Zoetic Morphologies

3d active wall systems through mycelial biomass

Over the past few decades, the fabrication techniques and materials have evolved in other manufacturing sectors, while the construction industry is yet to take full advantage of this change and it is one of the primary consumers of natural resources and one of the biggest polluters. This applies both to the construction and consumption of the built environment. “Zoetic Morphologies” is a research that attempts to develop living architecture through a material system by 3d printing living fungal mycelium with clay, envisioning how the materials are sourced and constructed while exploring the relationship of the built environment with nature.

Research has been conducted in three phases to develop the material system, fabrication method and complex system design. Different agricultural waste-based substrate mixes have been incubated in various environments to understand the growth rate and resistance to contamination of pathogens. Wall systems are designed via computational methods through multi-agent generative algorithms and growth simulations to develop data-informed systems that explore the water and wind channelization, porosity and diversified rate of incubation. The designs lead to a multi-material deposition through the robotic arm for a fabrication strategy which ensures the complexity of design stands to the fabrication and prototyping process. The presented research puts forward a material and fabrication system that can resist to the pathogenic contamination that can be scaled up to construct active structures where living mycelium of Pleurotus Ostreatus is 3d printed spontaneously with clay, incubated and grown for a period and then deactivated into a static building. Mycelium grows in the cavities of the structure and forms thick insulative biomass, creating an optimized building envelop while biodegrading agricultural waste in the process.

METHODOLOGY

The presented research follows a hands-on, experimental approach to develop a new material system for 3d printing mycelium on an architectural scale. Practical research has been conducted in a controlled laboratory. Unless stated otherwise, all the mentioned experiments and media are produced by the author.

The research starts with an overview of the current construction sector. It continues by focusing on emerging technologies in architecture in terms of materiality and fabrication. It starts by introducing the concept of living architecture. It also investigates further additive manufacturing with clay and mycelium in the architectural concept.

The second chapter focuses on the context of living architecture by defining the co-existential relationship between cities and natural systems. Furthermore, the research explores the over-sterilization of the built environment that is caused by the urban context.

The third part of the research explores the mycelium as a material by prototyping and testing. It defines problems in scaling up with mycelium and gathers information through experimentation and concludes by presenting an approach and a material mixture to 3d print mycelium on an architectural scale.

The fourth chapter investigates computational tools and various algorithms as a design and form-finding methodology. It explores generative algorithms and growth models through different platforms.

The fifth part moves onto the additive manufacturing as a fabrication technique and elaborates on the single material deposition. It continues by introducing a multi-material deposition through a single nozzle. It finishes by presenting a modular multi-material deposition tool developed for the robotic arm and turns attention to architectural applications.

The pre-last chapter starts by analyzing various geographical locations to identify suitable climates for a living building to grow. It puts forward a wall system that combines existence knowledge on 3d printing with clay and developed mycelium material system. The design iterations are presented as a catalogue and final wall systems are presented.

Finally, it concludes with recommendations for future work and a general overview and accomplishments of the research.

Introduction

Architecture is a multi-disciplinary field that requires an understanding of various disciplines and practices. From philosophy to engineering, different human-centric approaches have driven our understanding of how to build and interact with the built environment. Furthermore, as %80 of the world population will be living in urban areas by 2050, architecture carries the utmost importance on how society will be living. However, architecture has failed to adapt and understand the natural world it is residing in. Nature is segregated from the built environment and the construction industry became the number one pollutant in the world. Currently, a new approach is required to face ongoing challenges that will respond to changes, adapt and create a circular life-cycle for the built environment.

Living Architecture

The rapid expansion of urbanization after the post-industrial revolution witnessed the segregation of natural systems from the built environment through physical and socioeconomic factors. As a result, the biosphere is now changing beyond comprehension due to a direct result of the way we construct our environment. Changing the way we design our environments passes through changing our perspective towards the relationship between nature and built space.[16]

The cities and buildings in which we live in are constructed by ignoring the natural life, moreover promoting the lack of nature in our houses as a positive norm. This results in our built environment to lack the characteristics of the natural systems. That means aging, adaptation to changes, bio-degradation and circularity. Although, nature has been a source of inspiration for designers and architects for centuries, the integration of natural systems into architecture and construction has been a topic in the last decades.

“The architecture of the future will be soft and hairy.”

Salvador Dali, on the future of architecture, in response to Le Corbusier

Living architecture or biodesign means the integration of biology into architecture rather than bio-mimicry or greenwashing. The new approach of biodesign focuses on creating new material systems or construction techniques that respond, adapt, or mimic the properties of natural systems or organisms. A living building would show the characteristics of nature; it would age rather than decay. Furthermore, an aging building would grow rather than constructed and through this growth, it adapts to change. Adaptation of built environments means it can respond to the changes and unpredictability which comes as climate change.[17]

While the advantageous properties of bio-integration are visible in researches such as Bio Concrete, a concrete that heals itself through bacteria [18], we need to challenge our relationship with nature to fully embrace the new norm of coexistence. The adventitious properties can be economical, environmental, or social.

This thesis revolves around a new norm of a living building that inhabits humans as well as it does fungi and other life-forms that exists in the ecology of fungi. This requires a new perspective towards our relationship with the built environment. Currently, modern, new spaces are associated with sterile and cleanness. Governments promote sterilization of streets in a positive way while spraying chemicals to the built environment and cleanness of spaces revolve around the sterilization of chemicals in order to kill non-humans such as foreign bacteria or viruses.

In this research, the built environment is redefined as ecology and a living organism. The living walls make up an organism where the clay works as a skin of a body or a bark of a tree, a protective shell for the active part inside while the inside of the cavities, like a human cell, is active and growing. The whole wall the building is connected, forming a singular organism. The walls are not just constructed, but also grown, and rather than decaying, they age. This approach contradicts the current human relationship with the built environment which is inert and while the walls of buildings are just seen as separators.

Coexistence: Humans, Cities and nature

The relationship between humans and nature in an urban context is quite complicated. As urban life grows to be more chaotic than before, eradication of the natural systems that were once present is visible. This not only happens in practice but as a collective, we have a historical construct where we have an illusory division between humans and nonhuman beings such as bacteria, plants, or animals. In every aspect of our lives, nature haunts us because it does not respect our human borders, i.e.. fungi do not respect humans borders, its spores are constantly in the air, come through the window, or whichever gap it finds in.[19] But we reach an uncanny realization when we think of that we are actually made of the bacteria that we are trying to keep out, that we have more non-humans parts than human parts such as bacteria in our guts.[16] When designing for a living building that is made up by fungi, it is important to understand the relationship of human between the built environment where the fungi become the house and human becomes the caretaker of the building, hence the fungi that are undesired in our lives, become a permanent part of it.

Over-sterilization

Sterilization has become a part of modern life. It has turned into a daily practice where a clean and sterilized surface, house, even our hands are accepted as good and outside as bad in our historically established norms. Especially throughout the COVID-19 outbreak, the world is faced with an uncanny unknown. As a result, cities started mass sterilizations with sprays and chemicals using it as a positive propaganda tool. While it is not an effective disease prevention method [20], it is very effective as propaganda because it is aligned with the general perspective of the built environment as a sterile space. A similar attitude where we have seen on the “Four Pest Campaign” of Maoist-era China which had devastating effects and contributed to the great famine [21]. Unnecessary cleanness is, in a way, a syndrome of modern life and a symptom of non-humanizing and removing natural elements from our life.

This attitude result creates a dilemma as we start to think buildings as living objects, and brings up the question of “how are we going to live in a building where we will not able to sterilize?”. For a future of coexistence with nature, an acknowledgement of nonhuman objects such as micro-organisms is going to be necessary.

Design for Living Systems: Materiality

Designing living systems requires a new approach to materiality. When we design with living organisms, the properties of the organism are dictating the geometries and functions of the built environment. In this chapter, mycelium is explored in order to identify its role in the built environment, in the context of living buildings. Furthermore, mycelium is explored as an insulation material in construction by developing a mixture that is contamination resistant and can be scaled up to an architectural scale.

Mycelium

Pleurotus Ostreatus, grey oyster mushroom, is a strain that grows and feeds into the lignocellulosic materials, biodegrading them in the process.[22] This particular strain is easy to cultivate, growing on readily available substrates, and has powerful and fast-developing mycelium. It is also known for its digestive properties as it decomposes not only organic waste but even some classes of plastic, making In the current industry.[23] Furthermore, the main source of lignocellulosic materials can be found in the agriculture sector. Major agriculture and food industry wastes include straw, leaves, cobs, peels, etc., and damaged agricultural produces due to pre-harvest and post-harvest losses. For every one kg of grains harvested, 1–1.5 kg of straw, cobs, or other residues are generated. In this research, Pleurotus Ostreatus is chosen as a strain for the ease of access and its resistance to pathogens, as well as the high velocity of incubation rate.

The of the main function of the mycelium is the transfer of nutrients between various organisms and mycoremediation, bioremediation through mycelium breaking down hazardous substances into a less or non-toxic matter. In practice, mycelium has been used for its binding characteristics. Once the substrate is fully incubated by mycelium, the dense root system, the mycelial biomass, turns the granulated substrate into a solid object with high tensile strength and insulative properties. It is widely used as a replacement for foam packaging and insulation panels [24]. Mycelium based composites have good potential as thermal and acoustic insulation. It is reported that the composites have similar properties with styrofoam panels with high specific heat capacity (7.4–10.2 kJ kg-1 k-1) while it absorbs over %70-75 at 1000 Hz, even by the worst-performing panels.[25][26] It also shows enhanced compression and tensile properties compared to its foam alternatives while proving safer under fire.[27]

Advantageous and Inhibiting Properties of Mycelium

As all living organisms, mycelium is also effected by pathogens and needs special care while being used and grown. While Pleurotus Ostreatus proves resistant to pathogens compared to other strains or organisms such as bacteria, pasteurization and controlled environment is still required.[28] This research focuses on developing a material system that decreases the dependency of pasteurization and increases the resistance of mycelium against pathogens, creating a gateway for further bigger scale applications.

