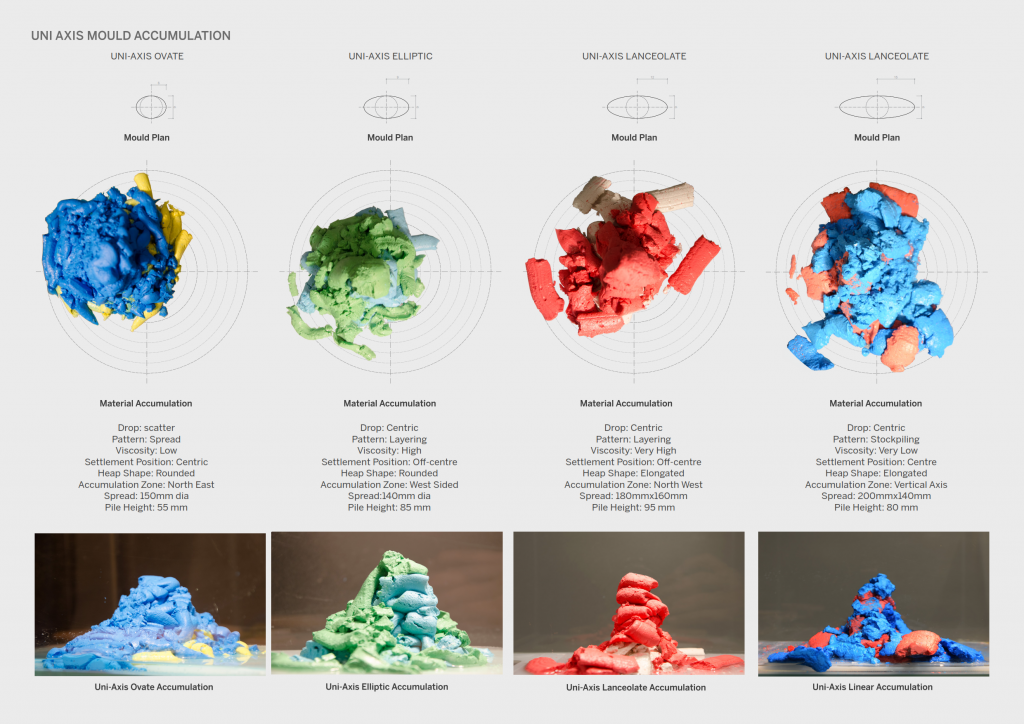

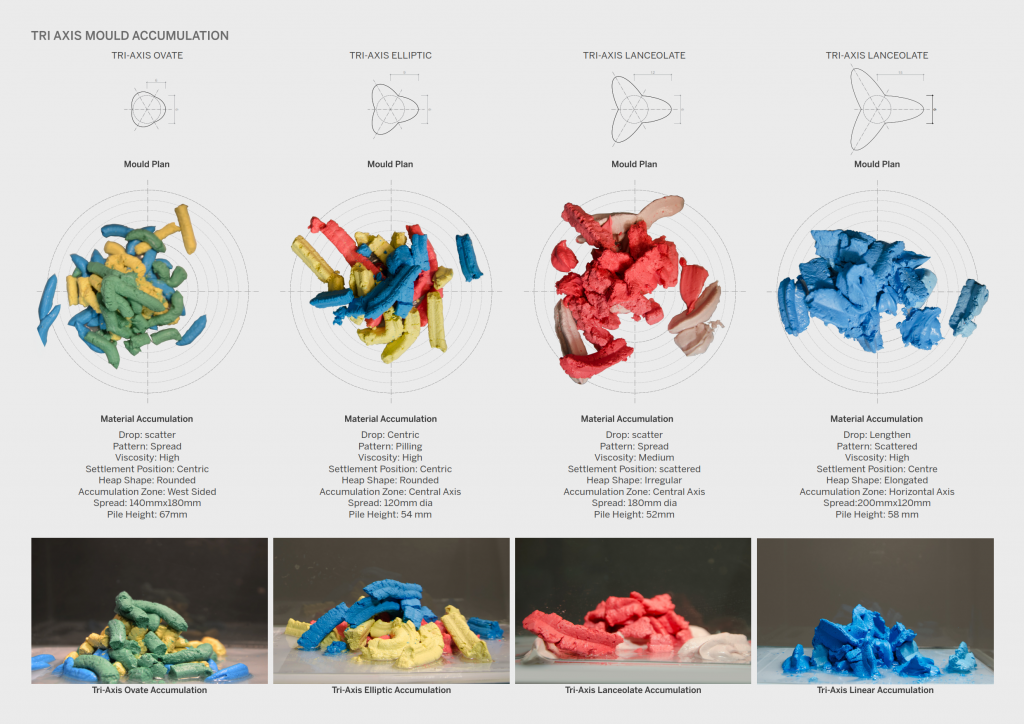

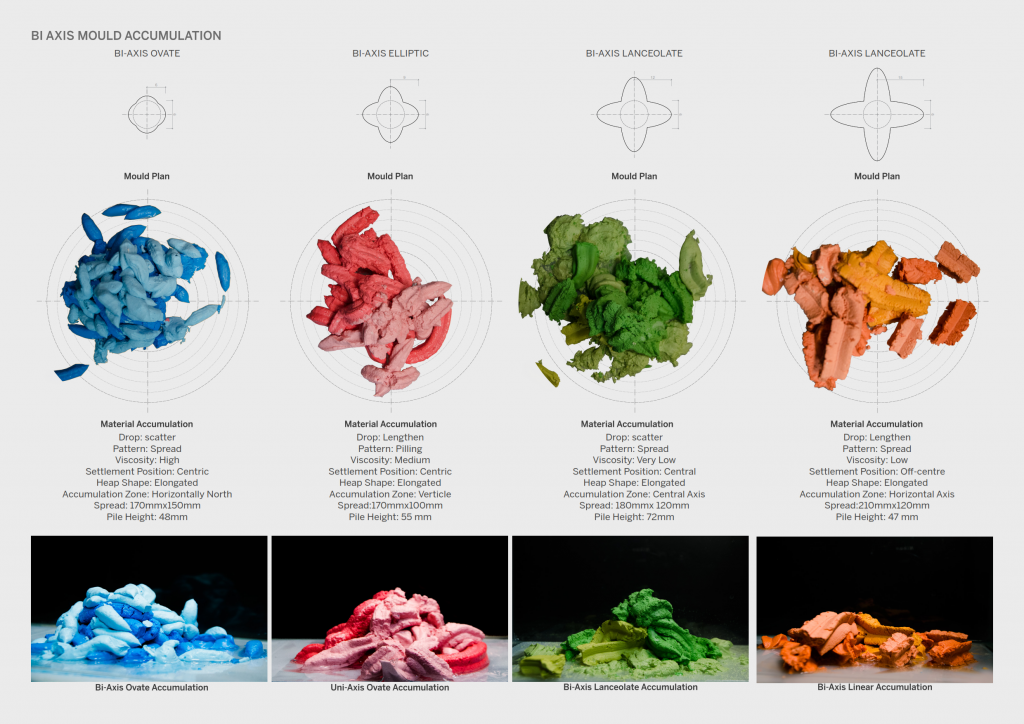

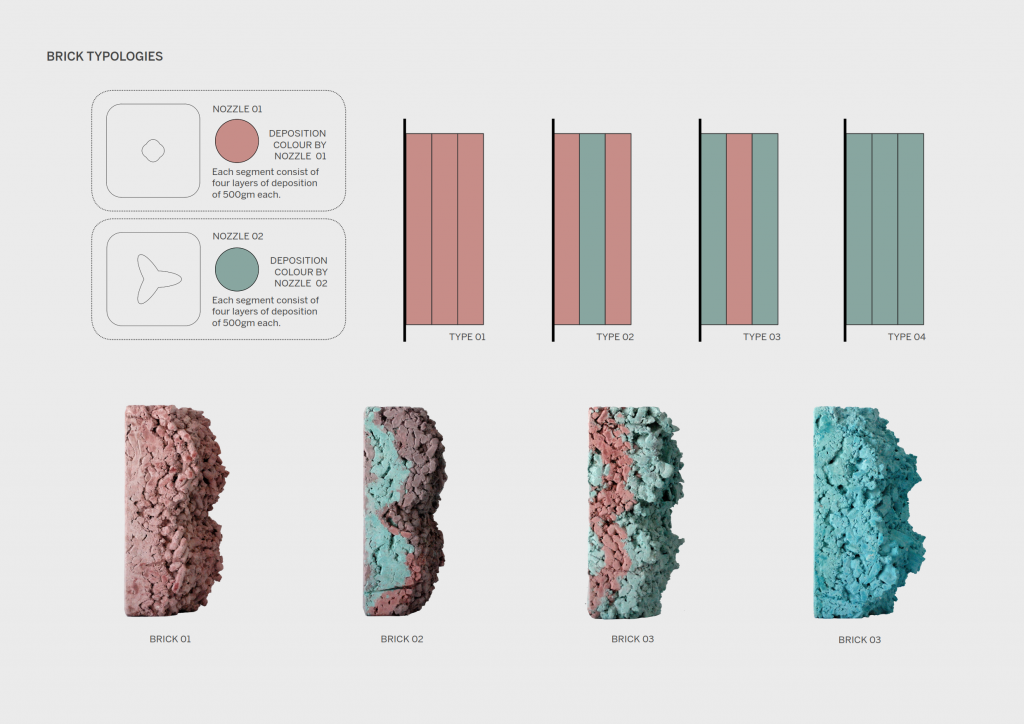

By dealing with the ambiguities and incongruities of material this research has led to define a new process or new methodology or system of basic building blocks through material itself. This research focus on fabrication techniques related to deposition of material under water which response towards climate and creates its own microclimate. Material accumulation experiment has done in order to identify the behavior of material. For which 3 sets of nozzel is designed of fixed shapes varying its length. the aim here is to observed its deposition, drop area, accumulation pattern.

