REINFORCEMENT STRATEGIES FOR CONCRETE PRINTING USING K-MEANS CLUSTERING

CONTEXT

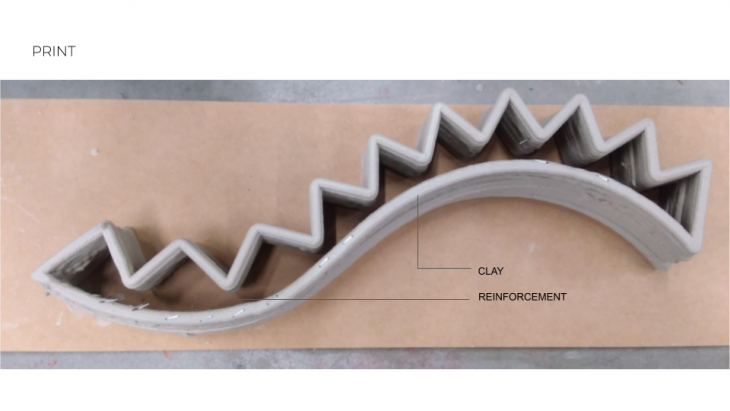

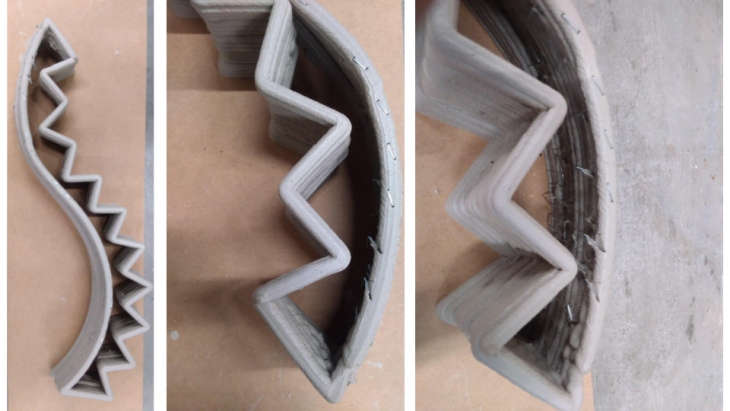

This project evolved from another studio project where we attempted to print concrete using a robotic arm while simultaneously embedding steel reinforcement in the shape of a staple with the help of a modified staple gun trailing the extruder. The project was an experiment in printing reinforced concrete that would could tackle tensile forces using an additive manufacturing process.

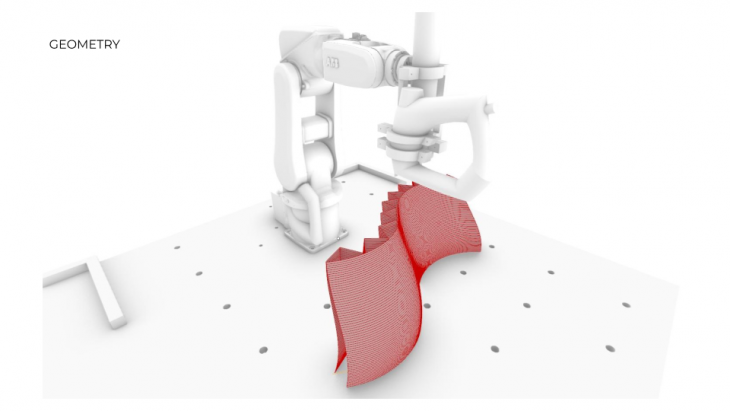

TOOL CONCEPT

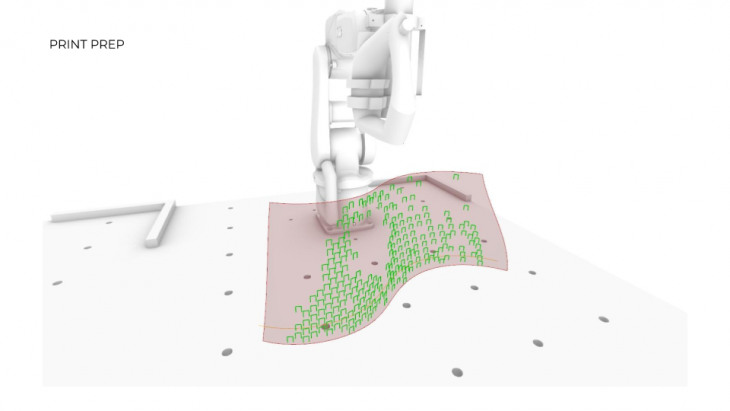

The tool developed involved a modified electrical staple gun attached to an extruder and mounted on a robotic arm (ABB-120).