In the current literature, the widest threat for mycelium is identified as green mold disease that is caused by Trichoderma aggressivum. This strain of fungi infects the substrate and grows approximately three times faster than Pleurotus Ostreatus, spreading throughout the substrate and inhibiting the mycelial growth.[29] It is reported that Trichoderma species show maximal mycelial growth at 25-30°C, while limited, or no growth was observed at 10°C. Woo et al.[30] reported that the temperature optimum for the growth of Pleurotus was 28°C, while Trichoderma could grow well at a wider range (20–28°C), and exceeded the growth rate of Pleurotus by three times at 25°C. These findings suggest that the temperature of the growing room should be maintained between 15 and 18°C after spawn-run in order to minimize the possibility of green mold infection. Although green mold is a global contaminant, it is suggested that changing ecophysiological parameters, we can slow down the growth of pathogens. That means higher ph levels, lower temperature and humidity can favor the mycelium growth over other pathogens.[31]

Material Explorations: Decelerating Pathogen Growth

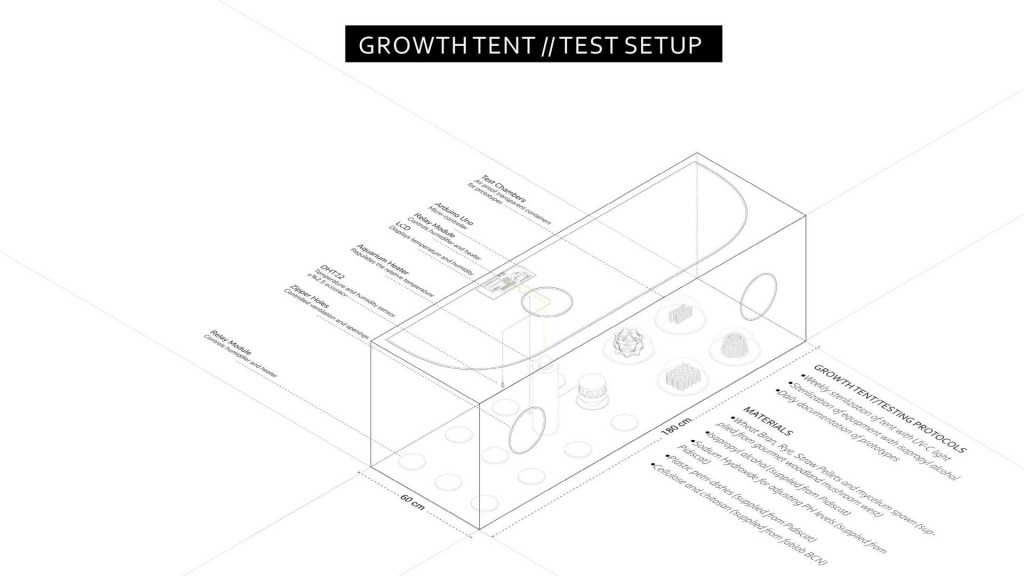

The experiment process for developing the mycelial substrate that is resistant to contamination started by developing a controlled testing chamber. In these tests, the In order findings of various researches towards controlling the contamination were tested and explored through various fabrication techniques as well as material mixtures.

In order to make experiments in a controlled manner, a growth tent setup has been developed where the interior weather conditions were kept under control. Plastic petri dishes and containers for bigger prototypes were placed in the tent. Through ultrasonic humidifier and aquarium heater, the relative humidity and temperature have been controlled. The measurements of weather conditions have been done by a dht22 temperature and humidity sensor. All the electronic setup was connected by an Arduino Uno micro-controller. As for the documentation, all the data was saved to an sd card through a micro sd card adapter shield and daily photographs of prototypes were taken. The tent is sterilized weekly with a UV-C light for 15 minutes.

For the preparation of the materials, a sterile working environment was established. All the tools and working space were sterilized with Isopropyl alcohol before use and plastic gloves were used.

Material Exploration 01

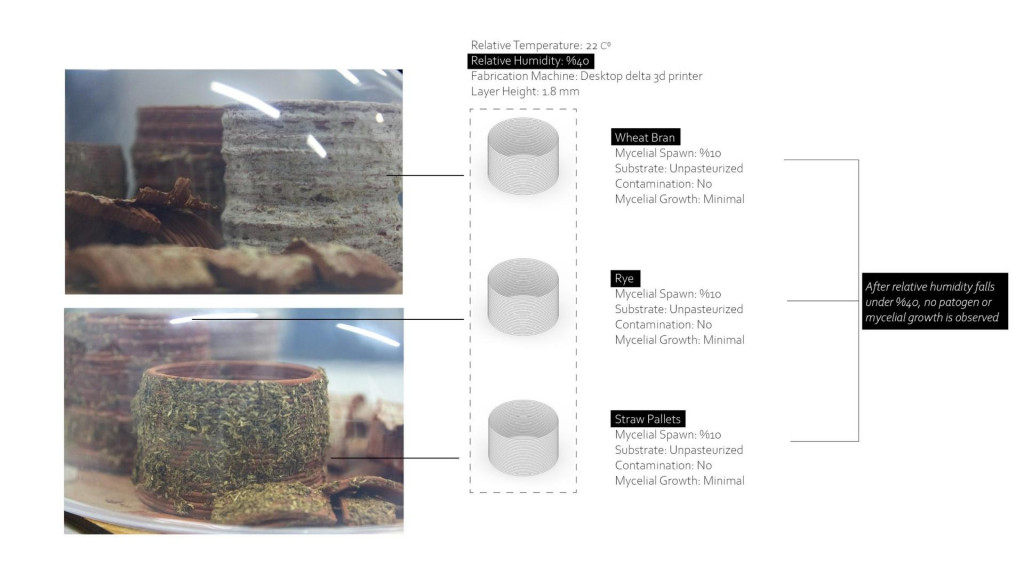

In the first series of experiments, wheat bran, straw pellets, rye, chitosan and cellulose were tested to narrow down the main substrate options in terms of mycelial growth rate.

All ingredients were pasteurized by boiling and incubated by mycelium spawn to compare the substrates. In the 24 days of time, cellulose and chitosan have shown little growth while others showed a very healthy incubation period. While the wheat bran and straw pellets showed exponential growth, rye showed a slightly slower but healthy growth, cellulose and chitosan showed minimal growth where there was almost non-existential growth in chitosan substrate.

Material Exploration 02

Establishing main substrates as wheat bran and straw pellets, a series of tests were conducted in order to develop substrates that slow down contamination, retrieving the material approach from studies that were held in Hungary. Substrates were tested to see the growth rate of mycelium in high ph level and as a result, no change was observed in mycelial growth suggesting that the mycelium is able to grow in higher ph levels without any problem. While the substrates were pasteurized, on one of the test there was a breakout of green mould in the 6th day but after the day 16, mycelial growth exceeds the green mould and took over.

Material Exploration 03

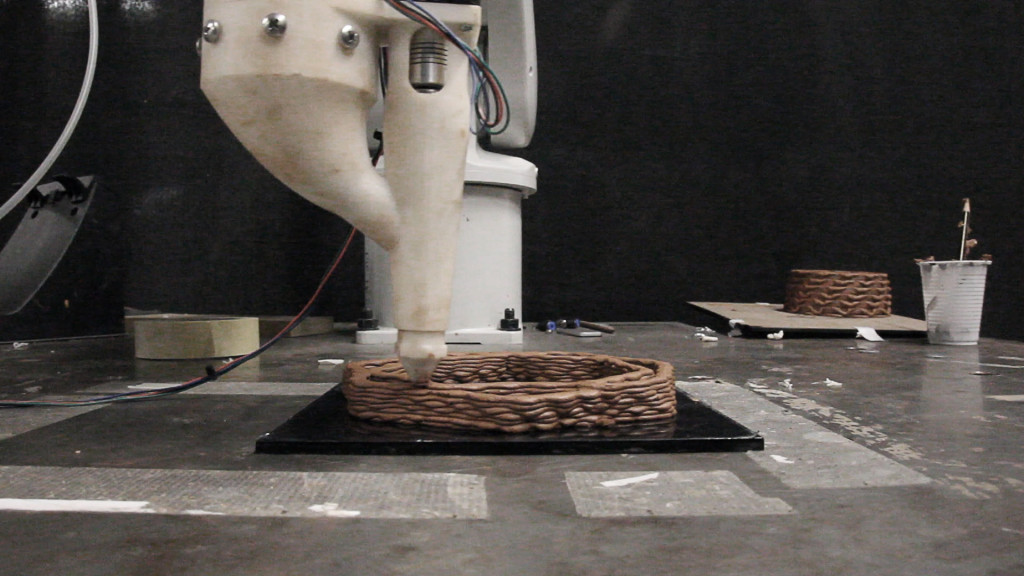

Scaling these tests up, 3 cylinders were 3d printed in the fablab of IaaC through a clay printer that is converted from a Anycubic Delta Kossel 3d printer. The printed test objects were covered with mycelial substrates, spread by a plastic bristle brush, to test mycelium behaviour in low humidity. These cylinders were not supplied by any extra water. As a result, the relative humidity stayed under %40 and eventually, the test subject was dried. In the end, minimal mycelial growth was observed while no pathogen growth was visible.

