Additive Manufacture of Cellulose-based Bio-Material on Architectural Scale_Theory and Knowledge

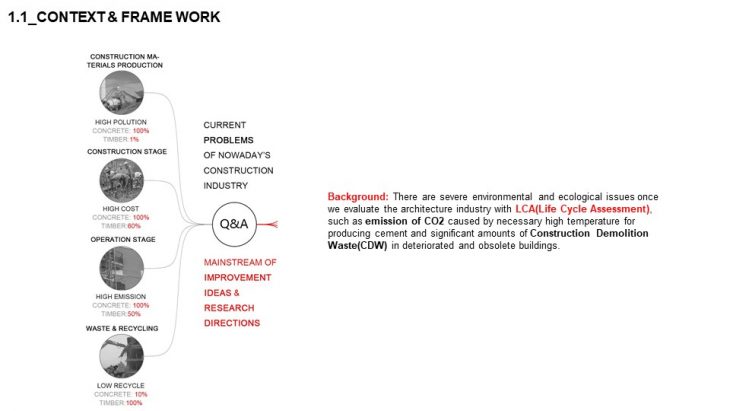

Background:

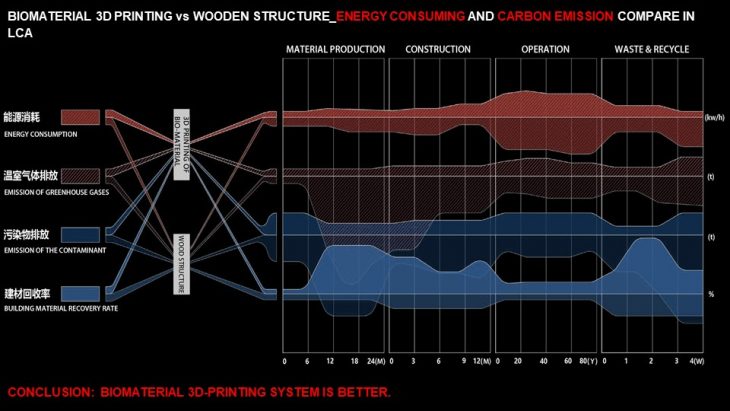

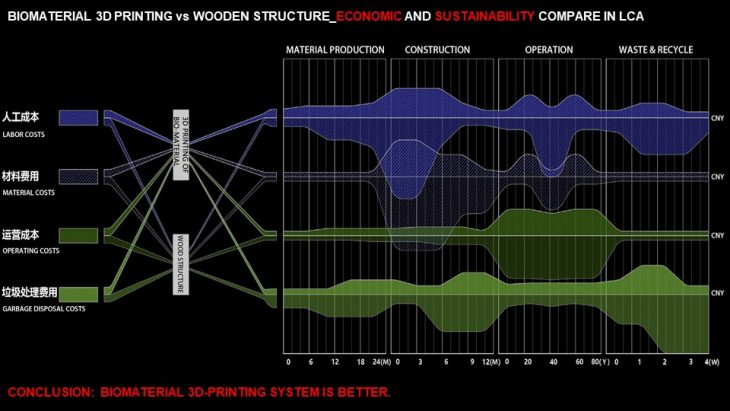

There are severe environmental and ecological issues once we evaluate the architecture industry with LCA(Life Cycle Assessment), such as emission of CO2 caused by necessary high temperature for producing cement and significant amounts of Construction Demolition Waste(CDW) in deteriorated and obsolete buildings.

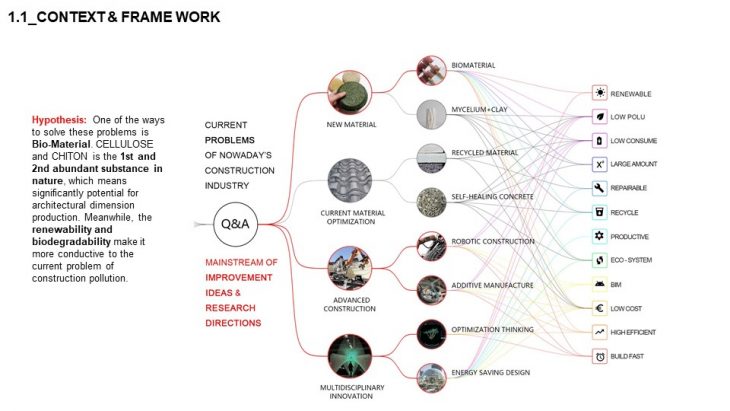

Hypothesis:

