The blog post shows a small summary of my Thesis, in case any process becomes part of your interest and you want to see the full presentation or need any help just reach me!

Contact: Uri Lewis Instagram: @urilewis LinkedIn: https:/www.linkedin.com/in/uri-lewis

ABSTRACT

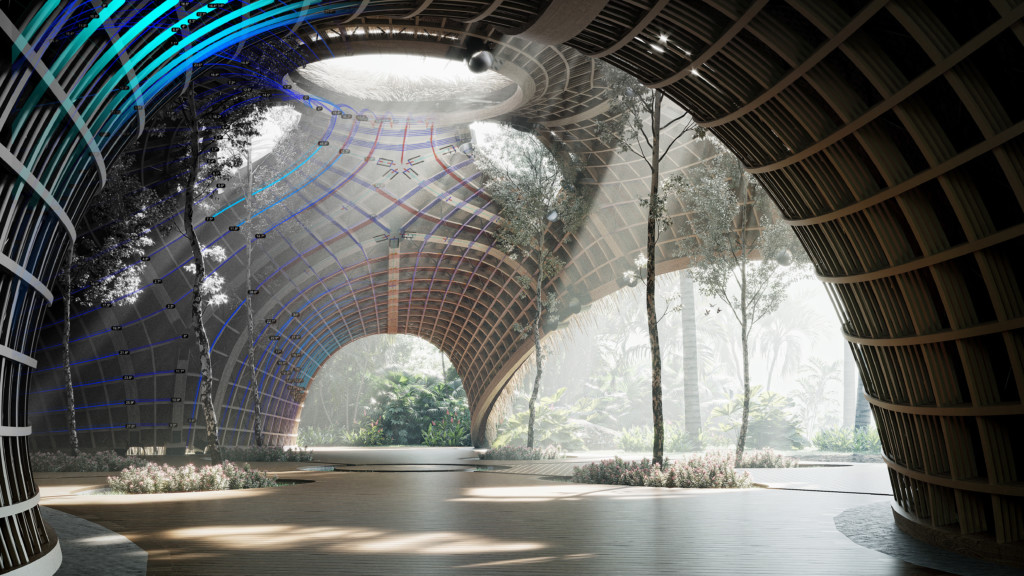

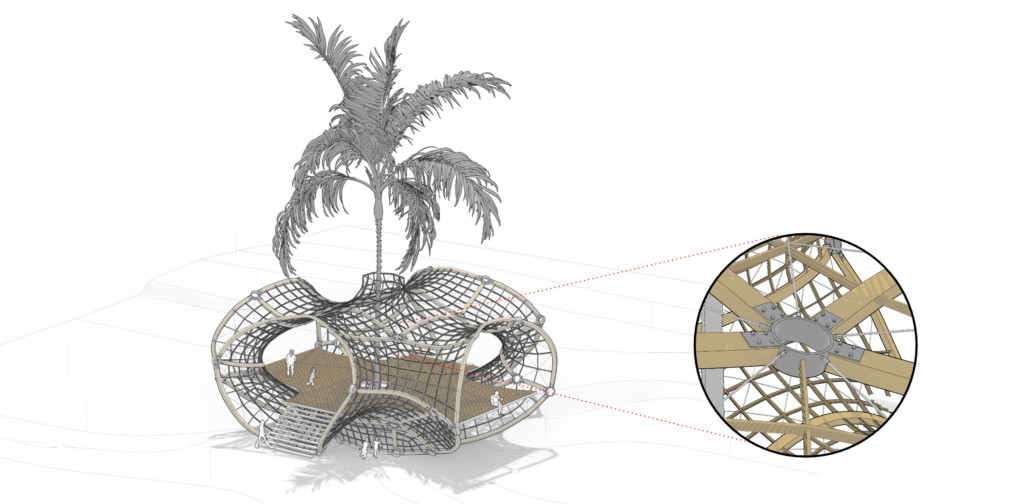

ABSLS “Advances on Bamboo in strip layered structures” Explores the architecture of a strip-based bamboo system which is developed in computation and procedural protocols of tessellation, as well as its analysis considering material properties from the design to precisely define the architectural concerns when working with bamboo strips on a 1:1 scale. Allowing to build large-scale, site-specific complex form structures and offer a diversity of design solutions and exact fabrication plans for an easy assembly.