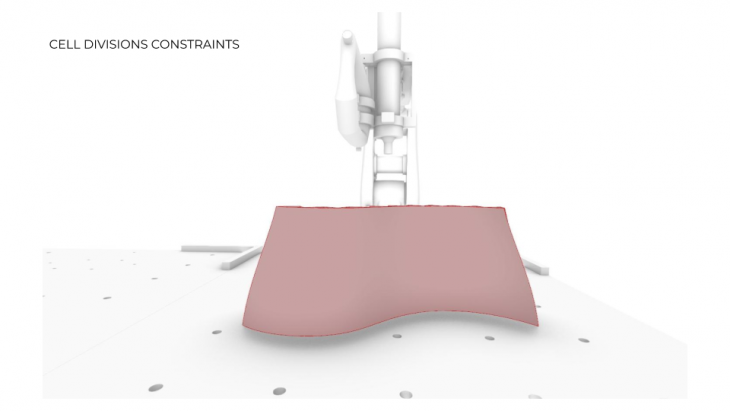

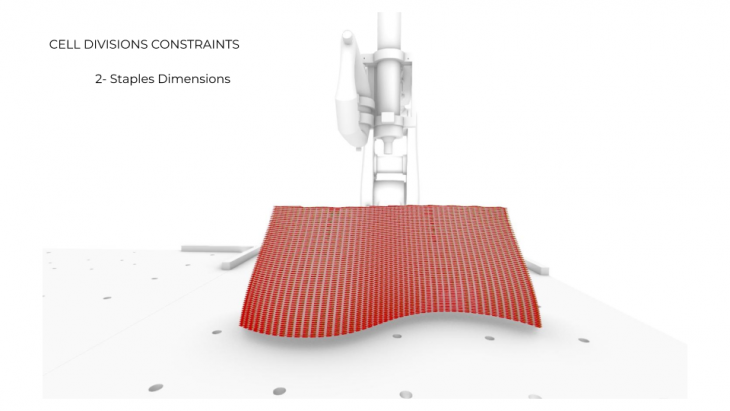

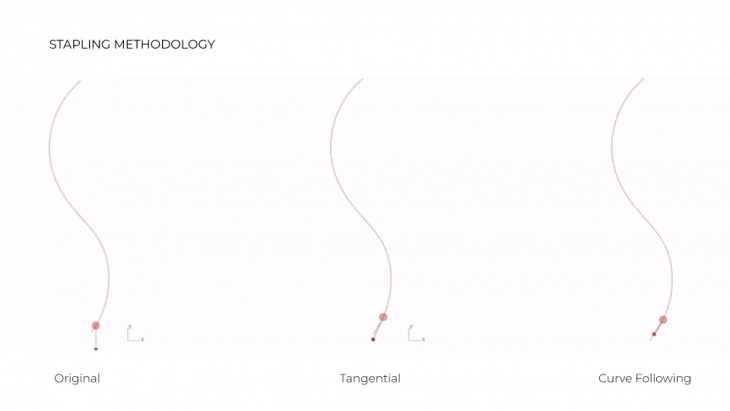

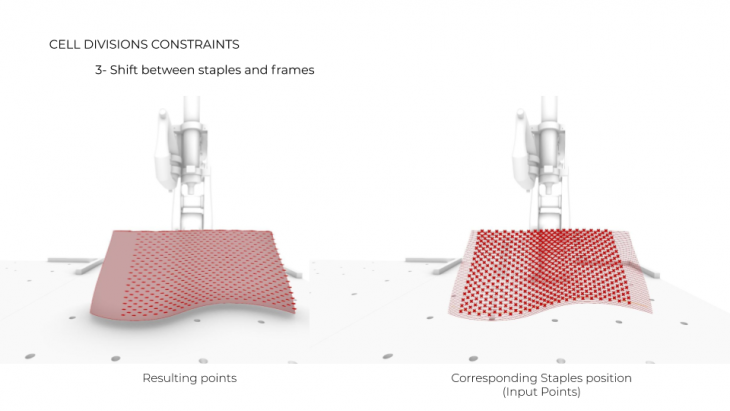

TOOLPATH DEVELOPMENT

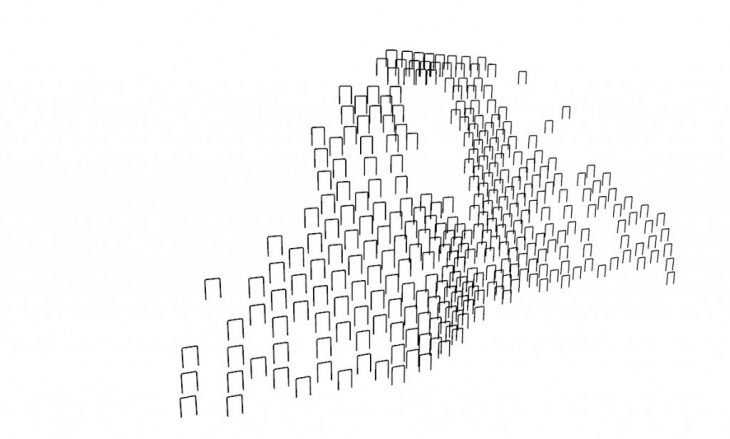

Identifying the area of influence of a staple reinforcement.

Due to the limitations of the tool the toolpath had to be modified so that the both the extruder nozzle and the gun tip move along the same line.

MACHINE LEARNING

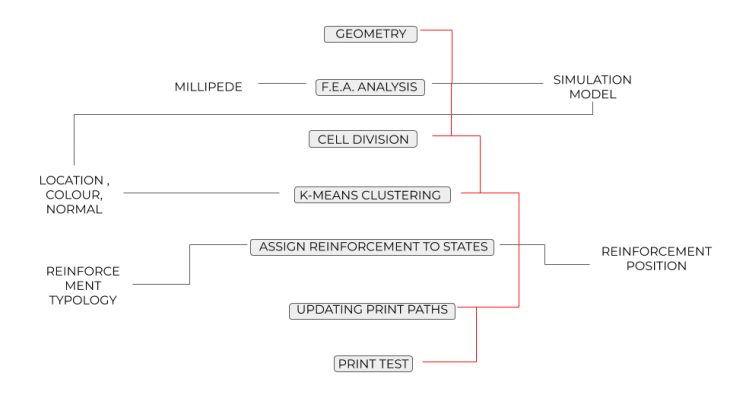

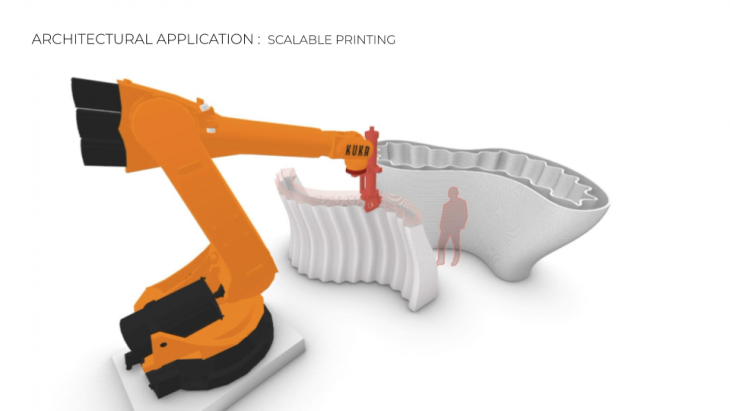

The process of evaluating a geometry to identify the key stress areas when acted upon by specific load conditions to identifying the type of reinforcement for each state to developing a strategy for print is a process that can be simplified if it can be automated using machine learning algorithms.

Different machine learning strategies like building a neural network can be developed to assign and optimize different types of reinforcement to different areas of the geometry thereby outputting the most optimum solution which utilizes the reinforcement sparsely.

