Redefining Joinery

surface expanded joinery system in shell structure

Author : Hsin Li

Supervisor : Jordi Pagès i Ramon and Lluís Viu Rebés

ABSTRACT

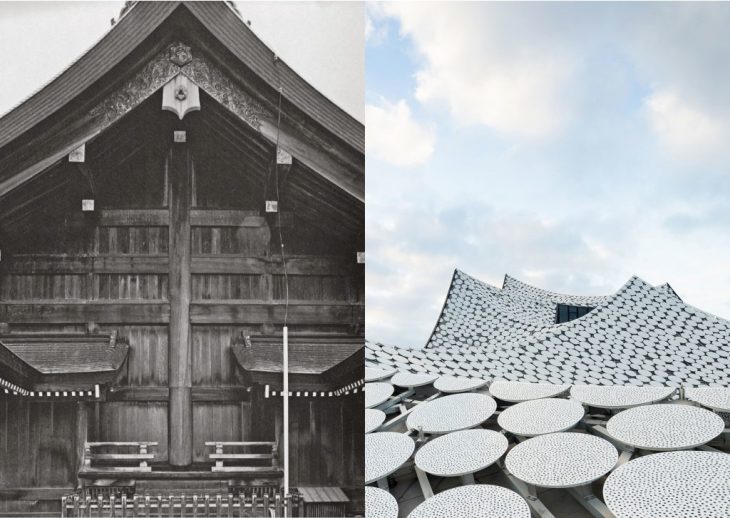

Joinery, the skills to join separate pieces to produce a more complex item of timber. It is now facing several obstacles since industrial revolution which has led to the decline of traditional joinery industry, such as cost, mechanize difficulties and structural aspect of problems, the traditional joinery is not able to satisfy the requirements of modern architecture. This research proposes a new design method to redefine traditional joinery from three perspectives, geometry, material and fabrication that lead to three main expected results, customization, panellization of the construction and enhancement of the joint by taking the advantage of revolution of 3d modelling software, material innovation and digital fabrication. This research tests the potential of joinery using parametric design software and fabricates it with 3d printing and robotic milling to process complex geometry and learn the advantage and disadvantage of digital fabrication by comparing with the traditional joinery fabrication process simultaneously. As a result, the joinery is able to be liberated from the traditional frame structure system to achieve more complex form and meet the modern architecture trend at the same time remains efficient and sutainable. The surface expended joinery in a multiple axis interlocking system can assemble to a shell structure with controllable joint, optimized division following principal stress line to achieve better efficiency of material utilization and structural performance.

——————- Basic analysis of joinery ——————-

With the advantage of parametric design tool, designers get to process the designing of complex geometry with out obstacle, it is the key for liberating joinery from perpendicular structure system to unrestrained system, calculation of 3 dimensional rotation between each joint is no longer a impossible task. Further more, cross laminated wood has eliminated the weakness of typical timber; the direction of wood grain that restricts the orientation of joinery, lead to a result that laminated wood can take forces from different direction which released joinery from perpendicular system.

