IAAC – Master in Robotics and Advanced Construction

Workshop A

–

Faculty: Aldo Sollazzo

Faculty Assistants: Eugenio Bettucchi, Kunaljit Chadha

REINFORCED FIBERS

Syllabus

CONTEXT

Today, emergent computational techniques allows designers to program materials, predicting structural behaviours, visualizing forces and future deformations.

Rapid advances in digital fabrication technologies and new materials development allow for direct control and programmability of physical material transformations (Correa et all).

Linear stages of design, analysis and fabrication are bending into a circular loop, where outputs from each step become input for the previous one.

This iterative design method allows to program design solutions, enriched by a conscious process of production and application.

PROGRAM

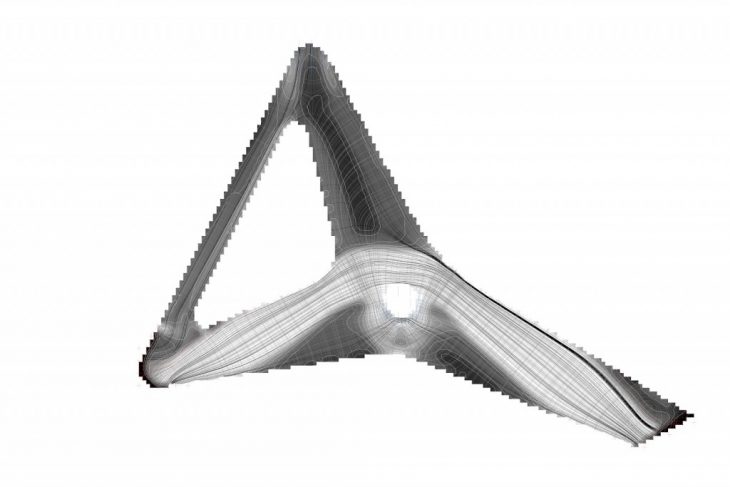

This seminar will explore how to introduce mixed computational and fabrication techniques informed by topology optimization strategies translated into subtractive manufacturing process.

The term ‘topology optimization’ is usually used for a certain type of problems appearing in structural optimization where the choice of design variables allows for a prediction of a general distribution of material in space (Bends et all).

As for subtractive manufacturing, it is related to CNC machining—a process that removes material from a larger piece through standard machining processes such as milling, turning/lathing or drilling.

Output of this seminar will be a 1:1 architectural component fabricated through cnc milling, while 3d printing reinforcements will be introduced along specific paths following the main stress lines identified by topology optimization analysis.

This mixed process of fabrication will involve cnc machining and 6 axis robotics manufacturing.