A.B.S.E.N.T. / FACADE SYSTEM // R.1 STUDIO I

A.B.S.E.N.T. (aggregation based skin effectively nuancing transparencies) is a project by MRAC 01 students Charngshin Chen and Helena Homsi during the Studio 1 seminar of the first term. The studio was taught by MRAC co-director Alexandre Dubor and IAAC faculty Raimund Krenmueller.

During this 7-week studio course, students were asked to explore bottom up and top down design explorations in order to come up with an aggregation system inspired by a random object that could easily be aggregated.

This group started with a simple poker card and designed a facade system using one component inspired by the initial object. Using digital fabrication tools and robotic assembly, students had to illustrate the design-to-fabrication process into a coherent proposition.

01. Context

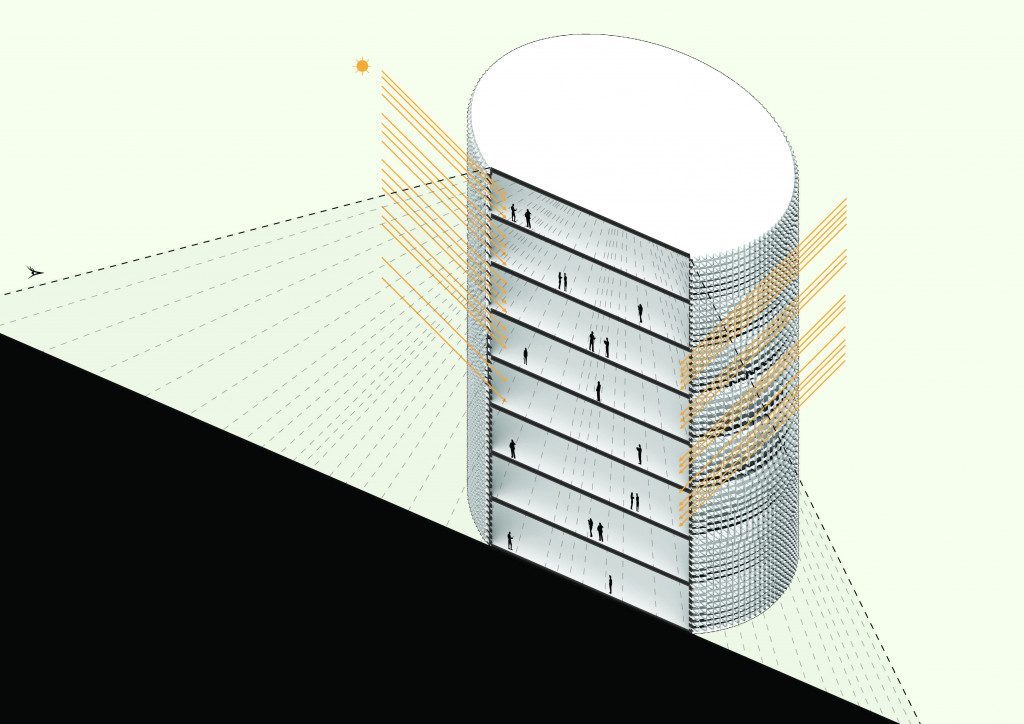

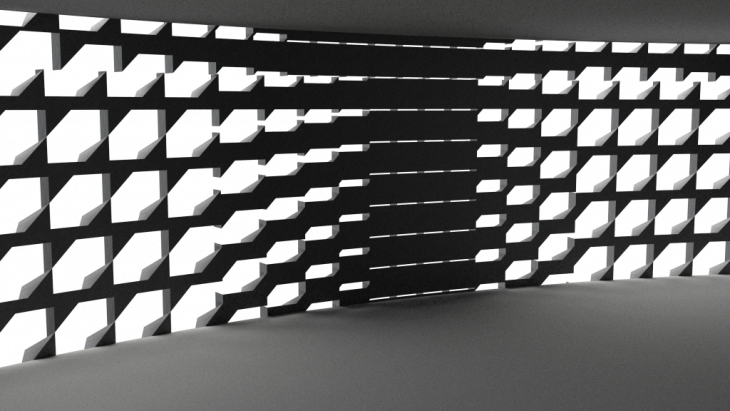

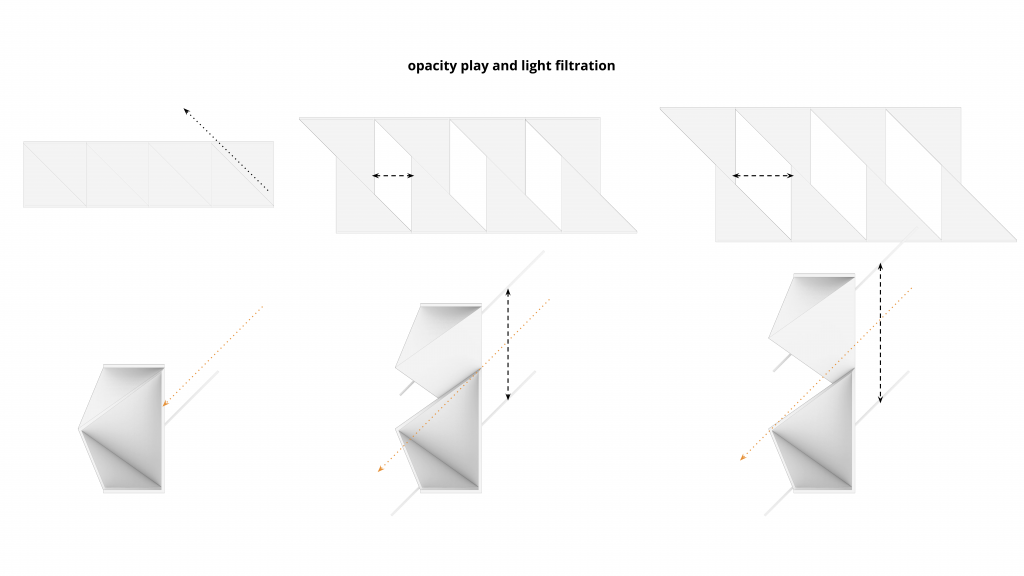

The facade does two things: It frames different views from each point inside the building and it acts as a shading system and light filtration skin.

