Advancing Wood Housing Tectonics

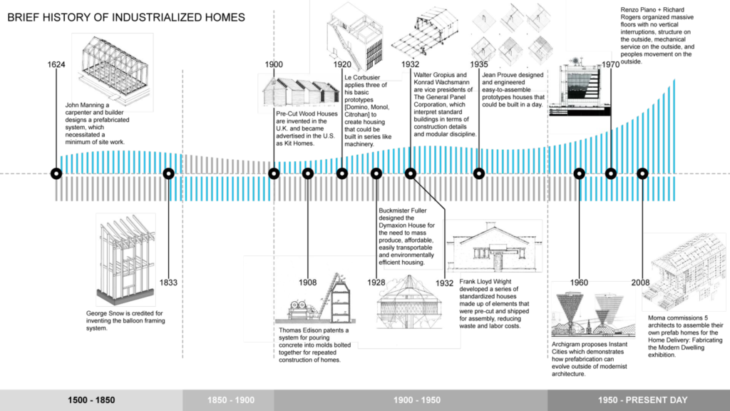

Shelter is a continuous factor which has allowed for human development to advance, and yet we are disconnected from current means on how homes are constructed. The goal of my research is to propose a housing kit which is affordable through the development of modular construction and fabrication manufacturing. The final development will be carried out by the simplicity of utilizing such kit, which educates and inspires people to become homeowners.

First, the research identifies key methods found in current industrialized housing and develops a new hybrid model for wood modular home assembly.

Second, typical methods used in home construction are evaluated to extract tried and tested methods.

