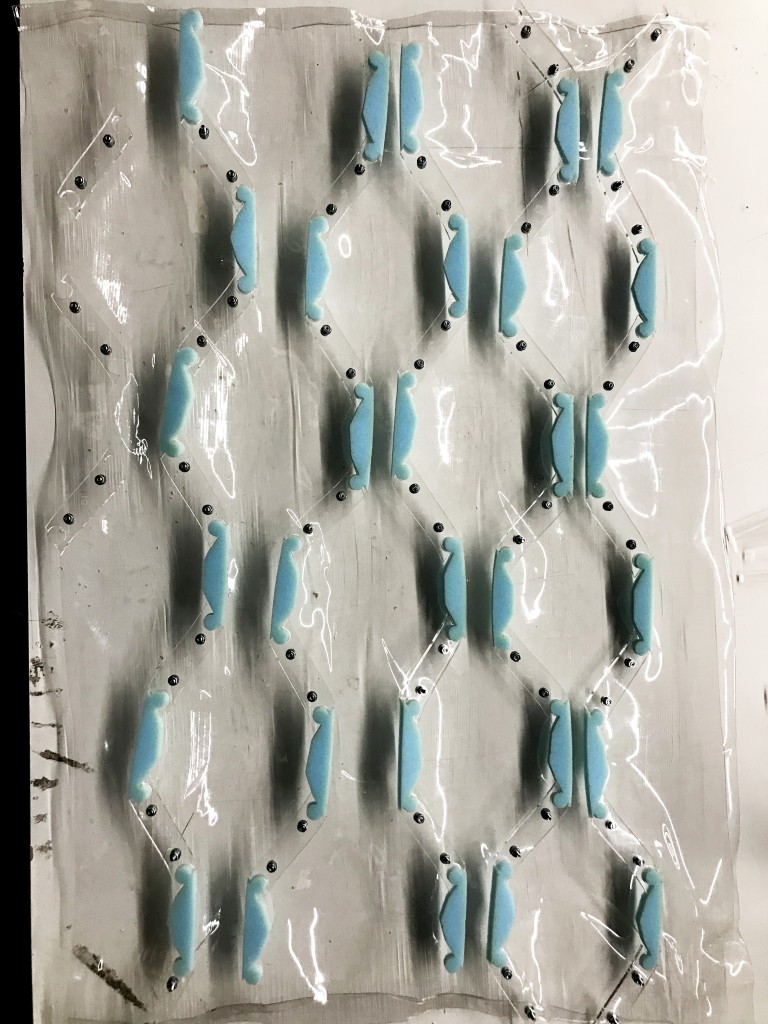

Vacuum forming is a fabrication method that is more favourable to thinner material. The advantage of using a thinner material is the flexibility that the material inherit. In order to seal and defined the chamber for light penetration mapping to the darken ground surface, strategies for rigid and soft joints arrangement are being explored.

