Research Objective

The Wall Challenge and Cantilever Challenge workshops concluded in the formulation of a structural toolkit that may serve as a reference to structural design with respect to additive manufacturing with clay.

Methodology

As a part of the research methodology, two workshops were conducted. The first workshop specifically dealt with the challenges with printing a wall as a surface. The second workshop focused on the challenges related to printing cantilevers. The workshop was divided into three parts to test cantilevers as a surface, volume and volume with an infill. A four-fold research methodology was adopted during each stage of both the workshops that included designing an extensive catalogue of geometries, fabricating a selected geometry using a 6-axis robotic arm. The third part includes structural analysis using a plugin for AutoCAD developed by Windmill Structural Consultants and grasshopper based geometrical analysis tools developed by the team. The fourth part of the workshops was to redesign the geometries based on the extracted conclusions from the physical prototypes, structural and geometrical analysis data.

As a conclusion to the research, we have developed a toolkit to analyse structural and geometrical parameters affecting the strength, stability and balance of the structure.

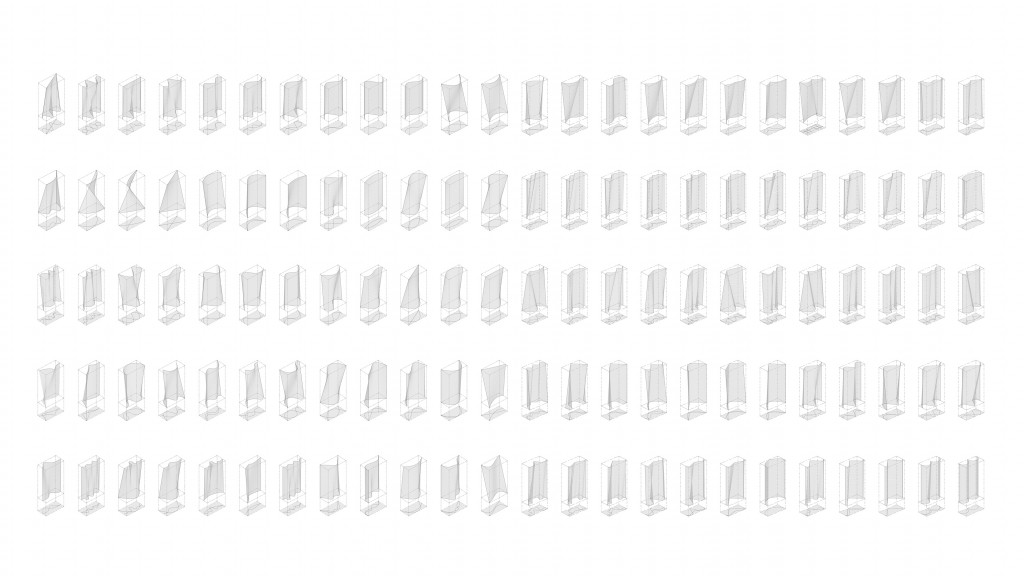

PART 1: GEOMETRY CATALOGUE

An exhaustive catalogue of geometries was developed by the team, to explore the concepts of structural design. The methodology adopted is described more in detail in Workshop 1 – Wall Challenge and Workshop 2 – Cantilever Challenge Geometry Catalogue

Geometry Catalogue

PART 2: FABRICATION

The second phase comprises testing the geometries for failures during the printing process. Thereby understanding the principles of structural strength, stability and balance during the fabrication process.

