The Future of Clay 3D Printing Architecture As a New Socialist Construction Method – Accelerationism for Sustainable Automation in Construction

As construction, along with other industries, become automated, this paper explores the question about how we will manage material use, social and economic hierarchies and conflicts of property in a socialist future scenario, as described by Peter Frase in his book Four Futures. The hypothesis is that open source 3D printed clay architecture must be accelerated beyond capitalist market structures to reduce environmental impact and ensure equal distribution of scarce resources in socialist society. This paper argues that open source 3D printing clay architecture must be adopted as the new socialist construction method to address environmental and socio-political concerns as construction, among other industries, becomes automated.

//The Capitalist Contradiction: A Future Without Work?

Assuming a capitalist market allowing for optimum welfare, competition drives prices down until there would be no profit, and the ultimate goal of capitalism becomes a contradiction to itself. In short, the “extreme productivity” made possible by automation would accelerate us beyond capitalism. Rapid automation and computerization are not only replacing human labor across almost every sector but also challenging employer-worker dependences and the assumption that economic resources are distributed based on contributions to production.

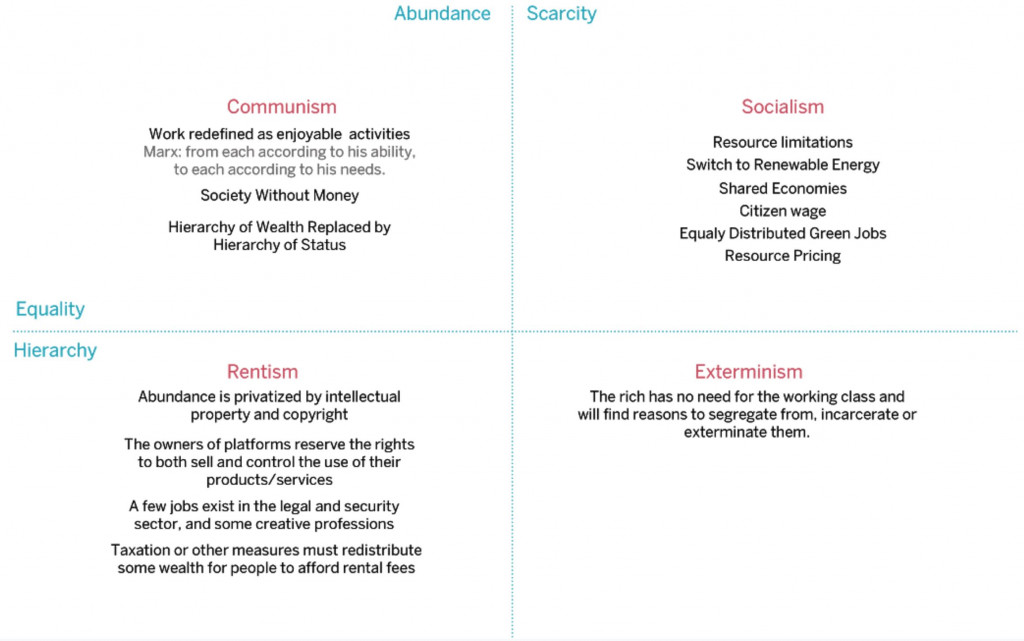

In his book Four Futures: Life After Capitalism, Peter Frase discusses possible post-capitalist scenarios based on the premise that automation will continue to push ahead until all the basic needs of humans can be met. The 4 scenarios – communism, socialism, rentism and exterminism, are presented as combinations of two contradictions – abundance or scarcity and equality or hierarchy.

He argues that the problem of technological unemployment is how it is presented as a scientific inevitability, not a social and political choice. Whether we are approaching a technological utopia or a marginalising dystopia of malign acceleration, depends on how we allocate resources and power as more sophisticated methods of production emerge and dominate. In the context of a socialist future scenario, as described by Peter Frase, how will we manage material use, social and economic hierarchies and conflicts of property as construction is automated?