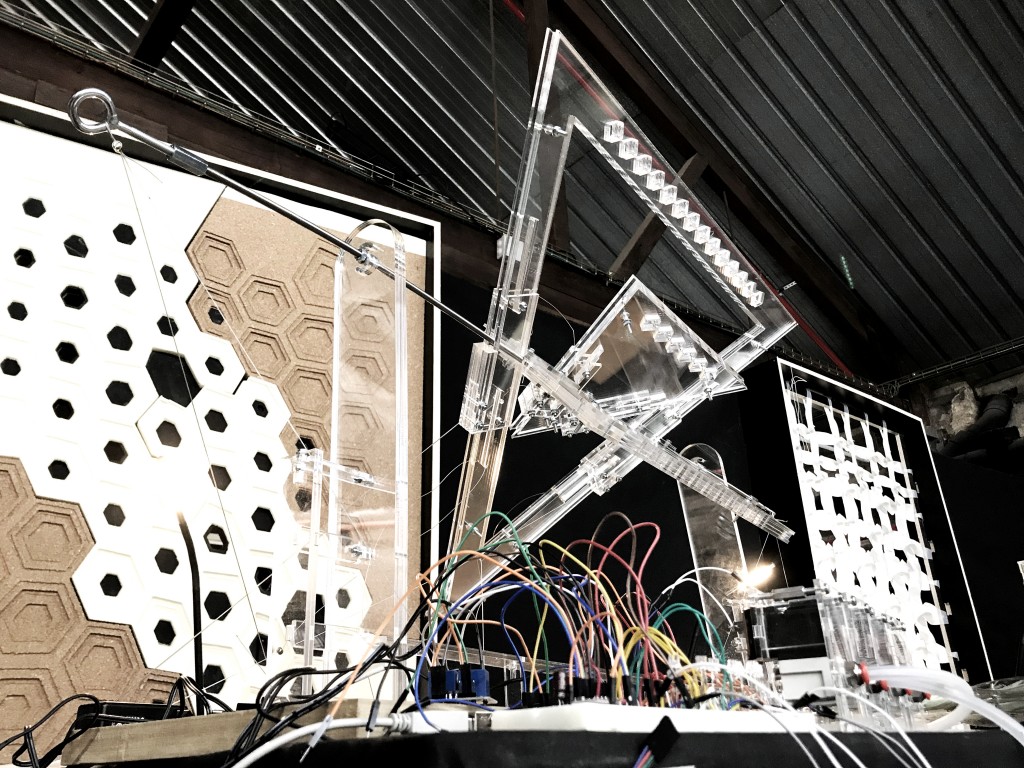

A parametric structural system is being developed for the cells chamber. Depends on the degree of flexibility that the geometry and the rigid vs soft joint combination achieve. This structural system make use of the loft edges in which when combined at different angle, give a different surface and that means shading a different profile at the ground.