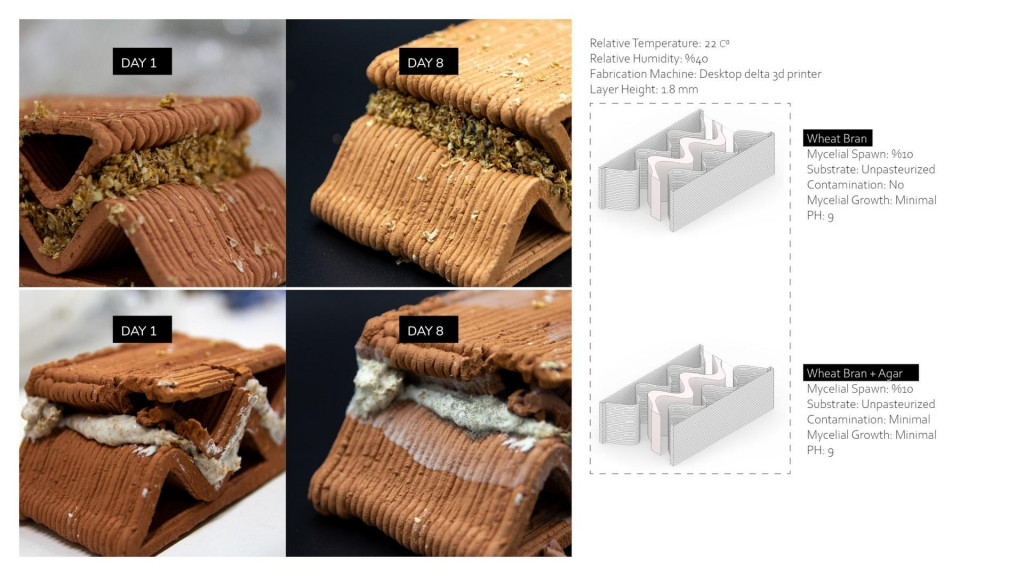

Material Exploration 04

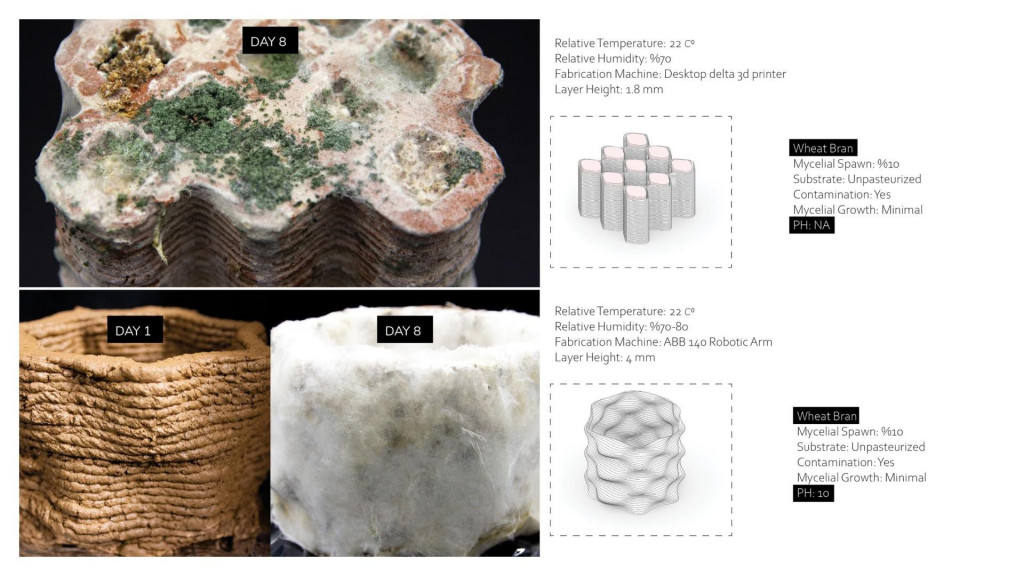

Finally, materials were combined with advanced fabrications tools and robotic additive manufacturing were tested. In these last round of tests, the aim was to observe the effects of high ph levels and controlled weather on mycelial and pathogenic growth, as well as testing different geometries. Through a single deposition paste extruder that is designed for ABB 120, a lattice structure and a deformed cylinder form were 3d printed. The lattice structure was printed solely with clay and the cavities were filled with mycelial substrate. The ph levels were not adjusted and the substrate was not pasteurized. Because the substrate ecophysiological properties were not changed, exponential pathogen growth was observed, mainly consisting of green mould.

On the second prototype, the same substrate as the previous test was also not pasteurized but the ph level was elevated up to 10. As a result, although there was contamination of green mould and anaerobic bacteria, the mycelium was able to incubate and colonize the whole structure.

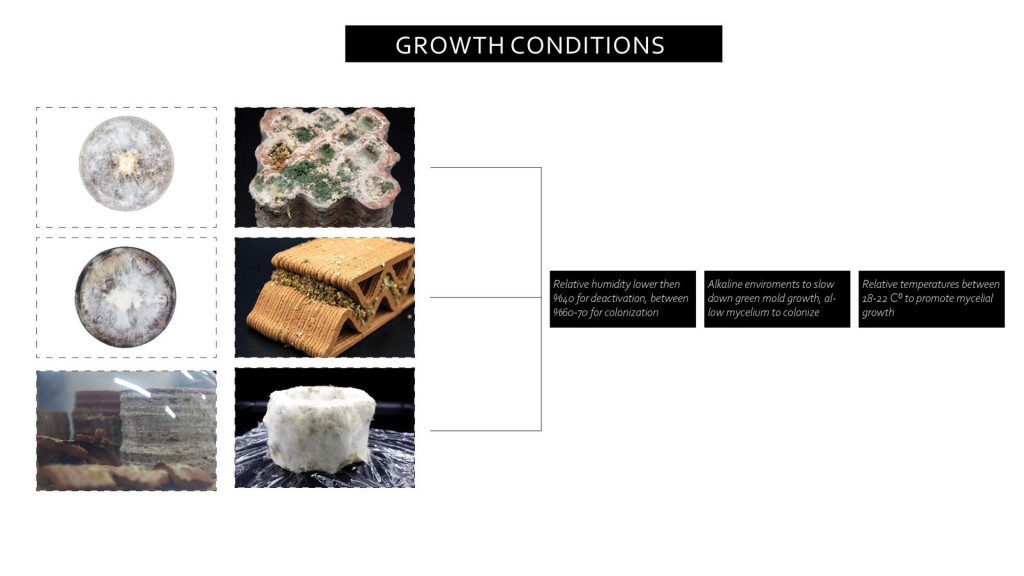

In the end, it was visible that the higher ph and lower humidity levels favoured mycelial growth over Trichoderma aggressivum. While numerous studies also suggest that keeping the temperature around 18-degree Celcius [9], it was not tested due to the lack of equipment.

As a conclusion, these findings suggest that in dry climatic conditions, if we can provide an environment with humidity around %60 percentage, mycelium can colonize the substrate and can be deactivated by drying it through cutting down the humidity source while keeping the ph level around 10.

Material Exploration 05

Finally, materials were combined with advanced fabrications tools and robotic additive manufacturing were tested. In these last round of tests, the aim was to observe the effects of high ph levels and controlled weather on mycelial and pathogenic growth, as well as testing different geometries. Through a single deposition paste extruder that is designed for ABB 120, a lattice structure and a deformed cylinder form were 3d printed. The lattice structure was printed solely with clay and the cavities were filled with mycelial substrate. The ph levels were not adjusted and the substrate was not pasteurized. Because the substrate ecophysiological properties were not changed, exponential pathogen growth was observed, mainly consisting of green mould.

On the second prototype, the same substrate as the previous test was also not pasteurized but the ph level was elevated up to 10. As a result, although there was contamination of green mould and anaerobic bacteria, the mycelium was able to incubate and colonize the whole structure.

In the end, it was visible that the higher ph and lower humidity levels favoured mycelial growth over Trichoderma aggressivum. While numerous studies also suggest that keeping the temperature around 18 degrees Celcius [32], it was not tested due to the lack of equipment.

In conclusion, these findings suggest that in dry climatic conditions, if we can provide an environment with humidity around %60 percentage, mycelium can colonize the substrate and can be deactivated by drying it through cutting down the humidity source while keeping the ph level around 10.

Advanced Fabrication

The computational based geometry exploration has made it apparent that additive manufacturing would be optimal for controlling the overall results of the fabrication. It was hypothesized that additive manufacturing would allow the complexity of the computationally driven geometries to be fabricated and the complexity of the geometries would stand in the fabrication process. 3d printing enables a level of control that allows the manipulation of geometries in micro and macro scales. In micro-scale, by changing the ingredients in the substrate, it is possible to control the growth patterns and density of mycelium while in macro-scale complex geometries can be implemented to optimize the structure for performance and growth.

Initially, a single material extruder was used for tests and later on a multi-material extruder was developed to be able to print clay and the mycelial substrate together or separately. This chapter of the research presents the results of a series of fabrications and a multi-extruder that was developed for this research.

Single material Deposition

Initially, the fabrication method has revolved around a single-material deposition additive manufacturing. The use of additive manufacturing proved fruitful for it allowed fabrication of the material mixture that consists of clay, wheat bran and mycelium spawn without waste and high precision.