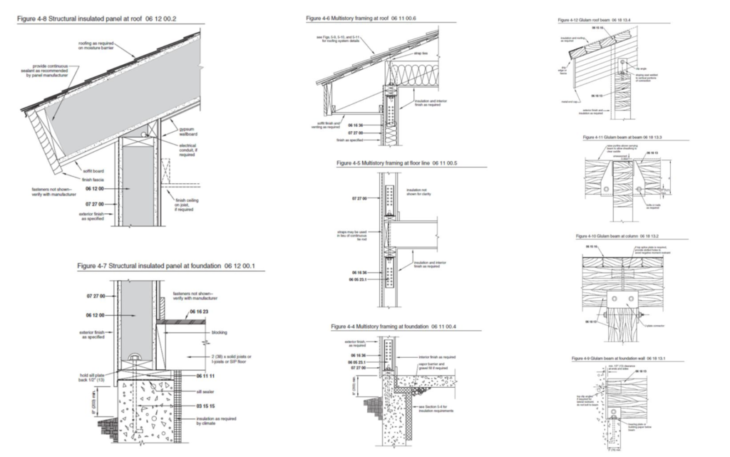

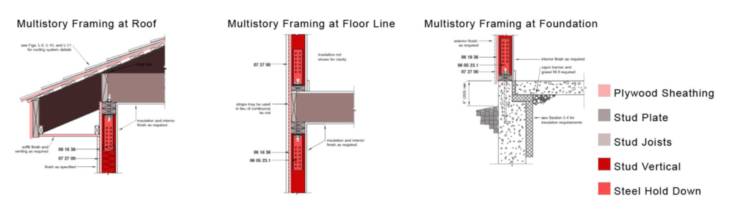

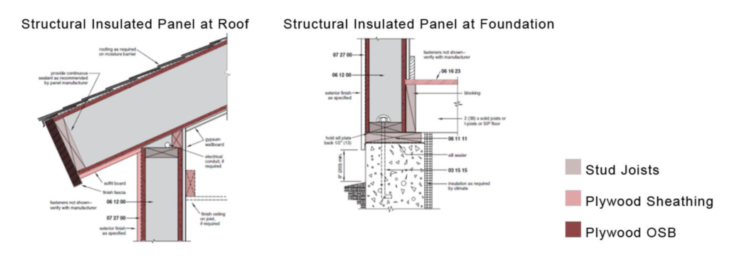

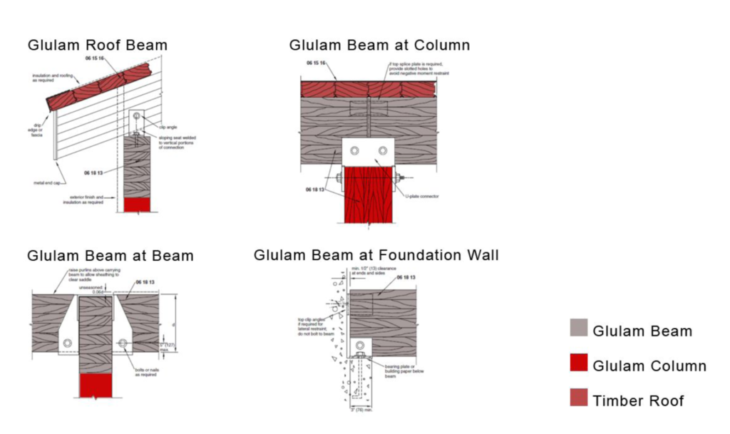

The complexity of the standards found in wood home construction are limited to only 3 categories. From left we have Structural Insulated Panels [SIP], in center multistory platform framing, and on the right glulam timber framing.

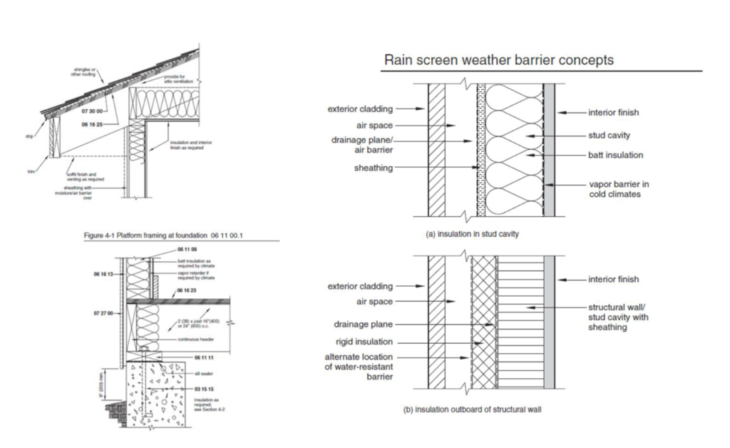

Platform framing is evaluated in section to the relationship between assembly of materials and structural elements.

Multistory framing is a combination of platform framing, but is supplemented with an additional reinforcement of a steel hold down.

Structural Insulated Panels, follow a similar logic to platform, but ultimately replace the vertical wood stud with a panel similar to all of the parts found throughout the system.

Finally, a glulam system makes use of density and makes use of volume for wood product elements based on their nominal sizes. This requires additional reinforcement of steel connections.