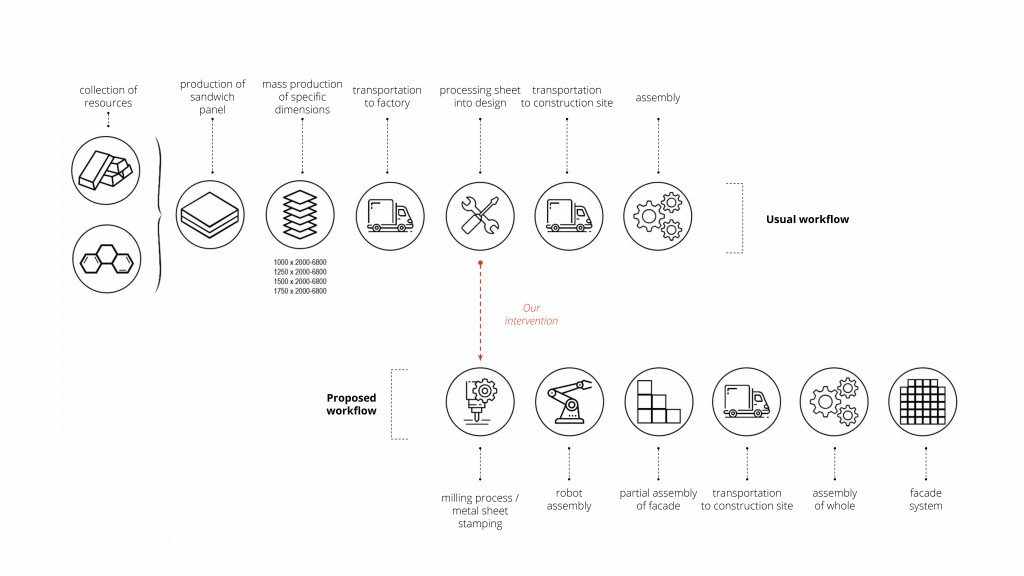

The general overview of the proposed system, from the starting point of collecting the ressources to the current existent component already has an established workflow. We propose to intervene at a specific point and alter the process.

