The chosen technique is stacking, supported by also the kerfing one on the more curved edges. Indeed our concept inverts the notion of traditional structure where corners tend to be heavy and structural, connecting light elements.

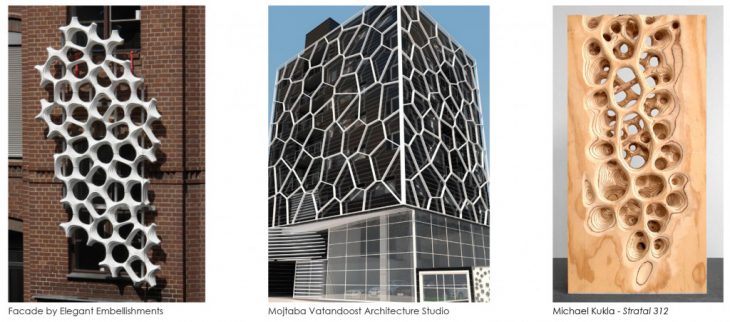

//REFERENCES

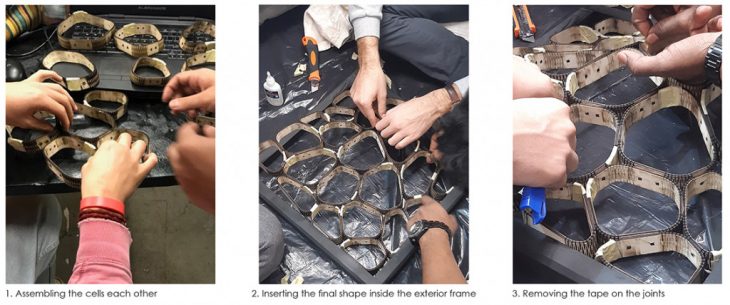

//PHYSICAL MODEL

FEATURES

The model of 40×40 cm has 26 modules with different lengths and same width. The total area of all the pieces is 2212,2 cm2, so a sheet of 50×50 was needed.

CUTTING TIME

Since the plywood presents a 4 mm thickness, the cutting speed had to be decreased at 0,5. Therefore this got the cutting time longer, but it also allowed to achieve the final modules in the proper

way without uncut pieces.

The total cutting time was 2 hours and 10 minutes.

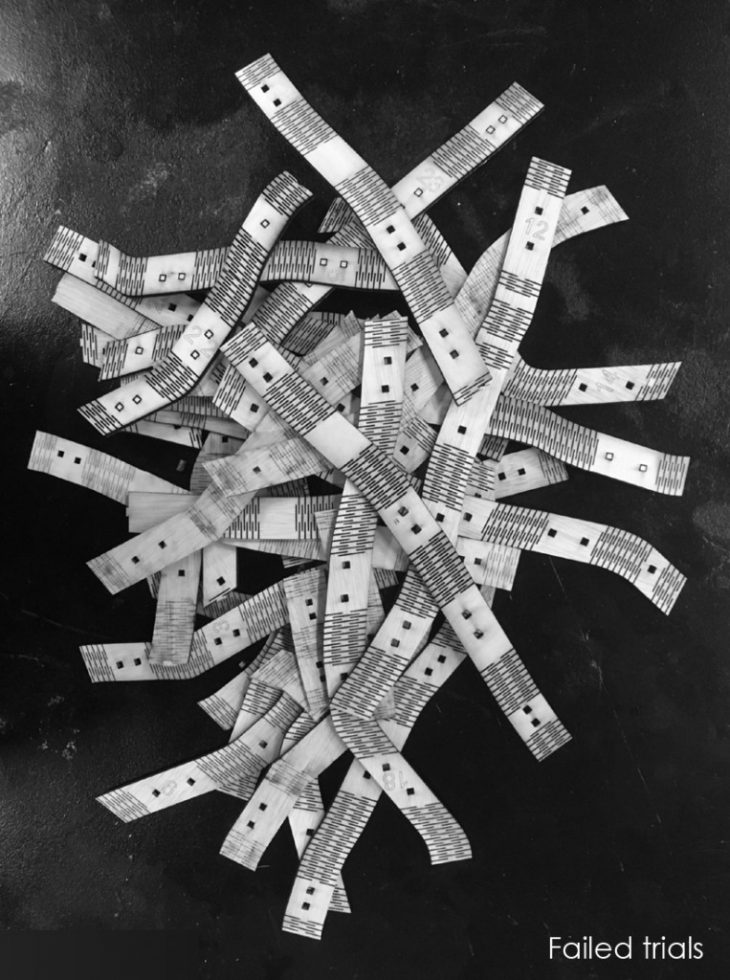

TRIALS AND ERRORS

The process is been characterized by a lot of trials and errors, experimenting with different settings such as power and speed.

> ATTEMPT 1.1 // BIRCH PLYWOOD

The characteristics of the material were perfect for kerfing due to its flexibility. However, due to the irregularity of the surface laser cutter was out of focus, thus not cutting through the sheet.

> ATTEMPT 1.2 // BIRCH PLYWOOD

Our target for the attempt 1.2 was to cut already existing lines all the way through; that is why we did not modify the settings. It resulted in missalignment.

> ATTEMPT 2.1 // PINE PLYWOOD

We changed material getting a more common plywood. The laser cutting process went smoothly, cut were clean and pieces were coming out right away. However the material qualities were not ideal for our type of assembly. Plywood was too fragile and rigid, thus the kerfing was impossible to achieve.

THE JOINTS

Almost on each flat surface of the voronoi modules there are two cells that will be filled by a piece of plywood orthogonally. The curved parts, characterized by the kerfing technique, won’t ever touch other objects.

The cells are connected with eachother via plywood joint. The corners of each cell remain free.

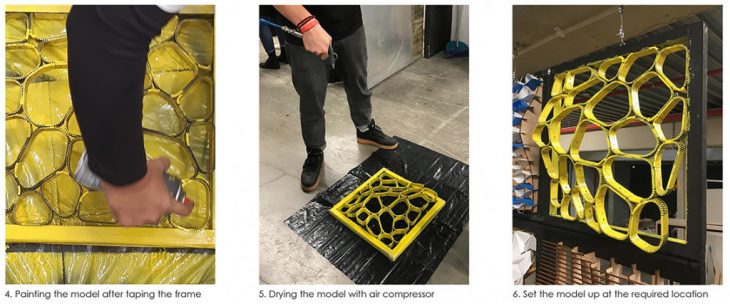

//ASSEMBLING

//ARCHITECTURAL APPLICATION

The main theme of the exercise was the privacy. Our model can be replicated many times, in order to get a continuous facade that works as a filter among two different spaces, such as a garden and

an exterior corridor. The wavy shape and the interior treatment of the cells turn the space into a flexible area, alternating covered and opened spots.

Privacy partition // Laser is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Master in Advanced Architecture in 2019/2020 by:

Students: Francesco Polvi, Dusan Savicevic, Suyash Chandrakant Sawant, Dinesh Kumar Vellingiri

Faculty: Ricardo Mayor Luque