The research contributes to the thermo-responsive glazing system based on the phase change material (PCM) system to truly control the indoor temperature.

abstract

In the era of energy consciousness, phase change material (PCM) represents an innovative solution to contribute to the improvement of energy performance of the building. Recently a growing trend of phase change material within transparent facade components has been observed. This research presents a novel strategy of integrating phase change material within glazing system. This is achieved by using computational design tools to derive the morphology & simulating its thermal performance and physical prototyping and testing to prove the concept. The result of the physical testing reveals a significant reduction in peak temperature which compares with the self-assemble double glazing system.

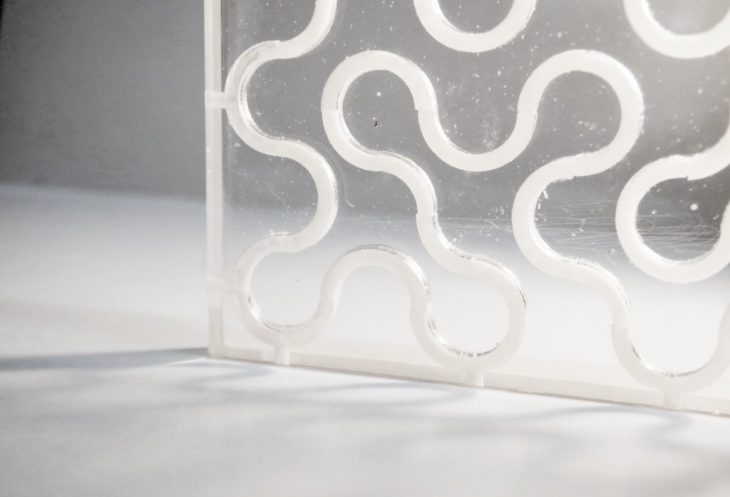

paranel, the final prototype

Introduction

Numerous researches on building envelop optimization suggest that glazing system is one of the most vulnerable components that influence diurnal temperatures within the building. To address this issue, various shading strategies, glass surface treatment, and fixture options have been implemented on numerous building across the globe. But most of these solutions do not address the negligible thermal mass of glazing system, leaving it vulnerable to conductive heat exchanges from immediate surroundings. Thermal mass in buildings refers to materials like stone and masonry, which are capable of storing solar heat. Since the application is glazing system, thermal mass needs to be optically transparent or translucent to the visible spectrum of light.

This research aims at investigating the thermal & visual performance of phase change material in a thermo-responsive transparent building envelop capable of adapting to transient temperature flux.

What is Phase Change Material(PCM)?

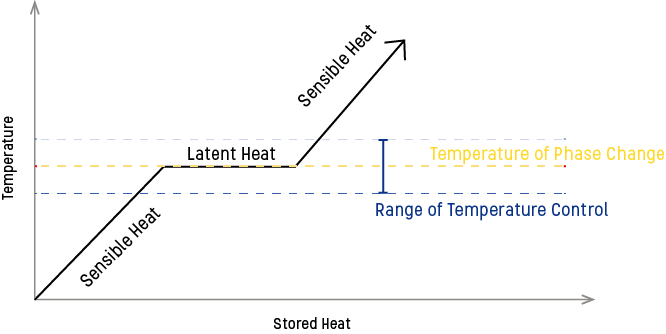

Phase Change Material is a substance of high heat of fusion. It is capable of storing or releasing a large amount of energy while undergoing the phase change, which is either solid to liquid, liquid to gas or vice-versa. Hence, they are classified as latent heat storage units.

It’s important to note that phase change in phase change material occurs without a significant change in temperature. This property finds application in architecture where phase change material can store 5-14 times more heat per unit volume than conventional storage material such as water, masonry or rock.[1] Specifically, phase change material embedded in the architectural envelope is potentially allowing a reduction in daily temperature fluctuations of the indoor environment, both peak temperature delay, and peak temperature reduced

PCM, phase change process

About Paranel

figure 3.1 , Conceptual Diagram

Desired criteria for glazing system from energy savings point of view is to possess higher transmission in the visible spectrum and lower transmission in infrared spectrum without compromising on visual transparency. In addition to this, glazing must be insulated to minimize conductive heat exchanges.