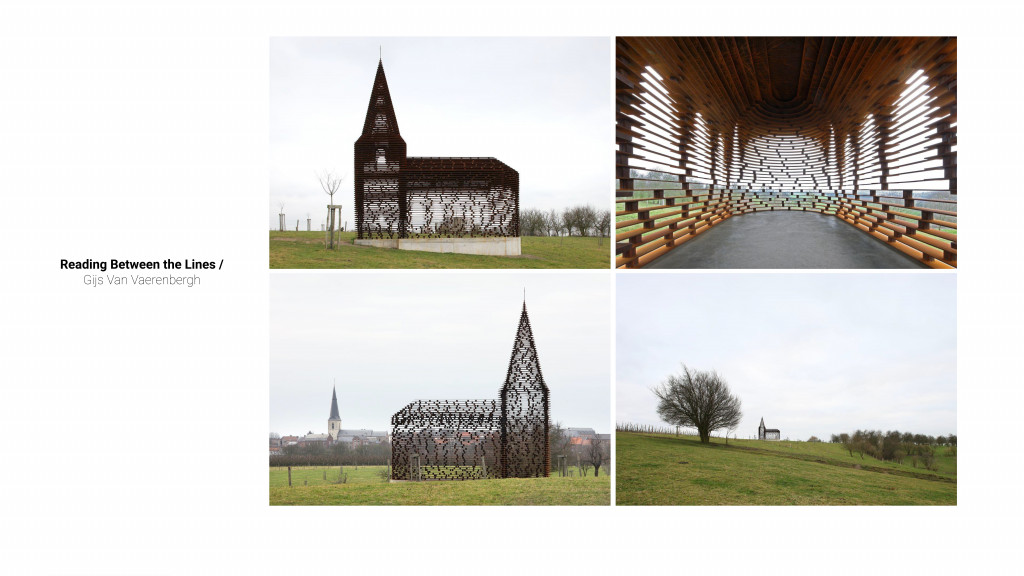

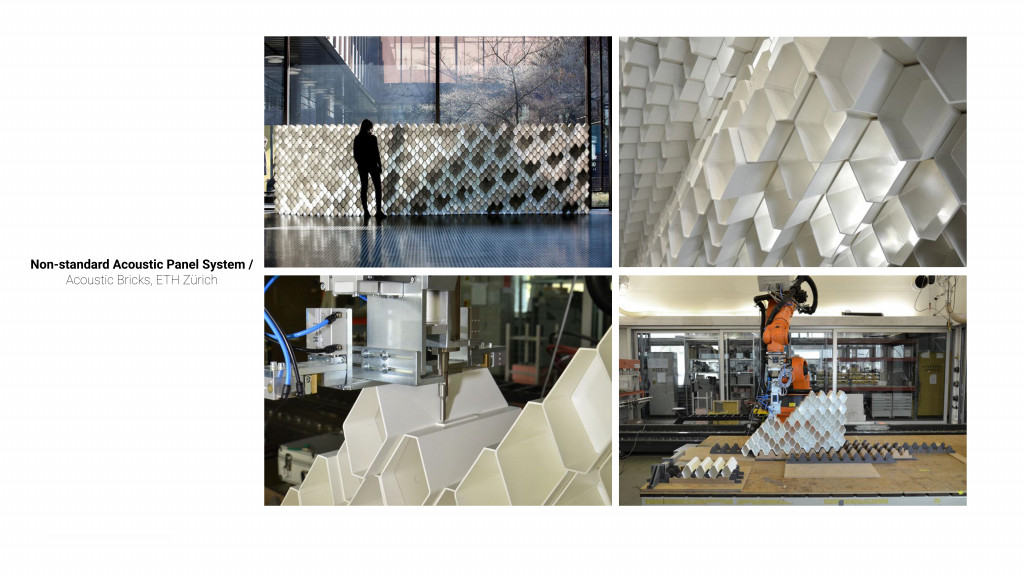

The project aggregation concept, creating nuances of opacity while framing views and using robotic assembly to push components in and out as they are aggregated into a dynamic shading system, was inspired by the following two projects:

02. Process

Emergence of Unit

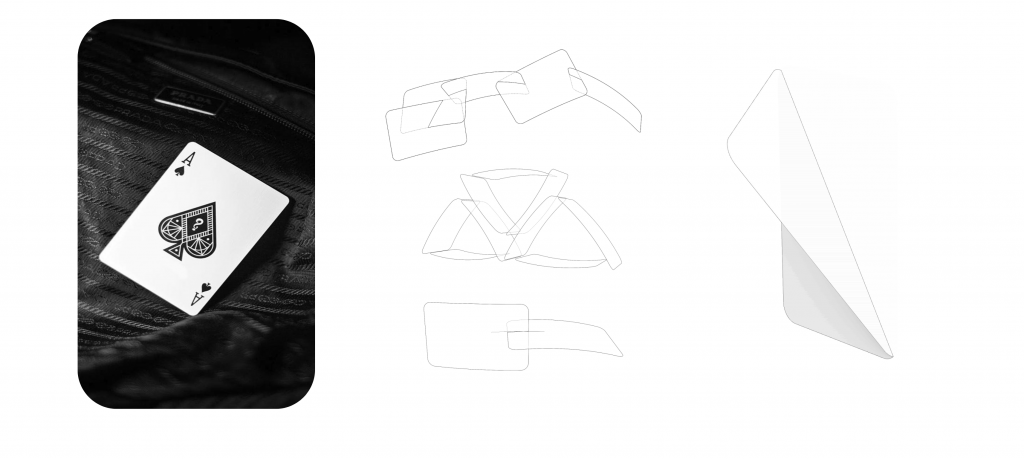

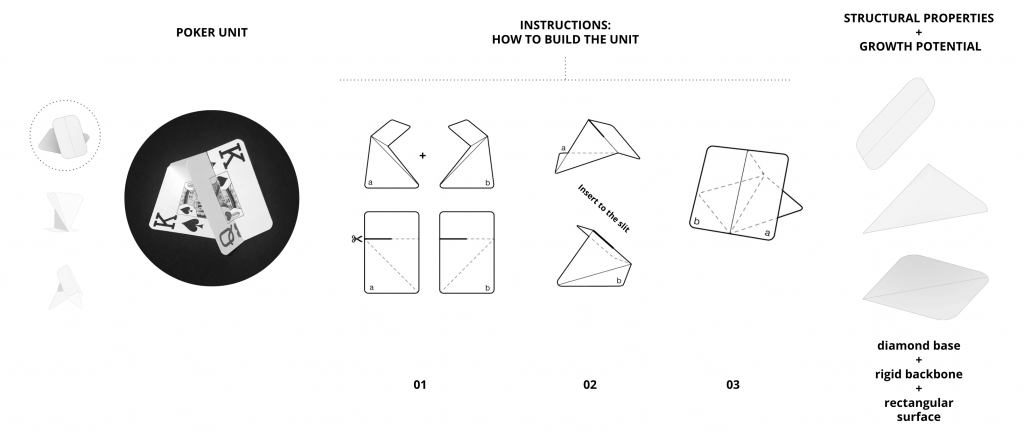

It all started with the poker card. Its characteristics were what drove us to explore unit plays and aggregations. By folding, cutting, creating slit connections, (etc) we were able to create a catalogue of different results.

Through several aggregations, we picked the 3 units that had the most potential and diversity in terms of spatial aggregation and connection possibilities. They were made with one core unit that was repeated throughout the process.