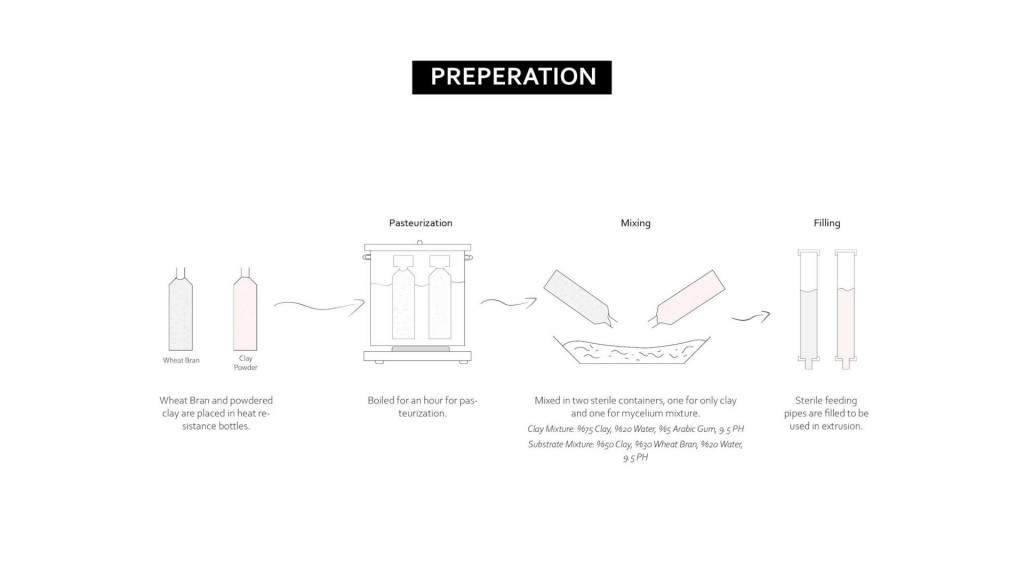

A straight forward method was used to prepare the materials for fabrication; the materials were boiled in a cooker to pasteurize the materials in auto-clave bottles and they were mixed in PVC pipes to be 3d printed. In the beginning, an Anycubic Delta Kossel 3D printer was converted into a paste extruder in IaaC fablab and used for small scale prototypes and material explorations. In this scale, it was obvious that the additive manufacturing of the paste materials would increase the control over the material to make data-informed explorations. Experiments started by 3d printing only clay to adjust the necessary viscosity. Later on, the wheat bran and straw mycelium spawn were introduced. Implementing the solid materials to the material mix creates problems when working with extruders that pushes the materials as a printing method. To successfully 3d print high viscose materials that consist of solid particles, using an extruder with an auger bit as a pushing method is advised. The stepper motor provides a high torque that rotates the auger bit with high precision, pushes down solid particles and does not create air bubbles inside the tool.

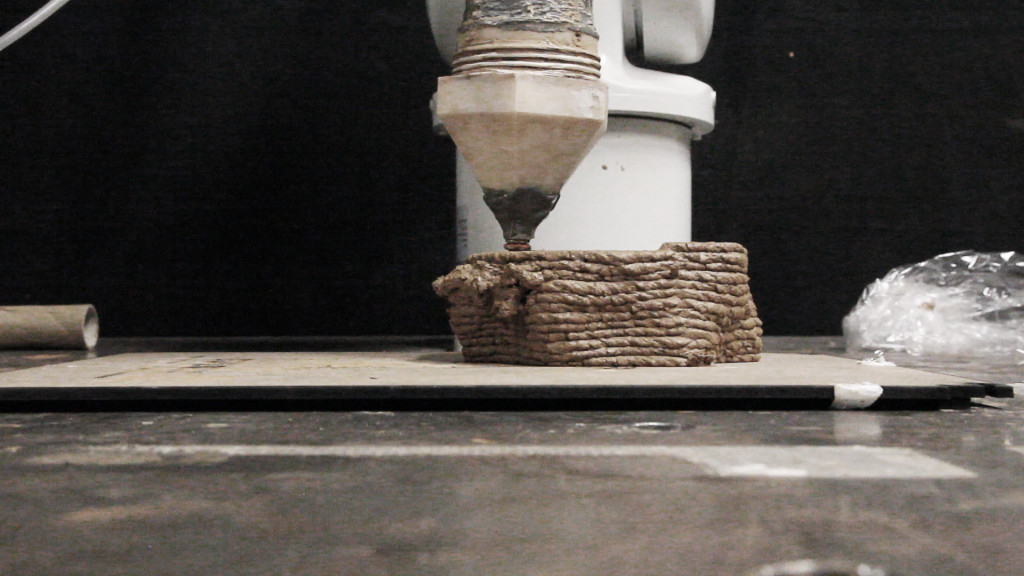

Scaling up to an ABB 120 robotic arm from desktop 3d printers showed the feasibility and adaptability of the fabrication method. In this stage, a single material extrusion tool that was developed by IaaC Fablab for ABB 120 and ABB 140 was used. Testing has initially been done in simple geometries. The exploration was started to master the fabrication technique and the material mix. A series of cylindric geometries were 3d printed to compare various material mixes. The aim stayed on developing and testing the growth rate of the mycelial substrate on a bigger scale and observing the effect of various ecophysiological conditions on contaminants, specifically on green mold.

Mycelial Substrate for 3D printing

Before creating material mixes, the effects of the various materials on the final performance of the 3d printed structure had to be understood. In clay mixtures, the water ratio is highly important for it is the biggest factor that effects the material plasticity while printing and the amount of shrinkage as well as the tensile and the compression strength of the final structure under stress. While working with mycelium, a high amount of humidity source is required, but it also needs to be limited to a ratio of around %60 relative humidity for a certain period of time in order to avoid contamination and ensure the colonization. In addition, adding a source of nutrients for mycelium is necessary and using wheat bran as a substitute provides a fast drying process as well as high hardness without cracking.[33] Furthermore, colonization of the substrate by mycelial roots increases the durability of the printed structure as well as turns the whole system aquaphobic.[34]

Regarding the material exploration presented in previous chapters and the optimal mixture for colonization as well as of ease of fabrication in the contaminated environment have been established as %75 Clay, %20 Water, %5 Arabic Gum, 9.5 PH.

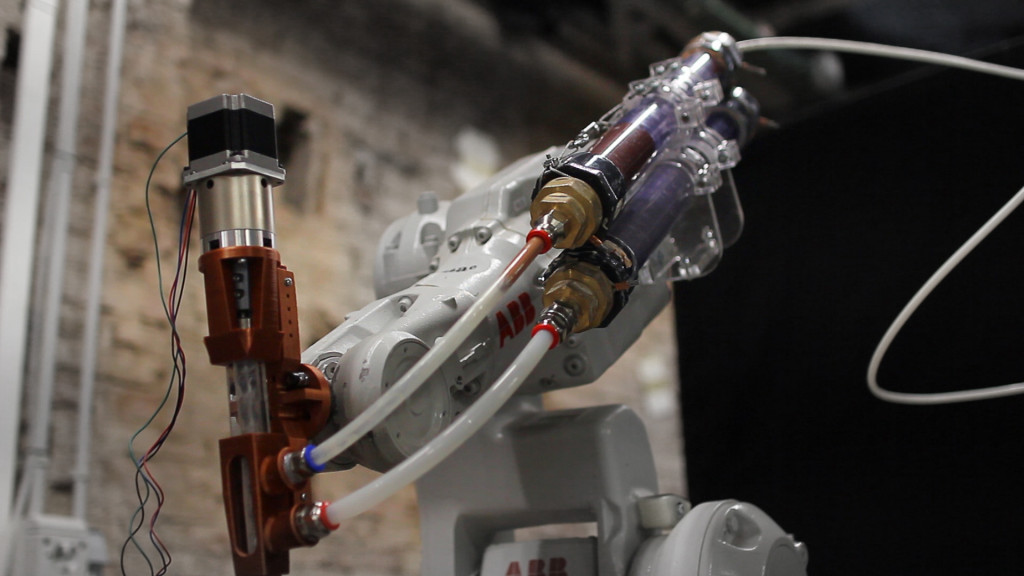

Multi-Extruder

While the single deposition system proved to be sufficient for controlling and manipulating the material system, this research aims to create a wall system as a living organism that has various levels of complexity. First of all, mycelium is approached as an insulative agent that coexist in the cavities of the wall and needs to be separated from the human habitation space. This requires the extrusion of multiple materials in different ratios. For this purpose, it is hypothesized that the extrusion of clay and the mycelial substrate or mixing the clay and the substrate in the extruder with different ratios would allow the wall system to have a various level with different functionality through different material ratios.

The multi-extruder was designed through various iterations for ABB 120 and ABB 140 though it is highly modular, detachable and can be used in other robotic arms. The tool is designed parametrically so the number of inputs can be increased if needed. The tool allows the input materials to be printed on turn bases or the materials can be mixed in the static mixer. The materials are pushed down from PVC high-pressure pipes, which are stored on the side of the robot, into the tool through plastic pipes. The material is pushed down by the rotation of the auger drill bit. Later it is mixed by a static mixer with four times in two cycles. Using the motor and auger bit for extrusion allows 3D printing to stop and start by instantly stopping the material extrusion.

As a rule, the solid particle sizes in the mixture should not exceed half of the size of the flute and the nozzle diameter. The material should be in a similar viscosity to toothpaste and high torque gearbox should be used if the static mixer will be used. On the other hand, without the static mixer, there is no need for a gearbox.

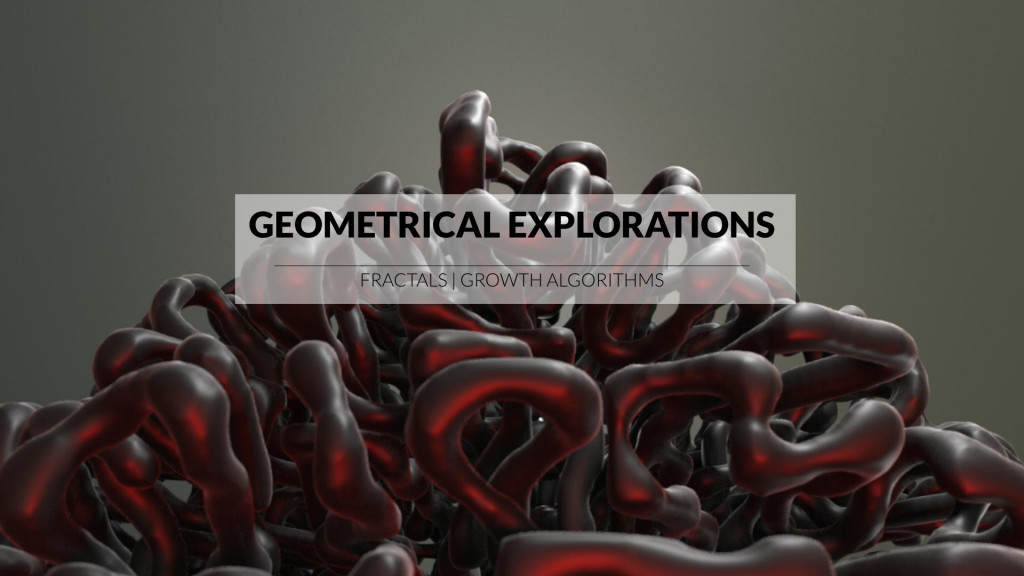

Geometrical Explorations

In parallel with material and mycelium experiments, a series of computational methods were explored. Designing for living organisms requires a habitation design that needs to be informed and designed for the characteristics of the organism. By designing algorithms, it was hypothesized that a habitation zone for mycelium and topology that would contain both humans and mycelium in the articulated space would be generated.