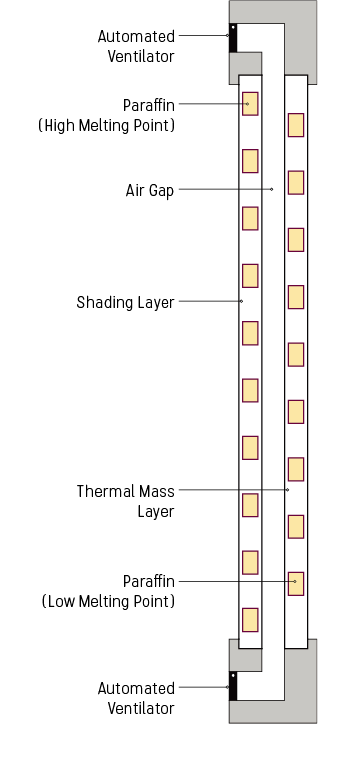

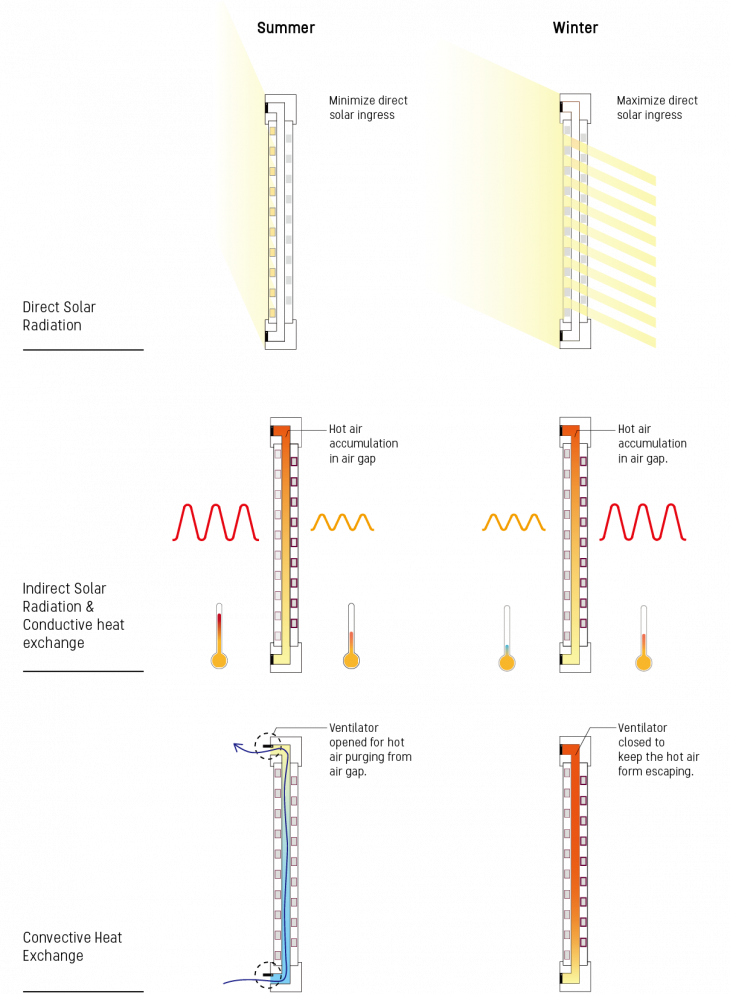

To achieve the desired performance, this research proposes a glazing system comprising of two paraffin embedded clear panel separated by a ventilated air gap (figure 3.1). It’s a three layer system where the exterior panel shades from direct solar radiation, interior panel acts as thermal mass and air gap as insulator controlling conductive heat exchanges across the panel (figure 3.2).

figure 3.2, Schematic Section Section

Proposed system functions (see figure 3.3) like a Trombe wall section, with the exception of convective heat exchange prevalent in the latter.

During summer months, the shading layer minimizes direct solar ingress to the building and insulation layer absorbs the indirect solar radiation and conductive heat exchanges without a significant rise in temperature. In case of overheating within the air gap, the motorized ventilators will open to purge the hot air with surrounding air.