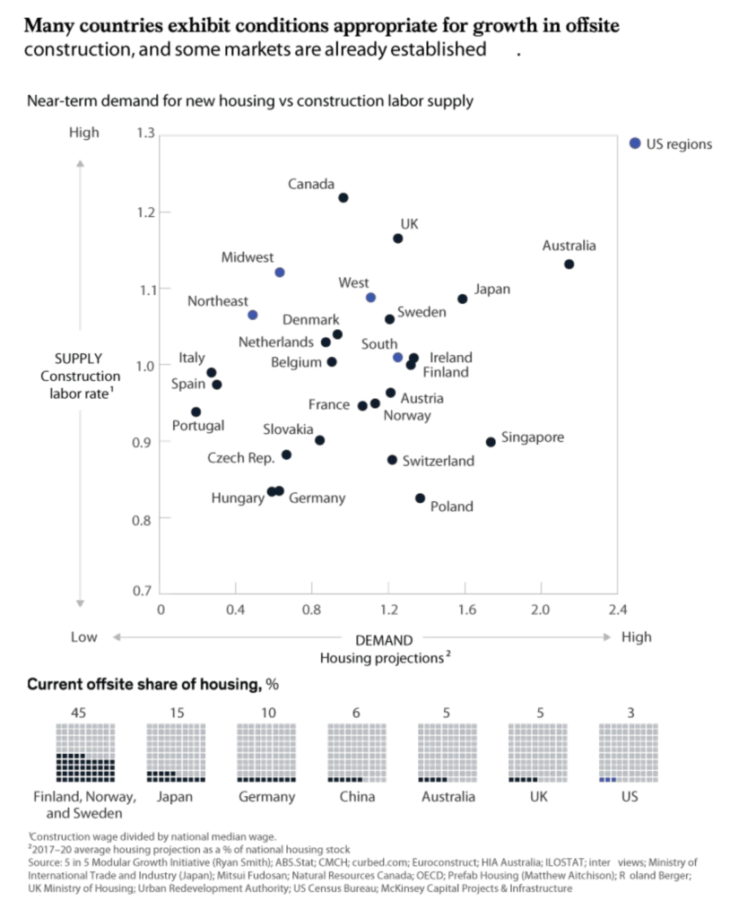

Globally we see that Eastern European countries are carrying out the use of modular fabricated construction systems. Additionally, this implies that a labor workforce is also shifting globally as Japan and German follow through housing projections.

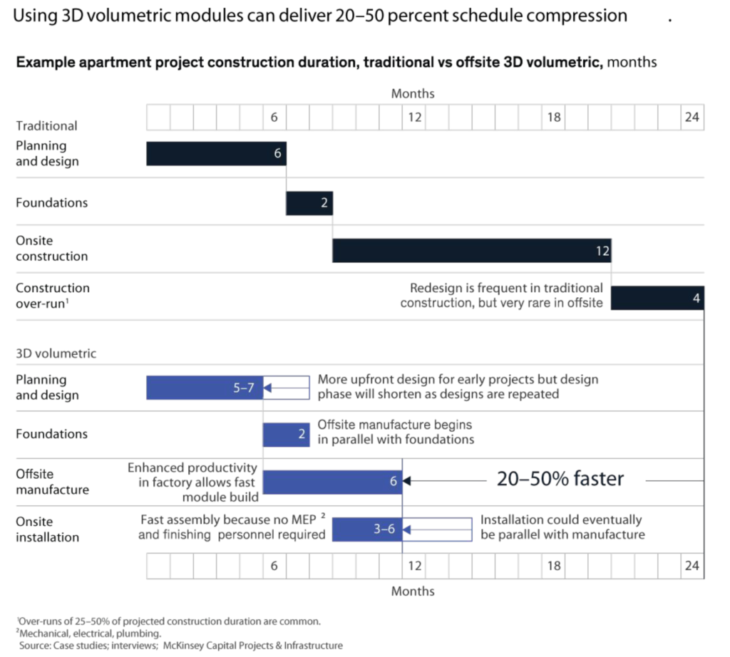

By designing a wood fabricated system it is possible to reduce cost and time found in traditional home construction methods. This is hypothesized in most economical analyses of construction industry innovation means.

