CONCEPT

The concept of ‘Arch Stereotomy’ is to explore how contemporary advanced fabrication method can innovate traditaional architecture form.

ARCH STEREOTOMY

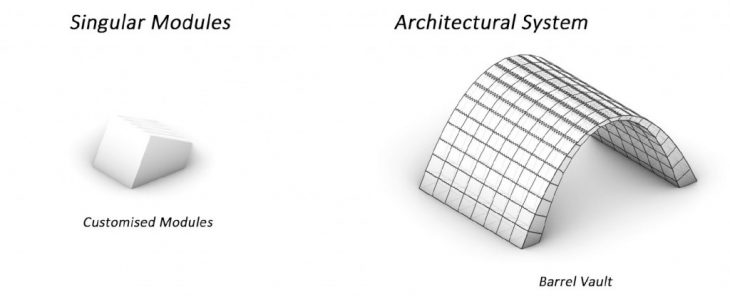

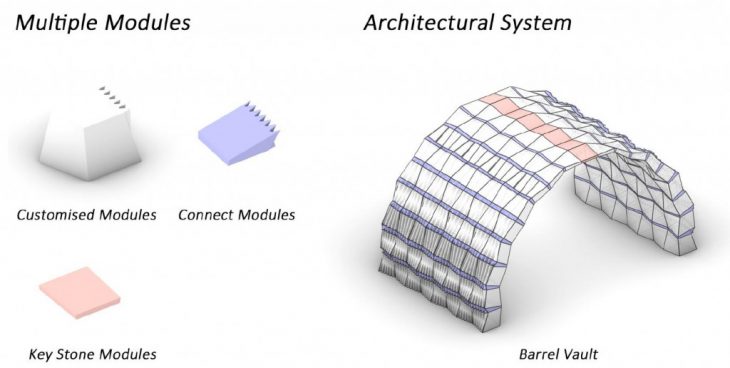

Start from the previous exploration of robotic hot-wire cutting, the main design and explorate objects are the connection system and how to fabricate them efficiently with robotic arm. Thus, our research goal is also to design a proper connection system and apply it into our design.

The advantage of robotic fabrication is that compare with manual fabrication, robots can give us more freedom to customize different modules easily and efficiently. Thus, to efficiently fabricate a performence-based archtecture with robot is possible.

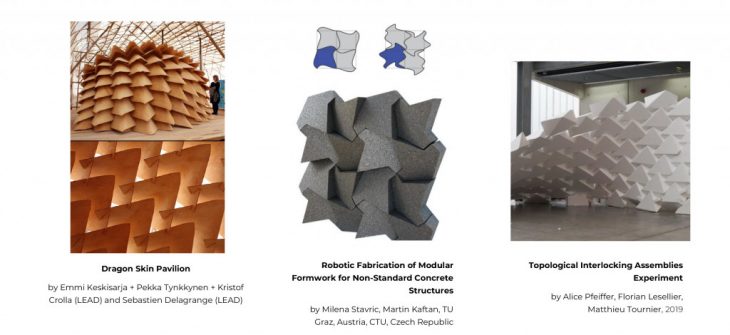

State of Art

Digital Exploration

In the digital exploration, the main goals include two parts: to design the form of the arch and to design the connection system.

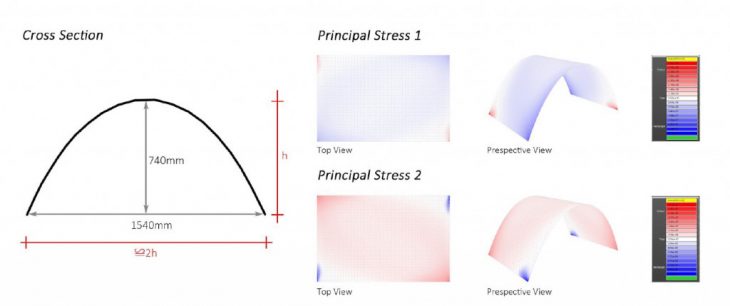

Form Exploration

The form of the arch is generated by Kangaroo. Furthermore, using Karamba to analyse the structure properties of the form. Based on those analysises, we obtained a variable cross-section arch, in which, the thickness values of the arch are determined by the principal strees.

