REINFORCED CONCRETE PRINTING

Strategies to incorporate reinforcement while printing concrete

For Part 1 check ..

RESEARCH PROBLEM:

Additive Manufacturing with cement-based materials is an emerging technology that opens opportunities in the construction industry by reducing labor and formwork costs and increasing reliability of concrete infrastructure. Since the development of 3d printing and additive layering technology, great advancements have been made in their attempts to incorporate that into various means of manufacturing. None so much greater than architecture and the building industry. The technology brought great hope with the ability to utilize contemporary building mediums like clay and concrete to print 3 dimensional structures. But while materials like clay can be easily adopted, r.c.c. poses a special problem. R.c.c. comprises of a compressive component i.e. cement concrete and a tensile component in the form of steel reinforcement.

While printing cement concrete for its compressive properties is nearly perfect, the problem remains in incorporating the steel reinforcement in it. While numerous studies have been conducted to incorporate reinforcement into concrete printing either inserting them post printing or by the use of tensile alternatives to steel or discrete filaments none has been successful in trying to incorporate steel simultaneously with concrete during printing.

Contour Crafting:

Behrokh Khoshnevis and Contour Crafting have conducted significant research in the 3D printing of a concrete house by the use of additive technology. But much of his research is in the utilization of vertical extrusions

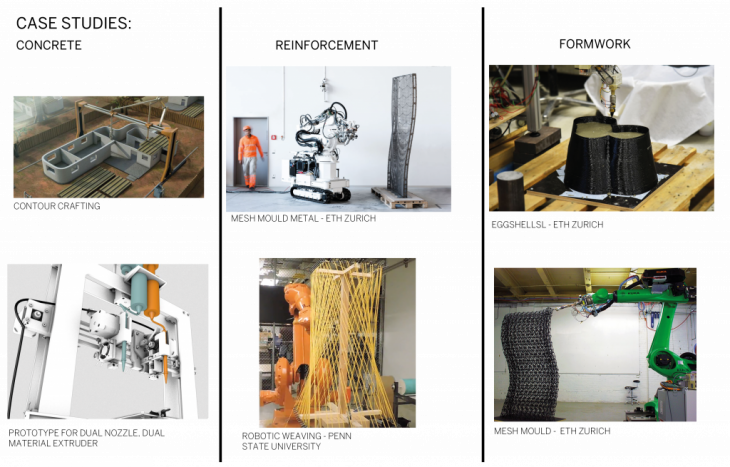

CASE STUDIES:

Under the umbrella of all of ongoing research within this area, the strategies can be broadly categorized into two types.

CONSECUTIVE PRINTING STRATEGY:

In consecutive printing reinforcement is framed first and concrete is printed later. This strategy requires the extruder to navigate around the framework and ensure the concrete is deposited in the right places, often ensuring proper encapsulation of the reinforcement and avoiding collision and air gaps.