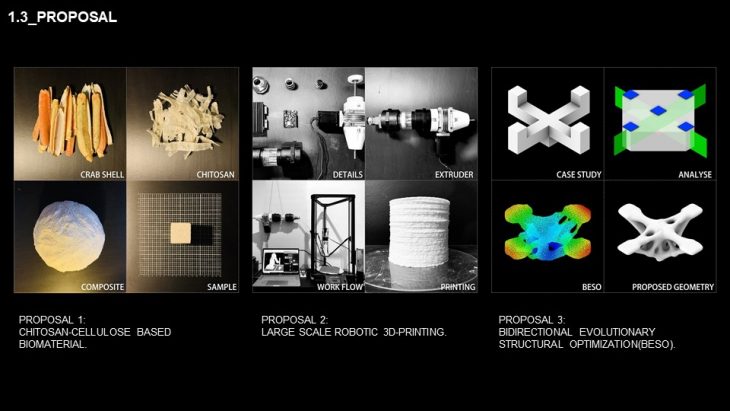

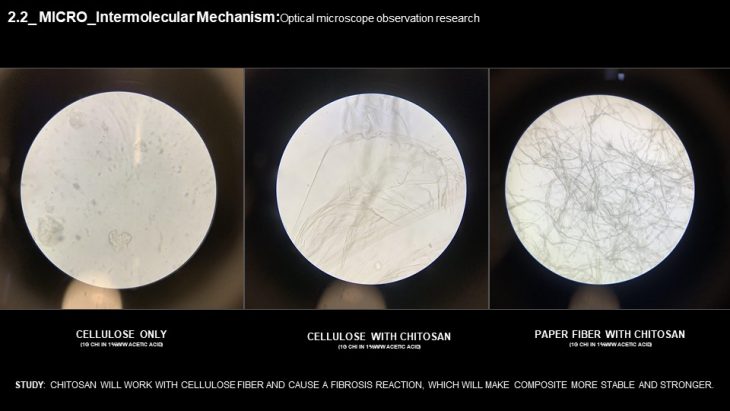

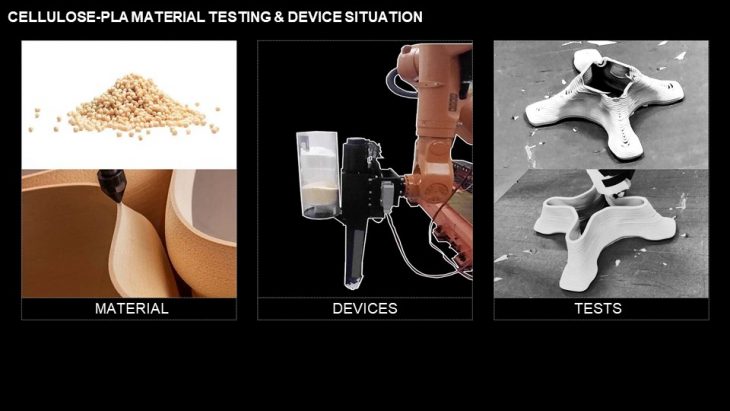

One of the ways to solve these problems is Bio-Material. CELLULOSE and CHITON is the 1st and 2nd abundant substance in nature, which means significantly potential for architectural dimension production. Meanwhile, the renewability and biodegradability make it more conducive to the current problem of construction pollution.