Kangraoo Shape-Forming Process

Karamba Analysis

Connection System Exploration

In the connection system part, the are two different methods: the first one is to apply a interlocked system to improve the stability between two blocks, which is widely studied and applied in contemporary stereotomy. The second one is to introduce a connection modules. The reason we apply a connection modules is that we found it is difficult to fabricate the interlocked joints with the robot arm in the early state. However, we solved this problems later, and went back to the interlocked connection again.

Interlocked Connection

Connection Method 1(Interlocked)

Assemble Process

Modules Connection

Connection Method 2(Without Interlocked)

Assemble Process

Physical Exploration

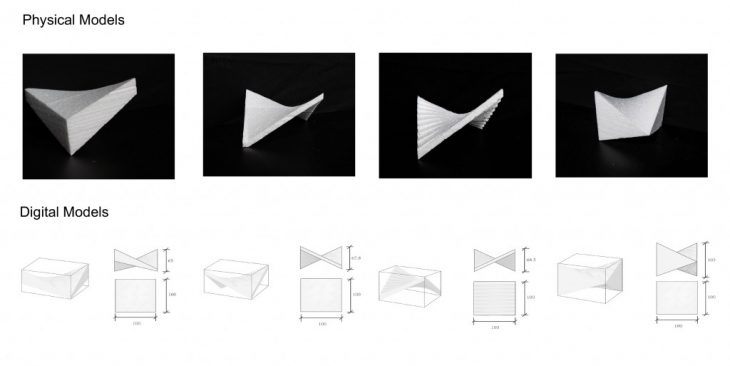

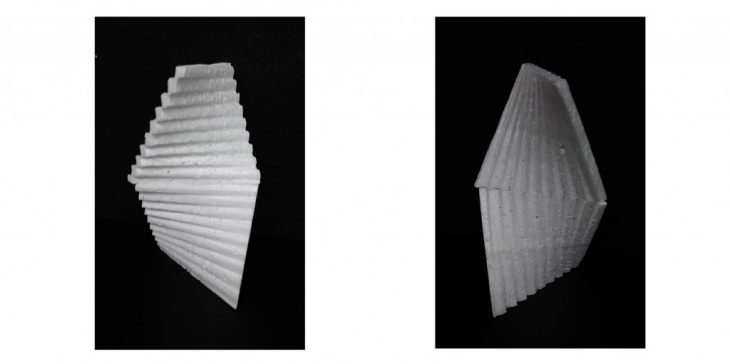

First Fabrication Exploration: Hyperbolic Paraboloid

The first exploration of robotic fabrication start from the hyperbolic paraboloid. For hot-wire cutting technique with only one robot arm, it can only fabricate ruled surfaces. And hyperbolic paraboloids are the only double-curvature ruled surfaces with high structure performance and aesthetics potential. Thus, our first exploration is to fabricate different kinds of hyperbolic paraboloid, and try to find the aesthetics potential of them.

Frist Exploration of Fabricating Hyperbolic Paraboloid

Except the forms, we also tried to apply texture to the surfaces and started to find the possible method to assemble them.