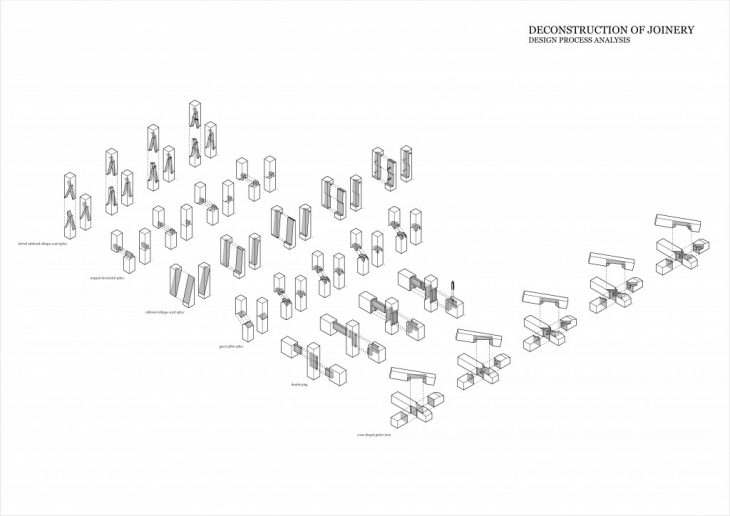

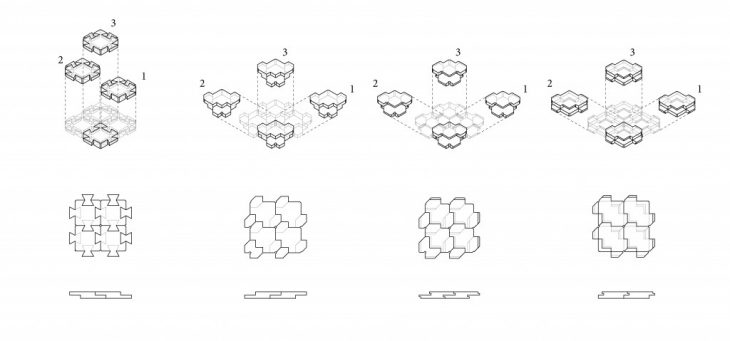

understanding joinery by deconstructing the geometry into design steps

joinery rotation in different dimension

——————- Surface expanded joinery system in shell structure ——————-

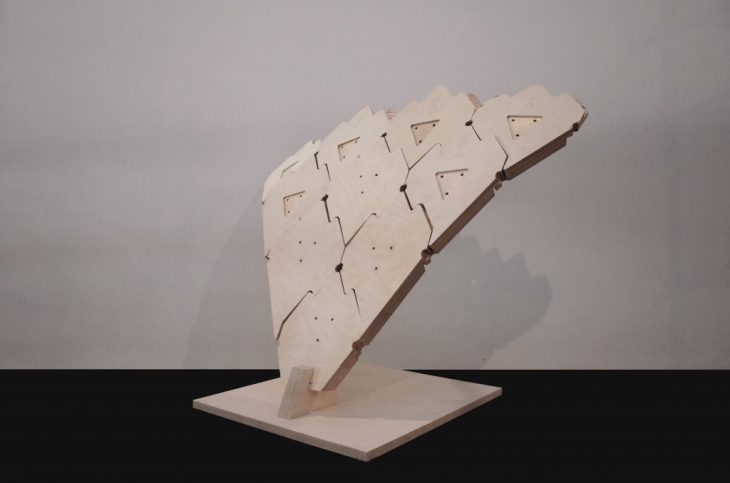

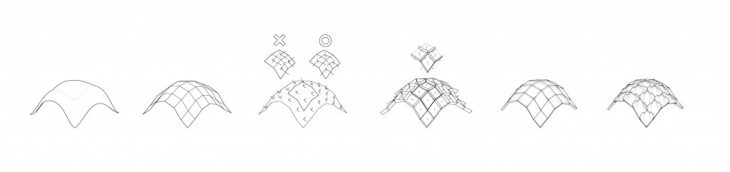

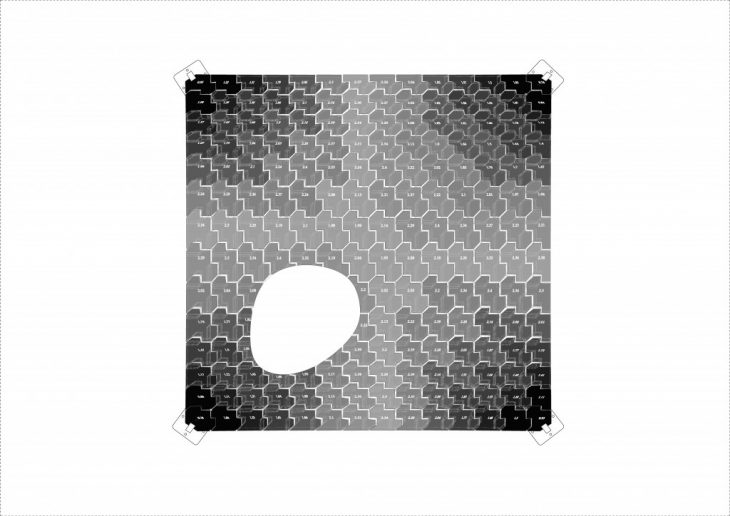

Panelization of the construction makes the surface extension of joinery possible, by dividing a shell surface into pieces of quadrilatheral with multiple axis joint, a comlex shell structure can be achieved with small scale of wood piece that cut out from flat wood sheet. To unify the joint orientation, a method is introduced in the system, when generating the basic pieces of joint, the front two side surfaces must be perpendicular to the surface normal and the back two side surface adapt to the adjacents, only in this case the pieces can be joint with neighbor pieces with out confliction of joining axis. The revolution of design tools, material, machinery transform the notion of traditional joinery into a customized, scaffoldingless, movable and easy assemble shell structure system.