Unit Play

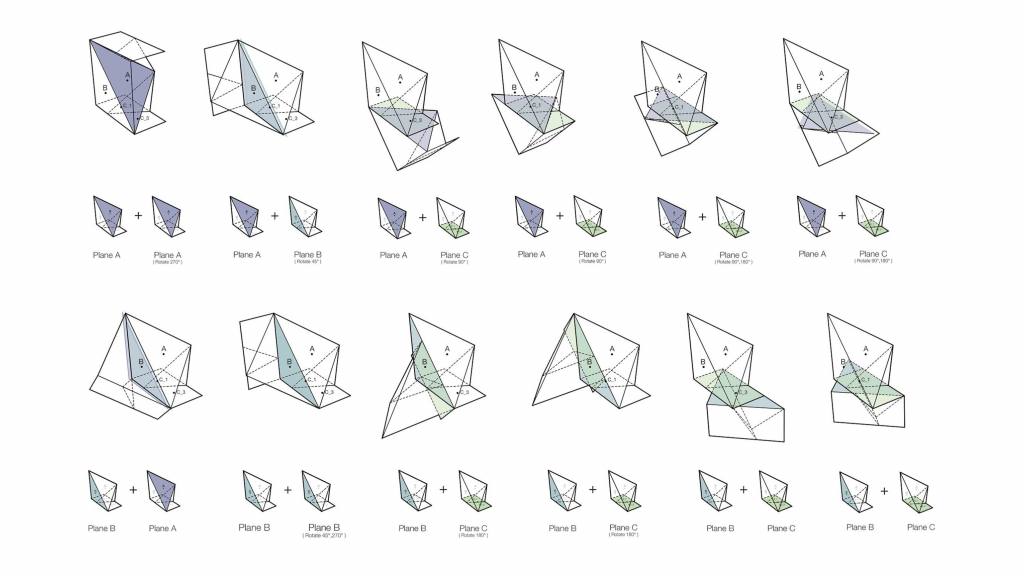

By exploring the unit further, we played with it’s angles and chose 3 units that were different from each other and used them to test digital aggregarions with grasshopper. We eventually settled on one final unit.

Robotic Assembly Test 01

With the first robotic test we noticed that slit connection were quite difficult to achieve as they require a lot of precision from our part. So we decided to explore face to face aggregations from this point on.

