Overview

The aim of this research is to study 3D printing construction in earthquake zones. As part of the research we investigate limitations, potential and possible modifications of 3dp construction to optimize it to withstand earthquakes. 3d printing technology being a vast field with different techniques and materials, we narrowed down our research to focus on additive 3d printing using adobe in seismic zones.

The Question

To what extent does 3dp in seismic zones be resilient to earthquakes?

Research Methodology

Research begins by understanding 3dp technology, its limitations and its applications. The study further dwells into shelters in belt of fire (world seismic zone). Picking three countries that lie in the belt of fire, we analyze by laws and conventional earthquake resilient techniques practiced to adapt with 3dp construction. Going from macro to micro the study looks into material research to understand the best possible adobe composition for both earthquake resilience and 3dp.

Additive 3D Printing

3dp technology

The three dimensional printing (3DP) is a manufacturing process that deposits successive layers of material to create a three-dimensional solid object from a digital model.

The main principle of 3DP is “Stereolithography” patented by Charles Hull in 1984. It is a system for generating three-dimensional objects by making a cross-section pattern of the object to be formed.

3DP Limitations

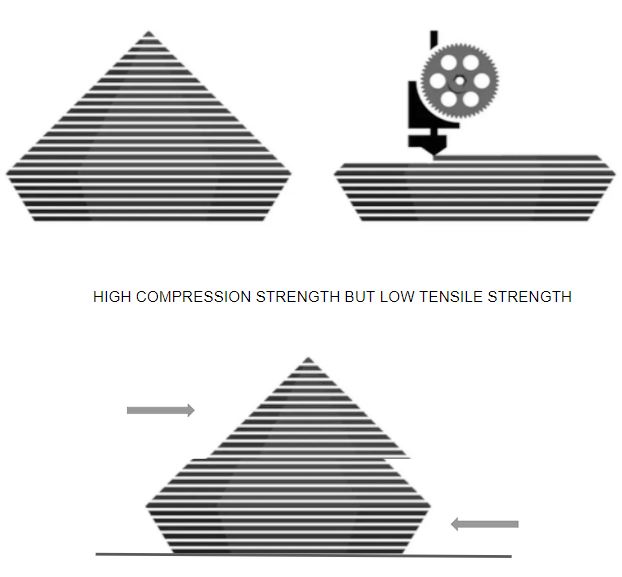

The layered structure is likely to be anisotropic, as voids can form between the individual filaments of the cement paste weakening the structural capability.

Also the bond between filaments, and between layers, influences the hardened properties of concrete components.

Additionally, a low shrinkage is essential as the freeform components are built without formwork, which could accelerate water evaporation and result in cracking.

3dp Applications

The rising housing crisis in the world has opened up opportunities for innovation and introduction of novel technology in the field of construction. This is setting the stage for 3dp tech to breakthrough into the mainstream. Although, 3dp has many advantages, its lack of structural integrity is a key limiting factor as many of these projects are in developing countries and many of these countries are located in seismic zones. The research studies construction in three countries namely, Nepal, Mexico and Peru.

Seismic Zones

The belt of fire and the three countries chosen for study.

Case Studies

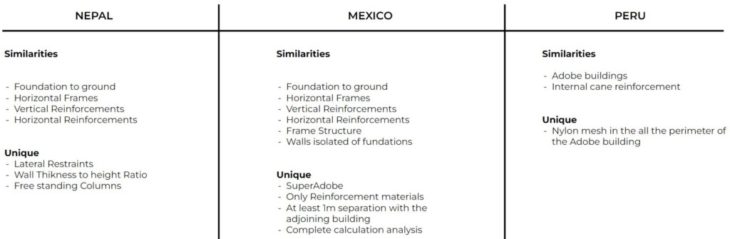

The case studies follow a structure that first reviews the existing by-laws in respective regions and studies an example of earthquake resilient techniques implemented.