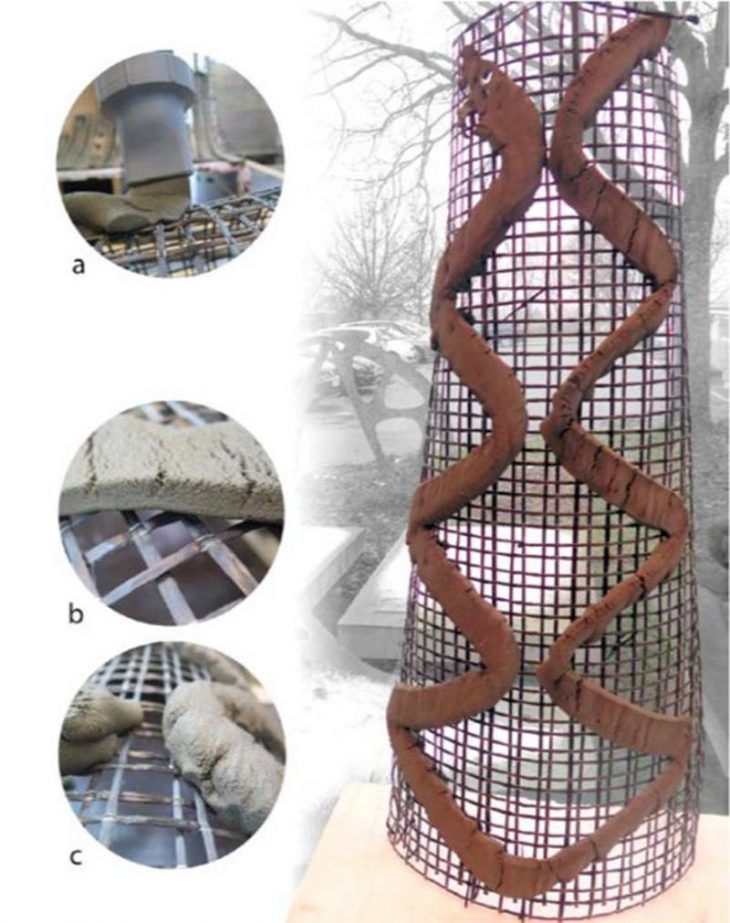

SCRIM

Sparse Concrete Reinforcement in Meshworks

Authors: Phil Ayres, Wilson Ricardo Leal da Silva, Paul Nicholas, Thomas Juul Anderson, Johannes Portielje Rauff Greisen

Publication: Robotic Fabrication in Architecture, Art and Design

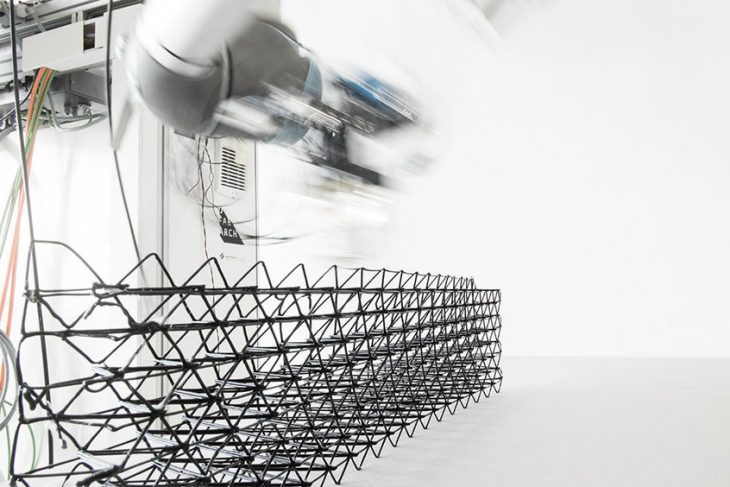

MESH-MOULD

Robotically Fabricated Spatial Meshes As Concrete Formwork and Reinforcement

Authors: Norman Hack, Willi Viktor Lauer, Fabio Gramazio, Mathias Kohler, Silke Langenberg

Publication: Fabricate

Concrete requires formwork to cast and reinforcement to compensate for tensional forces, both of which are expensive and labour intensive. Due to this concrete is cast in simple forms and not allowed to explore its true potential. Mesh mould investigates a technique of intricately weaving a tensile material that acts as form defining mould and reinforcement.

SIMULTANEOUS PRINTING STRATEGY:

This strategy tries to incorporate steel and concrete simultaneously during extrusion. Given the nature of printing, steel is usually deposited horizontally and not vertically.