Material accumulation experiment has done in order to identify the behavior of material. For which 3 sets of nozzel is designed of fixed shapes varying its length. the aim here is to observed its deposition, drop area, accumulation pattern.

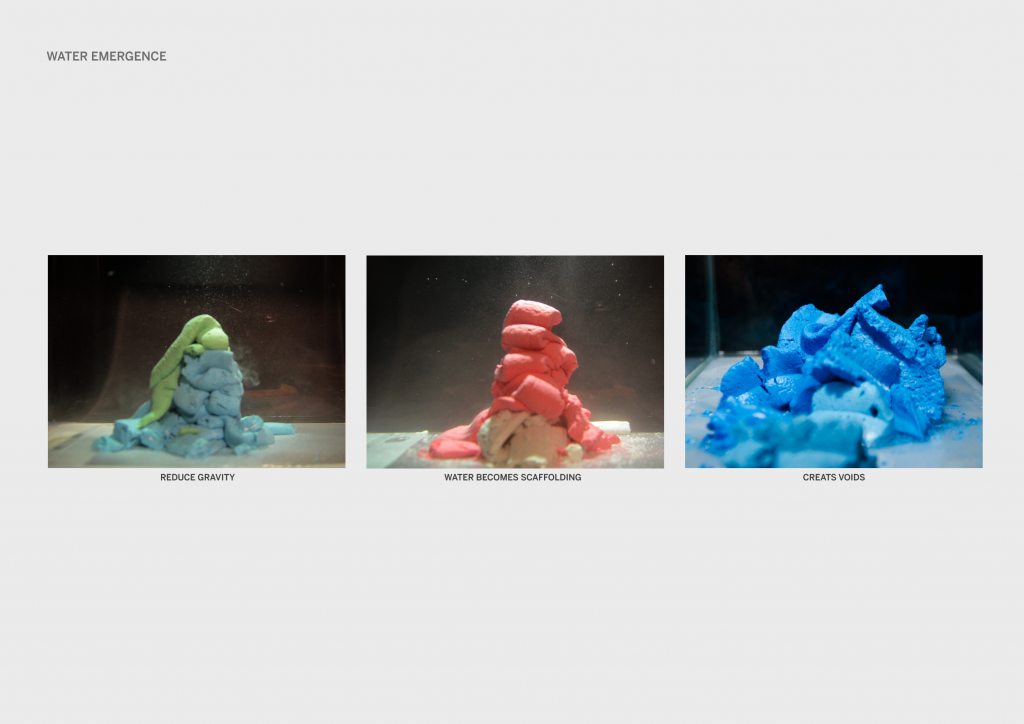

As per the hydrodynamics, when the lumps is smaller its scattered but when the lumps sizes increased the impact of lump hitting water creates the bubble around it which drag the material straight towards the base. With the addition fins in the lump, the material get scattered.