During winter months, the shading layer permits direct solar radiation through with minimal obstruction. This direct radiation is stored as thermal inertia to be released at night. The air gap is kept sealed to build up the thermal inertia, much like the Trombe wall.

figure 3.3, paranel system function

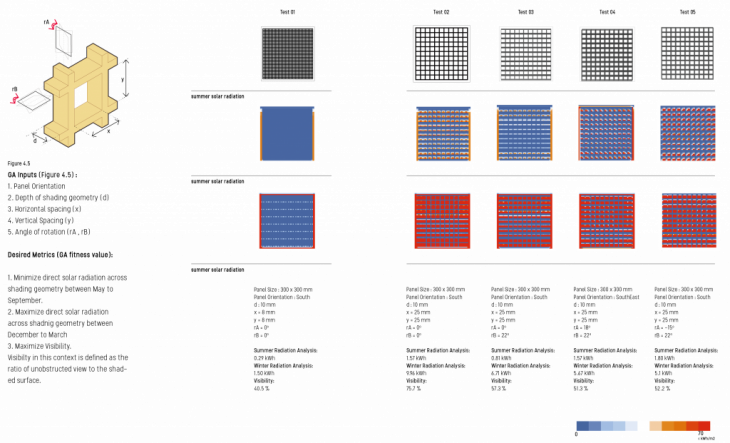

Shading layer

Analysis of energy plus weather data (epw) suggests that Barcelona experiences thermal discomfort during the summer months of June till September. Isolated solar angles of these months inform the shading morphology. The Azimuth and Altitude angle of the sun within this period is extracted using ladybug plugin for grasshopper. For optimizing better performance in both periods of summer and winter timer, Octopus generative algorithm (GA) solver has been used to derive the spacing between vertical and horizontal shading members. For more detailing computational information, you might able to refer to my previous blog post paranel, PCM embedded in the glazing system. Optimization outcome is in the following diagram.

Several Results from multi-objective optimization

Thermal Mass

The desired criteria governing the morphology of paraffin-embedded in the thermal mass layer is the volume of paraffin required for effective thermal regulation and visual porosity across the layer.

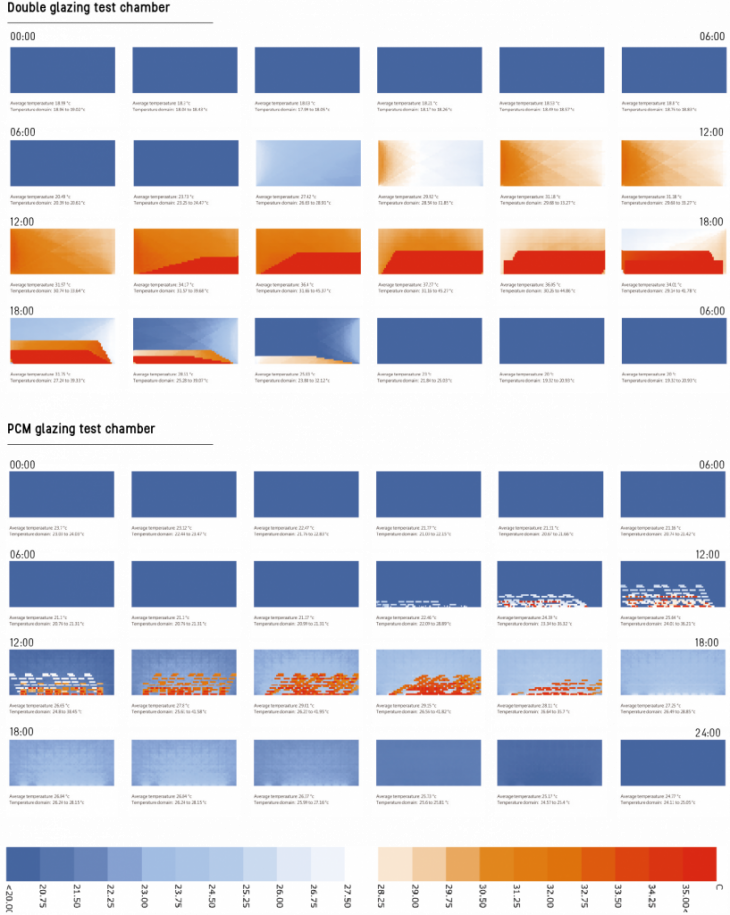

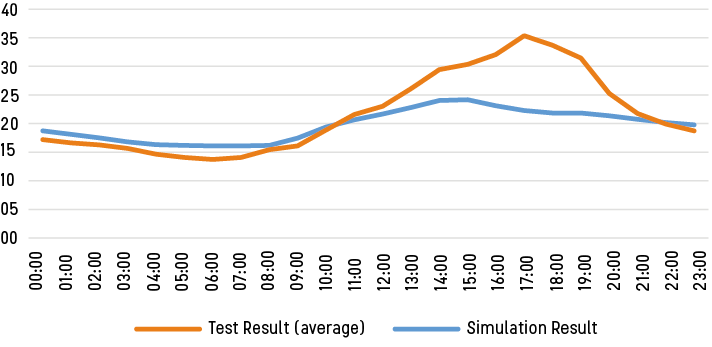

we testify the required volume by simulating through Grasshopper Honeybee, a parametric plugin for EnergyPlus. To calibrate the parameter setting, for instance, the thermal property of PCM, the surface convection algorithm and space discretization constant, same computational test chamber had been set up in a physical environment.