basic joinery design logic

basic joinery developement

plan

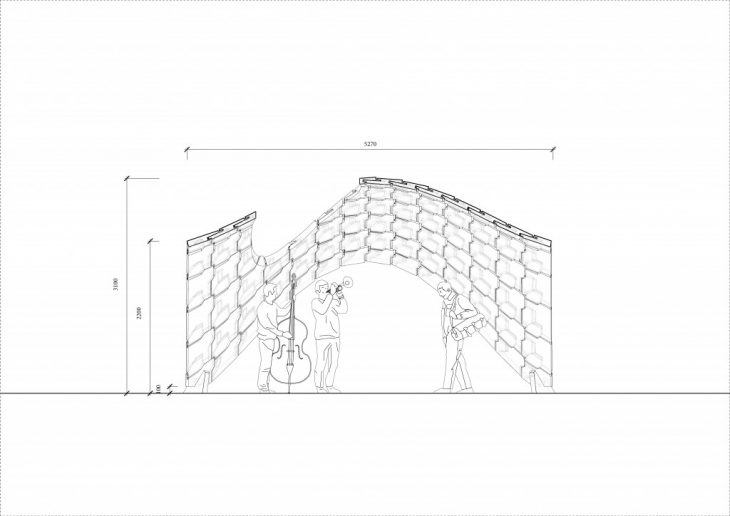

section

——————- assemble process ——————-

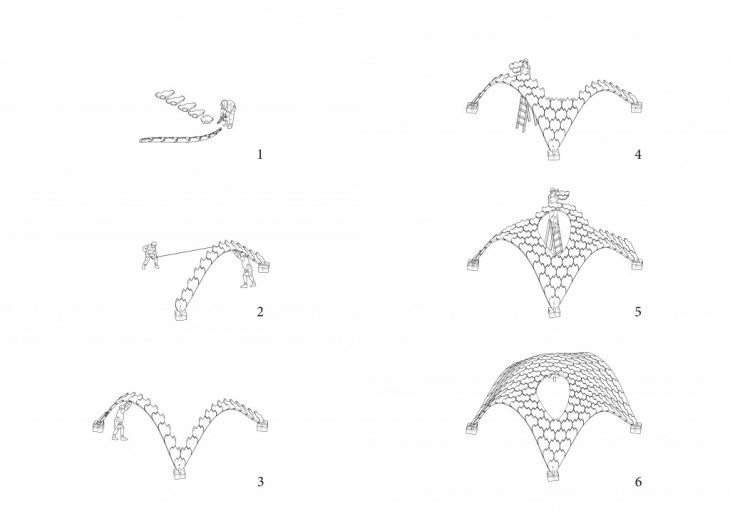

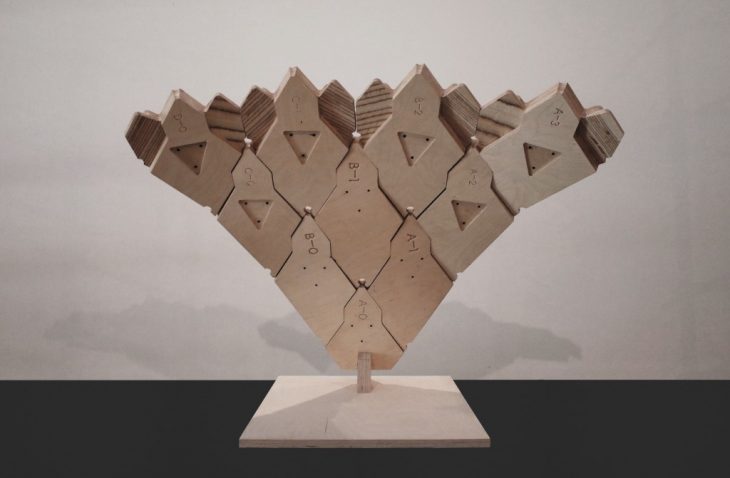

196 pieces assemble process

196 pieces assemble process

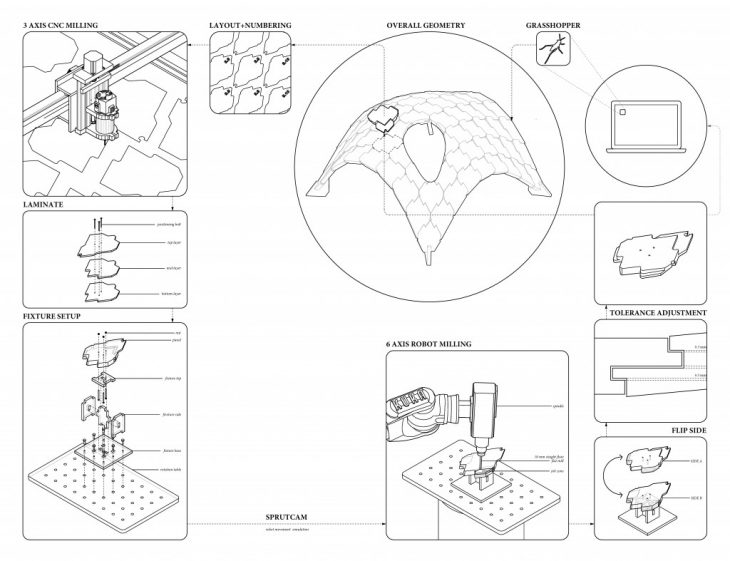

——————- fabrication process ——————-

1/2 prototype