Through the exploration of various geometries and algorithms, it was intended to understand the aesthetics, growth patterns and relationship of morphologies with spaces. Algorithms allow us to document and study various patterns of complex structures as well as speculate architectural morphologies.

This chapter mainly focuses on the outcomes of the geometrical explorations and the resulted geometries either by single method or a combination of multiple methods.

Initially, randomized growth algorithms were used to mimic coral geometries but proved to be uncontrolled and eventually replaced with generative and avoidance methods, fractals and reaction-diffusion in order to gain more control over the geometry.

The Mandelbulb and Juliabulb fractal formulas were explored in an attempt to create zones for mycelial habitation and create an increased but controlled volume.

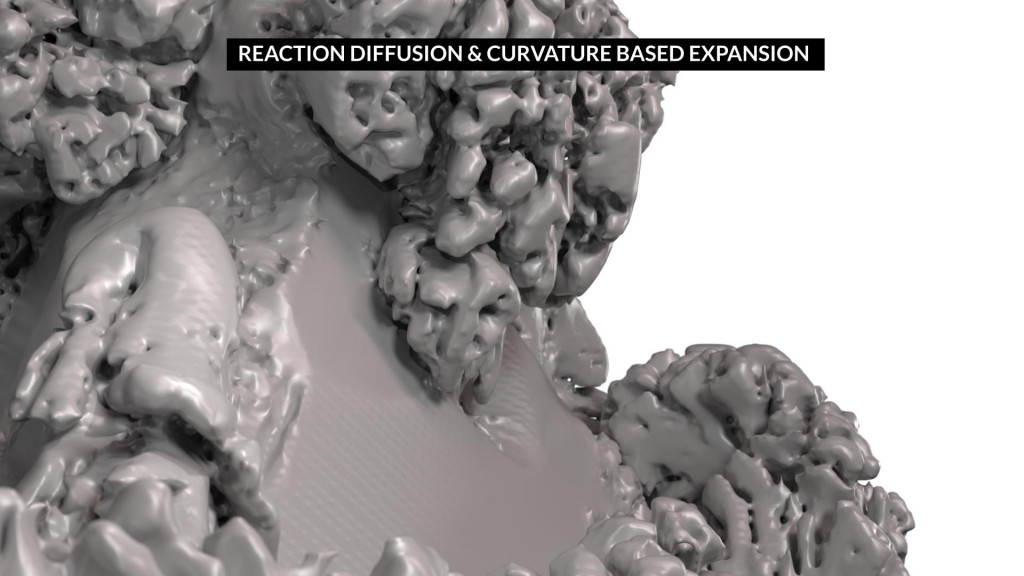

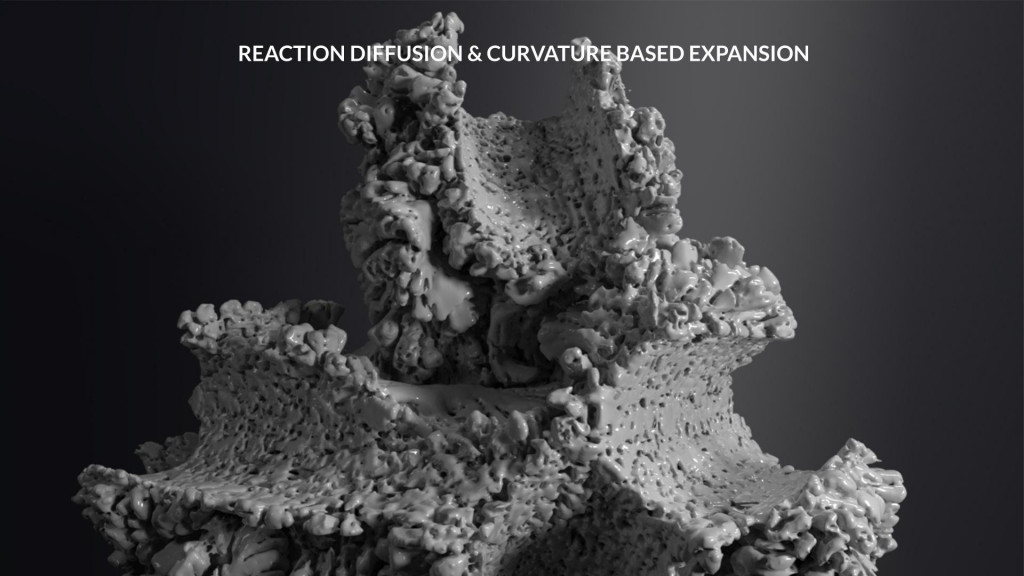

In addition, reaction-diffusion and curvature-based generative growth algorithms were developed in an attempt to understand and create complex spaces with various aesthetical identities. The shapes were generated by expansion, filling the space and growing while creating defined zones.

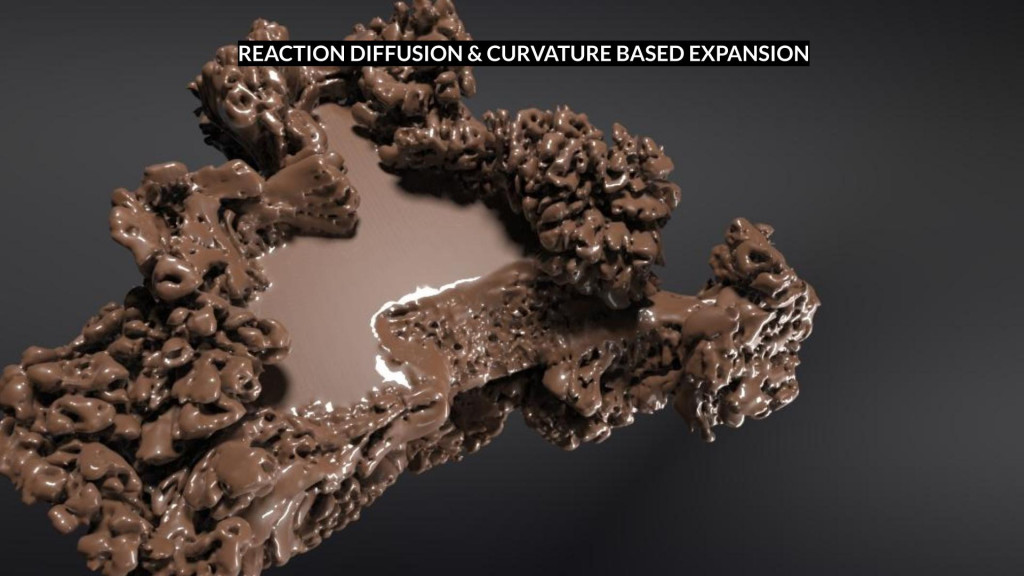

Reaction-Diffusion and Curvature based expansion methods

Initially, reaction-diffusion and curvature-based expansion algorithms were combined to generate a controlled growth of various primitive shapes. The aim was to create a morphology that consists of various defined spaces in and around it. Primitive shapes were deformed, twisted and grown through expansion. By combining reaction-diffusion with curvature-based growth algorithms, it was possible to control the growth of the whole structure as a system, stop the growth in predefined spaces and reactivate it based on the curvature of the surfaces. The growth patterns were used either to generate porous geometries or to increase the surface area and the interior volume by reaction-diffusion.

Later on, the whole algorithm was combined with Juliabulb in an attempt to use it as a pathfinder and lead the growth on the resulted point cloud. While it was promising to generate an informed growth path, it was not possible to control the parameters as expected, but rather they have resulted as randomly generated geometries. Because of it requires manipulation of the function, Juliabulb were not further used, and the growth algorithms with reaction-diffusion remained as a method of form-finding.

Design and application

In the design process, an object-oriented design methodology was followed, the focus and the purpose of the designs were narrowed down to create a living space and habitation zones for mycelium. The geographical locations were analyzed and have been chosen based on weather parameters that are required and observed from material experiments for mycelial growth. The walls are designed to create an envelope that forms a passive building by the use of thermal mass and insulation. The walls are designed and optimized through generative algorithms for thermal and insulative performance as a closed envelope. The design process was concluded in various iterations and different walls were generated for south and north facades.