The simulation date is 10th of June. According to the result, comparing normal double glazing and PCM system, in the afternoon time 15:00~16:00, the average temperature difference reach to approximate 9 degrees. The highest temperature in normal double glazing test chamber is around 45 Celcius degree, which is significantly higher than the PCM double glazing system.

In the night time scenario, the average temperature of double glazing test chamber is around 18 Celcius degree. The PCM test chamber remains the temperature around 21 Celcius degree. The simulation result reveals that phase change material in glazing system is promising. It is able to reduce the temperature fluctuation in the indoor environment and provide a desirable indoor environment.

Simulation Result form Energy plus

Daylight Autonomy

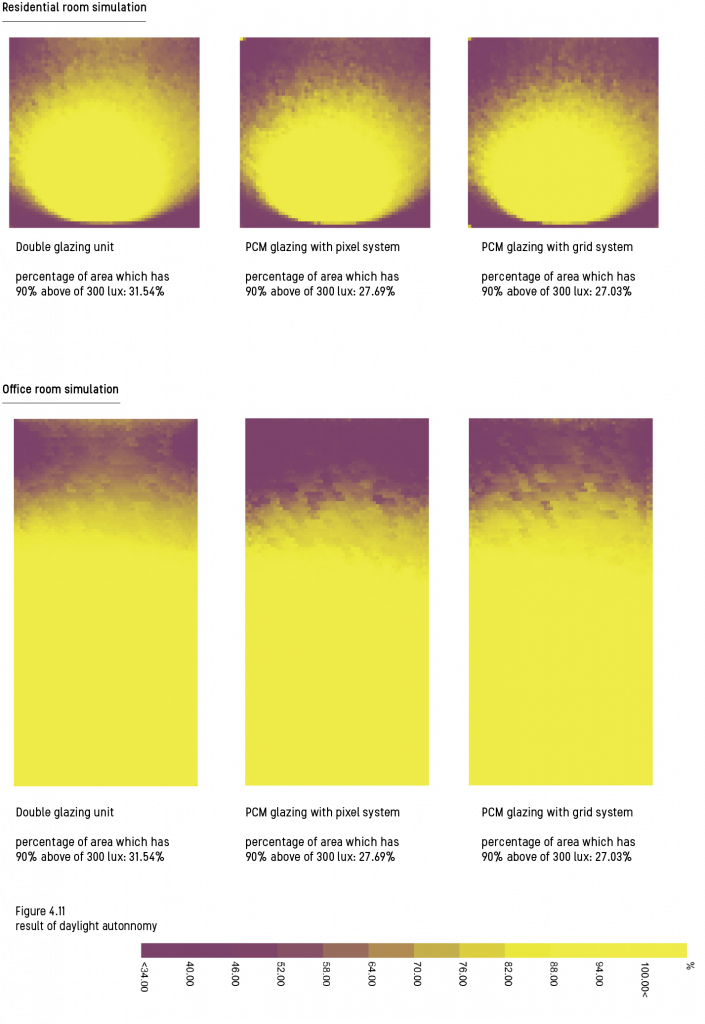

Since most of the direct sunlight has been blocked by the shading layer during the summertime, only diffuse sunlight is able to cast indoor. Therefore, it is crucial to understand the indoor light quality in the daytime.

The daylight autonomy has been performed in both residential and office environment. The setup of the residential building is a 3m*3m*3m room with a 1m*1m window on the southside surface. The office setting is carried on a 3m*6m*3m room, which has a 2.9*2.9m window faced to the south. In both simulations, three kinds of glazing system have been compared, which are normal double glazing, phase change material glazing with the grid system, and phase change material glazing with pixel system.

Result

In both residential and office circumstance, the phase change material glazing system performs merely similar light quality as the double glazing.