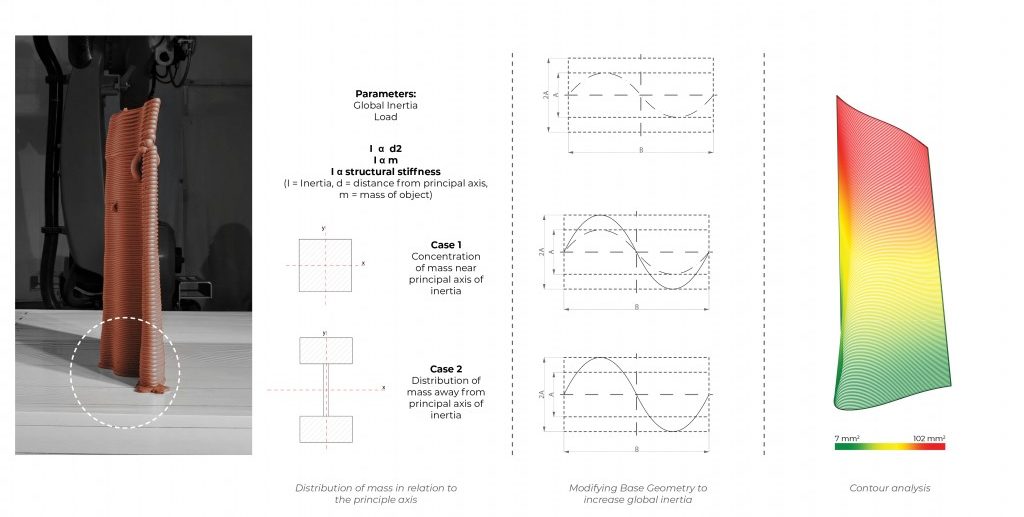

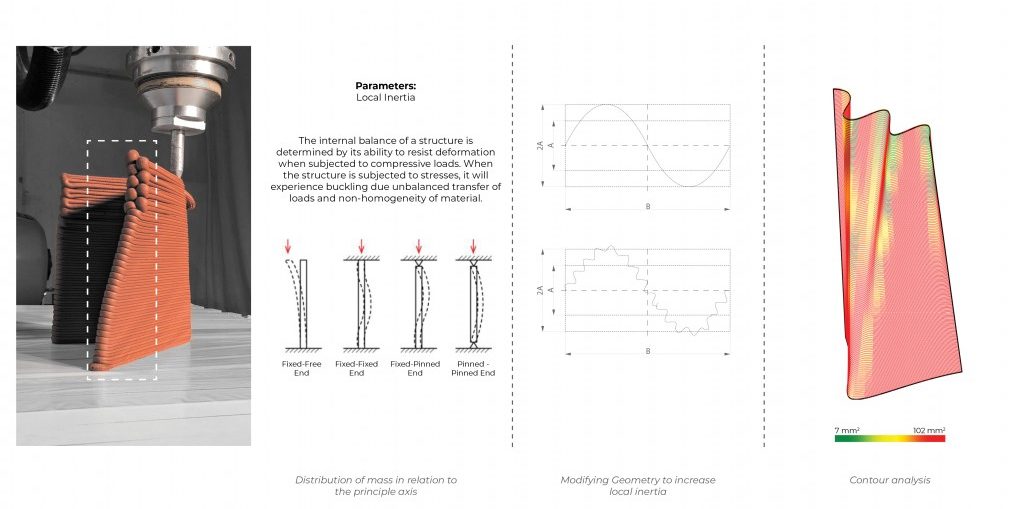

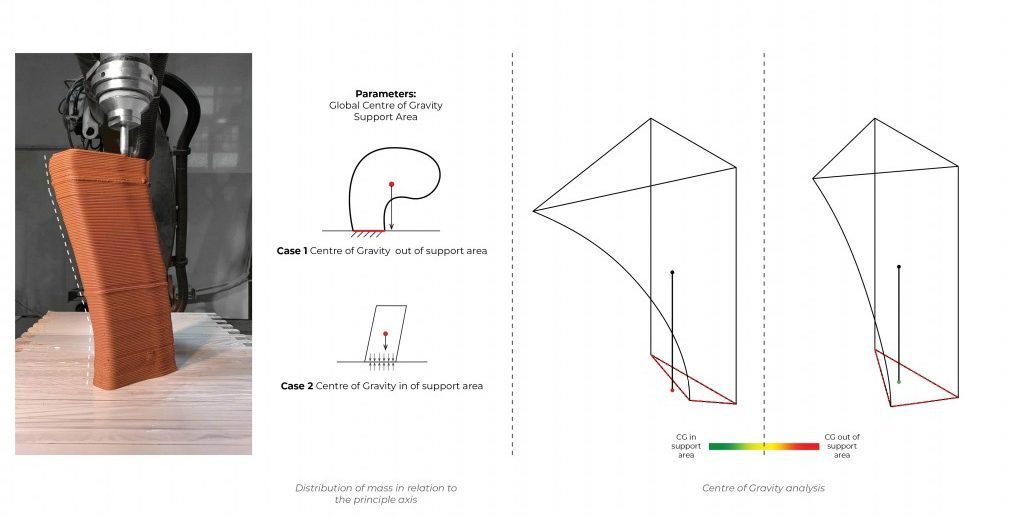

PART 3: STRUCTURAL AND GEOMETRICAL ANALYSIS

Global Stiffness

Local Stiffness

External Equilibrium

Internal Equilibrium

