Workshop 3A | MRAC 2018-2019

Faculty: Roland Snooks

Faculty assistants: Natalie Alima | Kunaljit Chadha

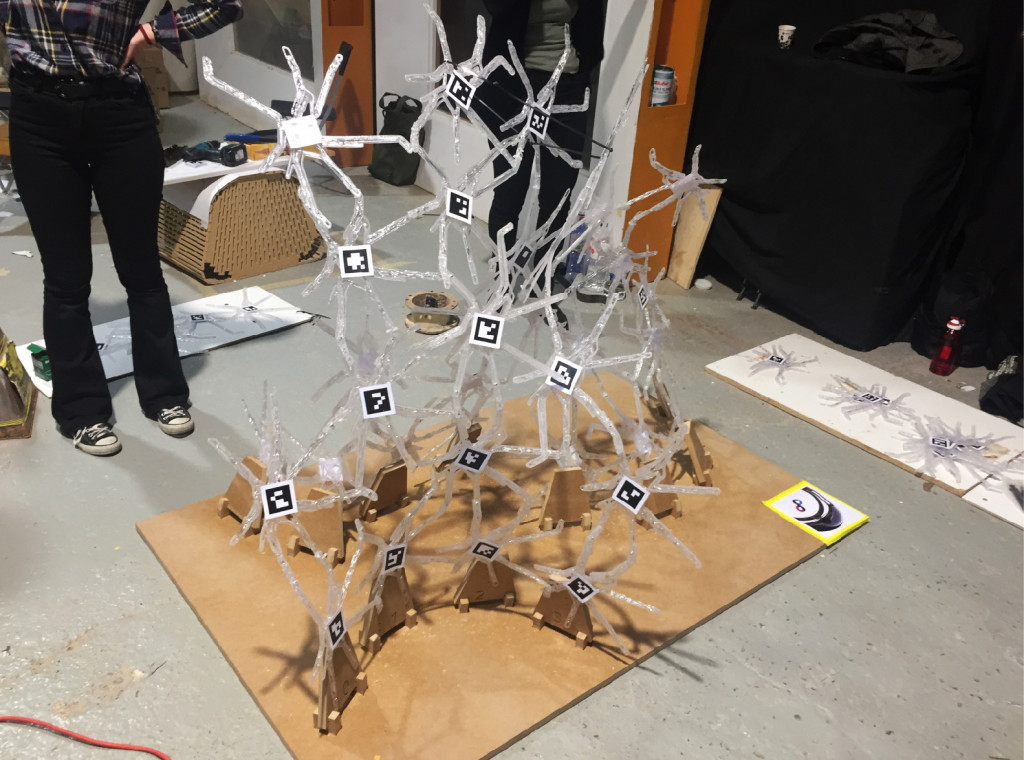

Student: Omar Geneidy – Assembly Team

Robotic and Mixed Reality – Assembly

Workshop Brief

This workshop was an exploration in the relationship between real-time robotics, augmented reality, material behavior and self-organising generative models.

Team Responsibilities

The first task assigned to the assembly team was to come up with a technique to attach the AR markers to each of the components in a similar fashion. So that each component can be referenced in the 3D model in the correct position and orientation as the actual structure in the physical world using the HoloLens.

The next task then was coming up with a methodology of attaching the different components together to form up the overall final structure.

The assembly process was done using HoloLense that provided a realtime reference of the exact position of each components informing the whole assembly process.

Challenges Faced

The first challenge we faced as the assembly started was that the plastic components were either too brittle but strong or too elastic but weak. Something that required a back and force fine-tuning with the 3D printing team to come up with optimum layer thickness and width suitable for the assembly process.

The second challenge was the difficulty of aligning each component in real life with the virtual version of it in the HoloLens. Orientating components was difficult as the model in the HoloLens had tens of other components all packed next to each another, making it difficult to identify which is which and what is the correct configuration of each component.

Another challenge was supporting the model as it was growing and preventing it from collapsing before it gains its strength from the final geomtery.

The last and the most important challenge was the fact that any small error in the assembly quickly builds up to become a much bigger error in the higher levels. Making it not aligned with the virtual model used to inform the assembly process.

Future steps

A way of solving the second challenge mentioned earlier could be by integrating a code into the HoloLens code that shows the model layer by layer as it grows from the bottom to the top during assembly. Hiding all of the unnecessary geometry standing in the way of understanding the geometry in hand.

Integrating structural simulation in the Assembly sequence could help in coming up with a studied sequence that would help having the structure stable and balanced as it is growing.

The error accumulating in the assembly could be tackled by integrating a realtime feedback using the HoloLens of what is actually built with reference to the original model. Then regenerating the remaining portion of the model with regard to the physically built portion.