Daylight Autonomy Comparison

Physical Experiment – Thermal delay

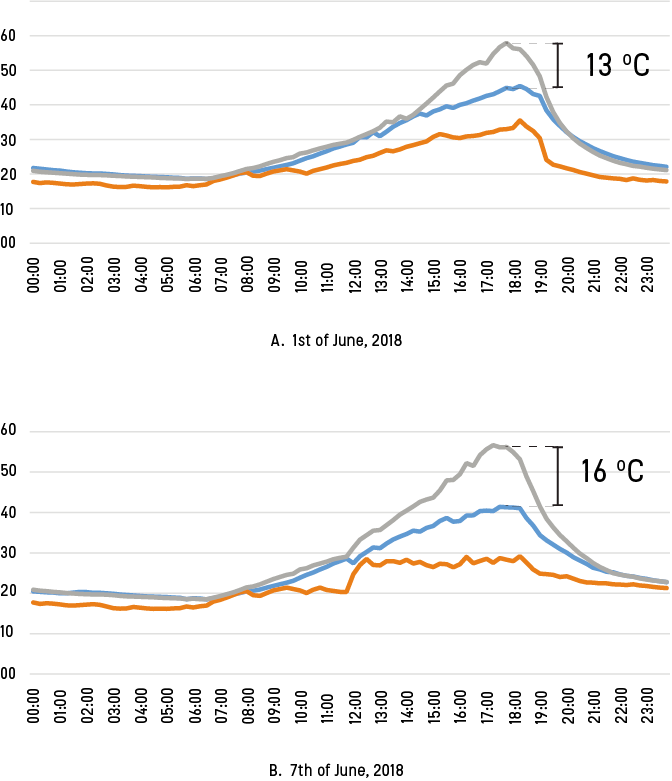

Indoor temperature analysis based on Energy Plus (EP) simulation was verified with physical testing between 1-12th of June in Barcelona.

MATERIAL AND EQUIPMENT SETTING

Polystyrene insulated MDF box was used as test chamber to monitor the thermal performance of normal glass DGU (6-15-6mm) and Paranel DGU (12-15-12mm). Both test chambers housed a DS18B20 temperature sensor and one sensor was placed outside unshaded (figure 7.2, 7.5). The Arduino recorded all 3 three temperature reading every minute. The critical temperature to activate the ventilator was set at 27 oC i.e. the ventilator would open in case the temperature inside test chamber rises above 27 oC.

RESULTS AND DISCUSSION

By the end of the testing period, we gathered temperature data for 1st, 7th, 10th & 11th of June and their performance was plotted on the graph.

The graphs suggest that paranel acts as a thermal regulator controlling indoor temperature fluctuation. At night, the indoor temperature is 3-4 degree higher than outdoor. During daytime, in some cases, it shows a temperature difference of more than 15 oC between paranel and normal DGU test chamber.