Exploration of Texture

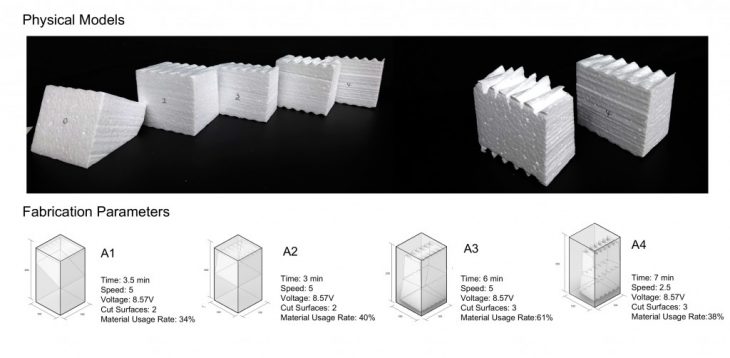

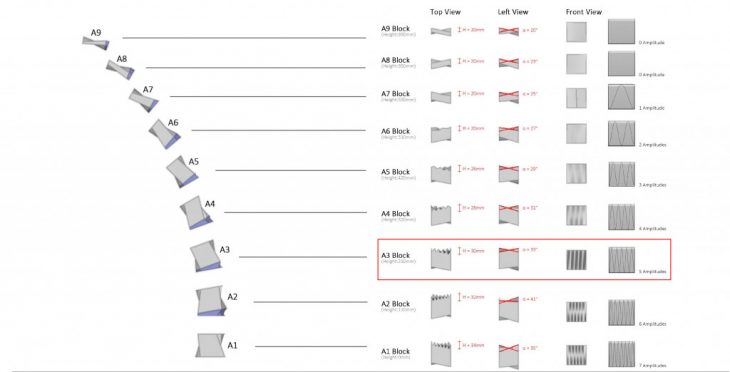

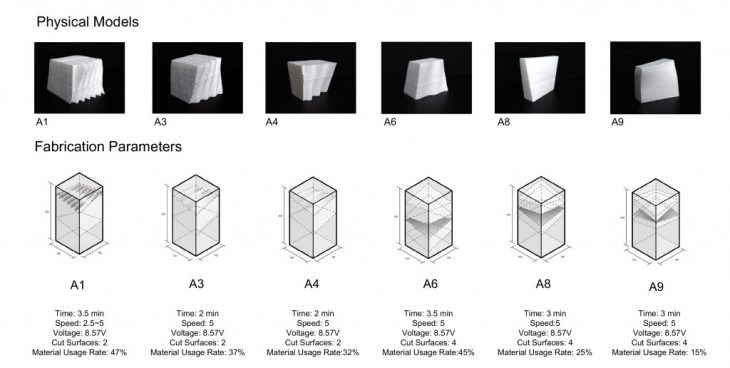

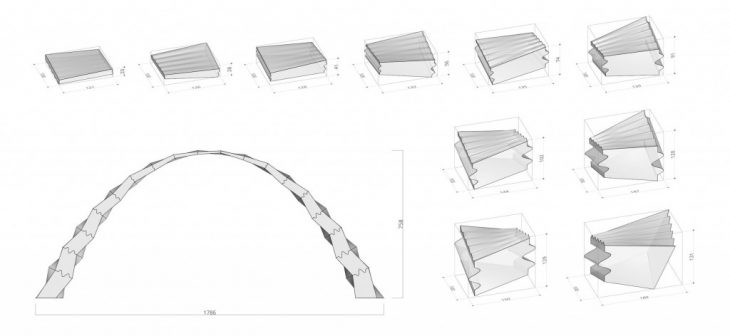

Second Fabrication Exploration: Arch with Interlocked System

The second fabrication exploration is to fabriate the interlocked system. In the fabrication process, we realize that it is important to balance the design proposal and fabrication technique. In order to reach a better connection performance between two blocks, it requires a large amplitude of intersection, however, for robot, it will be difficult to fabricates. And also the fabricarion tolerance will rapidly increase with large amplitude.