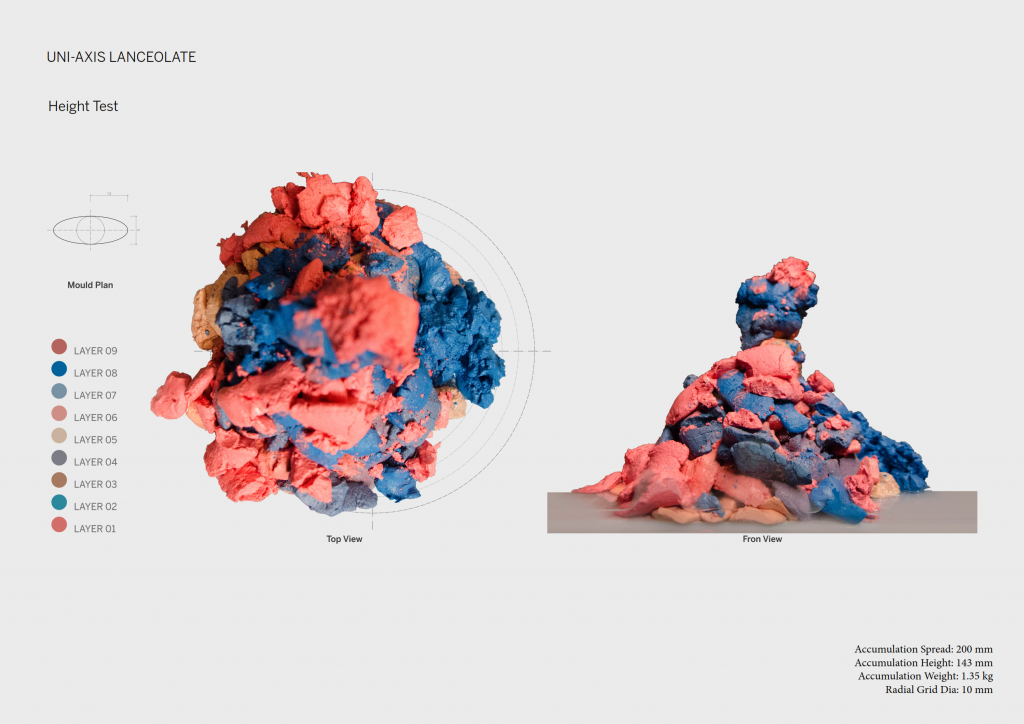

Here, the relationship between the height to its spread has been tested.