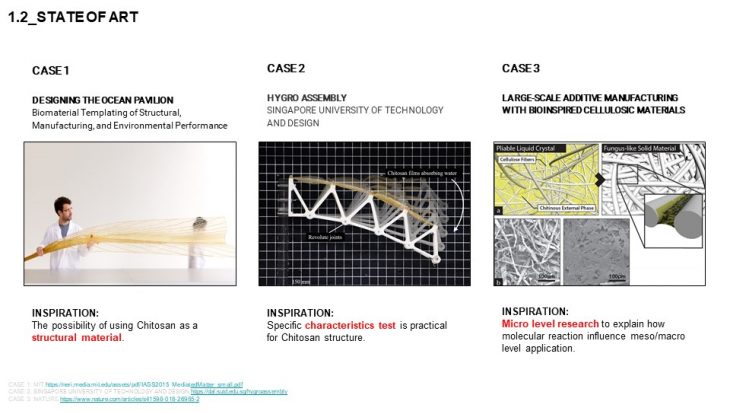

Method:

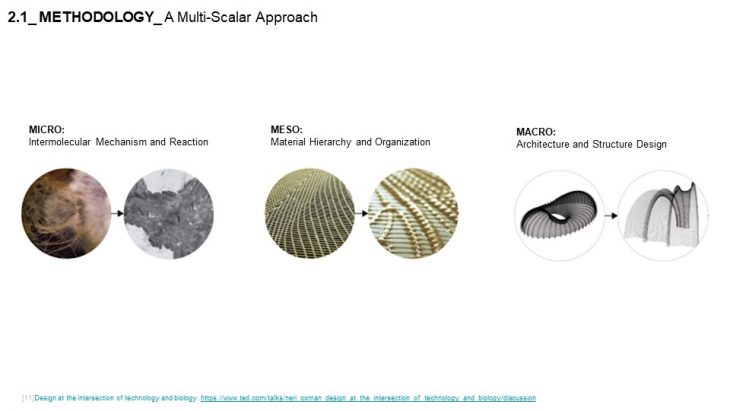

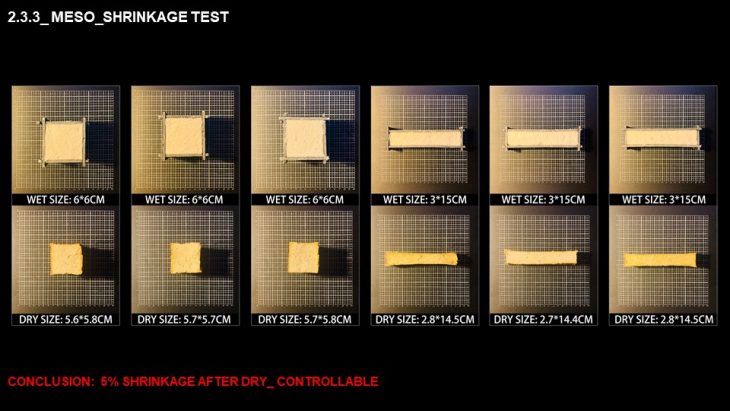

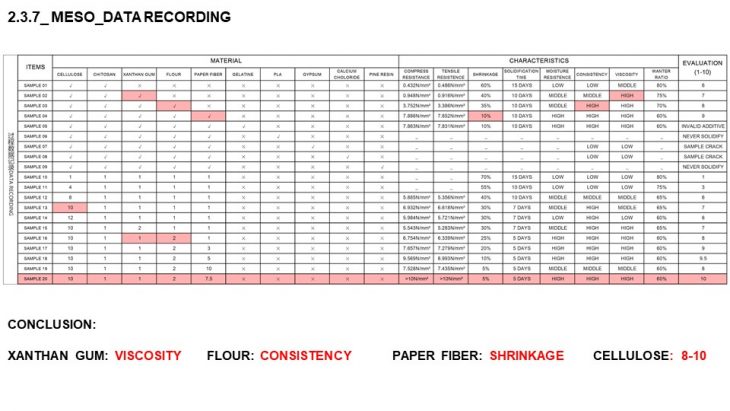

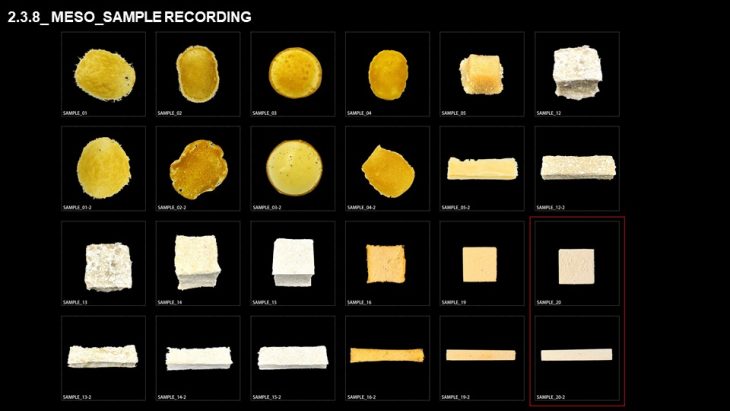

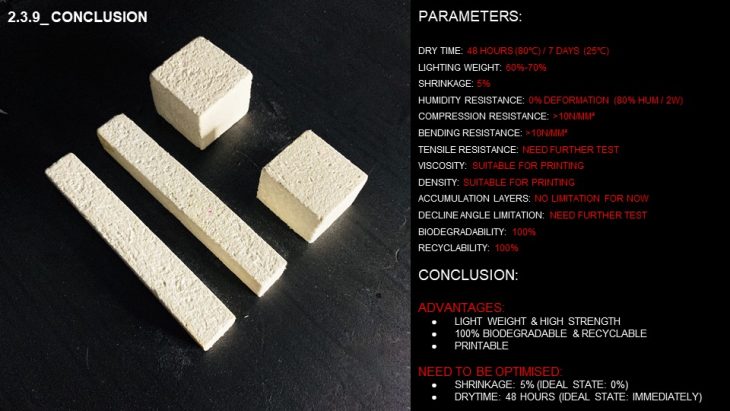