Nepal

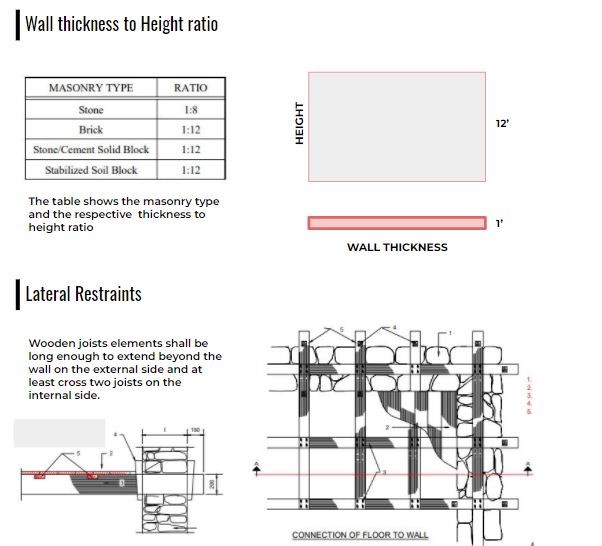

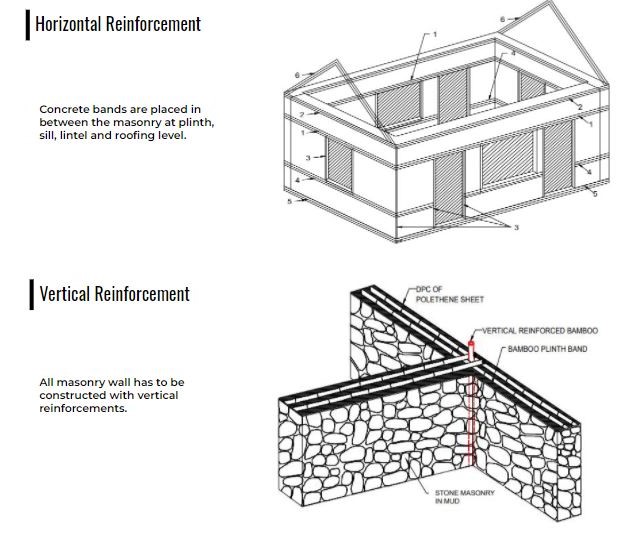

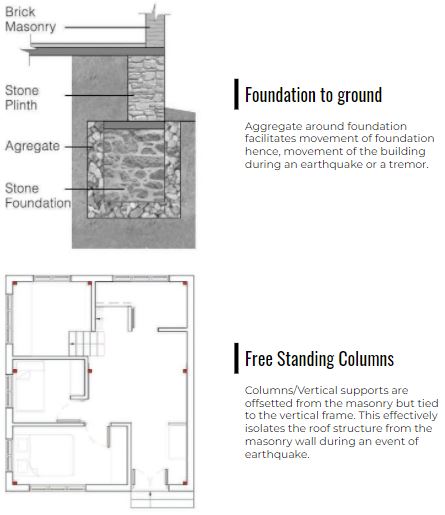

Nepal suffered a through a major earthquake in the April 2015 known as the Gorkha earthquake which killed 8,964 people and injured 21,952 more. This massive devastation across Nepal forced the government to review its building codes and reform it to protect the people and infrastructure. Following diagrams indicate key aspects of the building code.