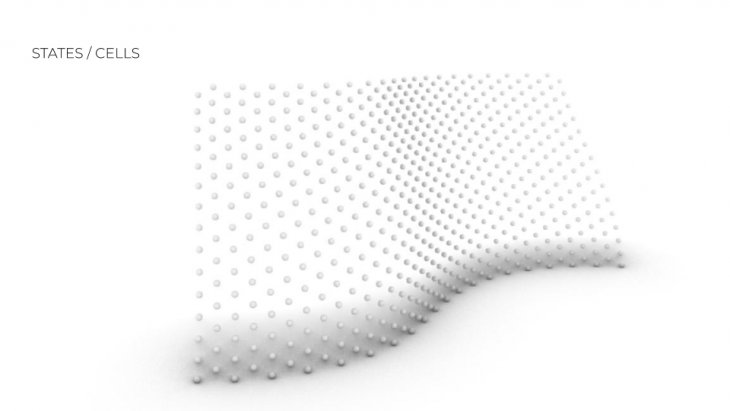

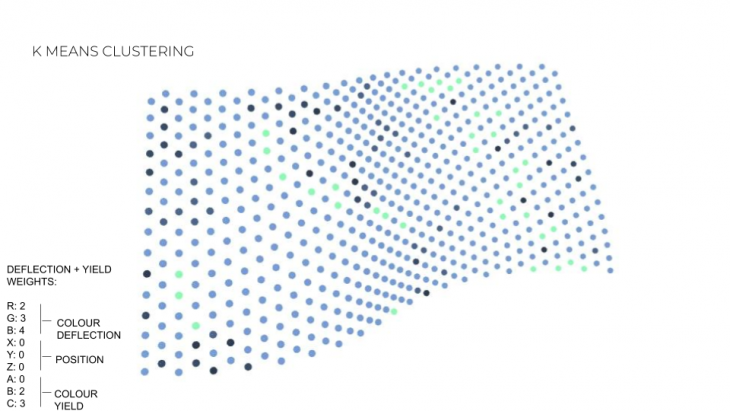

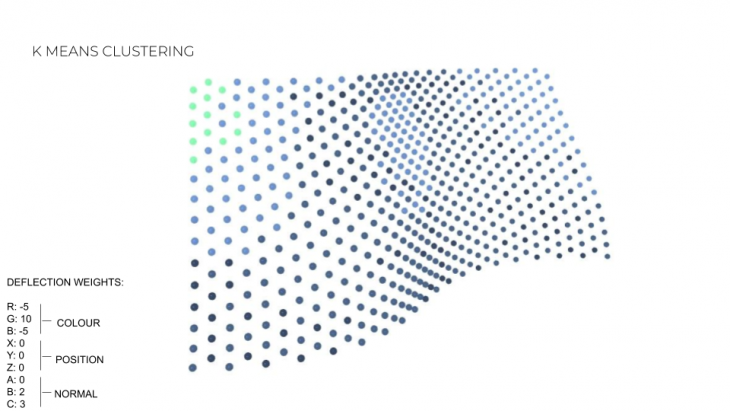

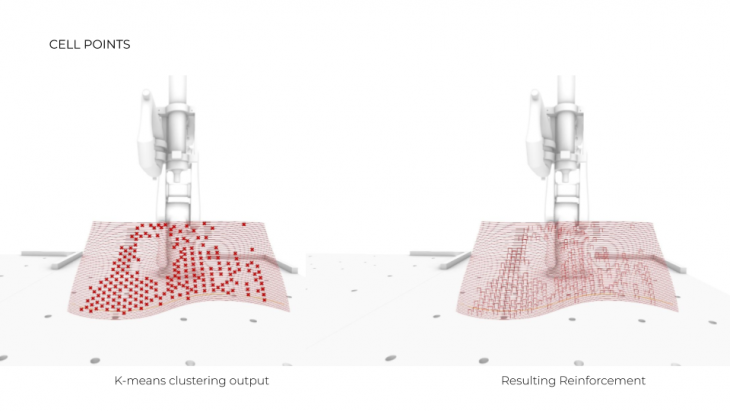

Another type of unsupervised learning called the k-means clustering can be used to group different states / regions of the geometry based on weightage and thus assign a specific type of reinforcement to it.

K – MEANS CLUSTERING

K-means clustering is a simple unsupervised learning algorithm that is used to solve clustering problems. It follows a simple procedure of classifying a given data set into a number of clusters, defined by the letter “k,” which is fixed beforehand. The clusters are then positioned as points and all observations or data points are associated with the nearest cluster, computed, adjusted and then the process starts over using the new adjustments until a desired result is reached. It aims to partition a set of observations into a number of clusters (k), resulting in the partitioning of the data into Voronoi cells. It can be considered a method of finding out which group a certain object really belongs to.