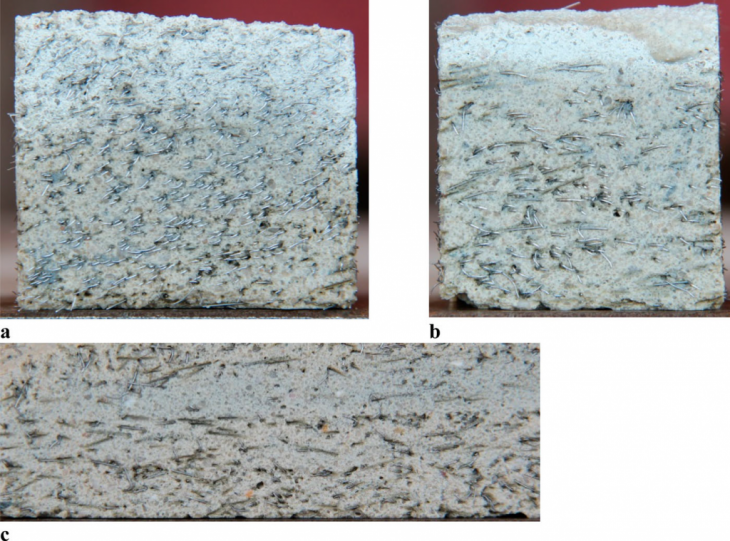

Ductility of 3D printed concrete reinforced with short straight steel fibers

Authors: F. P. Bos, E. Bosco & T. A. M. Salet

Publication: Virtual and Physical Prototyping · November 2018

The study explores the structural performance of Steel Fiber Reinforced concrete (SFRC) applied in a particular Digital Fabrication Concrete (DFC) process, namely the ‘3D Concrete Printing (3DCP)’ Fused Deposition Modelling (FDM) process.

3D Printing Concrete with Reinforcement

Authors: Freek P. Bos, Zeeshan Y. Ahmed, Rob J.M. Wolfs,

and Theo A.M. Salet

Publication: Researchgate.com

One of the major difficulties blocking large scale application, is the lack of ductility or post-peak capacity of 3D printed concrete. This is due to the fact that conventional reinforcement, with which ductility is usually obtained in structural concrete, can not (yet) be incorporated into the existing concrete additive manufacturing systems. In the limited number of projects that have been realized up to now, the strategy generally is to use the printed concrete as lost mould for conventional reinforced concrete.

CASE STUDIES:

There has been parallel strategies developed in each facet of reinforced printing namely, formwork, reinforment laying and concrete printing.

RESEARCH QUESTION:

“Can marrying of techniques usch as WIRE / MESH WEAVING and metal bending with additive concrete printing help develop reinforced CONCRETE printing strategies?”

HYPOTHESIS:

“Can specialized reinforced cement concrete like ferro-cement be printed continuously and in situ while incorporating its reinforcement in the printing process at real time by incorporating methods of mesh-weaving or layer printing during the printing process.”

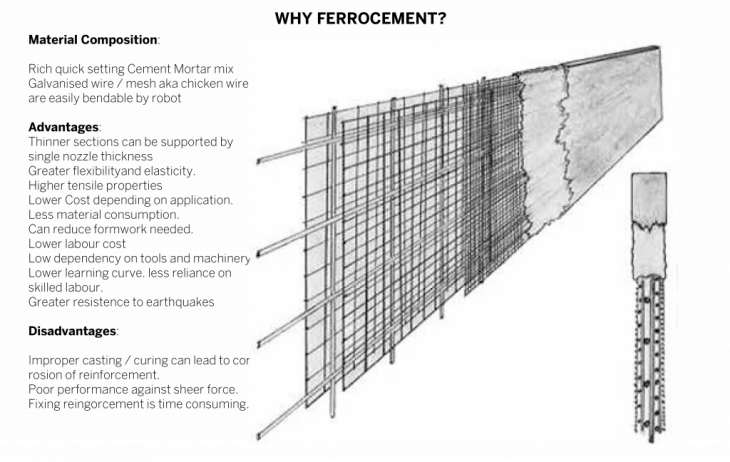

WHY FERROCEMENT?