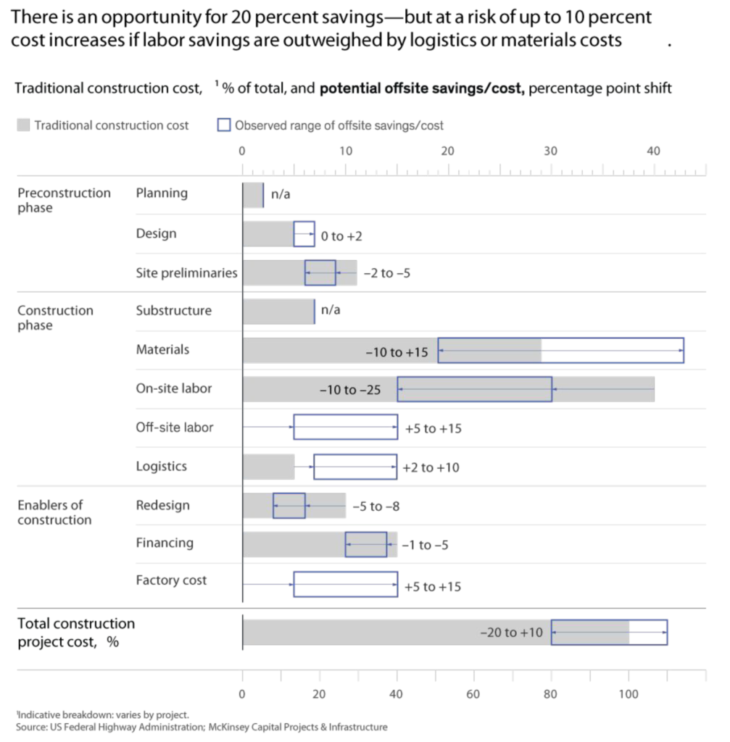

What this means is that any new construction system may fall in risk of either being under cost or over cost. The above graph demonstrates where those opportunities or risk can be expected [blue bar].