Parameters for Modules of Interlockd Arch

Evaluation of Second Exploration

Assemble Process

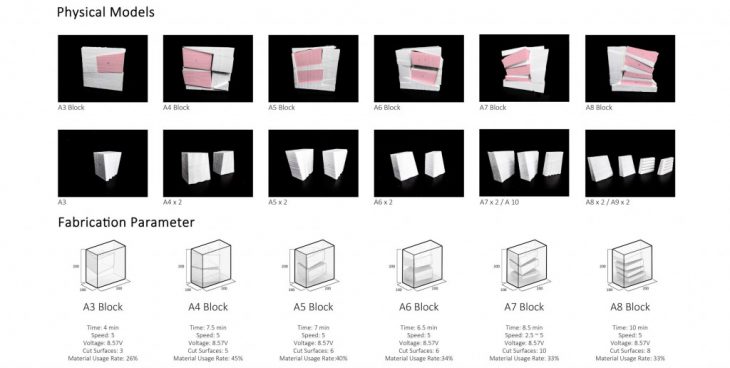

Third Fabrication Exploration: Arch with Connection Modules

The third fabrication exploration is to fabriate the connection modules. Even though it is easier to fabricate the connection modules, however the tolerance problem still exists. Furthermore, in this fabrication exploration, we concluded the best parameters that easy for robot to fabricate and also have a nice aesthetics performance.

Parameters for Modules of Arch without Interlocked System

Evaluation of Third Exploration

Assemble Process

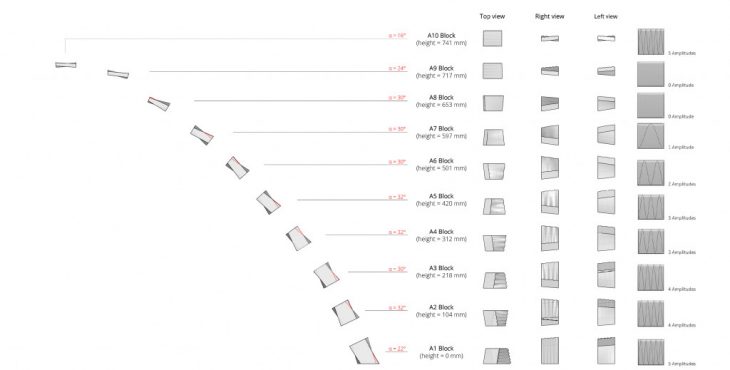

Fourth Fabrication Exploration: Parameters Improvement of Interlocked System

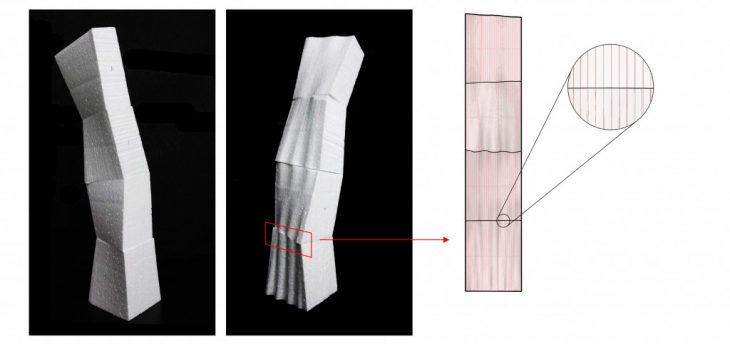

The fourth fabrication exploration is to improve the fabrication process for interlocked system. After a better understanding of the working principle, we improve the fabrication process: to increase the amout of planes for robot to orientate, and adjust the planes for robot, so that the robot can easily reaches the position. The prototypes show that our improvement works, but some new problem appears: the texture doesn’t match. Thus, we try to further simplify the parameters of the blocks.

Parameters for Modules of Improved Interlockd Arch

Evaluation of Fourth Exploration

Issues

Final

Parameters of Modules for Final Production

Parameters of Modules for Final Production

Evaluation of Final Production

Render

Physical Production

Final Production

Final Production with Early Exploration

Veido

</p>

Credits

Arch is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2020/21 by Students: Liang Mayuqi, Elizaveta Veretilnaya, Xingyu Zhang; Faculty: Alexandre Dubor, Ricardo Mayor and Student Assistants: Ilaena Mariam Napier and Madhavi Ojha.