POSSIBLE TECHNOLOGY TO “MARRY” WITH

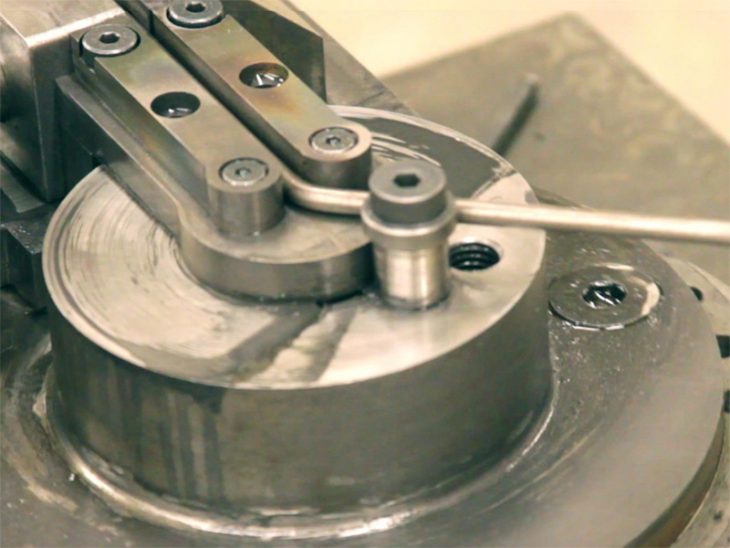

WIRE BENDING:

Wire bending technology could be incorporated in the weaving of metal mesh

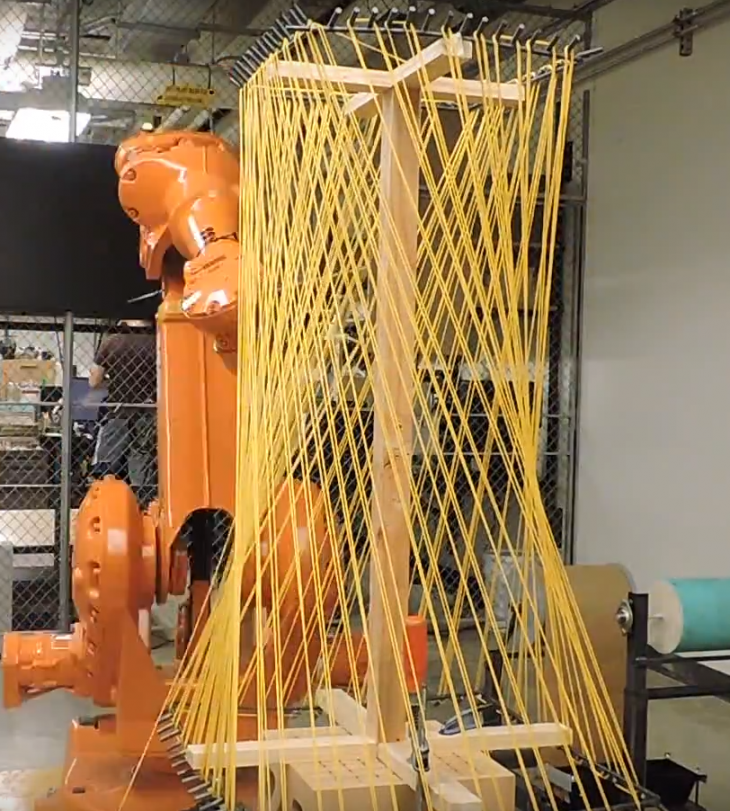

ROBOTIC WEAVING:

The baseframework could be created and the reinforcement could be woven by a robotic arm. A concrete extruder could then print over the woven mesh. Pic : ROBOTIC WEAVING – PENN STATE UNIVERSITY

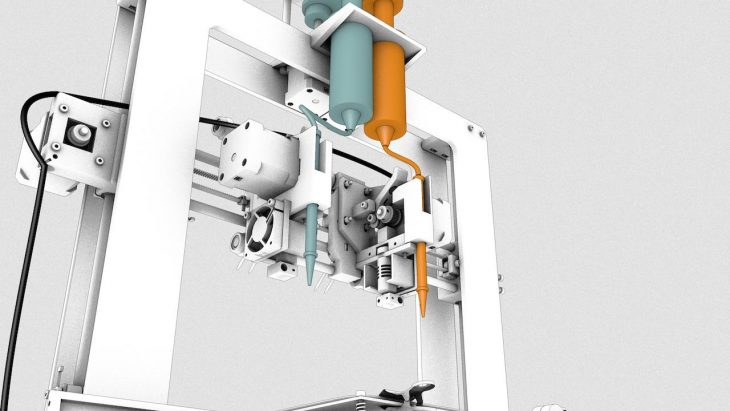

POLYMER MESH WITH MULTI NOZZLE EXTRUDER

Polymer mesh can be extruded using a pla extruder simultaneously along with concrete.