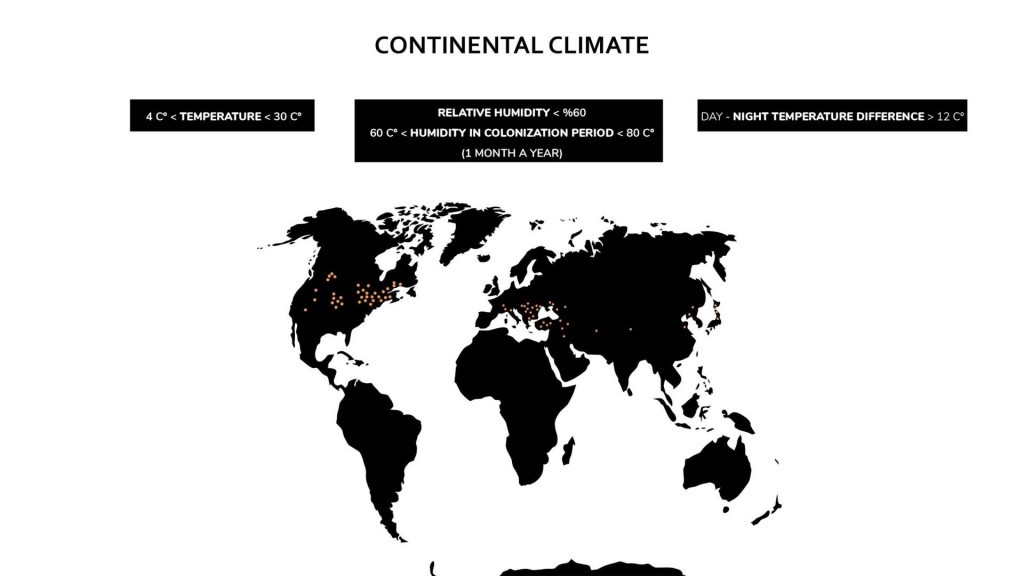

Geographical Locations for Subsisting Mycelium

When designing for a living building, we need to keep in mind that this is a living object. For that purpose, before starting to design with and for living organisms, suitable environmental conditions has to be studied. The set of required weather conditions and mixture properties from the conclusion of the material experiments acted as decider.

In general, relative humidity between %60-70 is required. Moreover, a temperature of 18-22 oC is necessary for a healthy mycelium and minimal pathogenic growth.[31] Furthermore, the mycelium growth needs to be controlled. It needs to be activated for growth after the structure is built, and needs to be activated after the colonization is complete. For that, various weather conditions are needed in different periods of the year. This level of control can be achieved through humidity. When the humidity is increased up to %60-%70 and decreases below %40, the mycelial and pathogenic growth can be controlled. When the relative humidity is in the range of %60-%70, the mycelium can be incubated and it can colonize the whole structure. When the relative humidity falls to %40, all subsisting organisms can be deactivated by drying the structure. If said high humidity lasts for around 30 days and the rest of the year is dry, it proves to be a suitable and optimal location for initial growth.

In addition to humidity, a big temperature difference between day and night is needed. This is because in the summer day, when the temperature starts to rise, the air will start to get dry and a humidity source will be required. To collect sufficient humidity, collecting morning dews were identified as an adequate technique. To collect the morning dew, the night temperature should fall under the dew point to ensure the forming of the dew on the ground and surfaces. Through this technique, humidity can be collected, absorbed and transferred to the cavities of the structure through the geometry of the walls, and as temperature increases on day time, the absorbed water in the wall will be utilized as a humidity source.

Overall, Cappadocia has been identified as one of the most suitable locations for the required weather conditions and 118 other locations were identified with at least %97 similarity based on the data of the website

http://www.codeminders.com/weather_similarity/.

In Cappadocia, 1 month a year becomes suitable for mycelial growth. In that period of time, the weather temperature in the day exceeds the dew point by 5 oC, which means the dew can be absorbed by the building and can be utilized as a humidity source throughout the day.

In the right geographical locations, the growth process of a building would take around 1 month, a growth process that consists of incubation and colonization. Overall, the construction of a functional wall will take the three steps of 3d printing, growth and deactivation of subsisting organisms.

Design for Performance

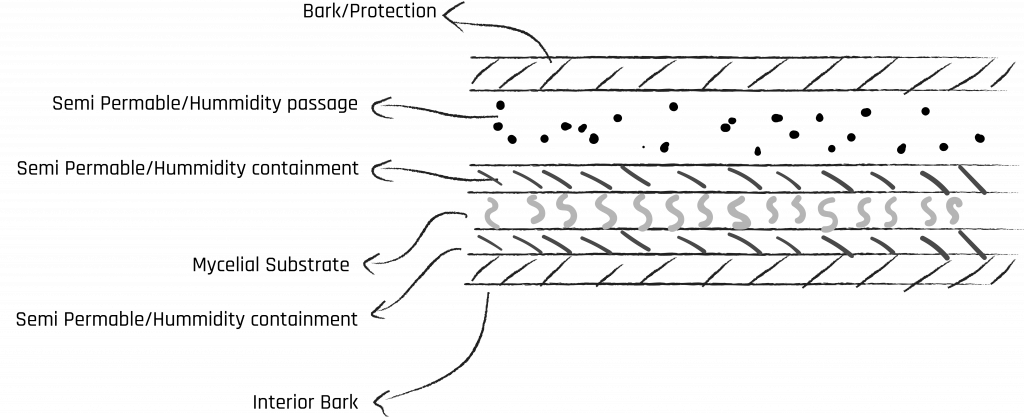

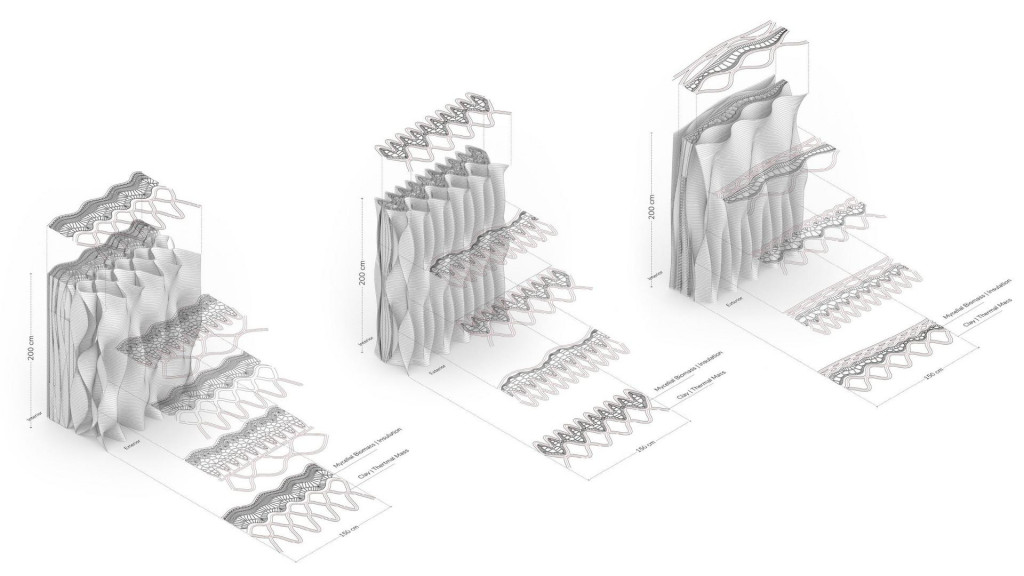

Designing for additive manufacturing and performance requires a process of environmental study as well as the material performance of clay and mycelial material. In this wall system, clay acts as a protective shell for mycelium as well as a thermal mass while the mycelial biomass is the main insulative agent.

Thermal Mass and Insulation

In the current literature, the thermal mass and insulation work in harmony. In passive buildings, thermal mass absorbs heat and performs thermal lag between spaces while the insulation retards heat flow, protecting indoor spaces from heat loss. Thermal mass is typically contained in walls, partitions, ceilings and floors and utilizes the solar energy available from the sun. Thermal mass stores the solar energy and releases it slowly at a later time and it is needed in arid and continental climates, where the temperature differences are high between day and night.[35] In summers, the heat is released in the night time, decreasing heat peaks as a result. In winter, the solar energy is stored and released over a long period, helping to regulate the indoor temperatures.[36] The correct use of thermal mass can reduce energy consumption %20 alone.[36] Furthermore, the insulation can be used to minimize heat loss or heat gain in buildings. Insulation becomes high importance, especially in the high energy loss areas such as the roofs or north facades of the buildings.

Integrating and optimizing the thermal mass and insulation in additive manufacturing can create a building envelope where the walls would be locally optimized for performance through geometry, density and thickness. That means the thermal mass or insulation can be adjusted based on the needs of different parts of the structure, forming a truly passive building.[37]