Case Study-

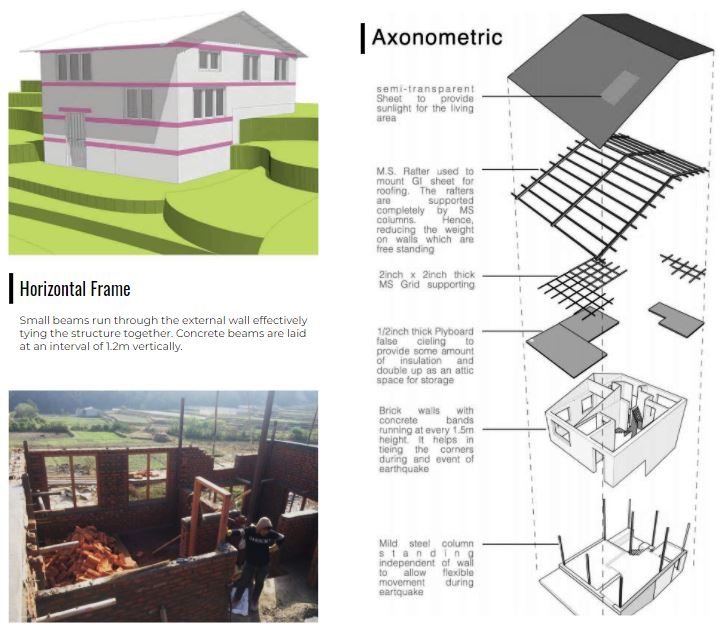

PROJECT DETAILS Name : Home4Ashima Category : Residence Location : Kathmandu,Nepal Architects : Swathi Suvarna, Shamanth Thenkan Description : Residence project done for a family of four who lost their house and livelihood during the 2015 earthquake. The project was crowdfunded and completed in a span of 6 months. The project integrated earthquake resilient techniques from the foundation to the roof.

Mexico

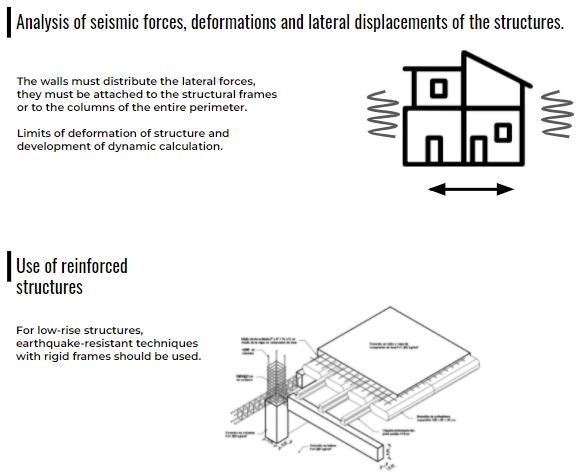

After the worst earthquake in Mexico in 1985 the construction regulation change completely for Mexico and several Latin-American countries. They start with disaster risk management and a strict construction regulation. Some of these regulations are the analysis of seismic forces, deformations and lateral displacements of the structures, use of reinforced structures, the distribution of loads, and the construction department should verify all the projects before the construction.

Case Study –

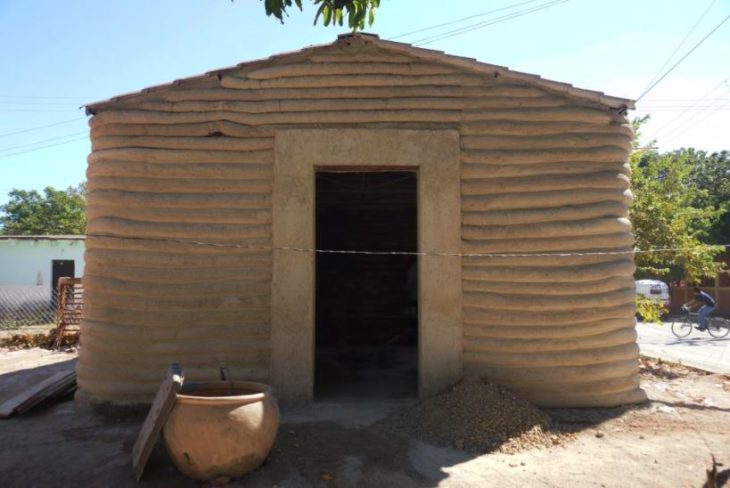

After the destruction of homes in Oaxaca, caused by the earthquake that occurred in September 2017. Alfredo Delgado Dávila started re-construction work made with super adobe. A mix between this construction technique and the dome geometry allows these constructions to be anti-seismic.

PROJECT DETAILS

Category : Housing

Location : Oaxaca, Mexico

Architects : Alfredo Delgado Dávila

Recovery of destroyed homes in Oaxaca, caused by the earthquake that occurred in September 2017. Construction made with super adobe. A mix between this construction technique and the dome geometry allows these constructions to be anti-seismic.