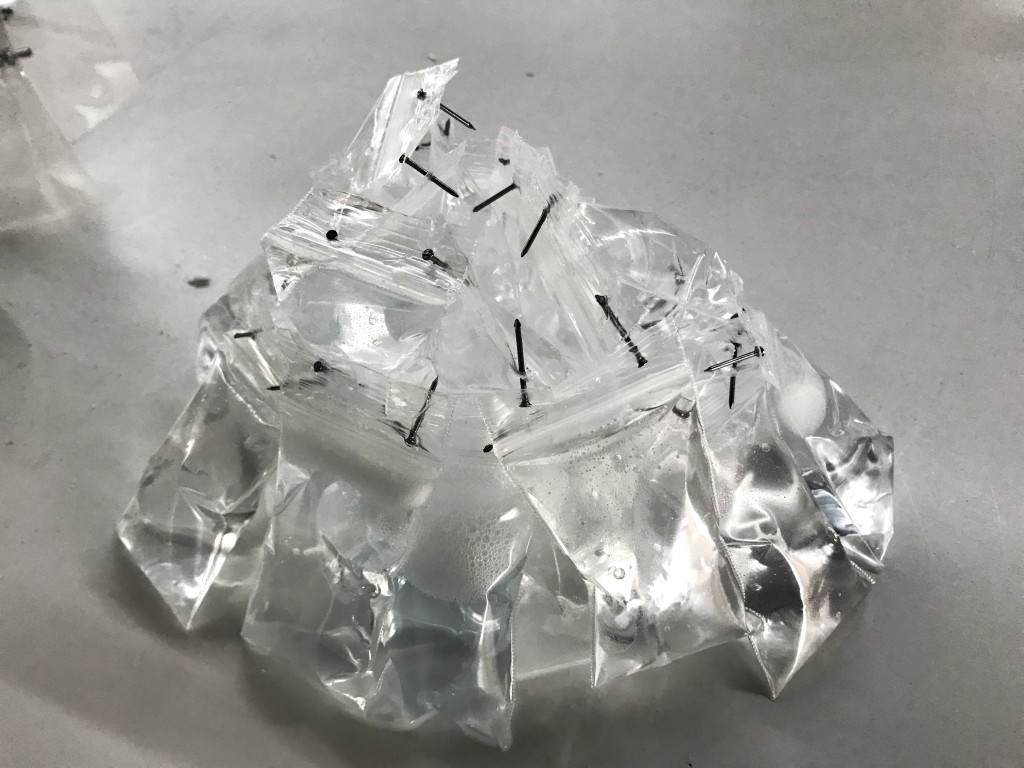

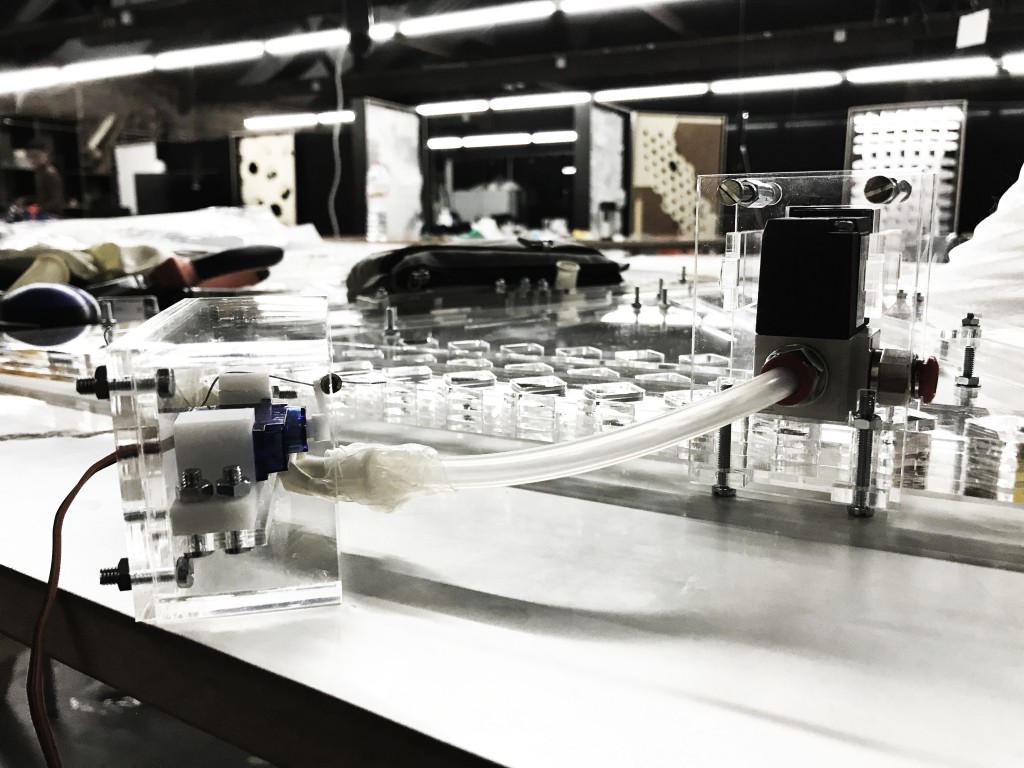

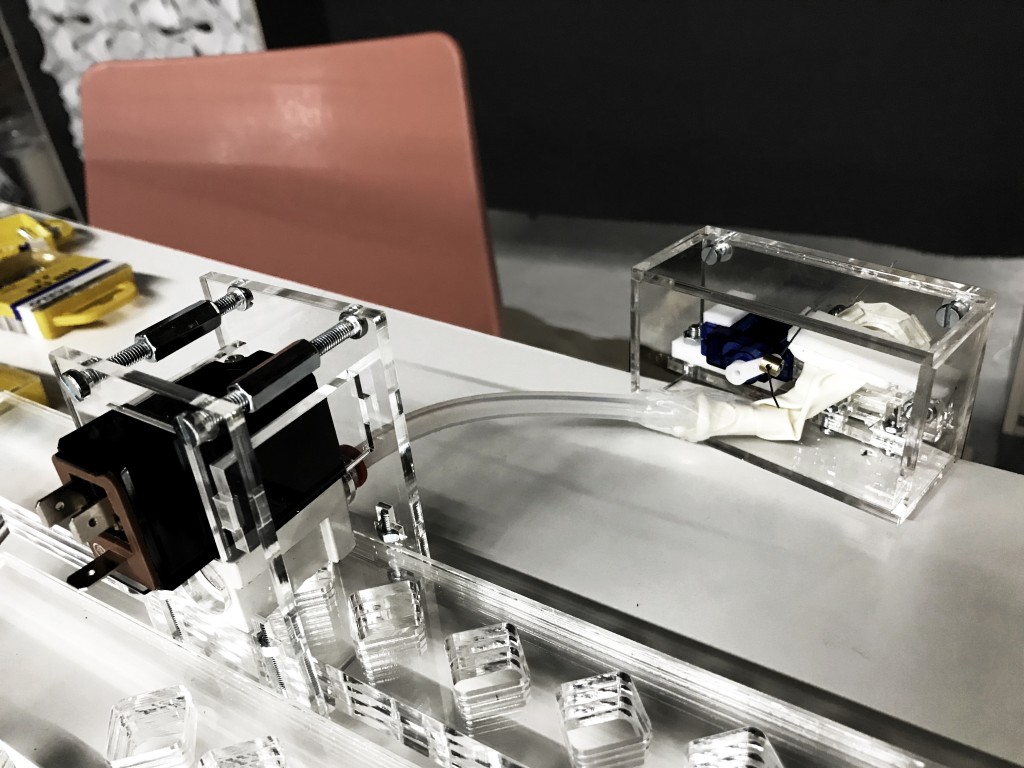

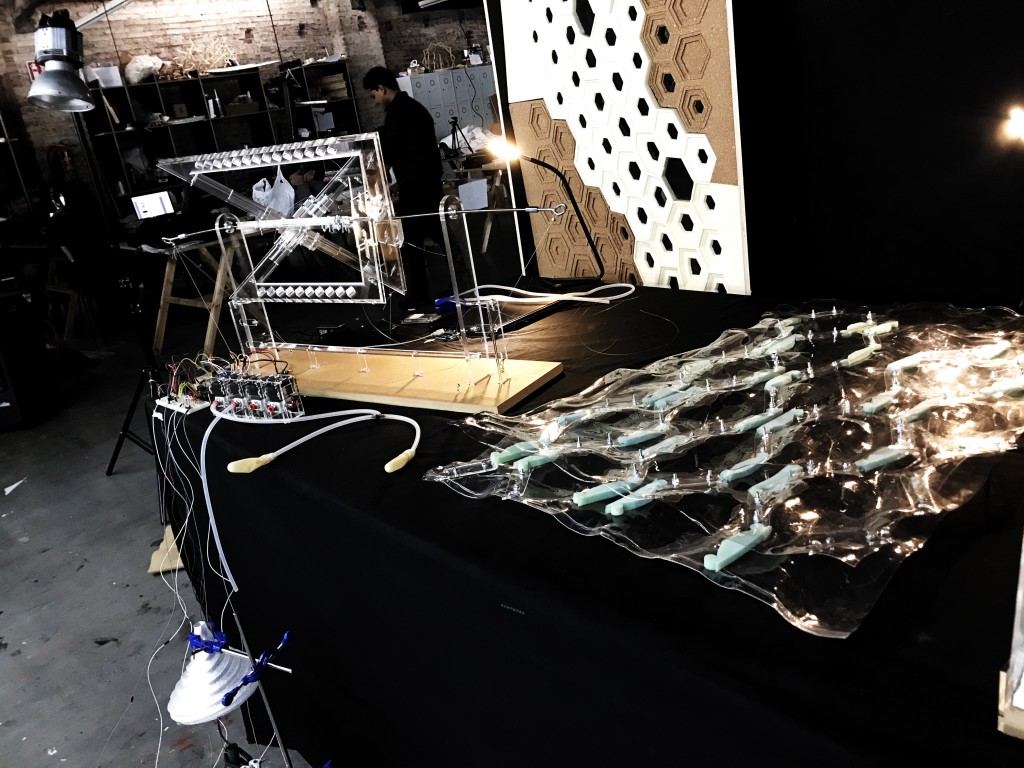

In order to contain the smoke at a specific cell and to read the light sensor value of the darken surface. Valve has to be the stopper of gas. And with vacuum form cells that has low precision, a solenoid valve balloon joint is developed. Options of whether using a compressor to regulate the pressure or using servo-motor controlled clip to contain and release air is being tested.