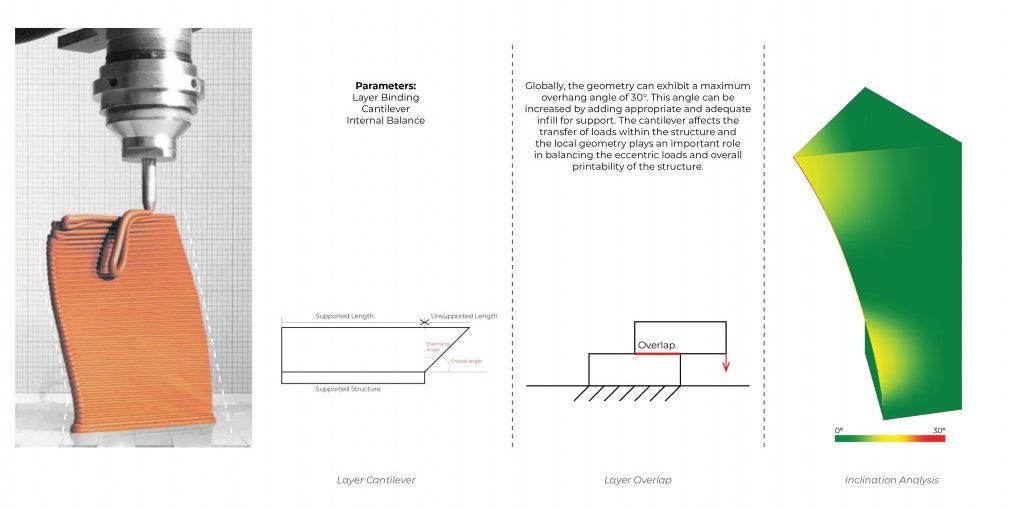

Overhang Angle

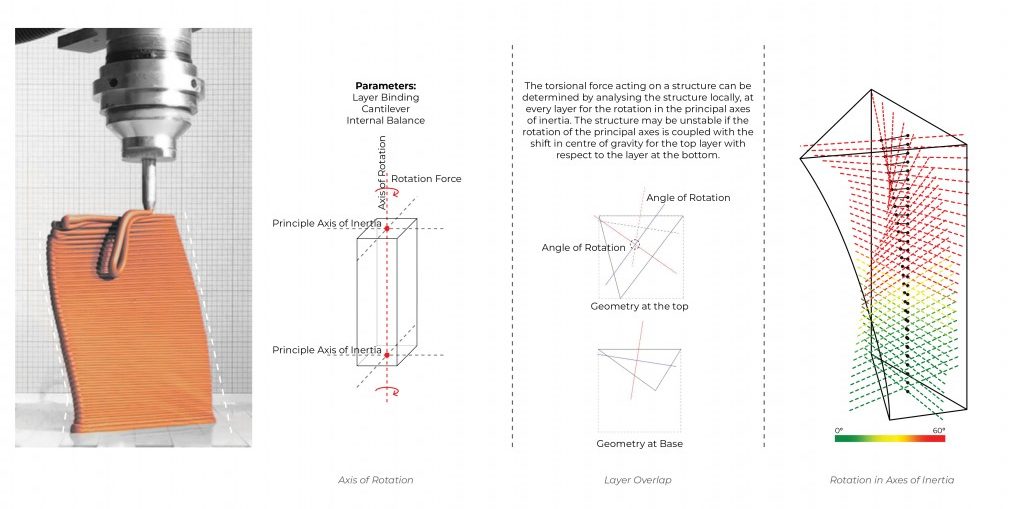

Rotation/Twisting

PART 4: DESIGNING BASED ON EXTRACTED STRUCTURAL AND GEOMETRICAL LOGICS

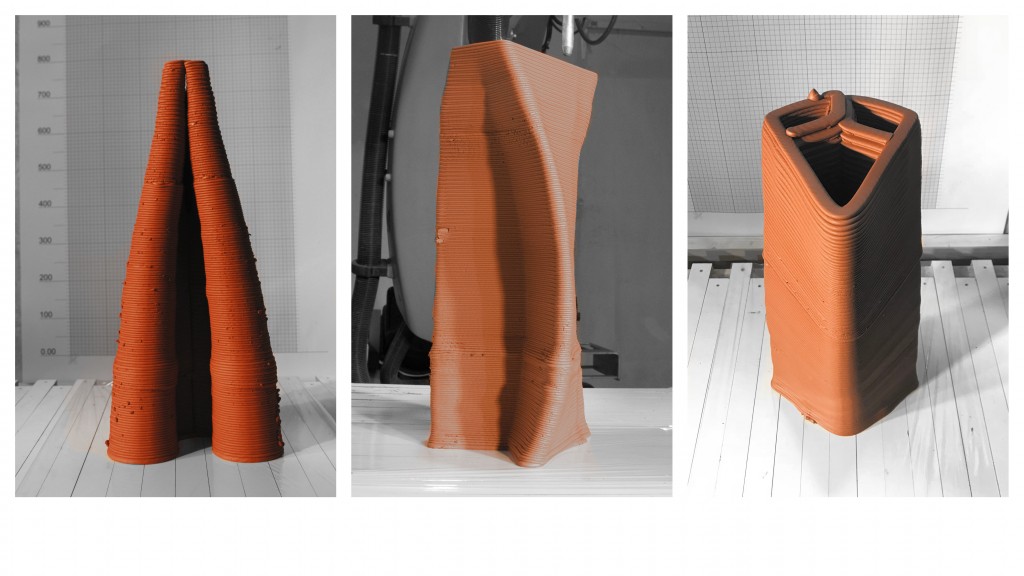

For the fourth part of the workshop, the geometries were adapted based on the logic extracted from the printing process, physical prototypes, structural and geometrical analysis. The modified geometries were further tested by fabricating them with a 6-axis robotic arm.