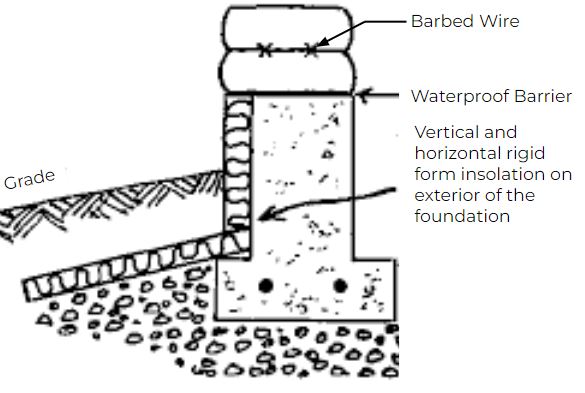

The layering of sandbags in super adobe is similar to deposition of material using 3dp. The modification in the super adobe technique is that between every layer of sand bag a barbed wire is laid to improve cohesiveness between each layer and also to provide additional reinforcement.

Peru

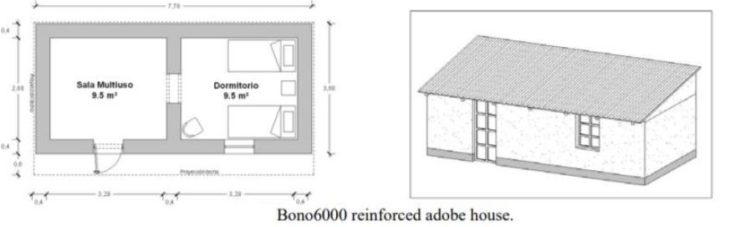

An earthquake in August 15th 2007 in Pisco towns and villages, killed more than 500 persons. A smaller adobe house was designed by a team from PUCP, CARE Peru, and the Swiss and German cooperation agencies CARE . This house was approved by FORSUR to be built in rural areas with the 6000 soles bonus. It has two rooms and a total floor plan area of 19 m2, based on minimum standards for humanitarian disaster response.

Peru has three major approaches to build earthquake resilient adobe shelters –

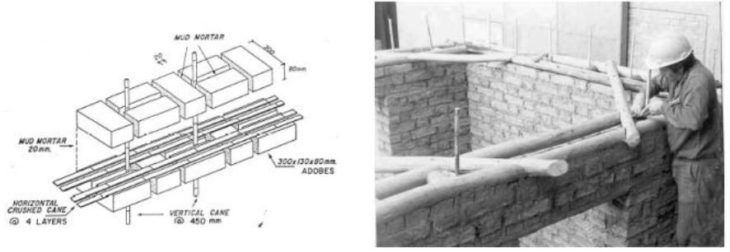

– Internal cane mesh reinforcement

The reinforcement consists of vertical cane rods anchored to a concrete foundation and placed inside the adobe walls. The adobe block layout defines the distance between the vertical cane rods at 1,5 times the thickness of the wall. Horizontal layers of crushed canes are placed every few adobe rows and tied to the vertical cane reinforcement. Finally, this internal cane mesh reinforcement is tied to a wooden crown beam.

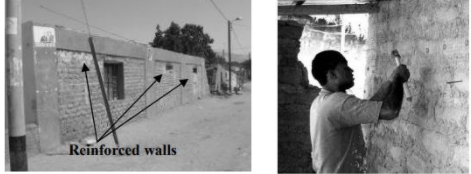

–External wire mesh reinforcement

This technique consists of nailing wire mesh bands against the adobe walls and then covering them with cement mortar. The mesh is placed in horizontal and vertical strips, following a layout similar to that of beams and Columns. Wire mesh and cement are prohibitively expensive for the inhabitants of earthen houses in developing countries. External reinforcement with welded mesh could cost up to US $200 for a typical one floor, two-room adobe house, which exceeds the economic capacity of most Peruvian adobe users.

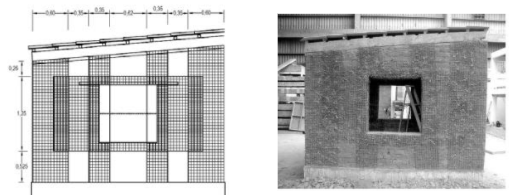

– External polymer mesh reinforcement

A recent study has been performed at PUCP to evaluate the possibility of using polymer mesh to reinforce earthen buildings. Several similar full-scale adobe housing models with different amounts and types of polymer mesh were tested on the unidirectional PUCP shaking table. The reinforcement provided consisted of bands of polymer mesh tied to both sides of the walls with plastic string threaded through the walls.