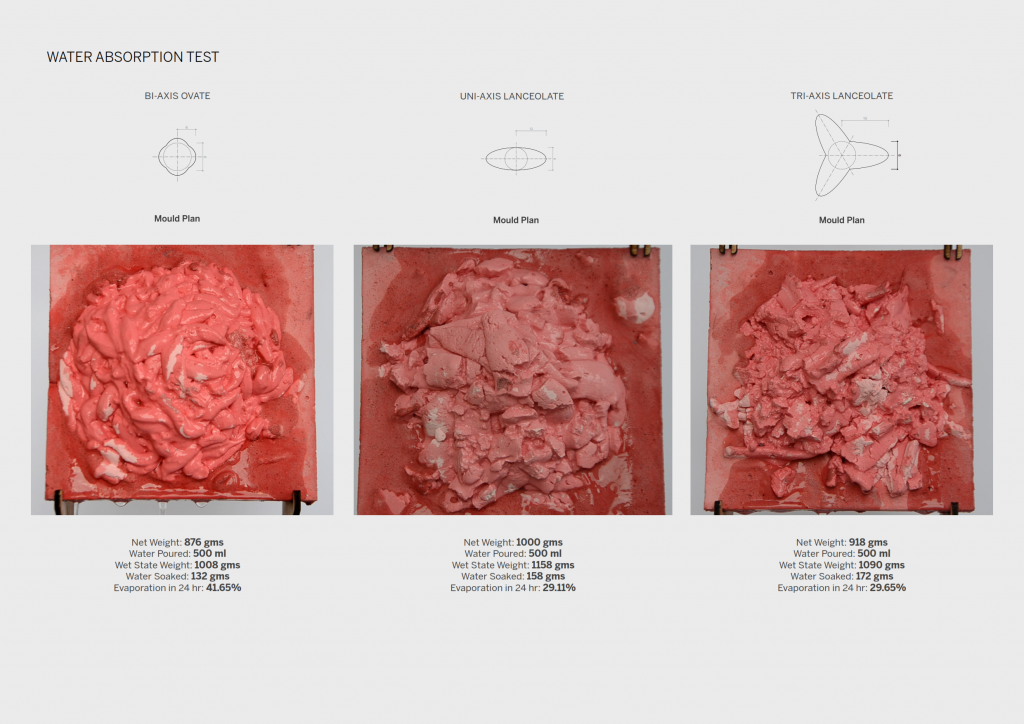

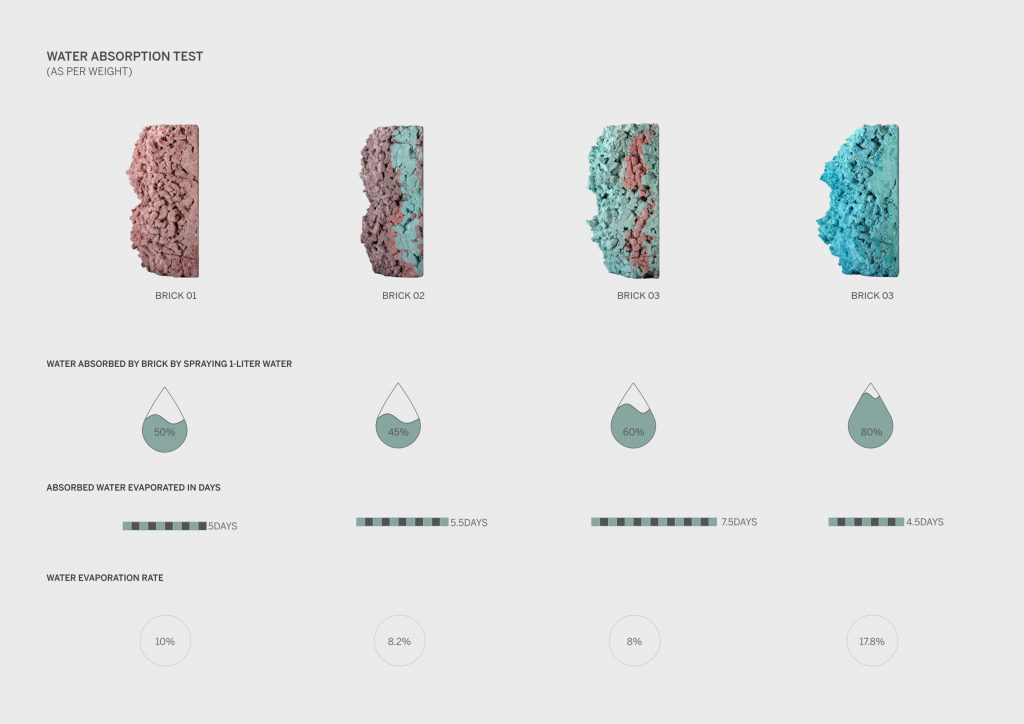

Here, the relationship between the height to its spread has been tested. Water absorption test is conducted by spraying 500ml of Water on top of surface and evaporation rate is measured based on its weight difference in 24 hrs.

Water absorption test is conducted by spraying 500ml of Water on top of surface and evaporation rate is measured based on its weight difference in 24 hrs.

Result: Evaporation rates is less in uni-axi and higher in tri-axis mould accumulation. Benefits of doing these experiment inside water

