QUARANTINE CABIN

Following the various stages of deep research and design development stages, we followed on to the final design by dividing the various aspects of the quarantine cabin as individual design challenges. each individual aspect of the design is interrelated with the other aspects and forms a symbiotic relationship with each other to form a seamless functioning system.

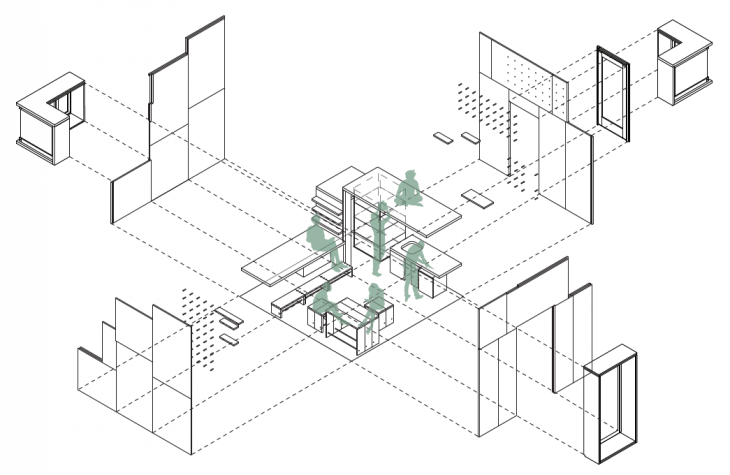

The interior of the Voxel follows the basic concept of Fixed-Dynamic-Fluid which invites the adaptability of the space according to different users while providing all the comforts of a house in a structured manner.

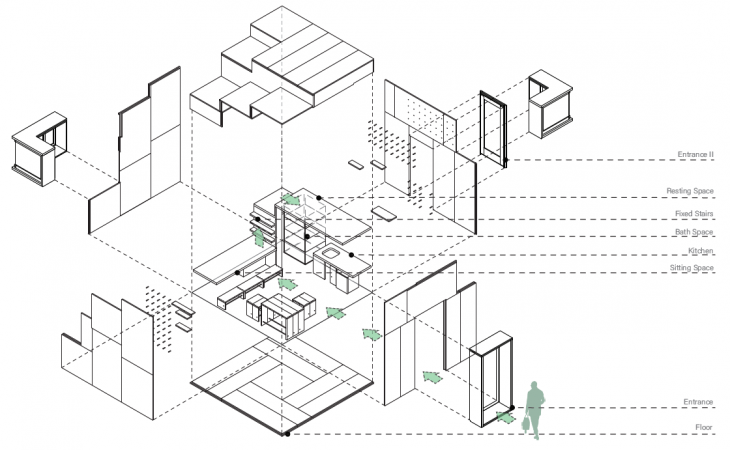

SPATIAL CONFIGURATION

One of the questions of the interior design process is the limitation of space. To avoid a dull space the interior space is designed to be a spiral form. With this organization the spatial experience could be enriched to the maximum extent.

To reach the purpose of simplicity and flexibility, some wall panels are designed with a series of perforations. Thus, with different prefabricated panels and dowels the user could design the shelf as per their requirements. Such panels are mostly placed in the main activity spaces where the user works and sits.

PROGRAM ORGANIZATION

The metabolic core is concentrated along the West façade to free up the space in the center. The furniture elements in the interior consist of fixed as well as reconfigurable elements. By not defining a particular program to an element but providing space for different activity we allow the user to reconfigure the space to their needs. The reconfiguration of elements is done through using dowels to connect various wood panels to add or reduce the size of elements to be used as seating, table or storage. A fixed element is provided on the upper and lower level each to fulfill the purpose of a sleeping space or a living space.