03. Architectural Projection

Component Fabrication

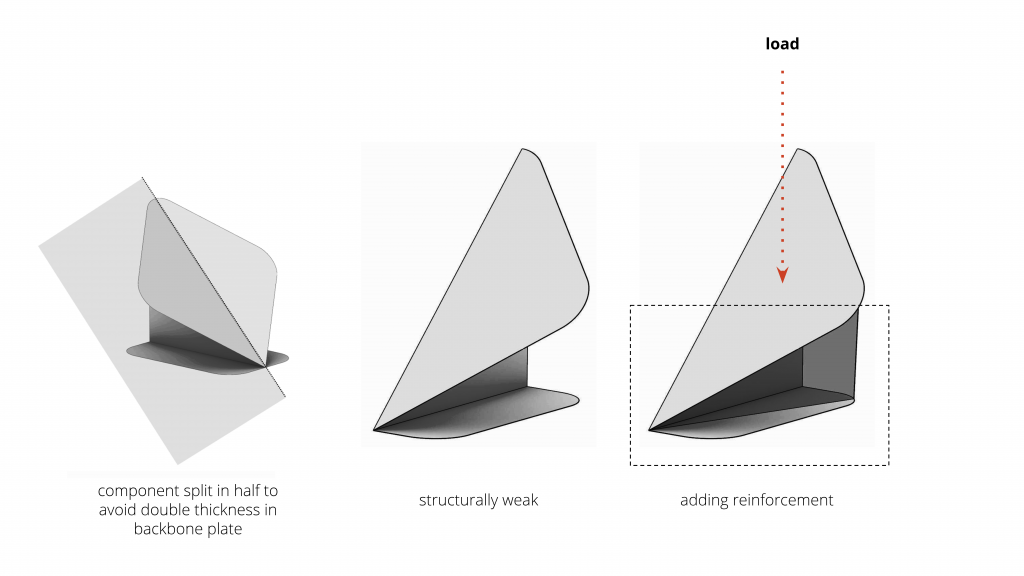

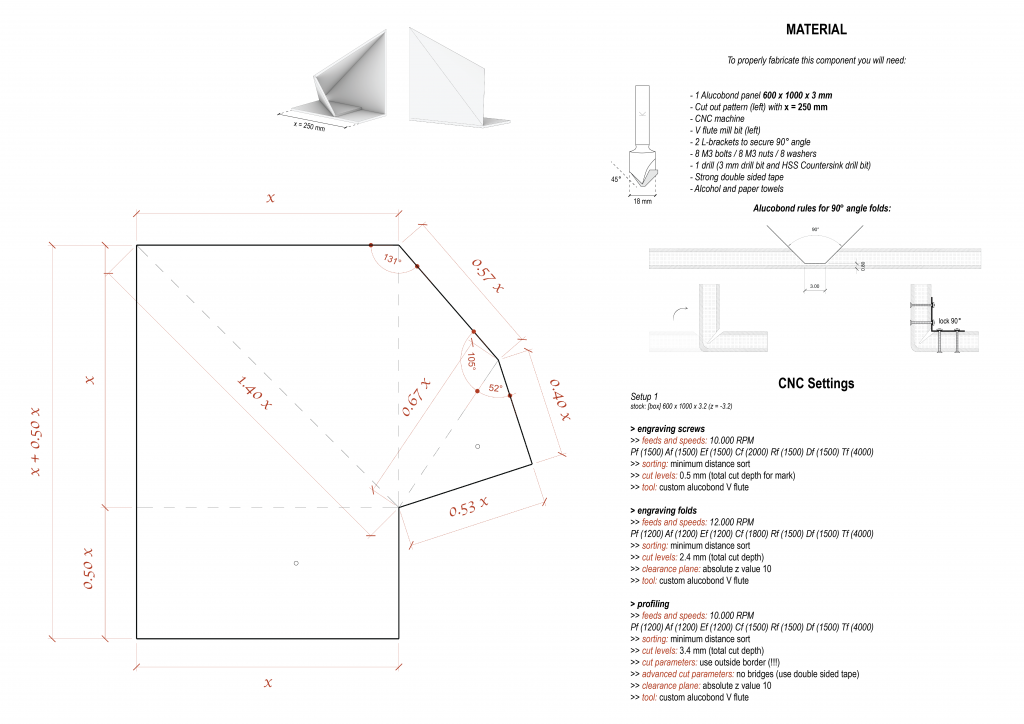

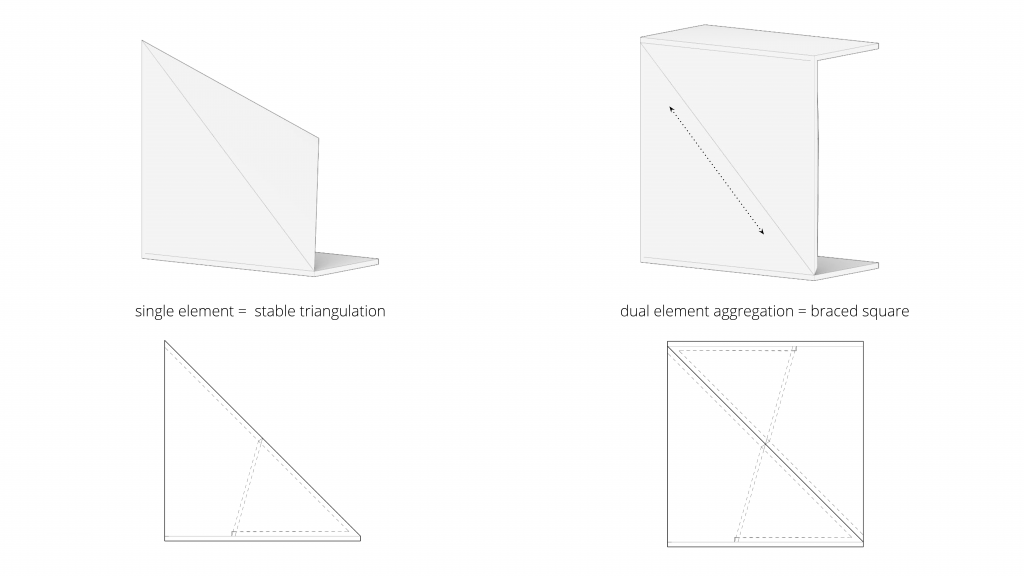

We started studying the component more strategically as we wanted to start testing prototypes. As we tried to make a 2D cut pattern for our unit, we noticed that there would be a double thickness in the rigid backbone. And so we decided to split the unit in half, and use half as 1 unit.