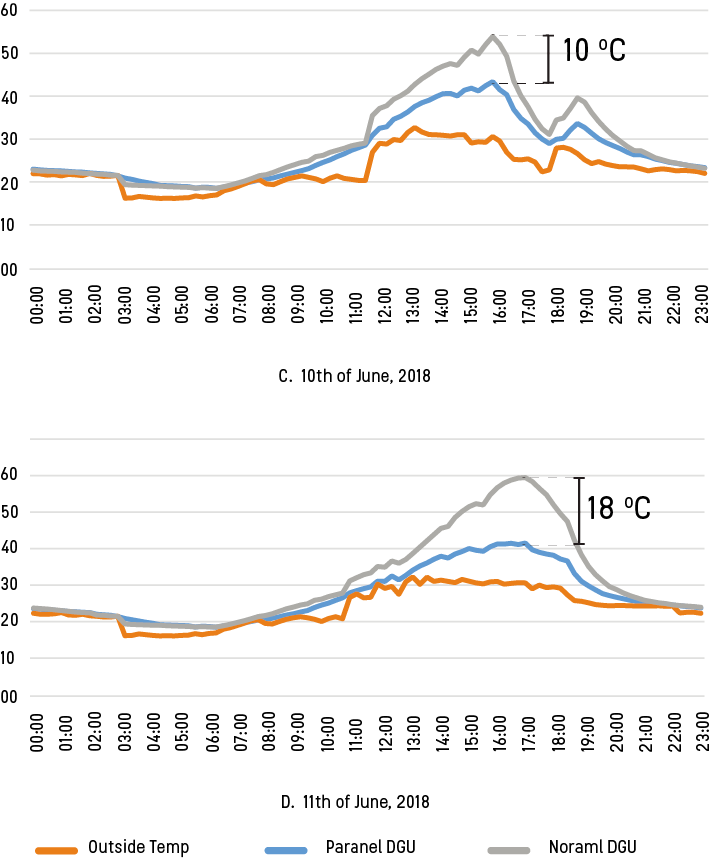

Comparing physical test data with simulated data for 10th of June reveals a difference in temperature between 12:00-20:00 HR (figure 7.4). The average temperature predicted by EP simulation (24.7 oC) is 2 degrees lower

than the average temperature revealed by physical test (26.7 oC). This difference could be attributed to sky conditions, old weather data, other environmental and contextual factors.

Comparison between physical test and computational simulation

Application

Energy consumption has been considered as an essential criterion in building design in both environmental and financial perspective. With the characteristic in peak temperature delay and peak temperature reduction, paranel DGU is promising in controlling the interior temperature to provide a desirable indoor environment.

Therefore, we expect paranel is able to apply in diverse architecture, location and weather condition to deal with the fluctuating climate.

paranel application

paranel application

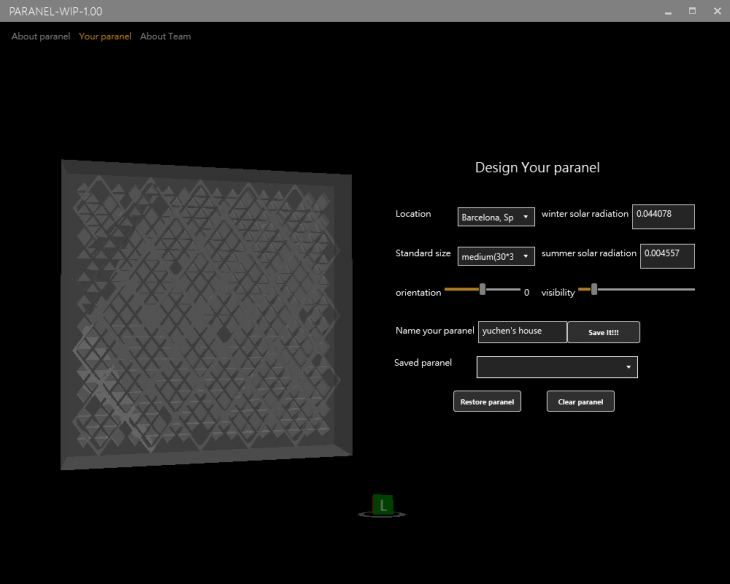

Moreover, except the thermal performance of the paranel GDU, the user experience is also critical in the design process. Hence, we developed the graphic user interface(GUI) for the paranel, which allow the user to decide on several criteria. For instance, the visual porosity of the glazing system might differ from users and buildings. The paranel GUI is still under developing. The beta version is allowing the user in controlling the location, window orientation, size and the desirable visibility.

GUI application of paranel

Conclusion

Building envelope can play a crucial role in building’s energy performance and integration of phase change material (PCM) in transparent building component presents promising thermal and daylight performance. This research paper has examined the performance of Paraffin-embedded glazing system both computationally and physically.

Experiments prove system’s effectiveness as a thermal mass without compromising on daylight & visibility across the panel. This paper presents research conducted over 6 months and presents some challenges like flammability of Paraffin, year-round physical experimentation of performance and adaptability into industry scale manufacturing that is yet to be addressed. It also opens up avenues for further research into this topic including ;

1. Refractive properties of paraffin within epoxy resin has potential in daylight control systems such as light shelves.

2.Geometrical typologies that arise out of the fabrication techniques and paraffin’s visual state due to diurnal heat exchange.

This exercise is part of the Research Studio- Digital Matter Faculty: Areti Markopoulo Faculty Assistants: Raimund Kremuller, David Andre Leon Computational Guide: Angelos Chronis Paranel, a thermo-responsive glazing system developed at MAA01 in 2017-2018 by: Students: Yuchen Chen, Aman Jain, Alberto Holguin, Takeru Osoegawa

If you are interested in more detailing of the paranel, how it is able to improve your home indoor comfort or another relative computational issue of PCM. You are welcome to email: [email protected]

We will love to response your doubt.