Benefits of doing these experiment inside water

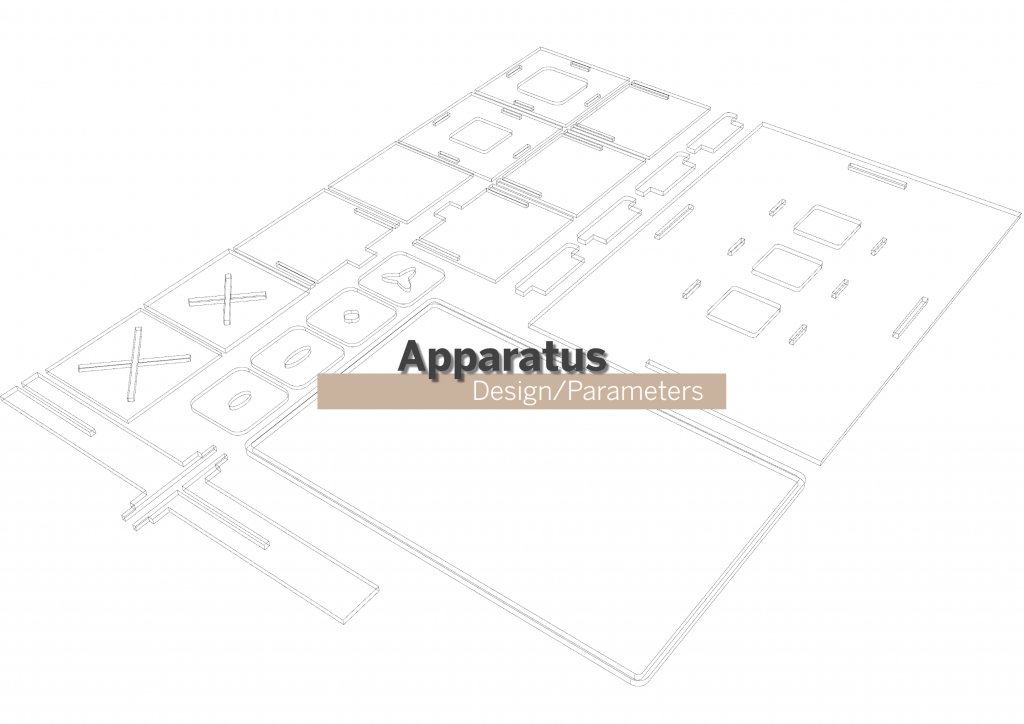

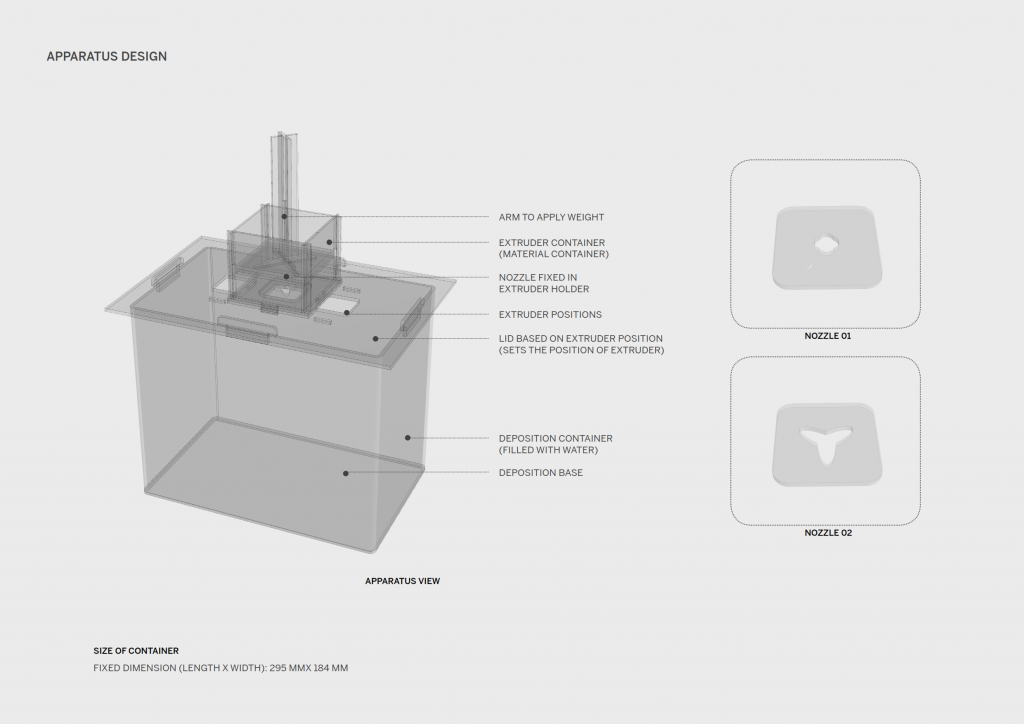

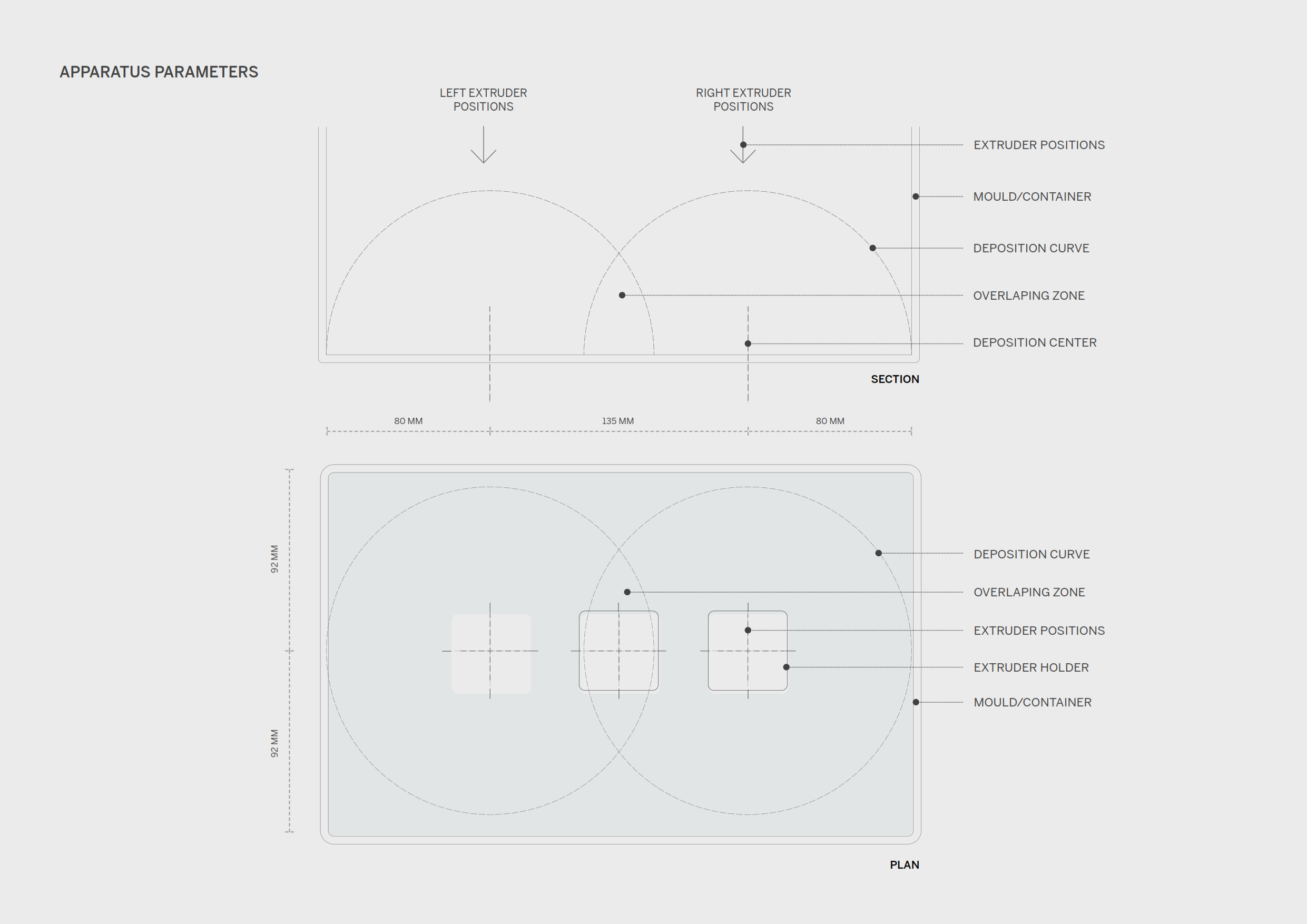

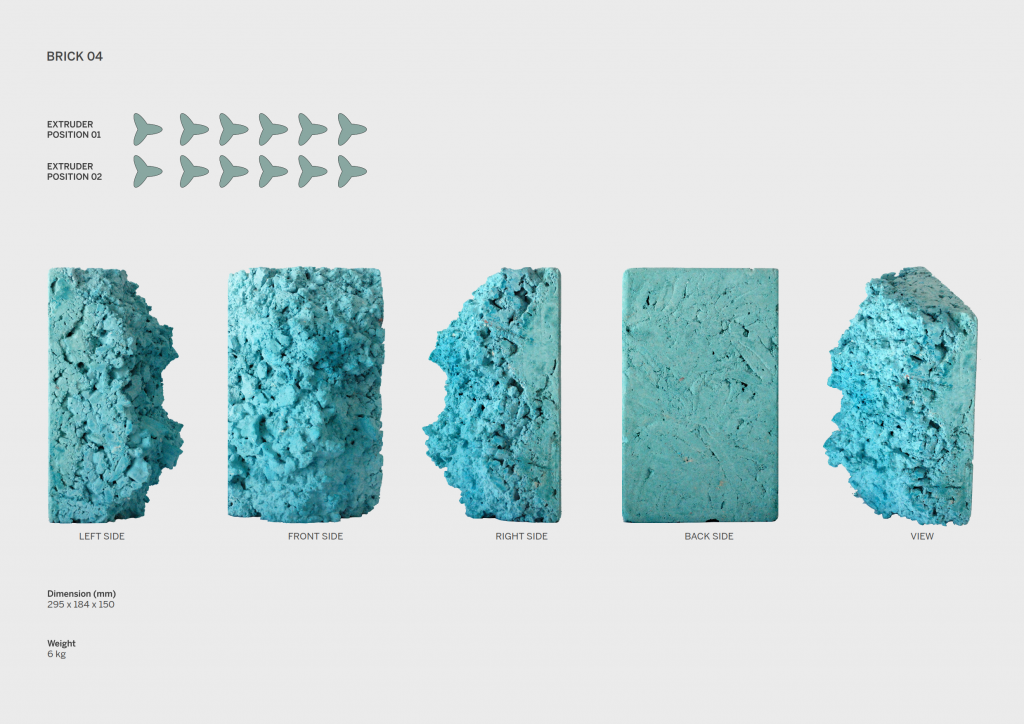

It should have a container which is filled with liquid, In this case its water. Extruder part s fixed on extruder holder based on your requirement. In the extruder container there pocket for the nozzle. Material is poured to the extruder container and then the weight is applied on top of it. Based on the shape of extruder mold, lump shape and accumulation pattern is achieved.

