As a means of creating a set of buildable parameters for a large scale prototype using 3D Printing with clay, the OTF team are developing a set of machines that include a controlled micro climatic simulation to test temperature and humidity differences on either side if the walls, or a customized load bearing machine to test the strength of prototypes.

The team is also developing a system using the robotic arm and an infrared light source, in order to simulate solar paths using the specific coordinates of their chosen site, in order to be able to optimize the daylight income.

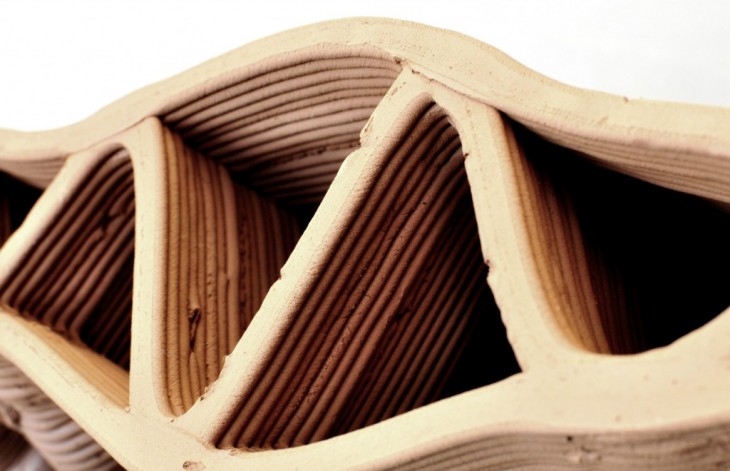

In order to test the machines, each of them was paired with a wall specifically designed to obtain a conclusive result regarding thermal conductivity, thermal conduction, thermal radiation and heat capacity.

Also, the geometry of the walls wat iterated and the team teste a solid wall, with infill, so that they can compare it’s structural behavior with the other 4 walls.

Program Directors: Edouard Cabay, Alexandre Dubor

Research Advisor: Areti Markopoulou

Students: Abdullah Ibrahim, Sameera Chukkapalli, Tanuj Thomas, Lili Tayefi, Chenthur Raaghav, Iason Giraud, Lidia Ratoi