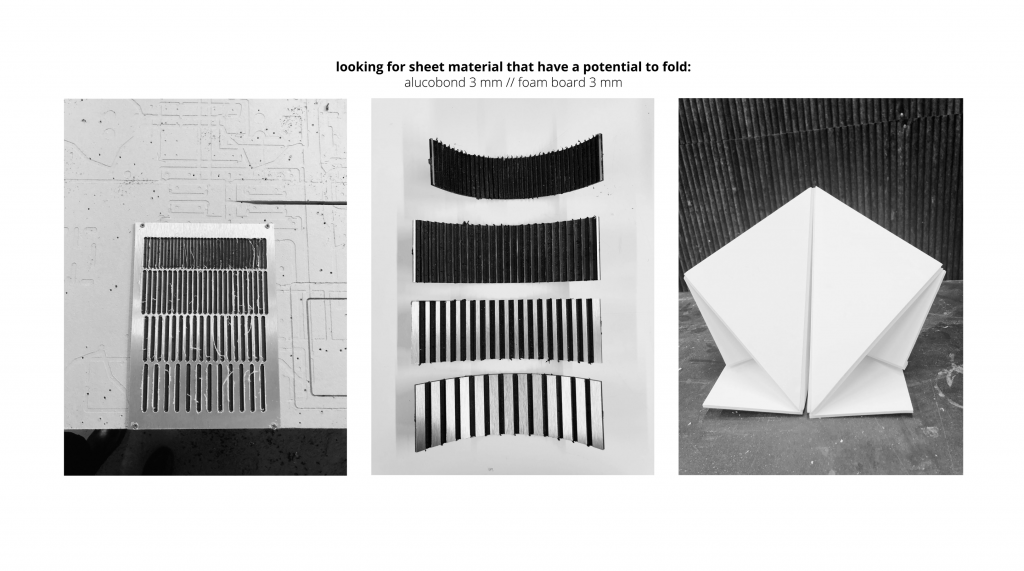

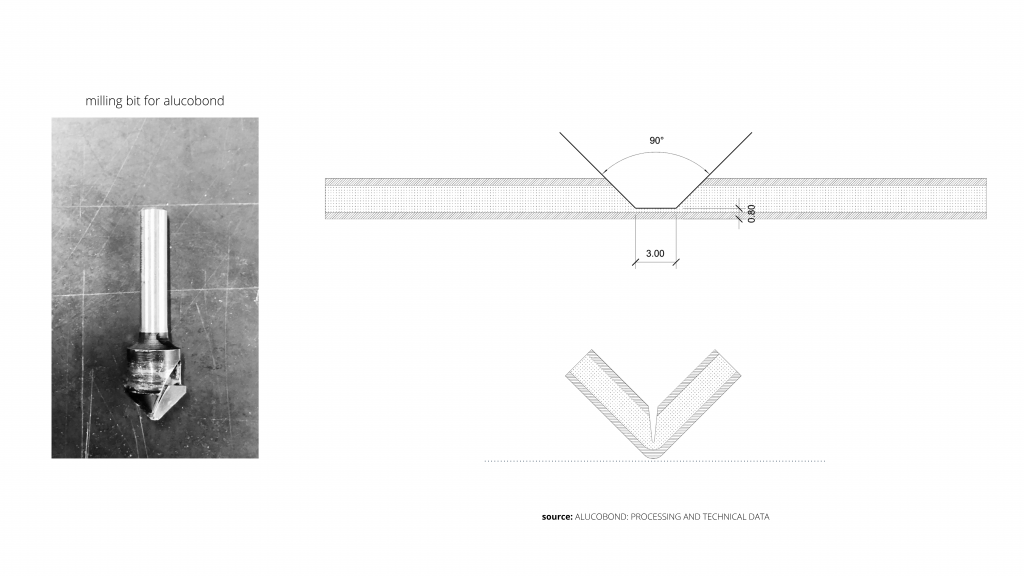

We also looked for sheet material that is able to fold.

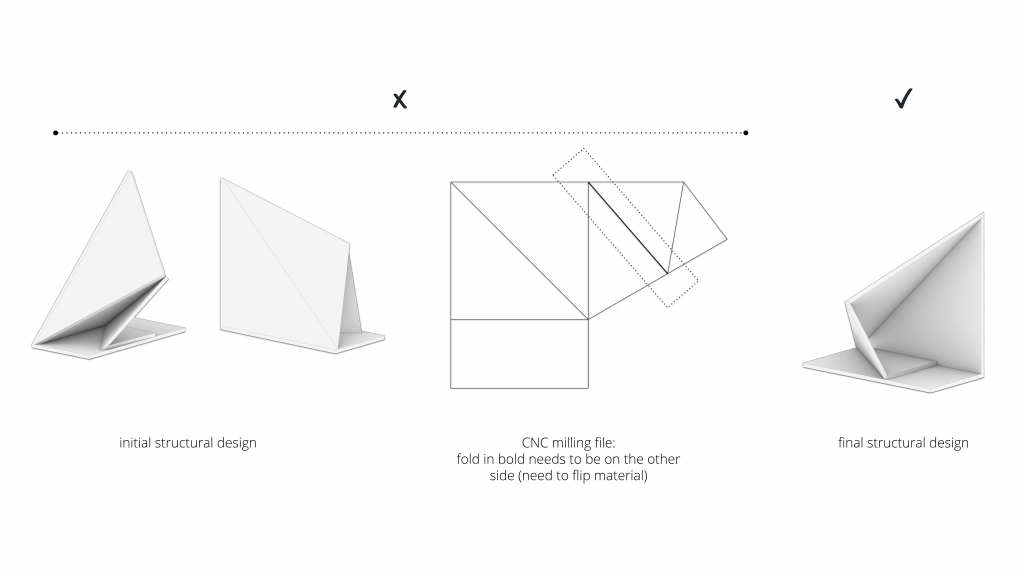

Our first attempt to add a structural element failed as we tested the production of the prototype. We needed to have a fold in the opposite direction and therefore flip the board during the CNC process, so we went with a different approach.

Our first attempt to add a structural element failed as we tested the production of the prototype. We needed to have a fold in the opposite direction and therefore flip the board during the CNC process, so we went with a different approach.

Using Karamba3d, we were able to test the structure of the element after stabilizing the 90° fold.

Using Karamba3d, we were able to test the structure of the element after stabilizing the 90° fold.