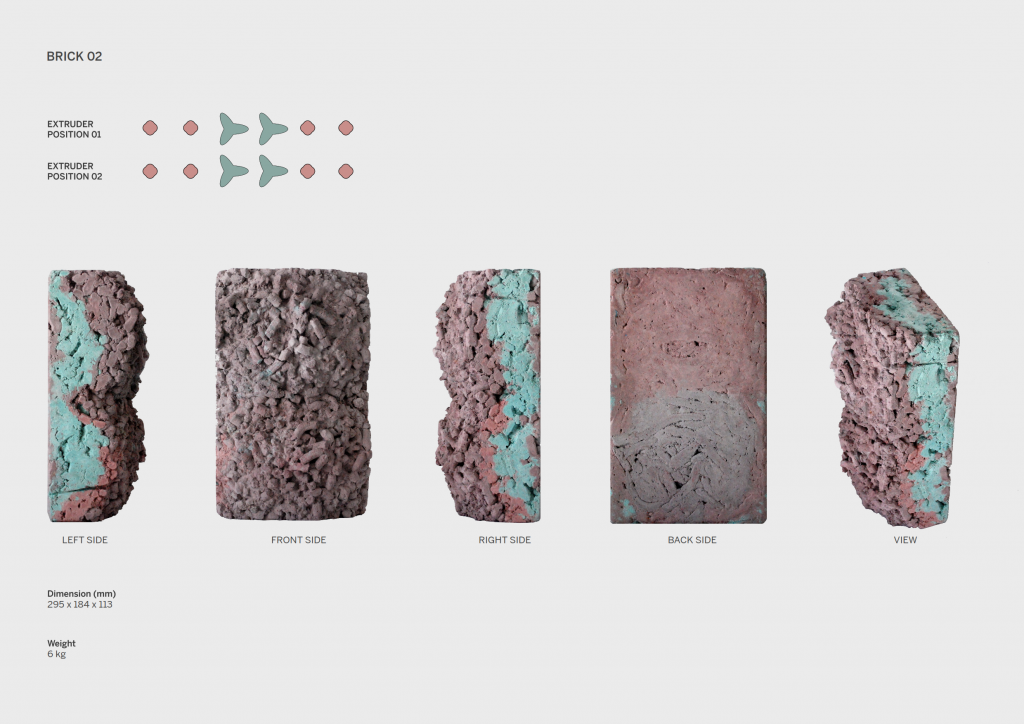

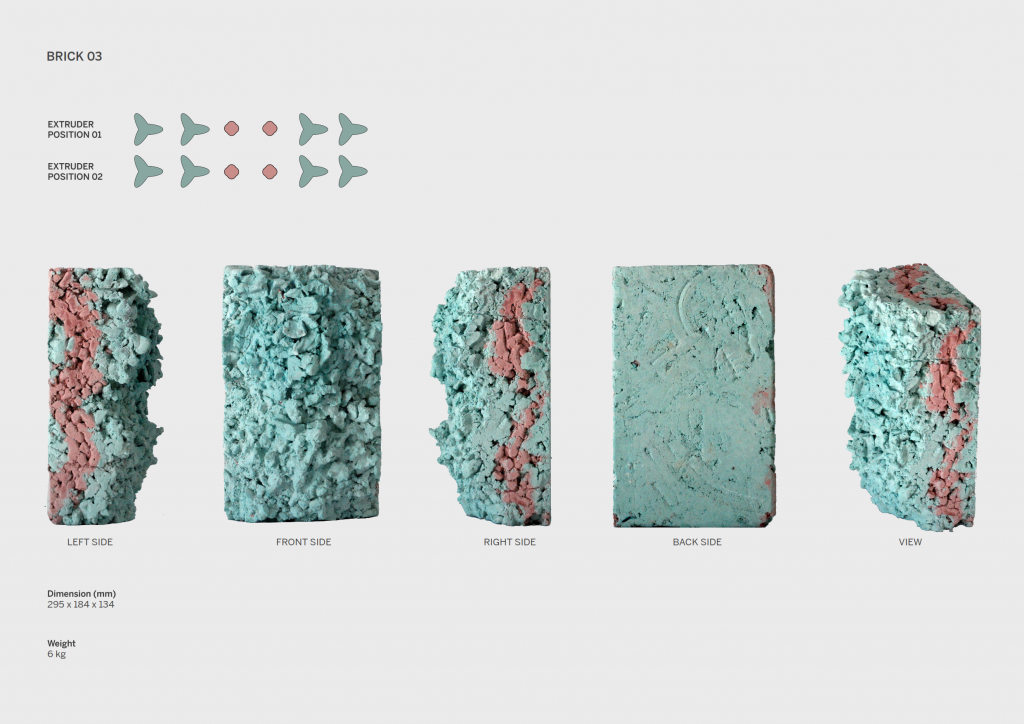

It should have a container which is filled with liquid, In this case its water. Extruder part s fixed on extruder holder based on your requirement. In the extruder container there pocket for the nozzle. Material is poured to the extruder container and then the weight is applied on top of it. Based on the shape of extruder mold, lump shape and accumulation pattern is achieved. Apparatus parameters: Extruder Positions and Nozzle Shape

Apparatus parameters: Extruder Positions and Nozzle Shape

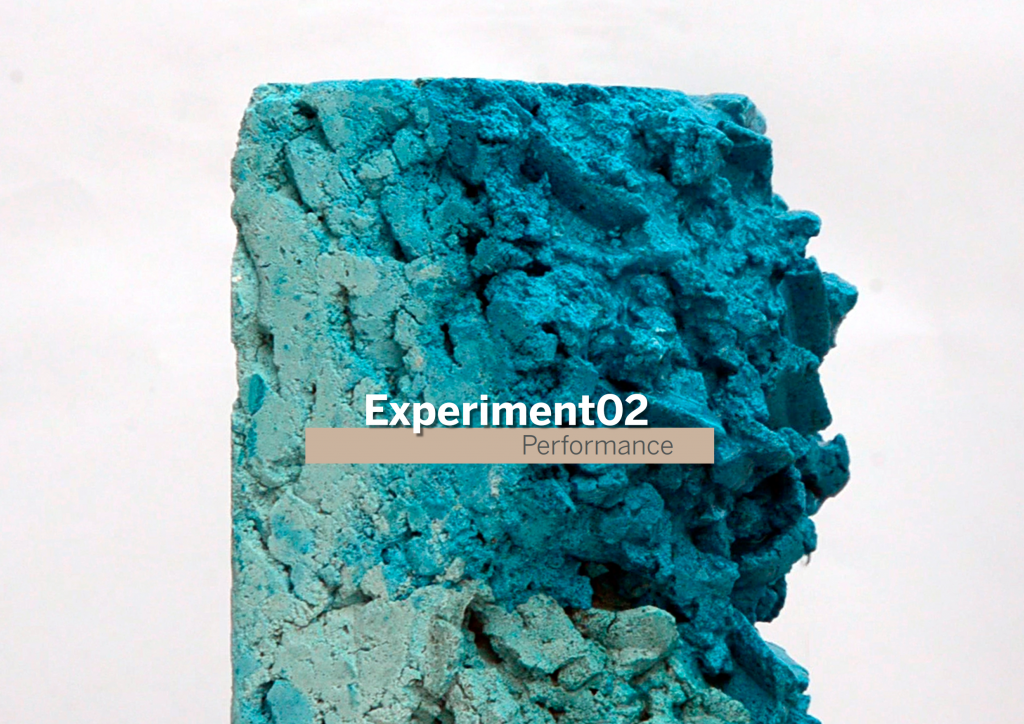

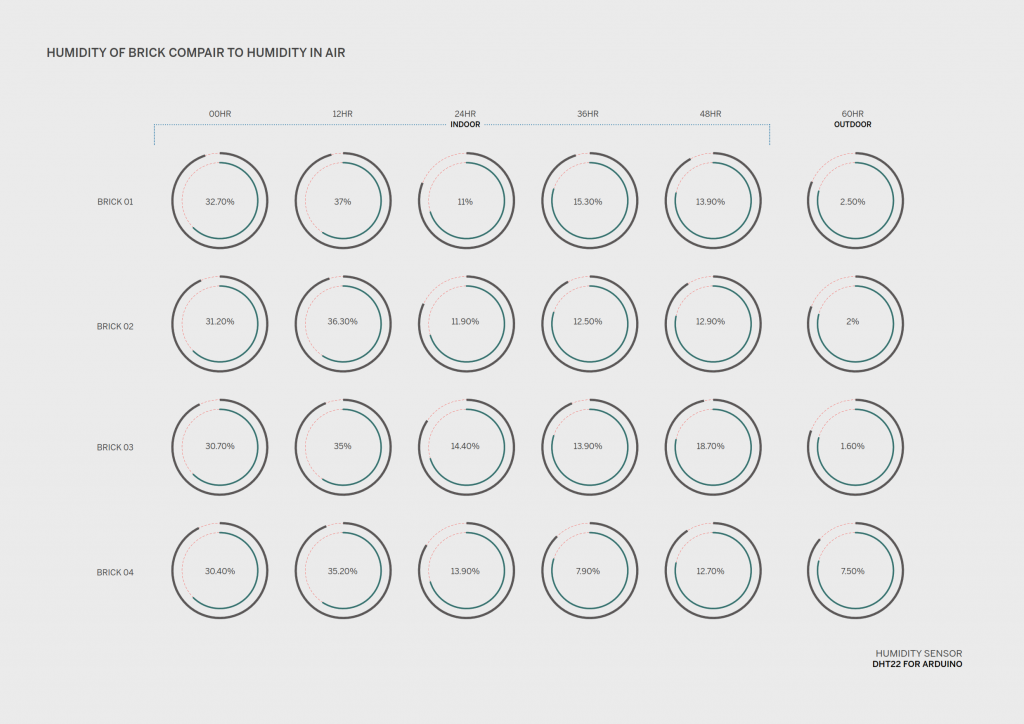

These bricks are then test based on their performance in terms of moisture content inside the brick, evaporation rate and humidity.