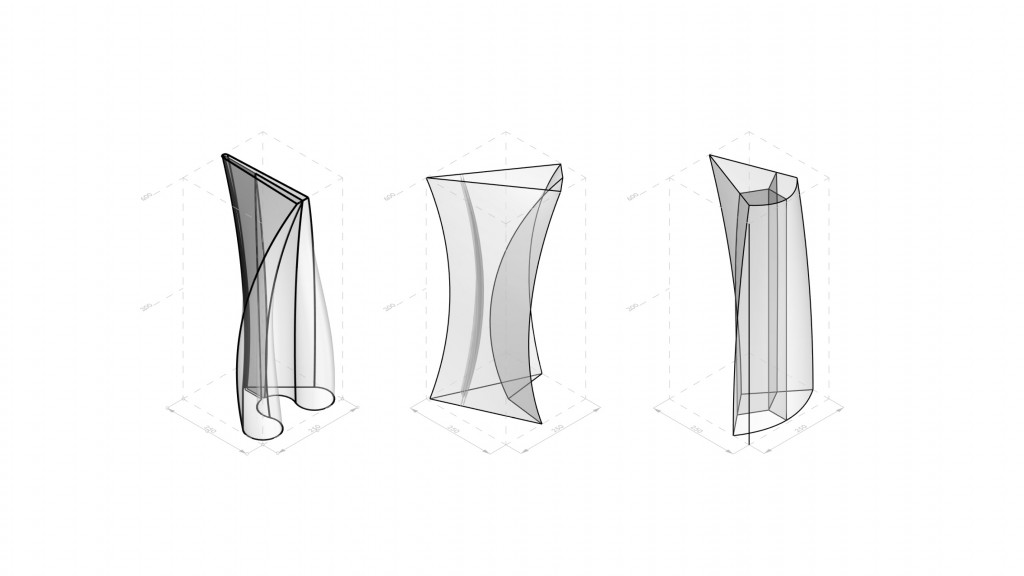

Geometries modified based on conclusions derived from the fabrication process, prototype, structural and geometrical analysis.

Photographs of the modified geometries tested by fabrication with a 6-axis robot.

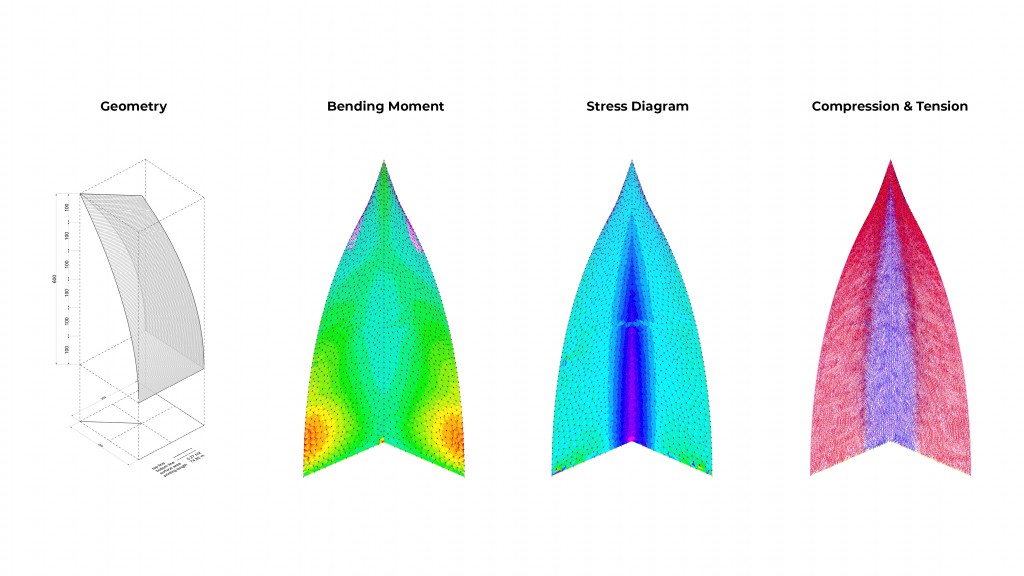

Alongside the tools developed for geometrical and structural analysis, we also analysed the structures using a plugin developed by Windmill Structural Consultants based on the Finite Element Method (FEM) Analysis. The geometries were tested for Bending moment and principle stress lines.

FEM Analysis

OTF 2018-2019

Faculty : Edouard Cabay | Alexander Dubor | Kunaljit Chadha | Joaquim Melchor

Assistant: Eugenio Bettucchi | Riaz Sheikh

Collaboration: Windmill Structural Consultants, La Salle, UNHabitat

Team: Ashkan Foroughi | Bhakti Vinod Loonawat | Ipsita Datta | Nusrat Tabassum | Ozgur Cengiz | Pavlina Kriki | Payam Salahinezhad | Shahram Cawsi Randeria | Yi-Fan Liao | Yuchen Chen | Yingxin Du