Case study take away –

From these studies we can infer both the similarities and the differences in the construction techniques followed in different regions of the world. Some of the differences in the techniques is a result of availability of the material and terrain. Studying the similarities we find out that building to ground connection is a key factor in all regions. Another aspect of earthquake resilient design is delaying the collapse of the building to facilitate evacuation of the occupants.

Material Research

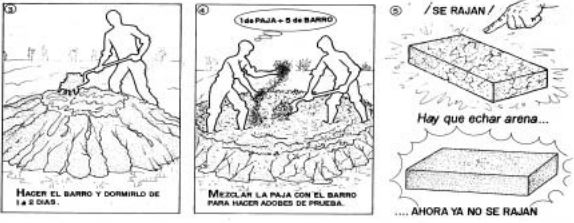

Adobe Technology –

The characteristics of the soils having the greatest influence on the strength of adobe masonry are those related either to the drying shrinkage process or the dry strength of the material.

- Clay: the most important component of the soil; it provides dry strength and causes drying shrinkage of the soil.

- Controlled microcracking of the soil mortar due to drying shrinkage required to obtain strong adobe masonry.

- Additives: straw and, to a lesser extent, coarse sand are additives that control microcracking of the mortar due to drying shrinkage, and therefore improve the strength of adobe masonry.

- Construction: the quality of workmanship plays an important role obtaining strong adobe masonry, resulting in the broad variations in strength on the order of 100%.

Dry Strength Test : Make two or more adobe sandwiches (two adobe bricks joined with mortar). After 48 hours of drying in the shade, the sandwiches are carefully.

Dry Strength Test : Make two or more adobe sandwiches (two adobe bricks joined with mortar). After 48 hours of drying in the shade, the sandwiches are carefully.

Controlled micro cracking test: Make two or more adobe sandwiches (two adobe bricks joined with mortar). After 48 hours of drying in the shade, the sandwiches are carefully opened and the mortar examined. If the mortar does not show visible cracking, the soil is adequate for adobe construction. Otherwise, use coarse sand (approximate size 0.5 to 5 mm) as an additive to control microcracking due to drying shrinkage

Controlled micro cracking test: Make two or more adobe sandwiches (two adobe bricks joined with mortar). After 48 hours of drying in the shade, the sandwiches are carefully opened and the mortar examined. If the mortar does not show visible cracking, the soil is adequate for adobe construction. Otherwise, use coarse sand (approximate size 0.5 to 5 mm) as an additive to control microcracking due to drying shrinkage

Rolling Test: Make a little mud roll. If the unbroken length of the roll is between 5 to 15 cm, the soil is adequate. If the roll breaks with less than 5 cm, the soil must not be used. If the unbroken roll is longer than 15 cm, coarse sand must be added.

Possible Recommendations for 3dpa in seismic zones

</p>

</p>

Conclusion

3d printed Architecture has potential to be feasible in seismic zones but as with any novel technology it has to go through the process of testing, experimentation and legal recognition to become a main stream construction technique. Countries such as Germany and Mexico have already begun work in this direction by slowly developing frameworks for 3dpa by updating building codes to include 3dp technology as a formal construction technique. With increasing research and development in this domain the question is not if 3dp be will be feasible in seismic zones but when will it be feasible?

Sources:

https://www.iitk.ac.in/nicee/wcee/article/10_vol10_5989.pdf

https://www.dudbc.gov.np/uploads/default/files/b8e8f70594055e66f43b739ed48ae057.pdf

http://cgservicios.df.gob.mx/prontuario/vigente/739.pdf

https://www.eird.org/cd/acs/Espanol/EvalCodi/HablaEsp/Sismos/MEXICecs.pdf

https://www.world-housing.net/wp-content/uploads/2011/06/Adobe_Tutorial_English_Blondet.pdf

3DP Architecture and Earthquakes is a project of IAAC, Institute for Advanced Architecture of Catalonia developed at Masters in Advanced Robotics in 2021 by:

Students: Andrea Najera, Abanoub Nagy, Shamanth Thenkan

Faculty: Mathilde Marengo