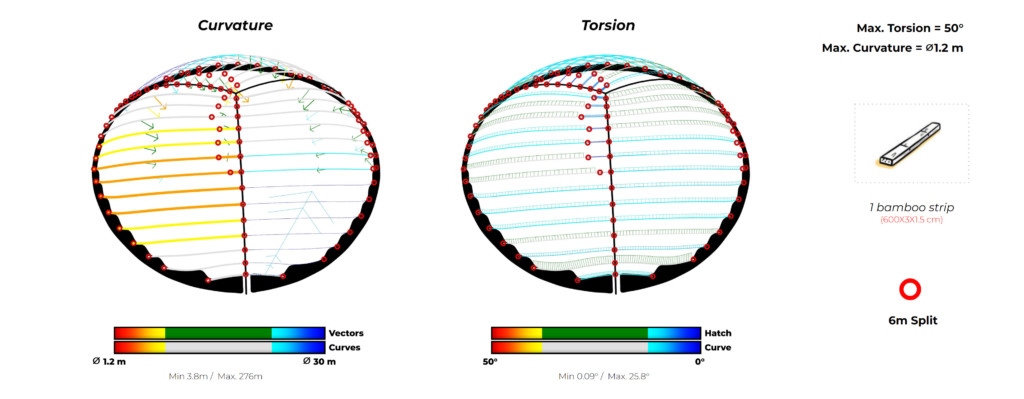

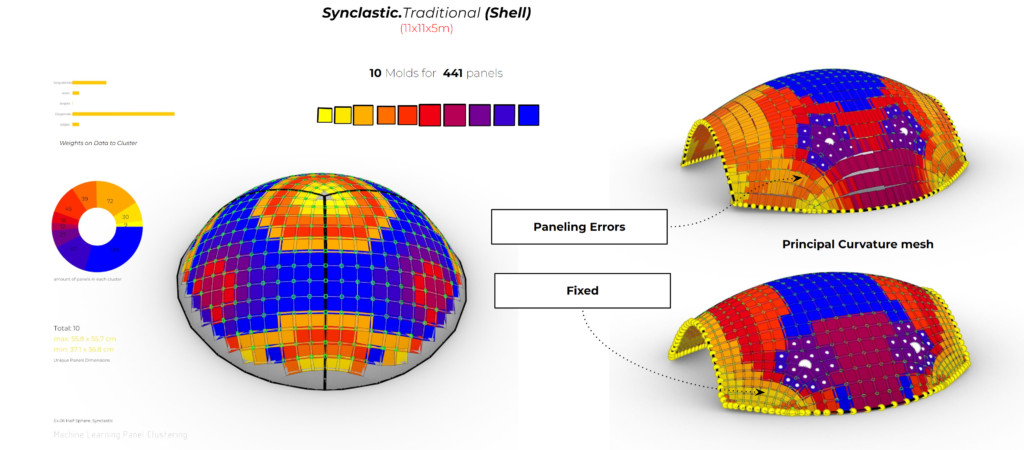

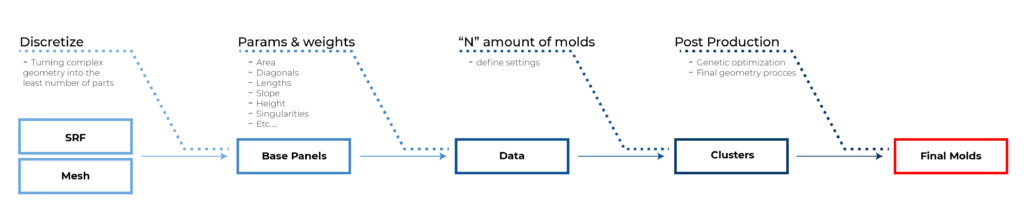

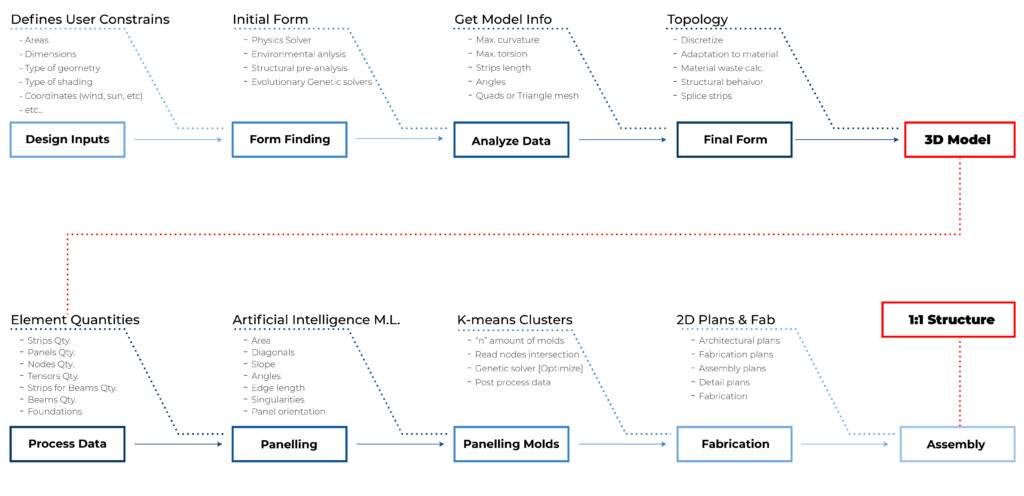

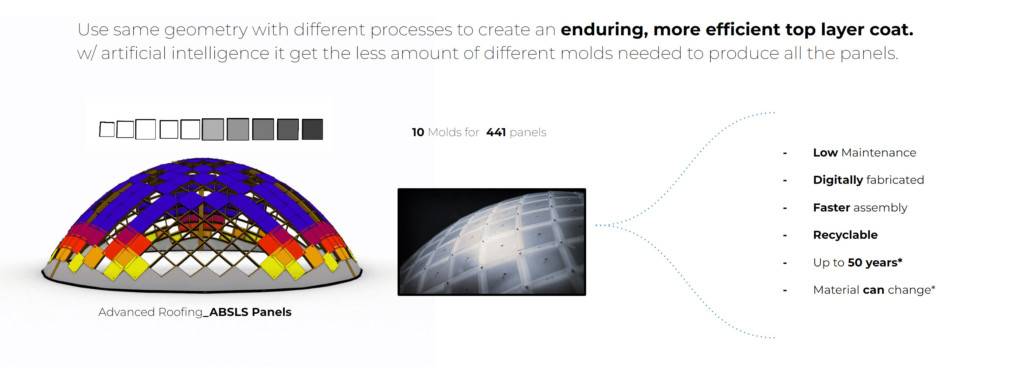

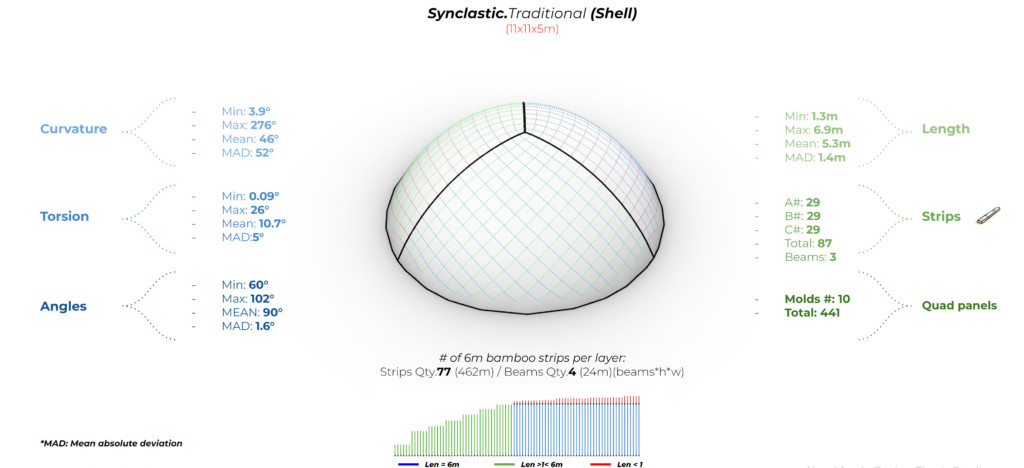

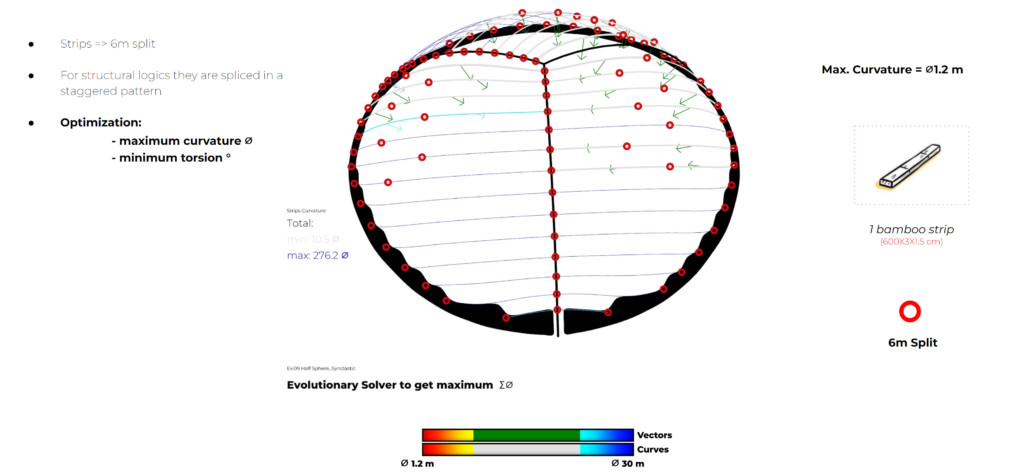

ABSLS it’s a workflow for complex forms to analyze, adapt and optimize geometry considering bamboo strips as a structural material for fabrication. To fully use all the information, geometry is decoded into numbers, which then is used for the analysis, optimization processes, and 2D plans for fabrication. The Script analyzes the designed geometry to splice and fix strips which not meet material properties bounds through a torsion and curvature analysis, it has different discretization methods based on the complexity of the forms to produce the most beneficial strips, beams, and nodes to fabricate; Using the same geometry with artificial intelligence (Machine Learning) plus extra processes gives less variety amount of molds to produce all the needed panels to cover the form; Finally, an evolutionary solver finds the best paneling solution for a 90° nodes intersection.