Multi-Layered wall system design

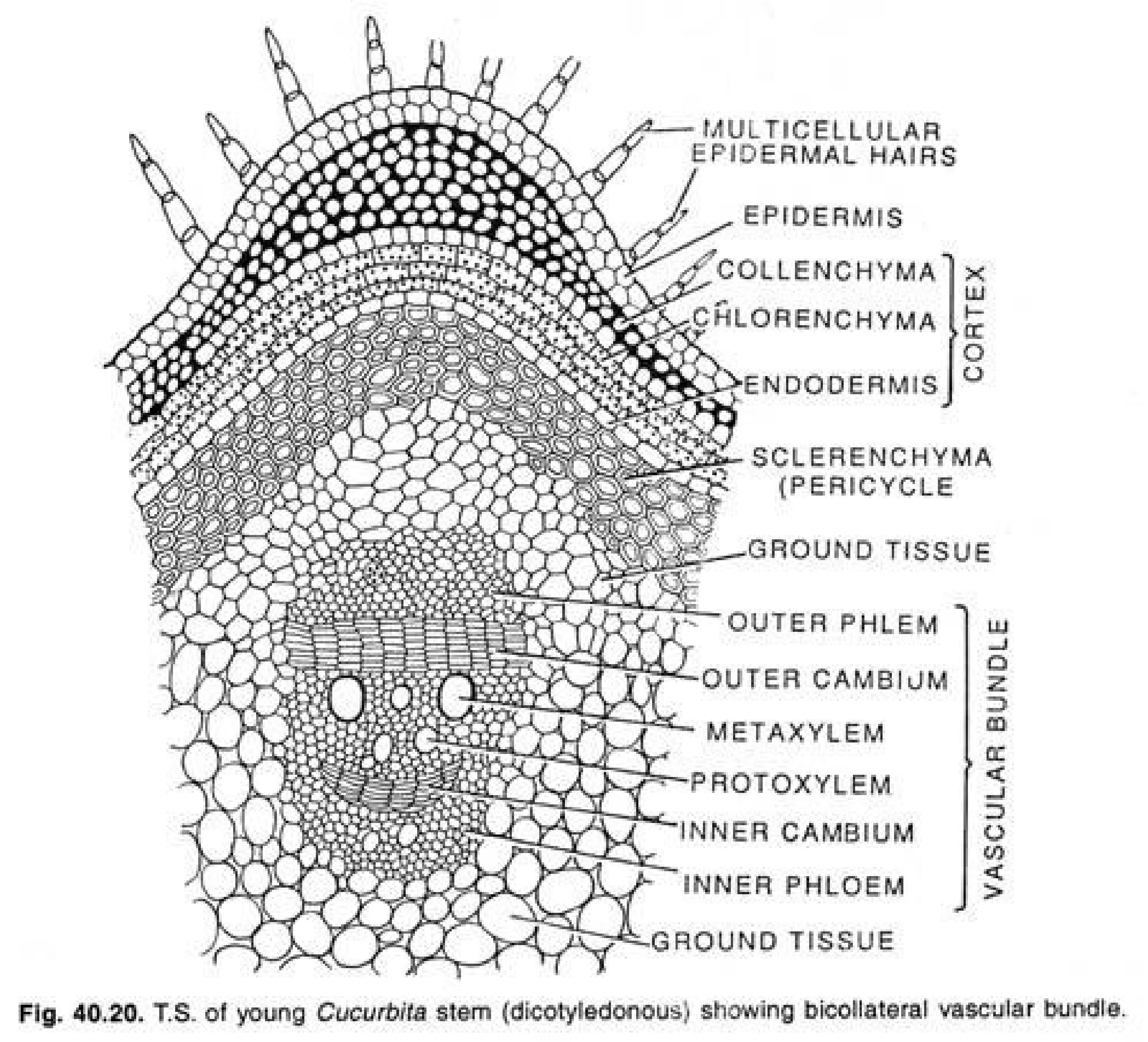

The design for the walls started by studying and extracting knowledge from existing in-house knowledge of ‘OTF 3D Printing Architecture’ of IaaC on additive manufacturing of clay in large scale applications, as well as studying tree stem structures and micro-organisms.

The plant stems show a level of complexity that is optimized by evolution for performance. These multi-layered organisms have various parts of their stems which have different functions. The bark in these stems is made of hard, lignocellulosic materials that separate the humid inner parts of the stem where the main subsisting function exists. The geometries of stems vary based on the location of the plants and the functionality. While the volume to the surface is increased in arid and dry climates, the surface area is increased in humid places. Material and geometry of the surface control the sun exposure, humidity storage and porosity.

When designing the walls, a system similar to stem roots were followed. In the wall systems, clay is responsible for heat storage and thermal lag. Using the L-system for infill geometries, the heat lag is controlled through calculating the thermal conductance of the clay. As a rule of thumb, the heat flow is reduced and divided by each branch of the infill system and calculated with the equation of (?Q/ ?t)=(-k*A/ ?X). Through this system, the infill geometry is designed in order to reduce the heat.

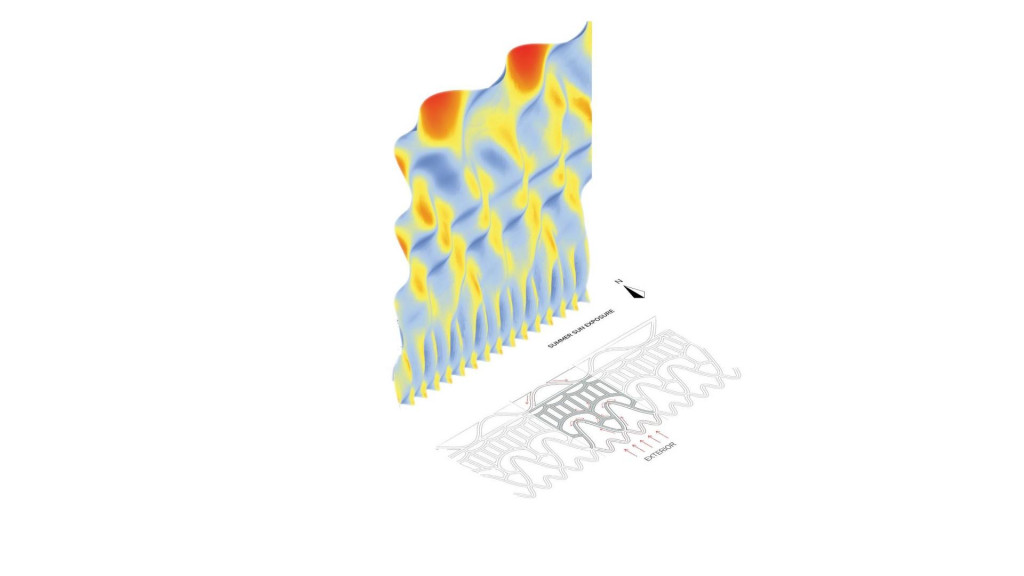

Furthermore, the geometry of the walls was used to utilize solar energy. By changing the surface texture and curvature, the shade and exposed areas were designed. Through the topography, the summer sun exposure is minimized while in the winter, the low angle sun exposure was maximized. This approach to temperature flow control through geometry and material performance ensures a passive building system and increases control over the indoor temperatures without artificial heating agents.

In addition, the infill geometries of the walls were specifically designed according to exposure of sun exposure as well as to minimize the heat loss from the interior. The infill geometry creates an increased inhabitation area for mycelium while absorbs the dew from outdoors and creates various bubble structures in the wall. This helps contain the air, thus regulates and divides the outdoor and indoor areas.

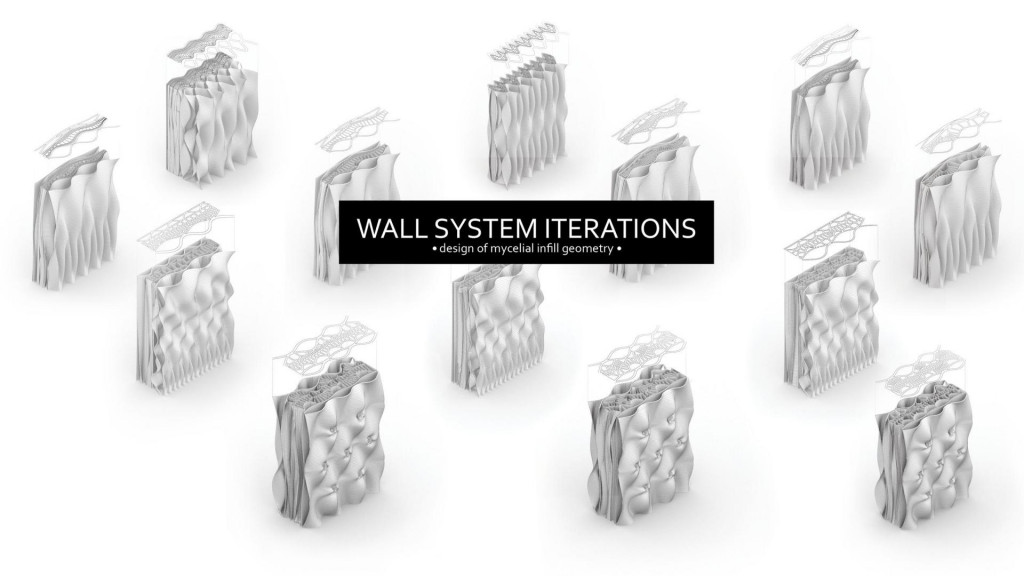

On the design process of the wall systems, several iterations were made specifically for the north and south walls. The parameters of sun exposure, dew collection, growth rate optimization and insulation were explored. Design of the infill patterns and topography were made by growth algorithms, generative algorithms and genetic optimization tools in the Grasshopper environment.

Design Iterations

The wall designs were conducted as a series of iterations, focusing on certain aspects of design problems in each. Custom growth algorithms were developed and the topologies of the walls were designed for thermal performance by environmental analyzation tools.

Iteration 01 – Geometry exploration

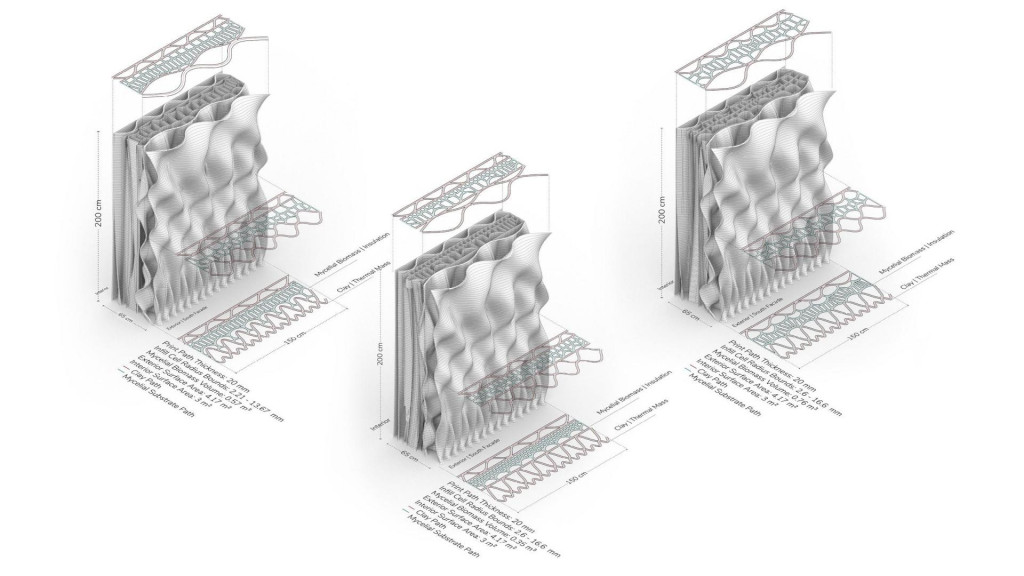

In the first set of iterations, various wall topographies were explored. Explorations were tested for environmental performance in Grasshopper Ladybug for south and north facades. Besides, several infill algorithms were designed based on growth to maximize the habitation area for mycelium. Various infill patterns were designed throughout each wall slice to explore the possibility of designing walls for local performance, which means the infill changes throughout the wall for optimal performance.