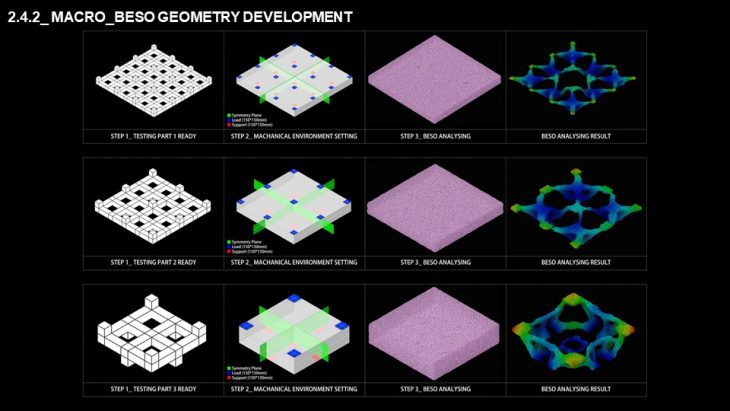

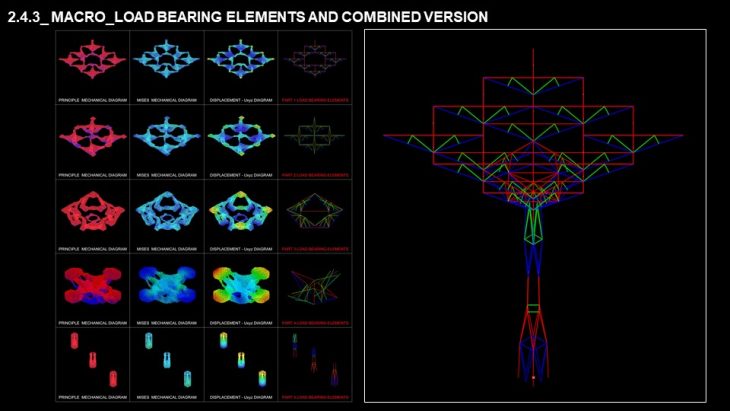

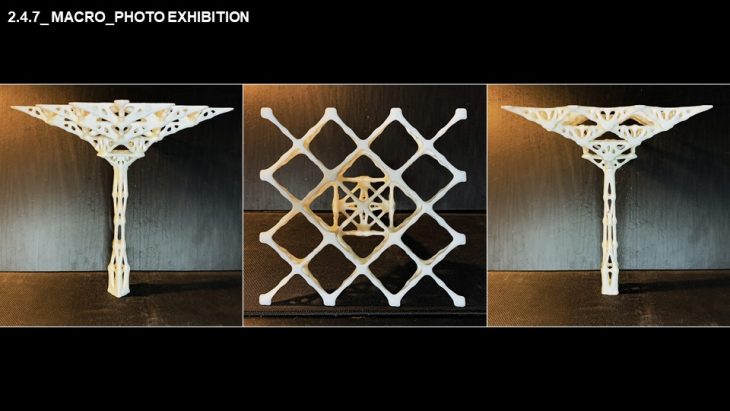

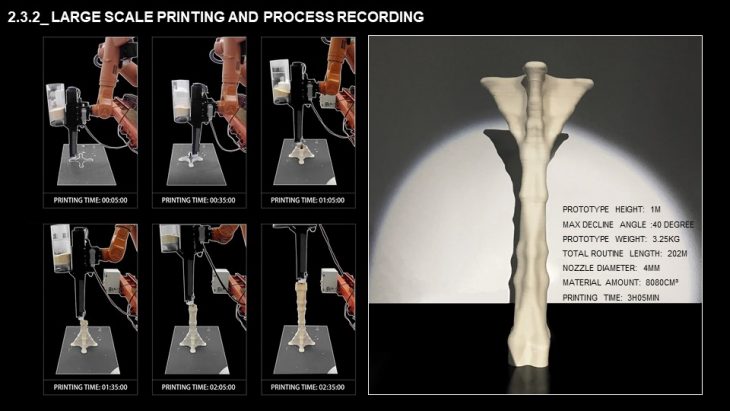

The purpose of this study is to explore Cellulose Based Biomaterial and bring it into architectural scale additive manufacture that engages with performance in the material development, with respect to time of solidification and control of shrinkage, as well as offering mechanical strength.

Result:

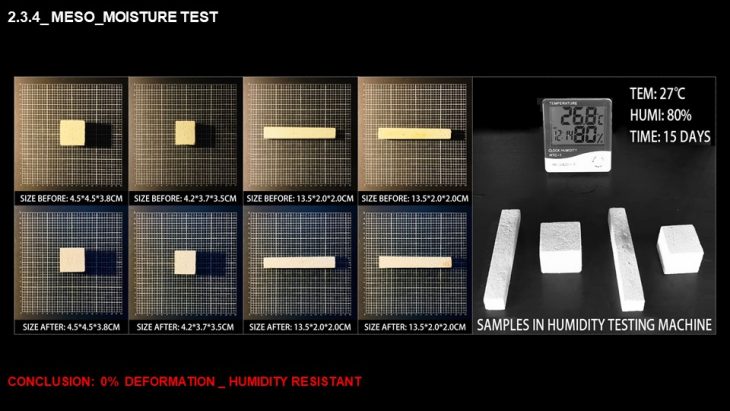

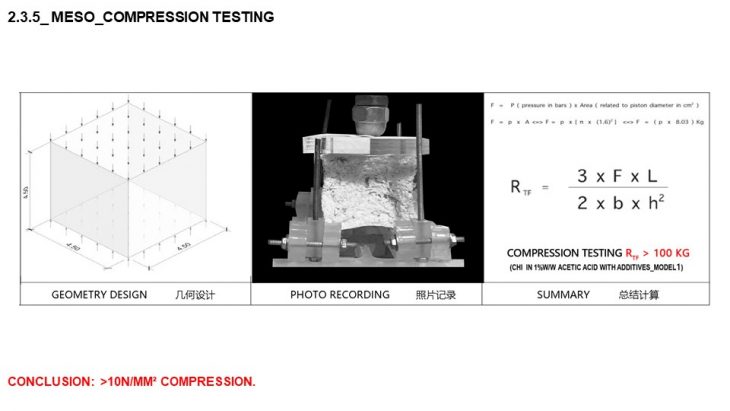

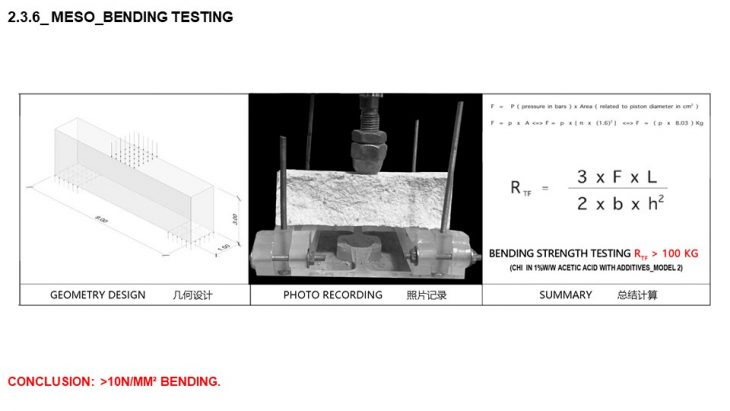

At present, the experiments have proved the possibility of developing a cellulose-chitosan based composite into 3D-Printing Construction Material. Moreover, The research shows that the characteristics (Such as waterproof, bending, compression, tensile, transparency) of the composite can be enhanced by different additives( such as xanthan gum, paper fiber, flour ), which means it can be customized into various architectural components based on Performance Directional Optimization.

Conclusion:

This solution has a positive effect on environmental impact reduction and is of great significance in putting the architectural construction industry into a more environment-friendly and smart state.

KEYWORDS: Chitosan, Cellulose, Biomaterial, Mechanical Strength, Environmental Impacts Reduction, Performance Directional Optimization.

BIBLIOGRAPHY:

Self-healing Organic Concrete: [1]Delft University of Technology, Faculty of Civil Engineering and Geosciences, Materials & Environment section, Stevinweg 1, NL-2618 CN Delft, The Netherlands. [2]Self-Healing "Bio" Concrete Repairs Its Own Cracks. Functional Graded Material: [3]Functionally Graded Materials Are Key to Fast, Effective Multi-Material 3D Printing. May 7, 2018 by Clare Scott3D Printing3D Printing Materials Science & Technology [4]Computational Blends: The Epistemology of Designing with Functionally Graded Materials. Dr Kostas Grigoriadis, Architectural Association School of Architecture, Londonhttps://www.architecture.com/awards-and-competitions-landing-page/awards/riba-presidents-awards-for-research/2018/computational-blends

[5]RESEARCH OF FUNCTIONALLY GRADED MATERIALS MANUFACTURING. [6]Broken Nature - symposium no.2 - NERI OXMAN [7]L'impression 3D révolutionne l'art et le design -- Objet pour Neri Oxman -https://www.youtube.com/watch?v=y4xq1NT8f1o

[8]Neri Oxman: A 3D printing pioneer and visionaryhttps://www.sculpteo.com/blog/2016/10/05/neri-oxman-a-3d-printing-pioneer-and-visionary/

[9]NERI OXMAN, FOUNDER OF MEDIATED MATTER LAB — PART 1 [10]NERI OXMAN, FOUNDER OF MEDIATED MATTER LAB — PART 2 [11]Design at the intersection of technology and biology [12]NERI OXMAN - Bio Inspired Design Structure Optimization: [17]SolidThinking Inspire - Lattice Structure Optimization\ [18]Altair Inspire(software for 15days trial) [19]Ameba Topology Optimization Software Based on Grasshopper [20]Topology optimization: Introduction(Force diagram and analysis) [21]The incredible inventions of intuitive AI | Maurice Conti Bio-Material 3D-Printing: 3D Printing of Mechanically Stable Calcium?Free Alginate?Based Scaffolds with Tunable Surface Charge to Enable Cell Adhesion and Facile Biofunctionalization Zifeng Lin Mingming Wu Huimin He Qingfei Liang Chengshen Hu Zhiwen Zeng Delin Cheng Guocheng Wang Dafu Chen Haobo Pan Changshun Ruan

CREDITS:

Program: Master in Advanced Architecture 2 (theory and knowledge project)

Student: Yimeng Wei

Faculty: Manuel Gausa and Jordi Vivaldi