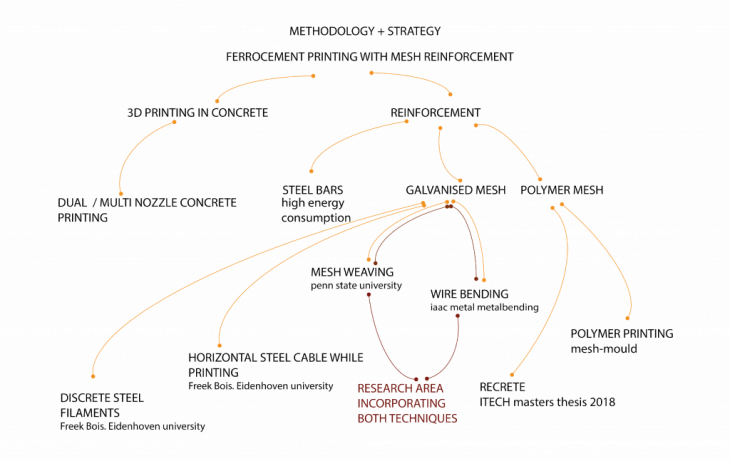

METHODOLOGY + STRATEGY:

STRATEGY:

Possible strategies involving marrying of different technologies.

TOOL DEVELOPMENT:

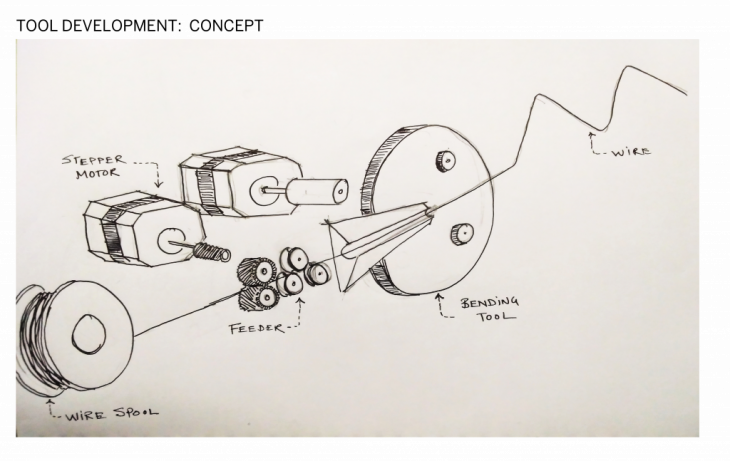

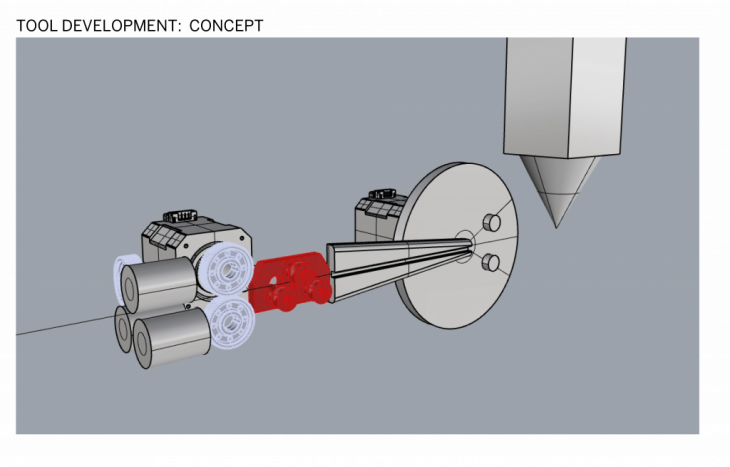

Incorporating wire bending along with concrete printing will require the development of a tool that leads before the extruder bending the reinforcement wire and then depositing the concrete.