Since the smoke use, is consumed completely once it is ignite, the thickness and volume of gas release upon burning is tested. In further development, the mid-section of the powder container and the possibility of splitting into multiple but smaller portion to avoid accumulation of gas pressure or leakage will be considered.

Different transparency of material is also being explored when designing the funnel module that divert the smoke into the chamber.

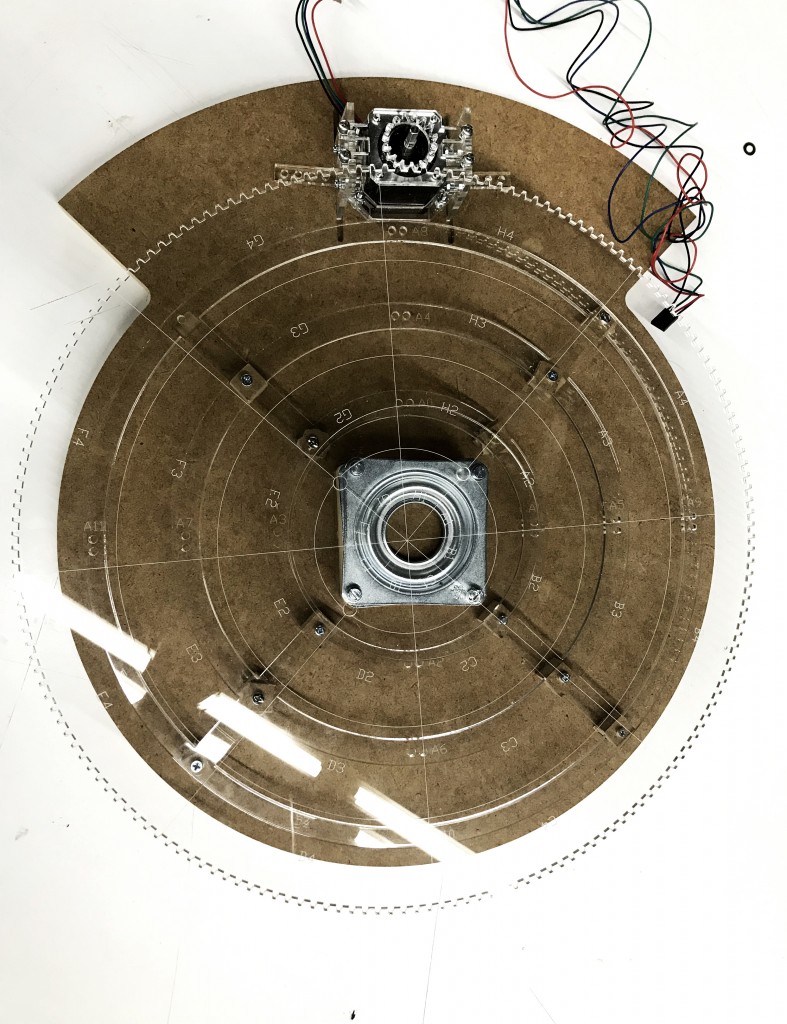

The ground surface simulation in this device and if possible in the future acting as a component that jet up snow specimen to cure portion by portion is designed as a turning plate that when the light sensor under a specific darken surface on top of it detect a decline in light penetrated through, caused by smoke finds and move into the corresponding cell, it turns away and another dark surface is positioned.

The final chamber form by multiple cells combination is shown in photos below:

To further develop the prototype in the next term, a number of aspects will be look into:

- Flexibility of geometry and combination of soft and rigid joint

- Optimize electronic placement and Coding

- Calibrate gas thickness, time-amount release, container of fuel etc.

- Testing of how z-glass react with gas

- Testing of darkening of sugar which resembles the property of snow

- Studied feasibility of device jetting up snow

ATMOSPHERE: TOWARDS A BLUE SKY _ Permafrost is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Master in Advanced Architecture

in 2018/19

by: Timothy Ka Kui LAM

Faculty: ENRIC RUIZ GELI, JOSEP PERELLÓ, MIREIA LUZÁRRAGA ALEJANDRO MUIÑO