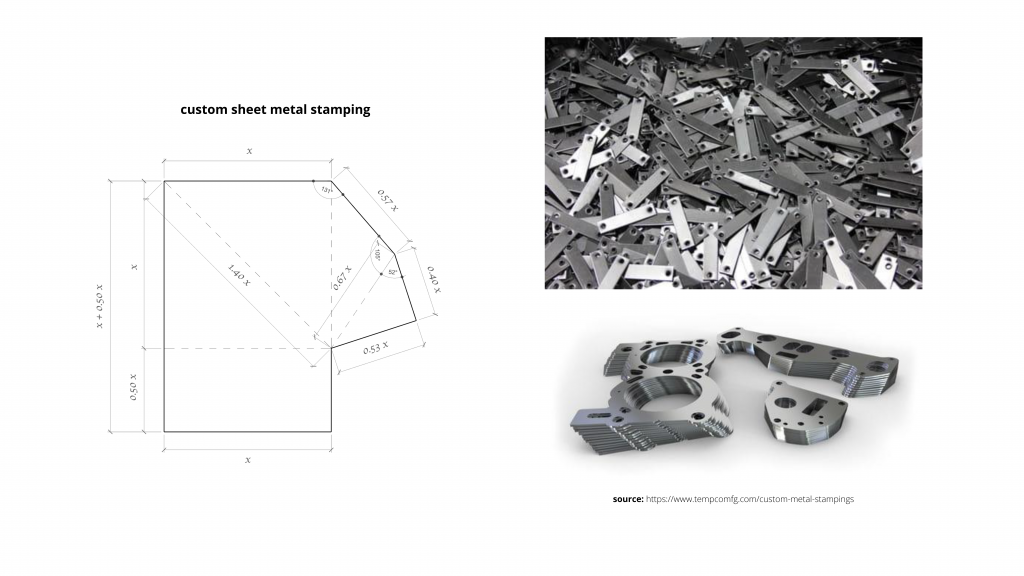

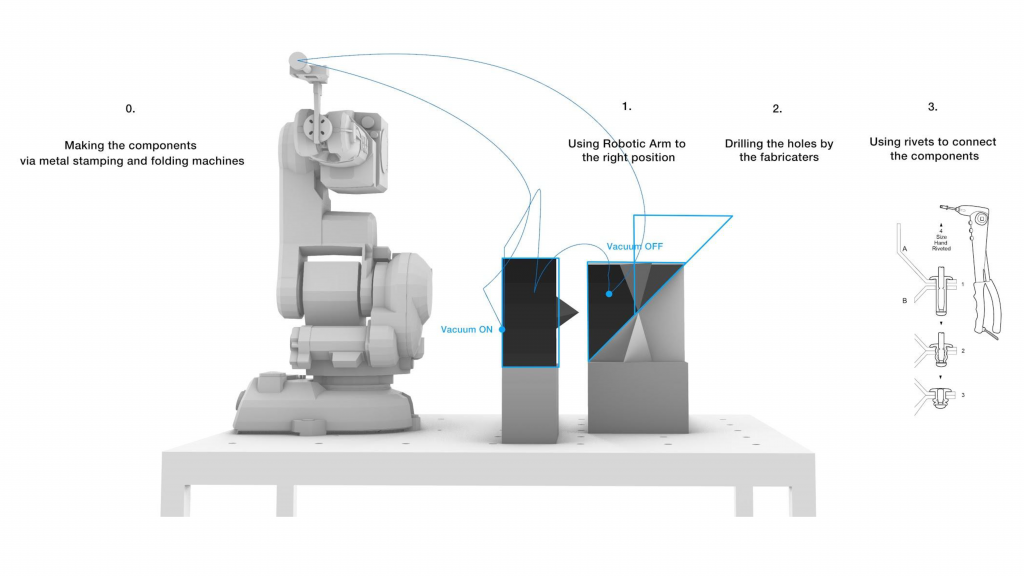

Component Mass Production

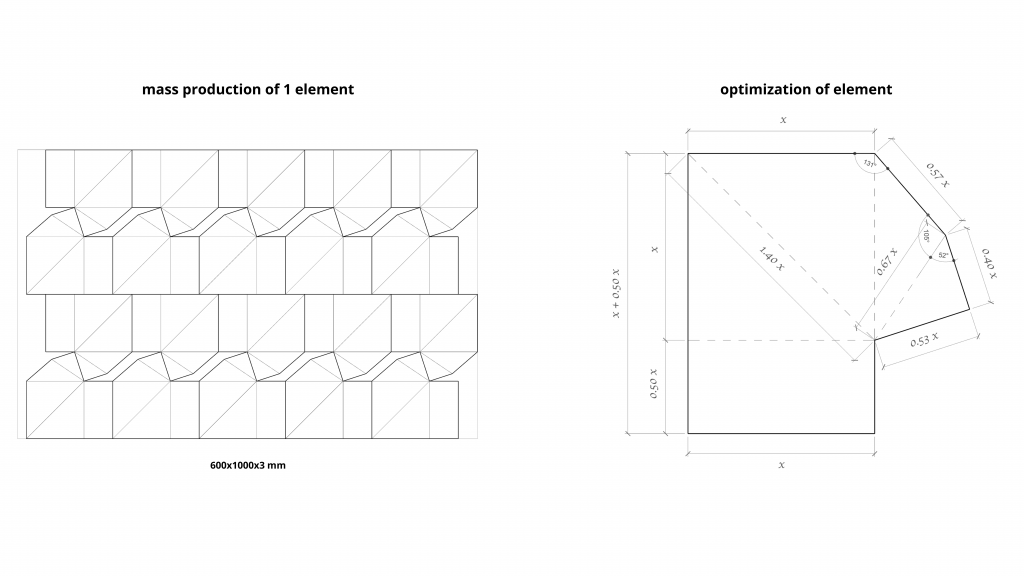

With the aim of mass producing only 1 element, we optimized the shape and dimensions to be able to nest it properly in alucobond sheets. In IAAC, we only had the CNC at our disposal but our aim for the project on a larger scheme is to be able to rely on custom sheet metal stamping.

Component Evaluation (aggregation)

We tested out, digitally, all the connection possibilities between two of our components and eventually picked the first one (top left and as illustrated in the previous photo) because of its ability to:

- With minimal modification, achieve a wide variety of results

- Filtrate light and play with opacity

- Create a dynamic system

- Implement artificial light inside component

Component Evaluation (geometry)

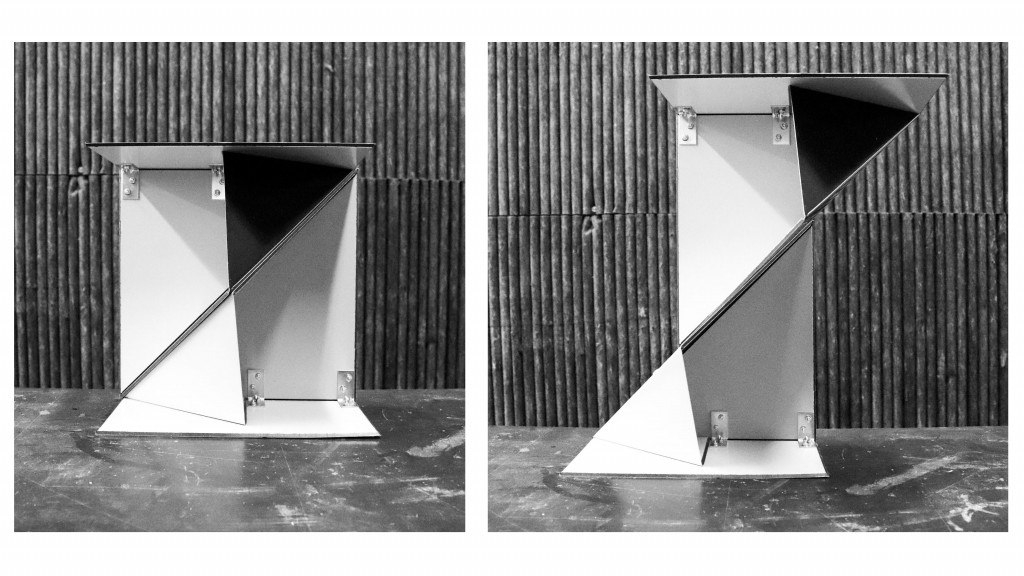

The geometry of the component allowed for a dynamic play on opacity and light filtration as well as provided structural stability throughout the aggregation.

