NOMAD | Folding Flax Pavilion

Light Weight Bio Composite Structures

“If you know freedom is somewhere to be found.

If the desert surrounds you everywhere.

If there doesn’t appear to be anywhere left to go.

Seek refuge NOWHERE”

Bio Composite

Nomad explores the agency and new potential of natural materials developing a digitally manufactured bio-composite for lightweight construction. Here robotic fabrication, bio-composite materials have been used to develop new fabrication strategies for performative architecture. Beginning with 1:1 scale models and material tests, Nomad is a large scale pavilion for Barcelona, for use in public space and community creation.

Origami

The model has been developed around the structural value of origami shapes. Rather that aiming towards a specific shape, the innate structure of folding has been used to generate the form. Therefor the purpose of this pavilion is to create a light weight bio-composite structure, meaning that organic materials are to be used to generate a structural form that can be made, fabricated and manoeuvred by people.

By creating this pavilion in a series of repeated sections, the form can be moved and constructed with ease.

Transportation

The structural issues revolve largely around the transportation of the pavilion from the fab lab to the ultimate location in the desert. Beyond the limits put on the scale of the pavilion by the fabrication machine, the size is also restricted by truck transporting the pieces. While it is ideal to fabricate as many fixed joints as possible in the Fab Lab, these restrictions have lead to alternative construction details to be made, in order to give this flexility.

The optimisation of the structure comes from increasing the depth of folds – in relation to maximising the usable floor plate. The deeper the bends, the greater the inherent strength of the piece. Using grasshopper, these relationships have been able to be tested and perfected.

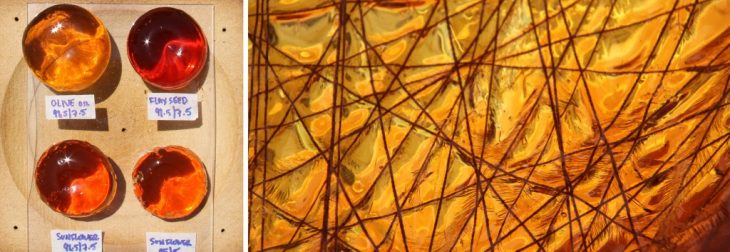

Resins

The bio-composite is achieved through the combination of timber frames, jute fibres and resin. The material used for the resin in the pavilion is Colofono, which is a combination of pine resin and olive oil. The pine resin itself is too brittle to work with on its own, therefore, olive oil has been added in order to plasticise the composition. The olive oil has high oleic acid, which helps to make the material malleable.

Tests have been conducted to establish the optimum combination of materials. A recipe of 90% pine resin to 10% olive oil has been established to be the best blend for the fabrication process, to apply to the jute and fly fibres; it is strong and the brittleness of the material is lowered.

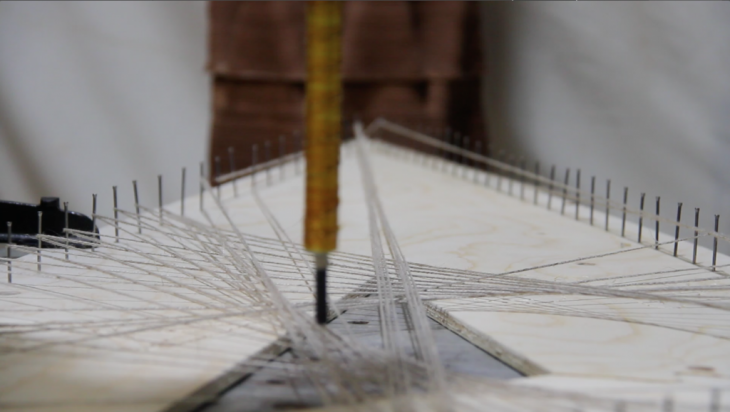

Robotics

Moreover, this has been tested to work best with the Kuka tool, which is necessary for the weaving of the jute thread. The robotic arm has 6 points of rotation to have 360 degree access to the timber base. Working in X, Y + Z axis, this tool has greater flexibility than common place fabrication tools such as a CNC machine, as well as being more efficient than manual processes.

For this project, the robotic arm is used to weave the jute thread based on a computationally generated pattern. Therefore, these threads are to be sandwiched between wooden panels to give the structure the ability to fold and hold.

While this pavilion combines digital fabrication tool as well as contemporary interpretations of natural materials to make a structure that combines the practical and the beautiful.

This project is a continuation of research conducted in semester 2. For more information of earlier iterations, refer to the links below:

Nomadic Fold Mobile Pavilion Sangam Parasitic Architecture Namasthe

NOMAD

For Light Weight Bio Composite Structures

Tutors Alex Dubor + Pablo Ross

Project Managers

Keesje Avis | Global Design

Valerie Frey + Johana Monroy | Resins

Guoliang Zhang | Construction Details

Irene Ayla Castro + Sotiris Yfantis | Musicality

Javier Lopez-Alascio + Ricardo Mayor | Robotics

Kathleen Bainbridge | Documentation

Prateek Bajpai | Fabrication & Assembly