Iteration 02 – Infill Pattern Exploration

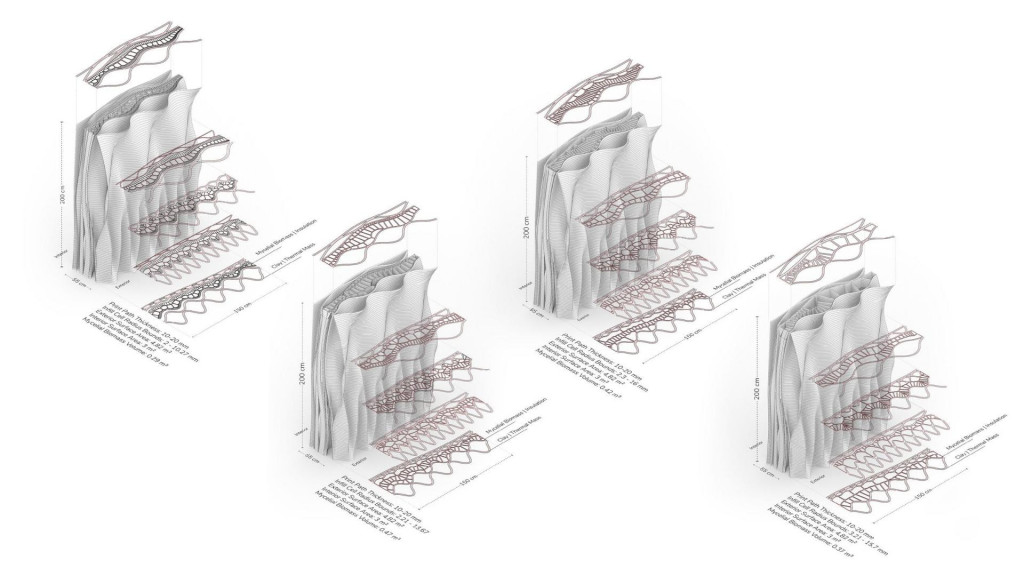

After the first set of iterations, a wall topography was designed and a set of iteration was made based on a single design. In this stage, the print path of clay and mycelial substrate were introduced. Parameters of mycelial biomass volume, print path radius and thicknesses were explored. Infill patterns were generated in order to achieve a feasible 3d print scenario.

Iteration 03 – South Facade

New parameters were introduced to the design algorithm to control the infill patterns and topology of the walls of the south facade. The topology of interior an exterior facades were optimized for thermal conductivity and solar performance. Infill patterns were generated in the limitations of the multi-extruder in terms of the stop and start numbers per layer and thickness of print paths while creating continuous areas as mycelium habitation zones.

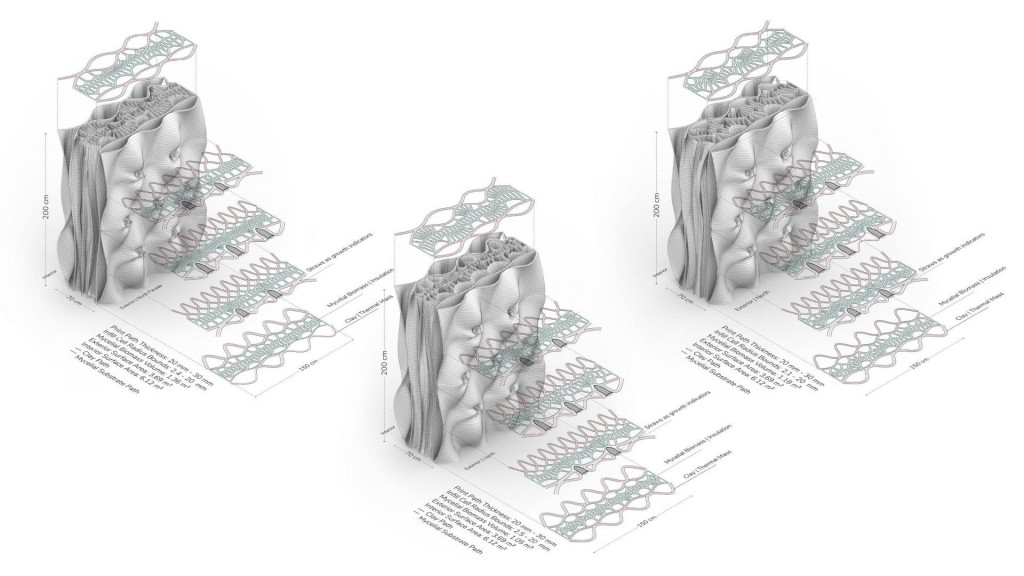

Iteration 04 – North Facade

North facades were designed to utilize the heat loss and gain as well as dew collection to ensure the initial colonization of mycelium. Several pockets were created on the facade and filled with wheat straw. Through these straws; the mycelium growth can be monitored and dew can be collected while these pockets create a circulation of air. Once the mycelium colonizes the inner substrate, it starts to grow towards outside where the straws are located. If growth on the straws is visible, that will mean the incubation period is finished and the building needs to be deactivated by filling the holes with clay. Furthermore, the wall topography leads the morning dew towards the straws where it is transferred to the inside. Through dew collection, the infill remains humid and the growth of mycelium is not obstructed.

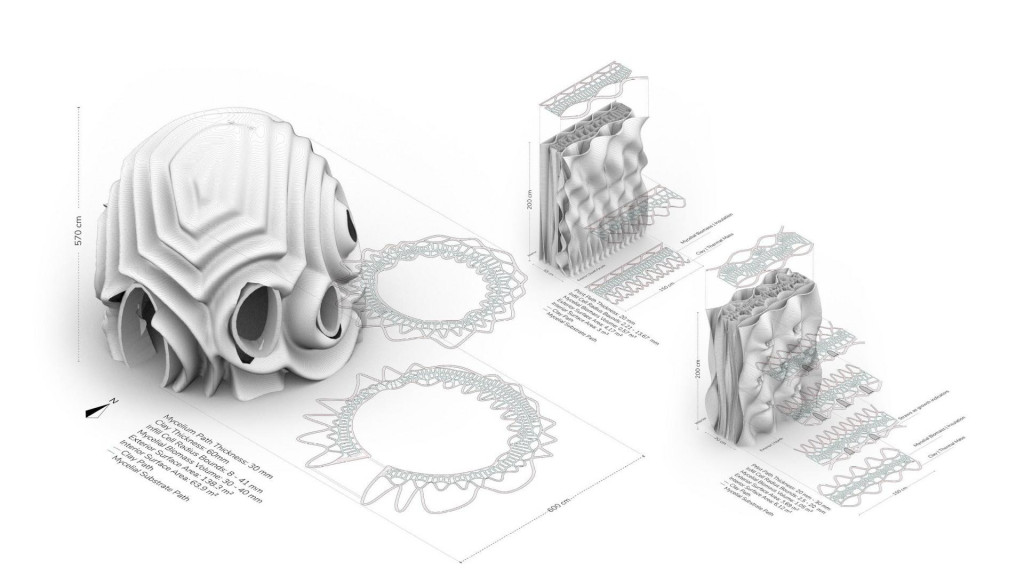

Iteration 05 – Simple hut Design

To conclude, a simple hut was designed based on the parameters developed in the wall explorations. In the end, it was visible that the infill pattern can be optimized in x,y and z direction based on the insulation and thermal mass necessities of the building, creating a passive building system where the thermal mass and insulative mass are incorporated to each other.

Conclusion

Zoetic Morphologies is multi-disciplinary research exploring a new approach towards the construction of the built environment by merging synthetic biology and robotic fabrication. The fungal mycelial biomass of Pleurotus Ostreatus was used as insulation in architectural scale applications by embedding them into 3d printed clay structures on the fabrication process. While a new contamination resistant material mixture, a robotic fabrication tool and a wall system were developed, the relationship between the built environment and nature was explored in the context of living architecture.

The material system has been developed by utilizing agricultural waste and altering the ecophysiological properties of the material. Various test chambers were developed through physical computing consisting of sensors, micro-controllers and activators to actively monitor and document the experiments. The final material mixture was tested in contaminated environments and showed fruitful results by inhibiting green mold growth. Series of prototypes were successfully incubated by mycelium through various advanced fabrication techniques. The prototypes were fabricated through desktop 3d printers and ABB 120 and ABB 140 robotic arms. Furthermore, a modular multi-material deposition tool for additive manufacturing was developed to 3d print mycelial substrate and clay spontaneously. A series of design iterations were made pointing toward a bottom-up approach where various wall systems were developed by designing a habitation zone for mycelium in the walls. By utilizing computational algorithms and mimicry of stem root systems, wall topology was optimized and analyzed. A series of final designs were created that embeds the growth into the construction of the built environment where the input and the output are biodegradable.

Future Work

The next steps of the project could focus on large scale prototyping and further testing of the developed material mixture. While various techniques and fabrication tools were developed, it was not possible to reach foreseen results and put the multi-extruder in use due to quarantine of Covid-19 for the four months of the research.

Moreover, further research on applications of mycelium would be essential for advancing the functions and roles of the mycelium in the built environment from mycoremediation to bio-degradation as well as a further investigation of the human relationship with living architecture.

Finally, the bigger picture of the project would include an urban scale application which connects the buildings through mycelial roots while sensors and electronics can be implemented to monitor the built environment in urban scale and promote biodiversity in cities.

Zoetic Morphologies is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at the Master in Advanced Architecture Student: Doruk Y?ld?r?m Faculty: Marcos Cruz, Kunaljit Singh Chadha