Component Evaluation (fabrication)

Several test and failures contributed to the refinement of the final prototype.

Robotic Assembly Test 02

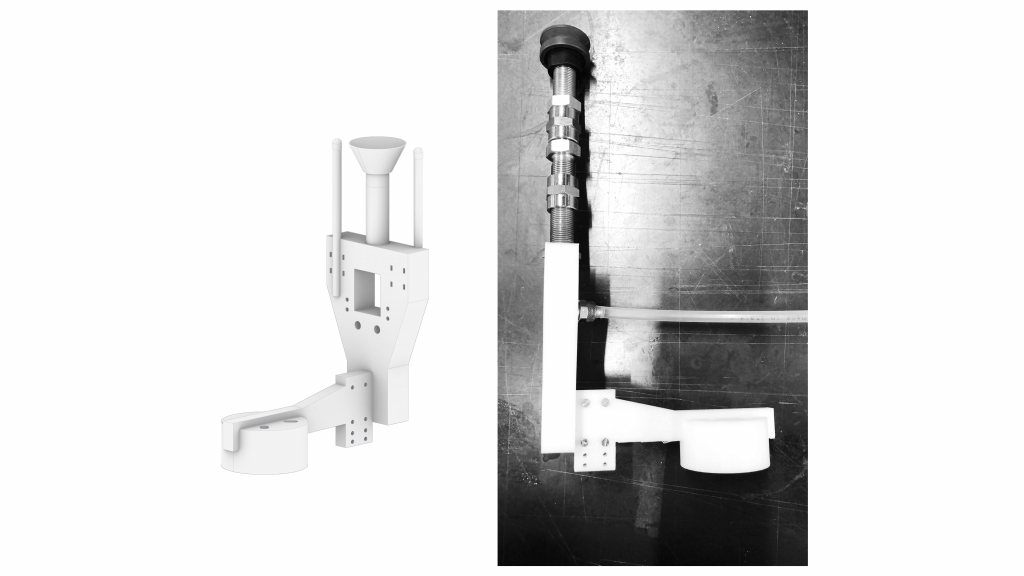

With the final components ready we designed a new end effector and tested the assembly again.

Case Study and Implementation

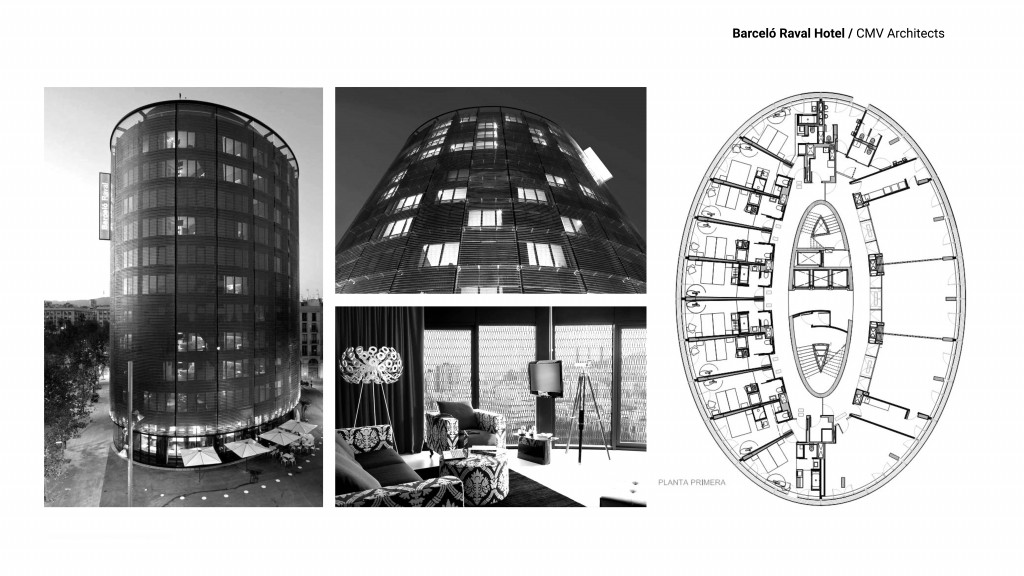

We used the Barceló Raval Hotel by CMV Architects as a base for the implementation of the facade. We chose this hotel because of its location and ability to frame different views all around with different light qualities.

Light Studies

With ladybug we carried out a sun study at this location and evaluated the component size and all its elements (responsible for shading and for opacity). We were also able to account for artificial light into the component to light up the facade at night.

</p>

A.B.S.E.N.T. is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Master of Robotics and Advanced Construction program in 2020/21 by:

Students: Charngshin Chen and Helena Homsi,

Faculty: Alexandre Dubor, Raimund Krenmueller

Faculty Assistant: Roberto Vargas