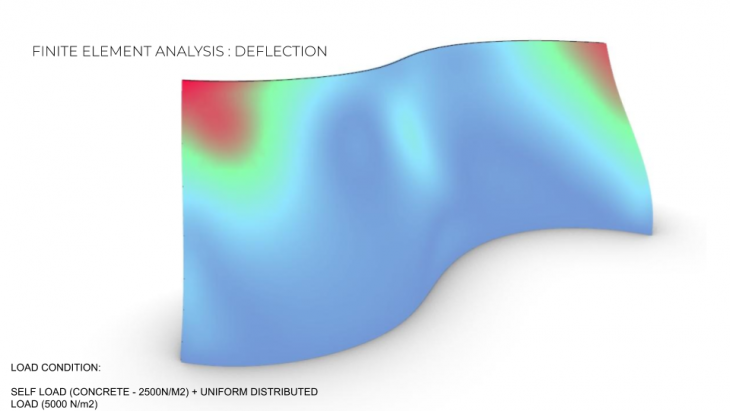

EVALUATION OF GEOMETRY.

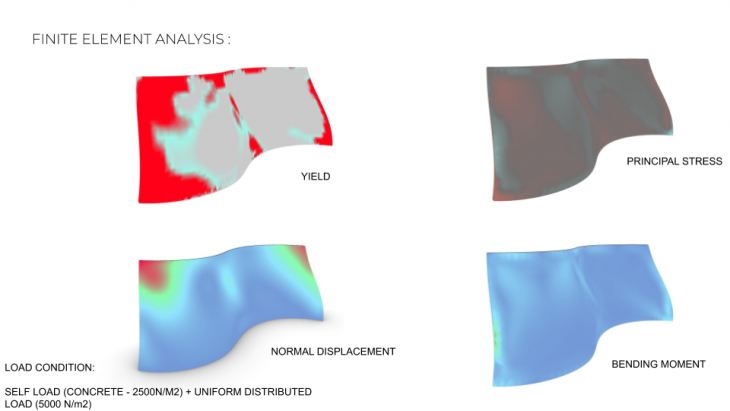

The geometry is evaluated using a finite element analysis method to understand the various forces and stresses acting on it.

FINITE ELEMENT ANALYSIS: The Finite Element Analysis (FEA) is the simulation of any given physical phenomenon using the numerical technique called Finite Element Method (FEM). To be able to simulatethe behaviour of an element under specific conditions, it is divided into millions of small elements that together form the shape of the structure needs to be created. Calculations are made for every single element. Combining the individual results gives us the final result of the structure. The approximations we just mentioned are usually polynomial and in fact, interpolations over the element(s). This means we know values at certain points within the element but not at every point. These ‘certain points’ are called nodal points and are often located at the boundary of the element. A F.E. Analysis is done on the same conditions as the test to check for accuracy and to train future models.

The FEA analysis gives the data necessary to define the reinforcement that will help stabilize the geometry.

Adjusting the weights of colour in the iterations

Combining separate data to create a clustering pattern

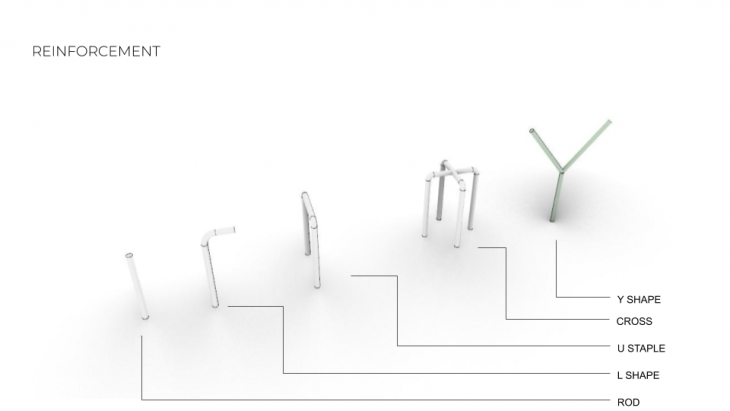

REINFORCEMENT TYPES:

As geometry gets complicated, the standard staple might be insufficient to tackle ll the problems faced by the geometry and the print. In such cases different types of reinforcement adept at tackling unique problems meed to be developed to address these issues.

A final print can therefore be envisioned as a combination of different types of staples, each designed to tackle a specific situation at a specific location in the geometry.

PRINT TEST

VISION

REINFORCED CONCRETE PRINTING & MACHINE LEARNING is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2018 by,

Students: Sujay Kumarji, Omar Geneidy

Faculty: Mateusz Zwierzycki, Jose Starsk Lara