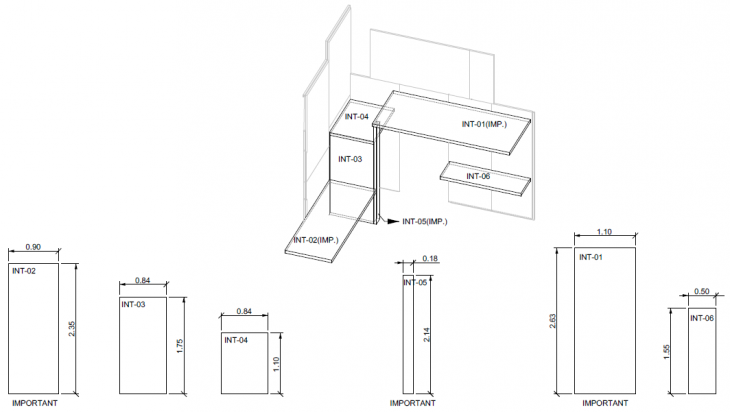

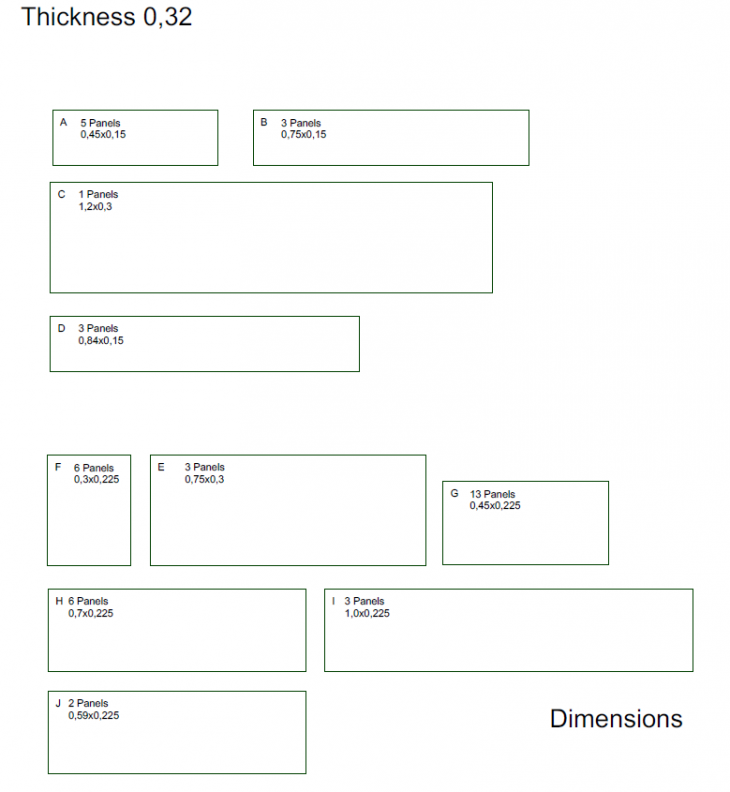

INTERIOR CATALOGUE

For the purpose of the production of the interior elements including the CLT structure panels and the panels of the furniture a catalogue was created that enlists the panels with the details of their dimensions and joinery. Here each panel is given a code to optimize the process of production which is used to physically label each lamella in a panel including the name of the tree for the purposes of traceability.

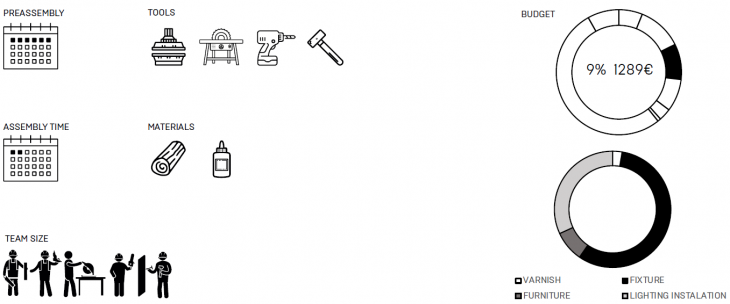

FURNITURE FABRICATION PROCESS

To maintain the integrity of the CLT construction and taking into consideration the weight and structural requirements of the furniture, a CLT style two layered panel is generated for the furniture using waste lamellas which were too thin to be used for structural CLT panels. By using thinner lamellas and reducing the layers we significantly reduce the weight of the furniture which is comfortable to use.

CATALOGUING

The first step after the initial processing of the lamellas was to catalogue all the lamellas according to the pieces of furniture. The process is done by first visually cataloguing and pairing the different lamellas of a part of furniture according to their appearance and grain. Then the next step would be marking each lamella with the code of the intended furniture panel from the interior catalogue, then the position of the lamella in a given panel and finally the tree the lamella is coming from for total traceability.

PRESSING

Once all the lamellas are catalogued for a given panel we then proceed with the pressing of the panel. Since the size of the furniture panels was significantly smaller than the CLT panels, the usual process of pressing with the CLT press couldn’t be adopted to get perfectly aligned lamellas in a given panel. Hence, a system using clamps to press the panels was adapted to apply equal pressure from all directions in a fashion similar to the CLT press.

DOWEL ASSEMBLY

Following the processes of the CLT structure assembly, we followed the principles of dowelled joint assembly for the furniture as well. The furniture uses two sizes of dowels, 8mm dowels for the fixed joints and 16mm dowels for the reconfigurable joints. The usage of dowels is also enhanced by using 16mm dowels as a linear bracing for the furniture.

RECONFIGURABILITY

The interior elements are designed to be dynamic in design and fluid in function, where various parts can be reconfigured to adapt to the usage and can be utilized for multiple functions.

PERFORATIONS

The first element that lends to the reconfiguration of the interior space are the strategically placed perforation walls in the living areas and the metabolic core. These enable the user to use a fluid storage system by using interchangeable shelves and dowels of various sizes for the purpose of hanging things.

These perforations were created partially using the CNC and partially done manually using a hand router and a specially created jig.

DETACHABLE FURNITURE

Each piece of furniture is made up of three parts consisting of two legs and a top. These can be joined with or disjoint from other pieces to form different types of furniture by extending the pieces or making them smaller. This allows for stools to be joined together to form a chair or to be separated to be used by multiple persons should the need arise. Similarly all furniture pieces can be adapted to the user needs.

FINAL RESULT

The Voxel: Interior is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at the Masters of Advanced Ecological Buildings and Biocities in 2019/2020 by:

Students: Shreya Sharma, Anfisa Mishchenko, Zhiqian Liu

Faculty: Michael Salka, Jordi Prat, Daniel Ibañez, Vicente Guallart