These bricks are then test based on their performance in terms of moisture content inside the brick, evaporation rate and humidity.

For testing, 1 liter of water at fixed position for 12 minutes.

As per the difference in weight before and after spraying water its clear that brick 4 absorbs the highest amount of water. Bricks are then kept to dry in order to see the time it takes to evaporate the water. Brick 3 retains the water for longer period. So its observed that brick 3 will be cooler for longer period but the Brick 4 will have more intensity for less period of time. Moisture test

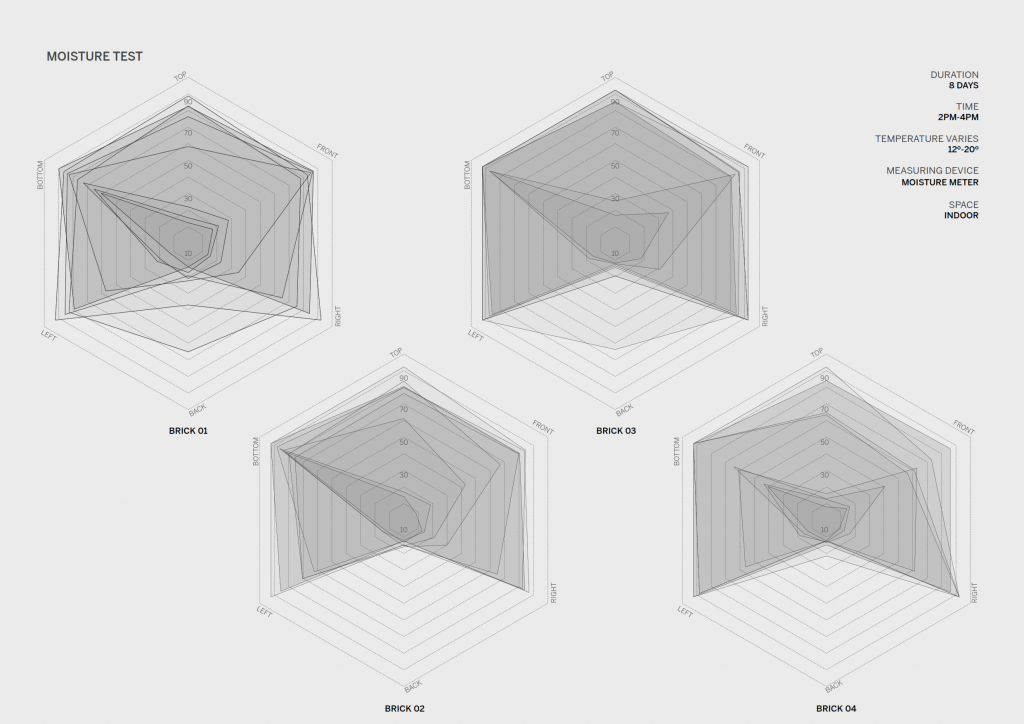

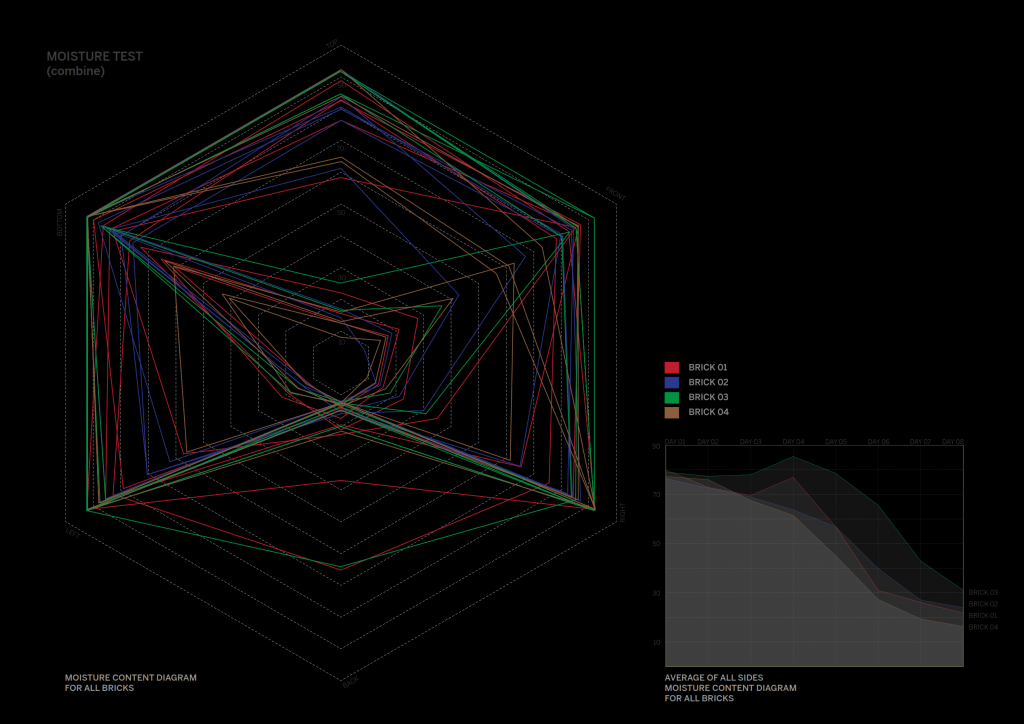

Moisture test

Here moisture meter is used to measure the water content on the surface of all 6 sides of brick. Since water is sprayed from the front surface, the back surface has less moisture content throughout the experiment. Also, the brick is kept upright position so the bottom surface has less contact of air so it remains high throughout the experiments which could be seen in these radar charts.

Comparing all these chart its observed that first three days the moisture content is higher and then reduce slowly except in Brick 3. Mostly its higher and then decreases the amount.

Water Driven Building Block – is ongoing thesis for Climatic Matter Studio for , Institute for Advanced Architecture of Catalonia, developed at Master in Advanced Architecture in 2017/2018 by:

Student: Mohammad Akram Khan

Tutors: Jordi Pagès and Lluis Viu