//Four Futures: The Socialist Future

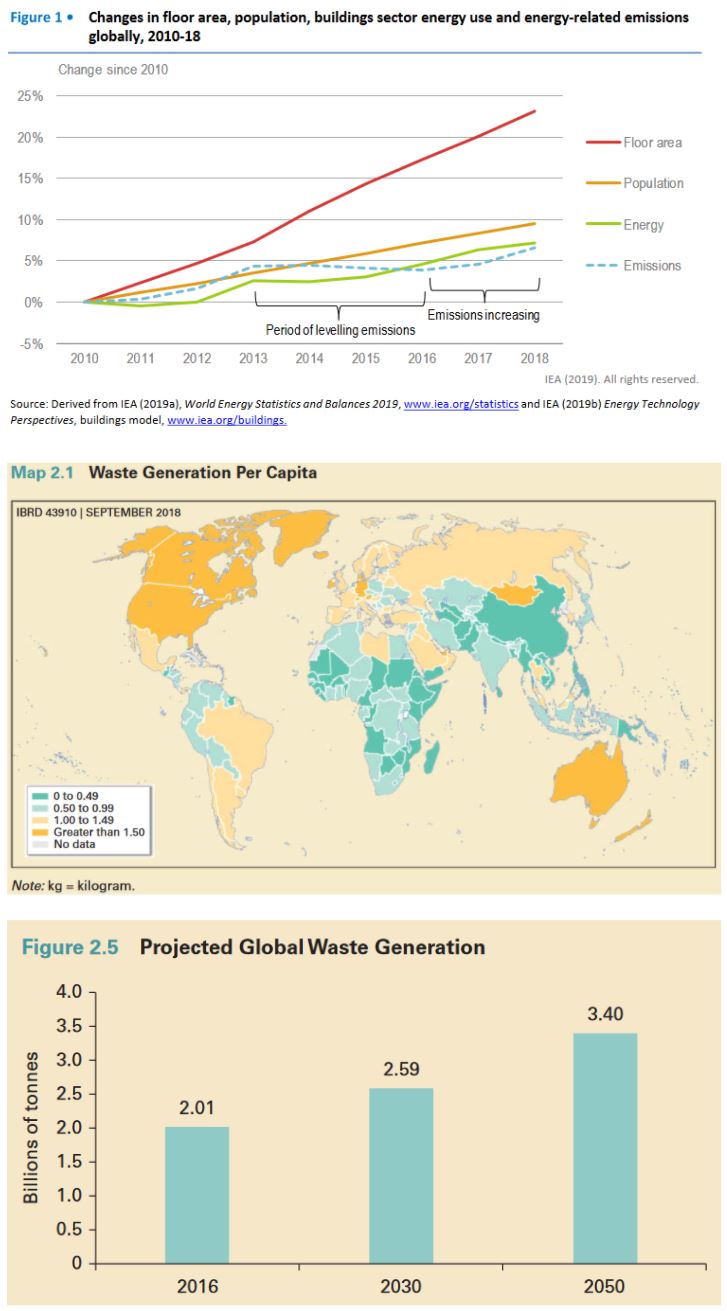

The Socialist future is a world of environmental limits, Frase describes it as “an egalitarian society that must work together to rebuild its relationship to nature”. The question becomes not if there will be abundance or scarcity from new technologies, but if they will bring equal opportunity for all. The socialist future deals with a different type of scarcity, not labor or goods, but raw materials and energy. While the socialist discussions have centred around economic planning of production, the future socialist society needs to plan the allocation of its inputs.

//Neosocialist Construction: Clay 3D Printing Architecture

Radical changes must be made to building construction if we are to reach this socialist future. A critical development towards socialist construction is additive manufacturing. 3D printing is revolutionizing manufacturing across a range of sectors. As construction, along with other industries, become automated, open-source 3D printed clay architecture must be accelerated beyond capitalist market structures to reduce environmental impact and ensure equal distribution of scarce resources.