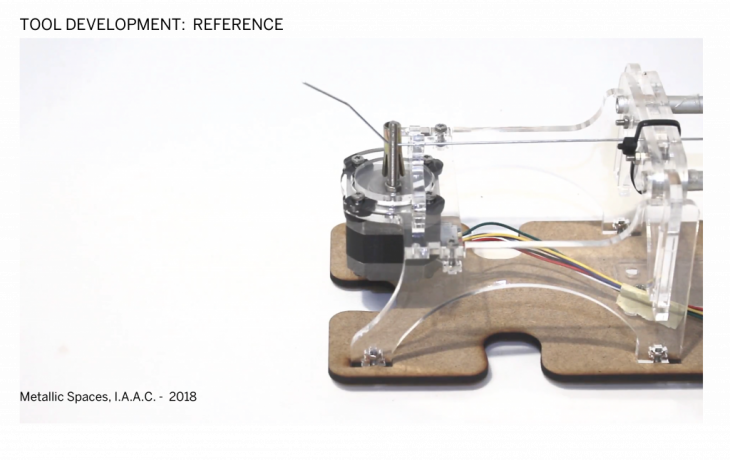

Metallic Spaces is an installation developed by the Global summer School program at I.A.A.C. in 2018. The program developed a tool that allows you to bend wire with the help of the Kuka robotic arm.

TOOL DEVELOPMENT:

The tool for bending reinforcement is a modification of the Metallic Spaces. the major difference of this tool over the Metallic spaces tool is that while I.A.A.C.’s tool is static with the robotic arm assisting the wire to pass through it, this tool will be mounted on the robotic arm and shall be mobile.

TOOL PROTOTYPE:

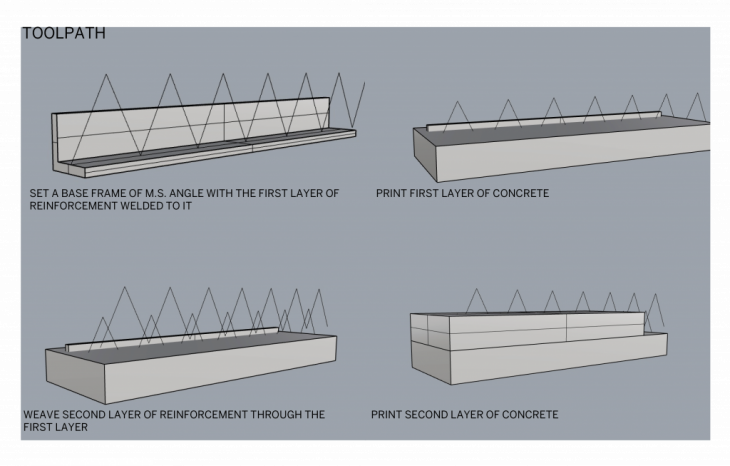

TOOLPATH:

NEXT STEPS:

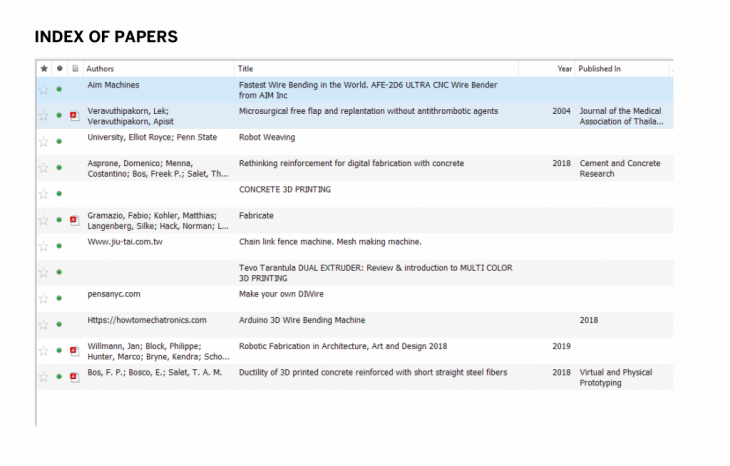

REFERENCES:

Reinforced Concrete Printing II is a project of IaaC, Institute for Advanced Architecture of Catalonia developed at Master in Robotics and Advanced Construction (M.R.A.C.) in 2019 by,

Students: Sujay Kumarji

Faculty: Ricardo Devesa