Bamboo Strip Layered Structures

bamboo culm sliced into strips

- Isotropic section

- Flexible material for nodes and continuity.

- Strips give extra elasticity and resistance (can be overlapped)

Complexity

complexity in forms is a procedural discretization on a 2-dimensional Euclidean space without a topological manifold mesh.

(NOTE: it’s measured in # of steps plus the sub-tasks needed to discretize for fabrication)

Simple Form w = < 5

Semi-Complex Form w = > 5 < 10

Complex Form w = > 10

Workflow

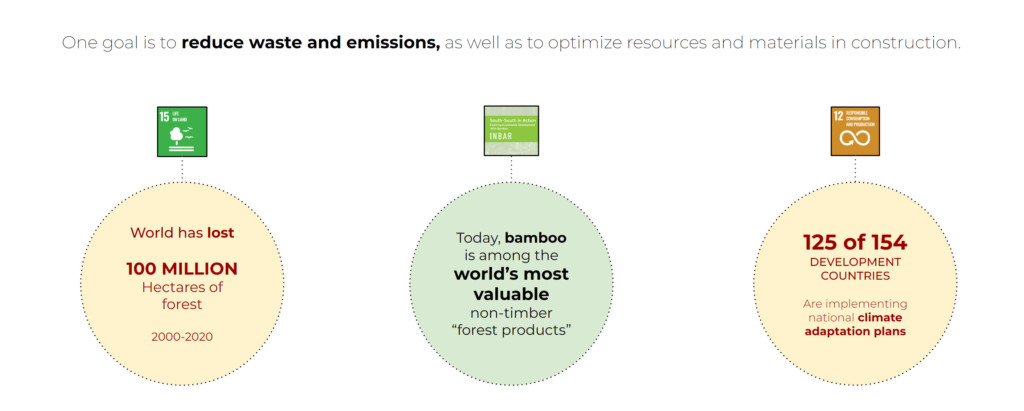

FRAMEWORK.Sustainability Goal

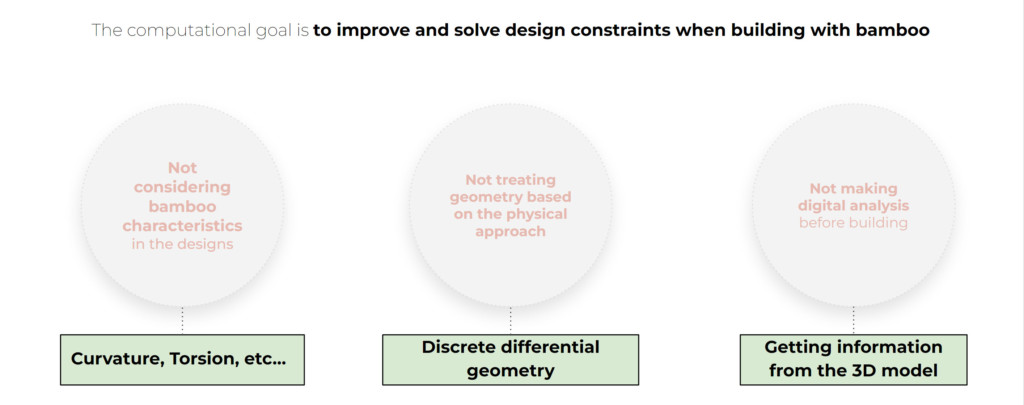

FRAMEWORK.Algorithmic Goal

FRAMEWORK.Coating Goal

These panels can be used as a base for testing materials and get a suitable solution for each case scenario. they can be made from natural materials like crushed bamboo to aluminum, copper, or zink.

STATE_OF_THE_ART

from left to right: MUDHIF HOUSES, 3,300 BC / MINIMA | MAXIMA, 2017 / LUUM TEMPLE, 2019

SCIENTIFIC_INTEREST.Discrete_Differential_Geometry

The interest becomes one of turning complex geometry into the least number of parts and at the same time innovating how this should be analyzed to achieve the most beneficial discretization for the panelling, fabrication & assembly.

Animated processes of discretization

AlgorithmS.Form Analysis

Before: normal splitting

After: Optimization process to find best t positions for splitting

Algorithm_Strategies.Paneling

———more content is in the process to be added to the BlogPost ————