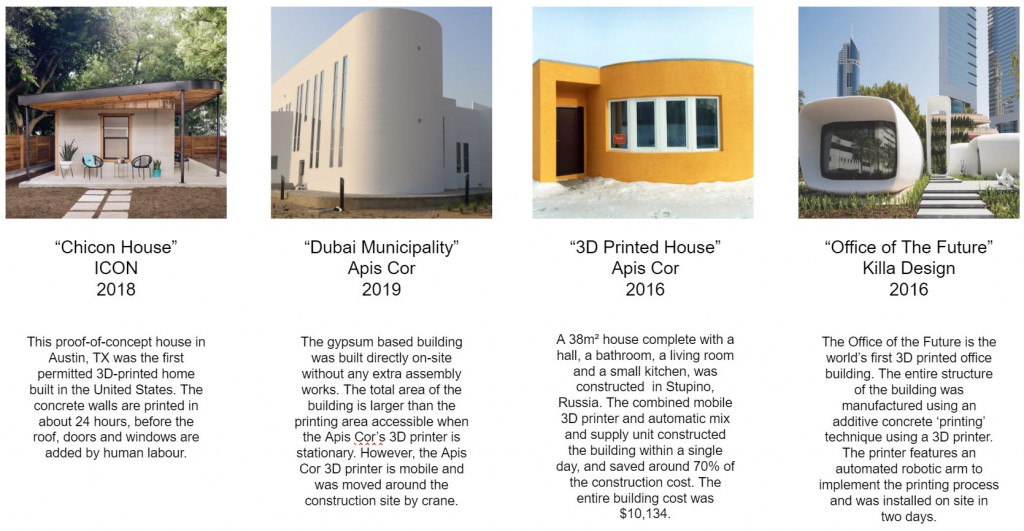

//Closer To Zero Marginal Cost Housing: Lean Construction

Conventional construction falls behind to meet the increasing housing demand. Lean Construction is a strategy adapted from the “lean manufacturing” philosophy from Toyota’s production lines. The lean ideal, giving customers what they want instantly with minimal waste, remains difficult to achieve with traditional construction methods. With 3D printing, this is now made possible. Adopting the concept of “lean construction”, 3D printing promises a radical shift in building design and construction, allowing for low cost, on-demand housing and massive reductions in construction waste and labour savings. 3D printed building construction has proved to be 10 times faster than traditional construction methods. The projects below show the technology of 3D printed architecture.

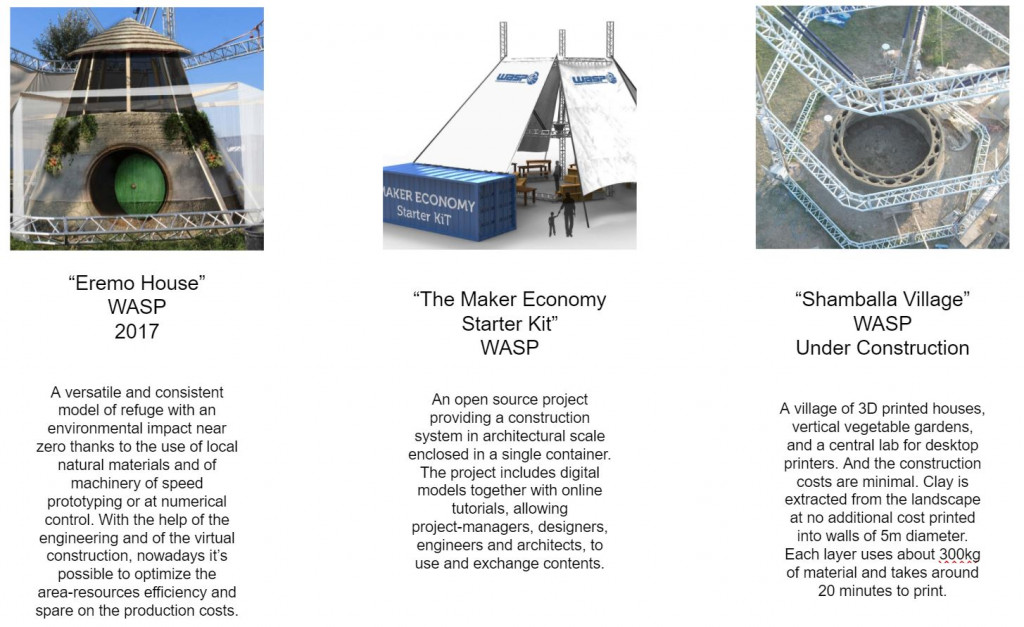

With the sustainability and low cost of lean construction, clay 3D printing architecture becomes the new socialist construction method, approaching a future where buildings can be produced with abundant, recyclable and natural materials at close to zero marginal cost. Clay is easily available all over the world. The material has major potential for circular design and automation for abundance. Once a print is no longer needed it can be rehydrated and reprinted, as long as it has not been fired. The projects below show the technology of clay 3D printed architecture.

In the socialist future of automated construction, the scarcity of housing would result from rationing construction materials and energy to avoid overconsumption as building construction becomes very fast and affordable. Even though clay is an abundant and reusable material with very low environmental impact, additional construction elements and the energy needed to print, heat and cool the building would need to be priced according to availability and carbon footprint. Systems like a universal basic income and environmental resource pricing could potentially manage scarce inputs as predicted by Frase. As clay is a widely abundant material, this would likely be preferred given possible carbon-taxing of more polluting construction materials. Another system could be a material bank, where people can trade scarce construction materials in a circular economy.

Additional limitations to building sizes arise from the scarcity of land. The height limitations of buildings that can be constructed with 3D printing technology would suggest that this type of housing would sprawl. In a future that is already struggling to sustain enough wildlife, limitations of buildable land and available infrastructure would pose concerns about our current construct of property.

//Redistributing Power of Production

To ensure equality from automated construction, the technology must be democratized with the intention to benefit all communities and ecosystems. 3D printing can provide fast and quality shelter in case of natural disaster and housing shortages. An example is the 3D printed village in Tabasco, Mexico (Figure 4). Building on the Chicon House prototype, a community of 50 houses are currently being constructed by New Story with ICON, a non-profit organisation tackling housing shortages to vulnerable communities.