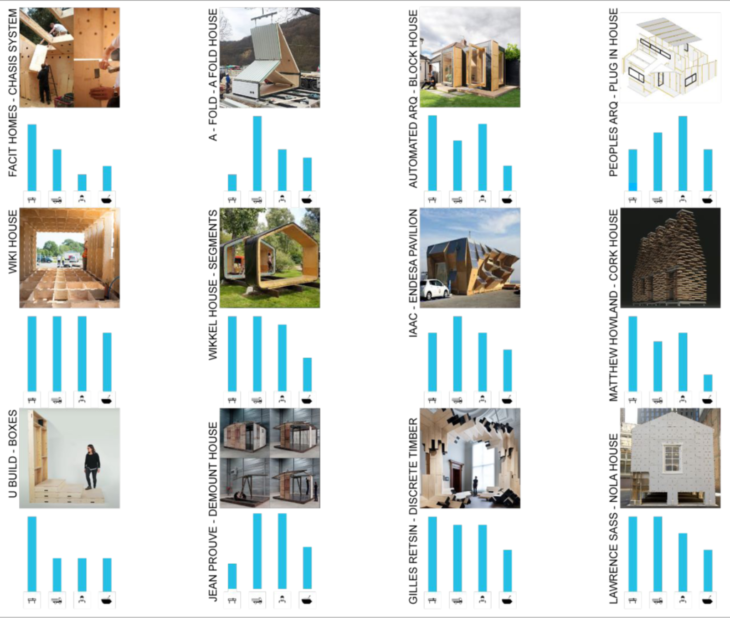

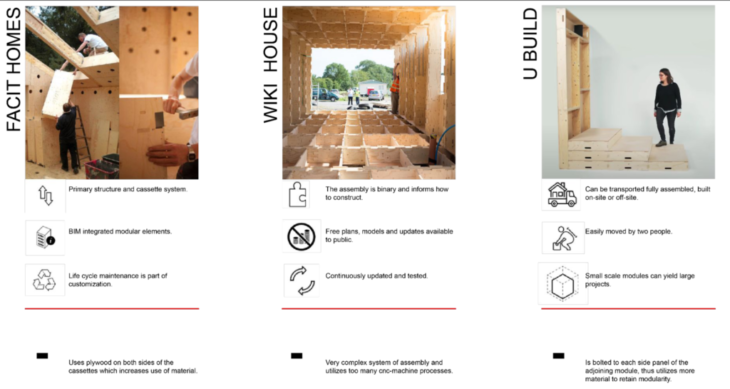

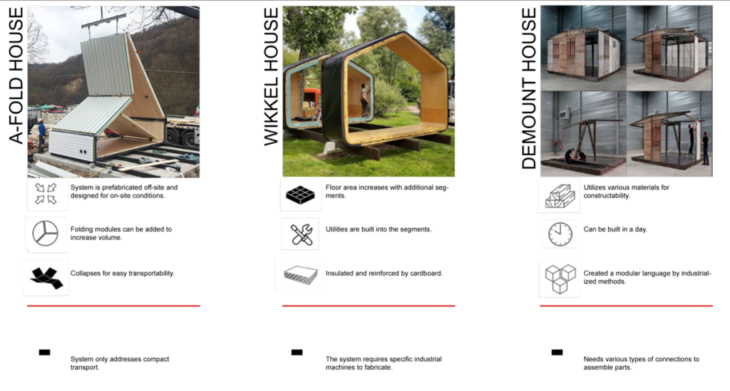

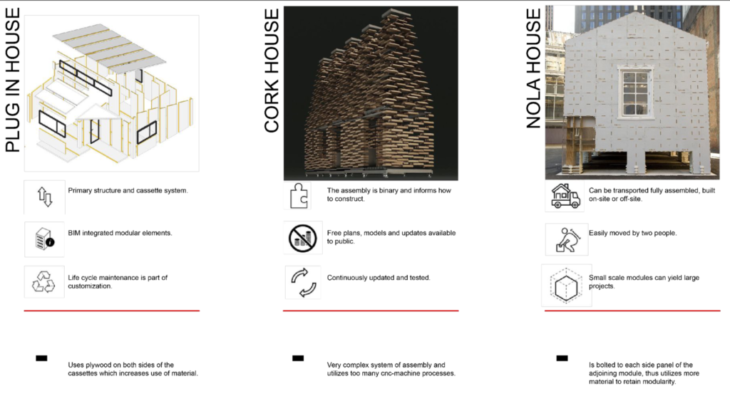

A series of housing case studies are evaluated to help direct the current innovations of designing housing systems with wood.

From this point of view a wood product can be computationally evaluated and adjusted to reform fabrication time, joinery connection, or performance.

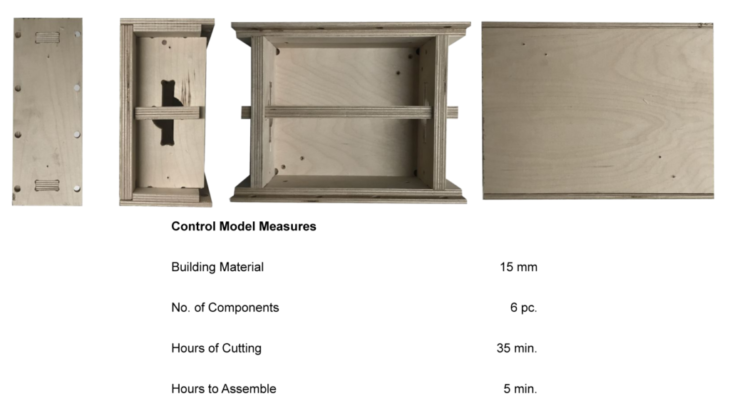

It may be possible to fabricate a module that replaces stick framing construction.

Tests were done with nominal sized wood [precut] then glue laminated to evaluate technical requirements for Cnc machining.

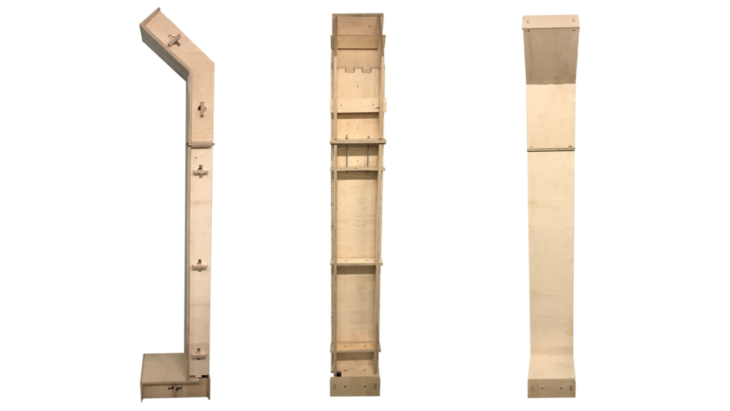

Integrating Joinery into Various Planes of the Module

Learning from Full Scale Fabrication A] Roof Node B] Wall Node C] Floor Node

Learning from Full Scale Fabrication A] Locking Blocking B] Overlapping Planes C] Insulation Cavity D] Envelope E] Extension for Modules F] Habitable Space