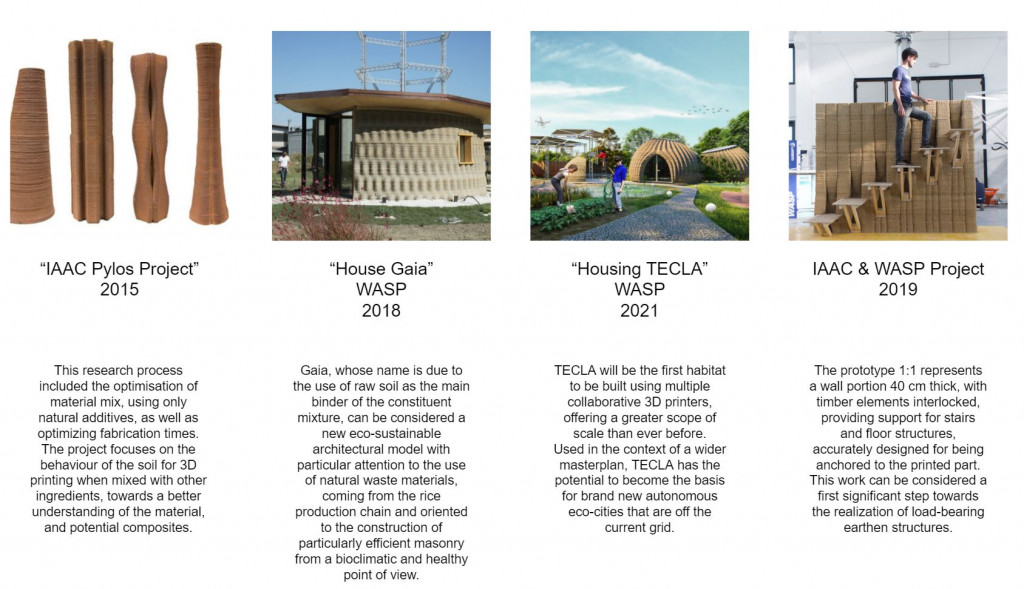

Additionally, projects aimed at ecological restoration can be shared and deployed around the world, in a collaborative effort to reverse the damage to natural habitat and ecosystems. Clay 3D printing has allowed several designs of artificial reef structures (Souza 2020), like the restoration structures for Hoi Ha Wan Marine Park in Hong Kong (Figure 5).

An analogy can be drawn to the development of desktop 3D printers through the Maker Movement. Similar efforts have been made to make construction printers smaller, more flexible and accessible. One example is the Hangprinter (Santos 2017) (Figure 6), developed by Torbjørn Ludvigsen at Umea University. The system can be built for about 200 Euros and can be suspended by thin fishing lines from any stable surface. The construction dimensions are limited only by the height and length of the suspension lines. By accelerating the development of such technologies, greater print areas, heights and design freedom can be achieved, even by cheaper, DIY machines.

//The Future Impact of Clay 3D Printing Architecture: The Creative Commons

The 3rd industrial revolution is creating an opportunity for the capitalist economy to be replaced by a new structure. What is required for a paradigm shift is a is a new “general-purpose technology platform” combination of 3 elements: a communication medium, a power source and a transportation mechanism. Three digitized networks: the communication internet, a renewable energy network and a mobility and transportation network, connect together to support a comeback of the creative commons.

Assuming we make the shift to open source, in such an expanded, digitized economy, people will have the possibility to access Big Data to generate and share their own designs and construction information. In the new socialist society, people can learn design software and machine operation through online, open source education platforms, download designs and print their own homes from the local soil and renewable energy grids, and share and reuse materials between the community.

We are already seeing some indication of this possibility in the 3D printed construction industry. WASP is offering a Maker Community Start-Up Kit. Through this platform, the company is printing a do-it-yourself community they call Shamballa, a village of 3D printed houses, vertical vegetable gardens, and a central lab for desktop printers. And the construction costs are minimal. All designs and tools are made available through the Start-Up Kit, allowing for this eco-friendly village to be replicated and developed upon through collaboration.

//Conclusion

In the light of the dual crisis of abundance and scarcity, clay 3D printing architecture could present a solution to the environmental and socio-political concerns about automation. By allowing for lean construction practices, natural, reusable and recyclable materials and an open source, collaborative network, a collaborative commons of housing construction can be realised in a socialist future, where people can design and print their own homes at close to zero marginal cost with minimum ecological impact.

The Future of Clay 3D Printed Architecture is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master in Advanced Architecture 2019/21 by:

Students: Hanna Lepperød & Ka Man Lee

Faculty: Jordi Vivaldi & Manuel Gausa